Coupling agent, porous carburizing coating fiber and preparation method

A coupling agent and carbon coating technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of low strength of activated carbon fibers, and achieve the effects of less environmental pollution, good mechanical strength, and less waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

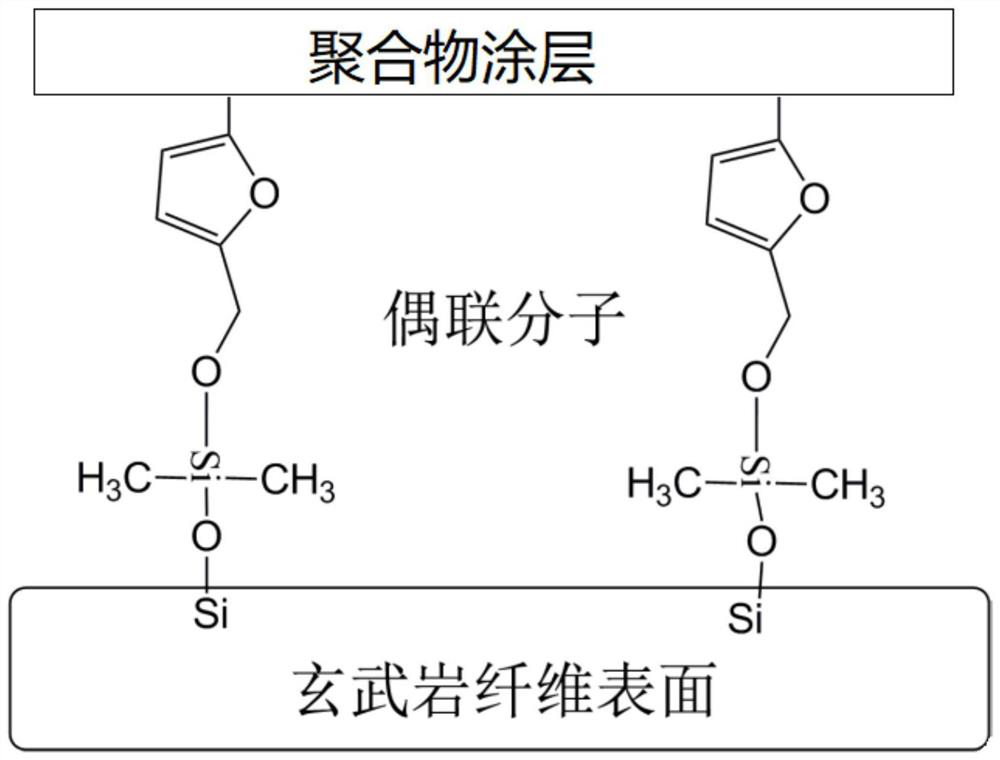

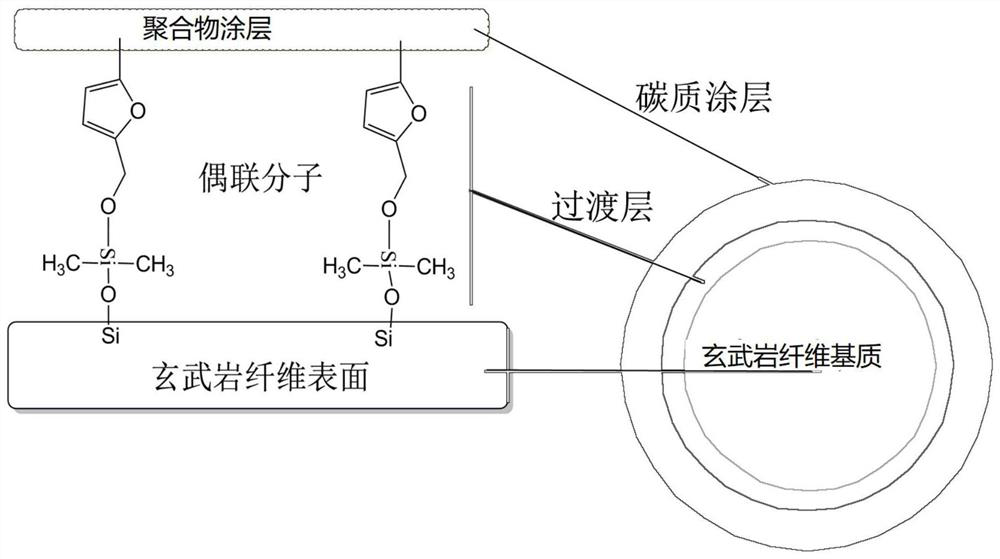

[0050] The present invention also provides a preparation method of porous carburized coated fiber, using the coupling agent bis(2-furylmethoxy)dimethylsilane prepared by the above method, and using basalt fiber as matrix fiber, the preparation method Including the following steps:

