Method for recovering vanadium ferrochrome from vanadium-chromium tailings

A technology of vanadium chromium tailings and vanadium chromium, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as inability to beneficiate, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

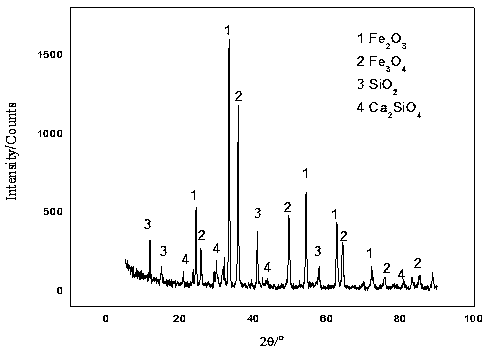

Image

Examples

Embodiment 1

[0039] A method for reclaiming ferrovanadium chromium from vanadium chromium tailings comprises the following steps:

[0040] (1) Digestion: the composition and mass percentage content are: Fe (总) 34.00%, S 3.40%, V 0.30%, Ti 10.25%, Cr 0.20%, Na 2 O 5.22% vanadium chromium tailings, most of S and Na 2 O is wrapped inside the vanadium-chromium tailings and does not dissolve in water. Grind the vanadium-chromium tailings until the particle size is less than 0.074mm, add lime with a diameter of 0.40mm or less and an appropriate amount of water. The quality of the three is the tailings 1000g, lime 50g, water 200g, stir and mix evenly in a mixer, maintain the temperature at 80°C by self-heating for 15min, and digest to obtain digested material;

[0041] (2) Expansion: Put the digested material in step (1) into the extruder and then close it. The process conditions in the extruder are controlled: the temperature is 230°C; the pressure in the extruder is 3.0MPa; Open the dischar...

Embodiment 2

[0046] A method for reclaiming ferrovanadium chromium from vanadium chromium tailings comprises the following steps:

[0047] (1) Digestion: the composition and mass percentage content are: Fe (总) 31.80%, S 6.00%, V 0.35%, Ti 5.15%, Cr 0.25%, Na 2 O 5.22% vanadium chromium tailings, most of S and Na 2 O is wrapped inside the vanadium-chromium tailings and does not dissolve in water. Grind the vanadium-chromium tailings until the particle size is less than 0.074mm, add lime with a diameter of 0.40mm or less and an appropriate amount of water. The quality of the three is the tailings 1000g, lime 100g, water 300g, stir and mix evenly in a mixer, maintain the temperature at 100°C by self-heating for 5min, and digest to obtain digested material;

[0048] (2) Expansion: Put the digested material in step (1) into the extruder and then close it. The process conditions in the extruder are controlled: the temperature is 180°C; the pressure in the extruder is 1.0MPa; Open the dischar...

Embodiment 3

[0051] A method for reclaiming ferrovanadium chromium from vanadium chromium tailings comprises the following steps:

[0052] (1) Digestion: the composition and mass percentage content are: Fe (总) 39.30%, S 2.70%, V 0.28%, Ti 10.25%, Cr 0.10%, Na 2 O 5.22% vanadium chromium tailings, most of S and Na 2 O is wrapped inside the vanadium-chromium tailings and does not dissolve in water. Grind the vanadium-chromium tailings until the particle size is less than 0.074mm, add lime with a diameter of 0.40mm or less and an appropriate amount of water. The quality of the three is the tailings 1000g, lime 50g, water 200g, stir and mix evenly in a mixer, maintain the temperature at 80°C by self-heating for 10min, and digest to obtain digested material;

[0053] (2) Expansion: Put the digested material in step (1) into the extruder and then close it. Control the process conditions in the extruder: temperature 150°C; pressure in the extruder 0.5MPa; Open the discharge port of the extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com