Preparation method of pleurotus ostreatus fermentation broth and application of fermentation broth in degradation of aflatoxin B1

A technology of Pleurotus pilosula and fermentation liquid, which is applied in the field of microbial fermentation, can solve the problems of fewer bacteria reports and more fungi, and achieve the effects of fast degradation speed, mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

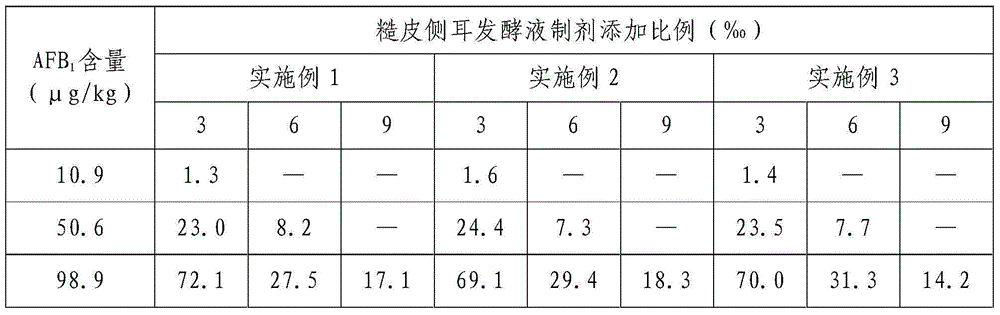

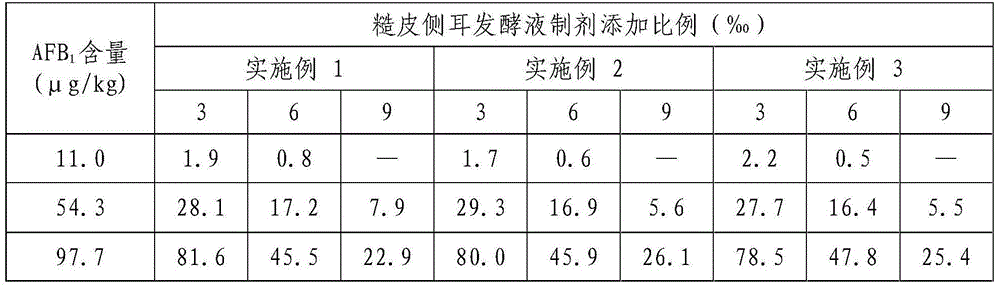

Examples

Embodiment 1

[0041] The preparation method of Pleurotus pleurotus fermented liquid comprises inoculating Pleurotus otreatus CICC14012 in a sterile medium containing carbon source, nitrogen source, inorganic salts and trace elements for aerobic fermentation to prepare a fermented liquid;

[0042] Fermentation medium is made up of the raw material of following mass percentage:

[0043] Potato starch 6.5%, sucrose 2.0%, yeast extract 0.18%, ammonium sulfate 0.31%, potassium dihydrogen phosphate 0.28%, magnesium sulfate 0.17%, vitamin B 1 0.0001%, trace element solution 6.0%, veratrol 450 μL / L, Tween 80 0.13%, the rest is sterile water, pH=5.0;

[0044] Trace element solution: calcium chloride 1500mg, ferrous sulfate 150mg, zinc sulfate 100mg, copper sulfate 150mg, manganese sulfate 1000mg, cobalt sulfate 200mg, aluminum potassium sulfate 20mg, boric acid 10mg, sodium molybdate 20mg, dilute to 1000mL.

[0045] The technological conditions of aerated fermentation are as follows:

[0046] The ...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

[0061] The fermentation medium is composed of the following raw materials in mass percentage:

[0062] Potato starch 7.0%, sucrose 1.8%, yeast extract 0.20%, ammonium sulfate 0.29%, potassium dihydrogen phosphate 0.25%, magnesium sulfate 0.18%, vitamin B 1 0.0002%, trace element solution 5.0%, veratrol 430μL / L, Tween 80 0.10%, the balance is sterile water, pH=4.9.

[0063] During the aerated fermentation process, the inoculum size is volume ratio = 6:100, the temperature is 28°C, the ventilation rate is 1:0.7vvm, the pressure is 0.04Mpa, and the culture period is not less than 265 hours.

[0064] The culture temperature in the preparation of the slant strain and the dish strain was 25° C., and the culture period was 5 days.

[0065] The preparation of the primary seed comprises the following process steps:

[0066] Inoculate the slant strains on the solid medium in the plate, culture at 25°C for 5 days, se...

Embodiment 3

[0072] The difference between this embodiment and embodiment 1 is:

[0073] The fermentation medium is composed of the following raw materials in mass percentage:

[0074] Potato starch 6.0%, sucrose 2.2%, yeast extract 0.22%, ammonium sulfate 0.33%, potassium dihydrogen phosphate 0.30%, magnesium sulfate 0.15%, vitamin B 1 0.0003%, trace element solution 5.5%, veratrol 470μL / L, Tween 80 0.12%, the balance is sterile water, pH=5.3.

[0075] During the aerated fermentation process, the inoculum size is volume ratio = 8:100, the temperature is 27°C, the ventilation rate is 1:1.2vvm, the pressure is 0.05Mpa, and the culture period is not less than 280 hours.

[0076] The culture temperature in the preparation of the slant strains and plate strains was 27° C., and the culture period was 4 days.

[0077] The preparation of the primary seed comprises the following process steps:

[0078] Inoculate the slant strains on the solid medium in the plate, culture at 27°C for 4 days, sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com