[0051] Step 1, carrying out surface alkali etching treatment and acid etching treatment to the basalt fiber;

[0052] Specifically, in step 1, the present invention uses basalt fiber as the matrix fiber, and needs to perform etching treatment on its surface in order to introduce a porous carburized coating. Basalt is a mixture with unique physical and chemical properties formed from the solidification and crystallization of magma. Its chemical composition is represented by complex silicate minerals, such as albite NaAlSi 3 o 8 , Anorthite CaAl 2 Si 2 o 8 , diopside CaMg[Si 2 o 6 ], olivine (Mg,Fe)SiO 4 , ordinary pyroxene Ca(Mg,Fe)[Si 2 o 6 ] and other forms exist.

[0053] According to ...

Embodiment 1

[0074] This embodiment provides a method for preparing a porous carburized coated fiber, which specifically includes the following steps:

[0075] Step 1. 50g of basalt fibers were etched with sodium hydroxide solution and hydrochloric acid solution (the treatment conditions are listed in Table 1). After the treatment, the fibers were washed with deionized water until neutral, and dried in air at 110°C.

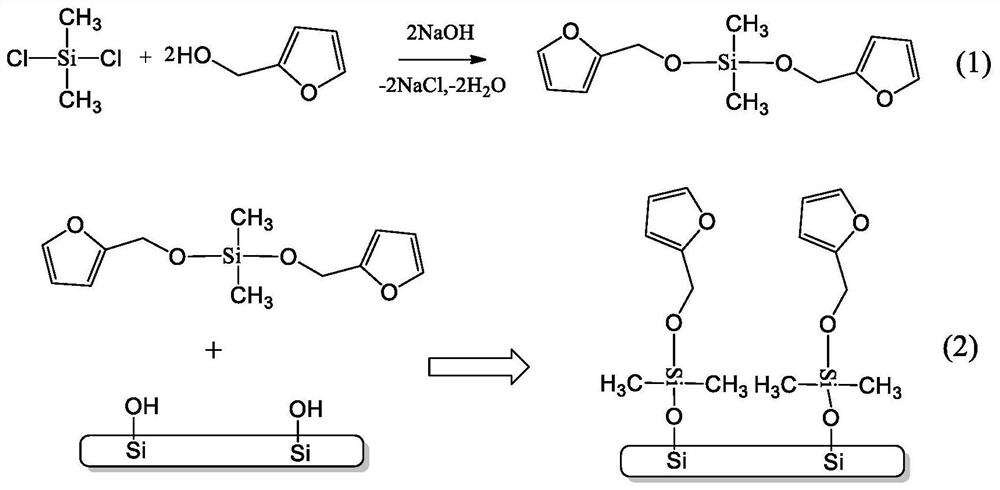

[0076] Synthesis of bis(2-furylmethoxy)dimethylsilane: mix 4.32g of furanmethanol and 1.84g of sodium hydroxide, cool to -5°C, add 2.58g of dichlorodimethylsilane dropwise, and wait until the addition is complete Afterwards, the temperature was raised to 25° C. to continue the reaction for 1.5 hours, and the solid salt was taken out by filtration, and the liquid product was bis(2-furylmethoxy)dimethylsilane.

[0077] Condensation of furanformaldehyde and furanmethanol monomer preparation: 9.6g furfuraldehyde, 22.56g furanmethanol and 0.65g catalyst maleic anhydride were heate...

Embodiment 2

[0085] Step 1. Soak 50 g of basalt fiber in a sodium hydroxide solution with a mass concentration of 3.5% at 40°C for 3 hours, take it out and wash it with deionized water until neutral; continue to soak it in a hydrochloric acid solution with a mass concentration of 5% at 35°C for 3 hours, After the treatment, the fibers were washed with deionized water until neutral, and dried in air at 110°C.

[0086] Synthesis of bis(2-furylmethoxy)dimethylsilane: mix 4.32g of furanmethanol and 1.84g of sodium hydroxide, cool to -5°C, add 2.58g of dichlorodimethylsilane dropwise, and wait until the addition is complete Afterwards, the temperature was raised to 25° C. to continue the reaction for 1.5 hours, and the solid salt was taken out by filtration, and the liquid product was bis(2-furylmethoxy)dimethylsilane.

[0087] Condensation of furanformaldehyde and furanmethanol monomer preparation: 9.6g furfuraldehyde, 22.56g furanmethanol and 0.65g catalyst maleic anhydride were heated to 85°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com