Patents

Literature

55results about How to "Convenient follow-up process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

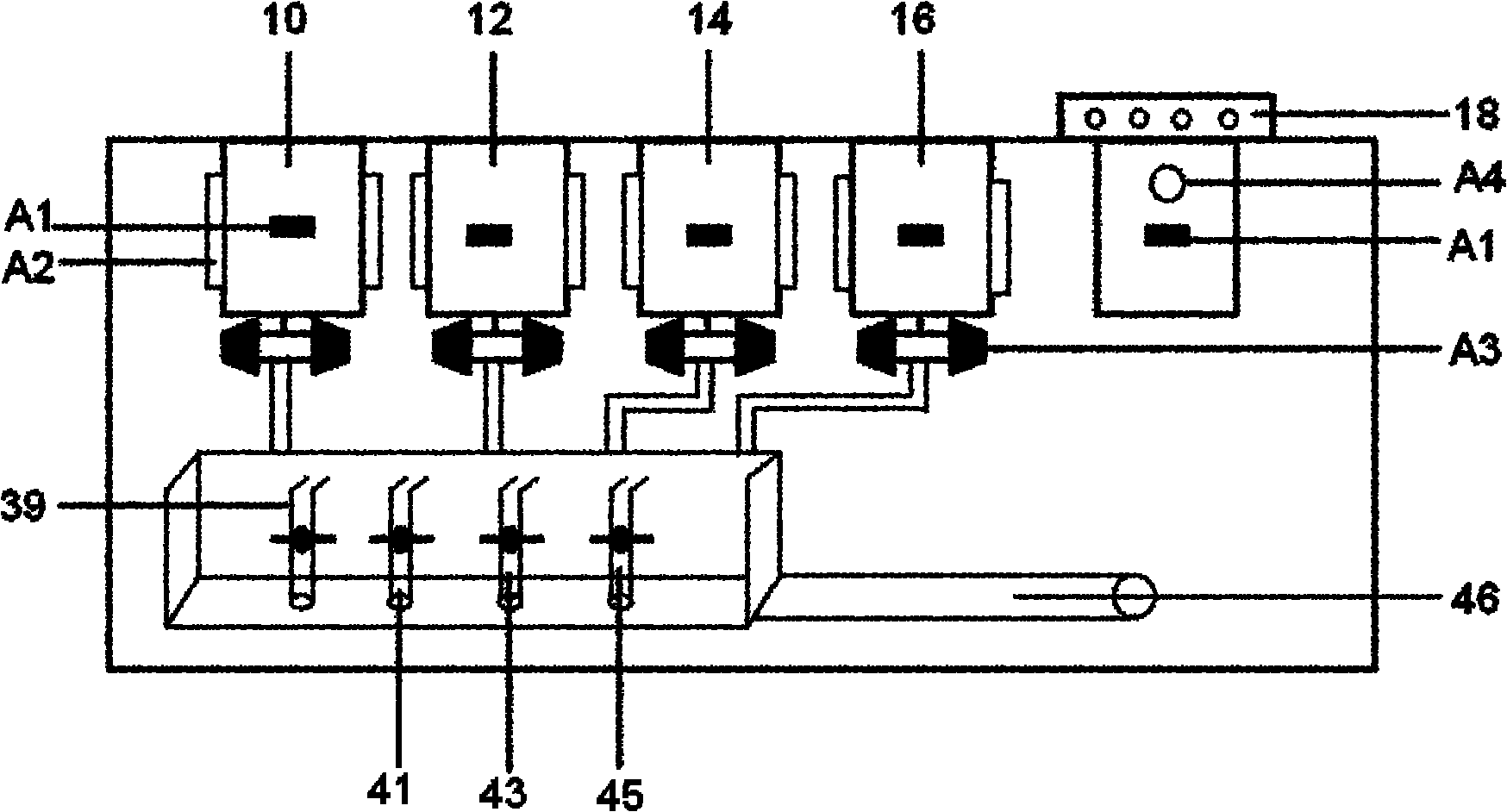

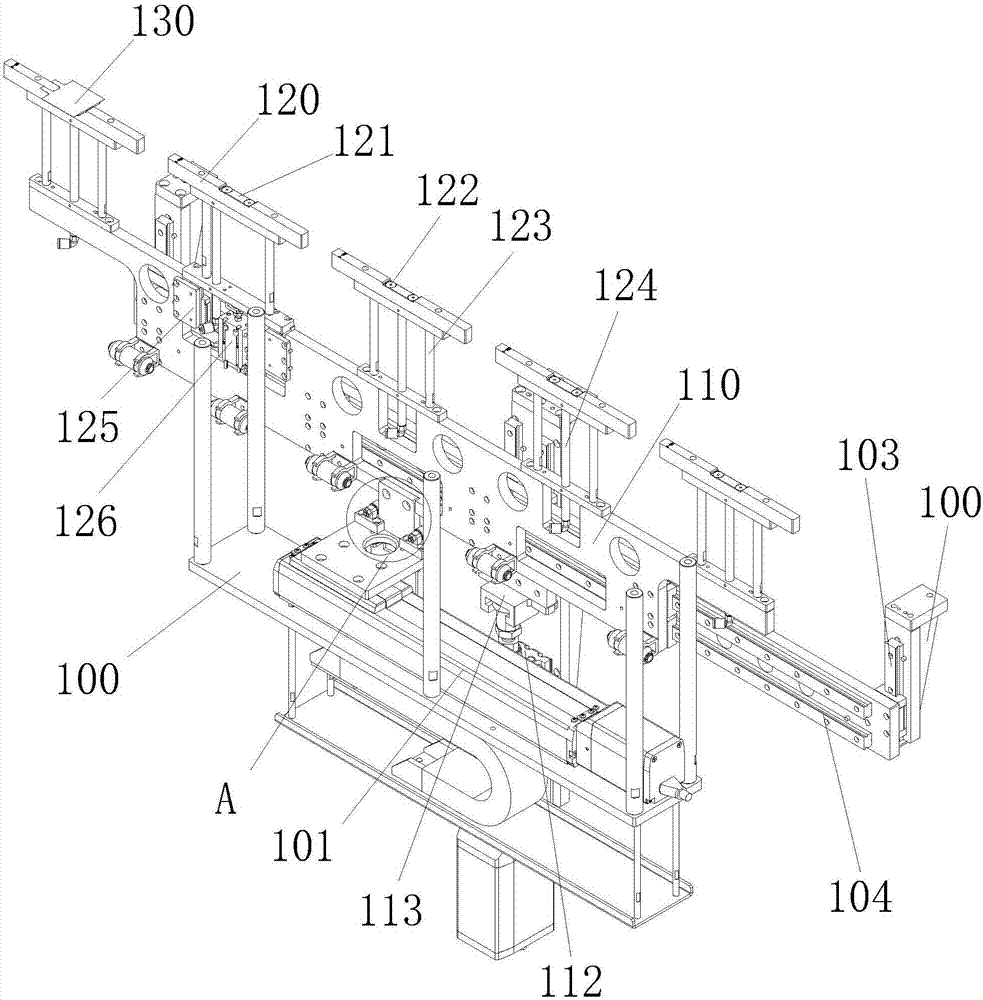

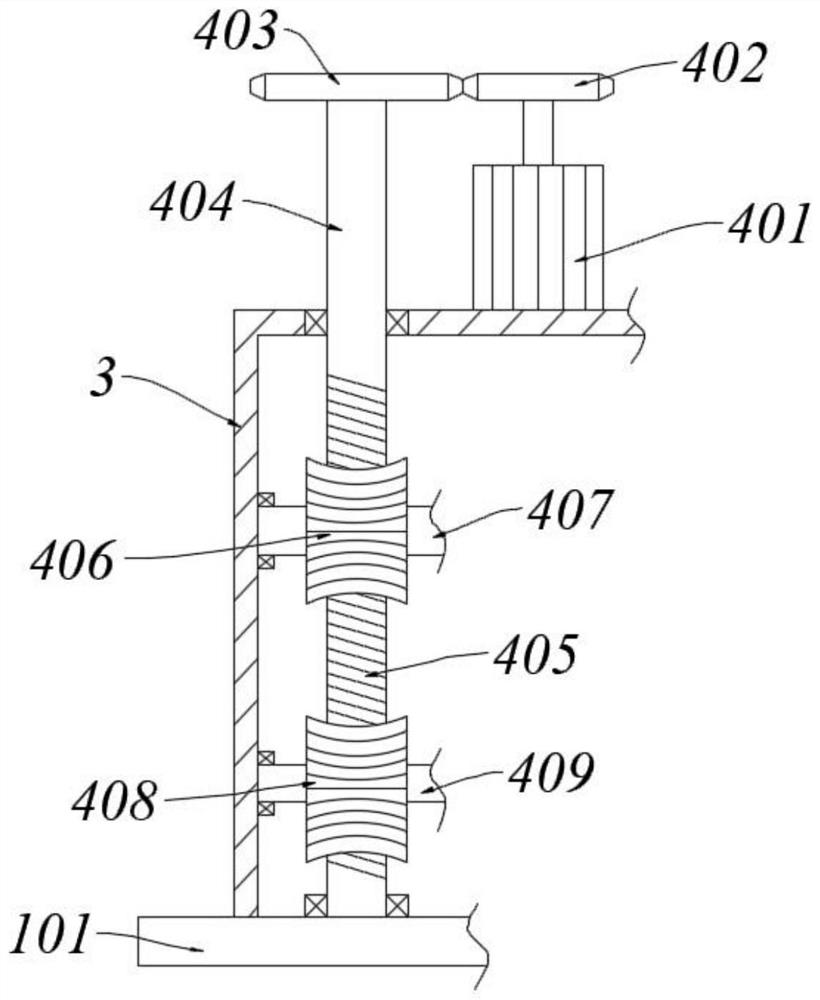

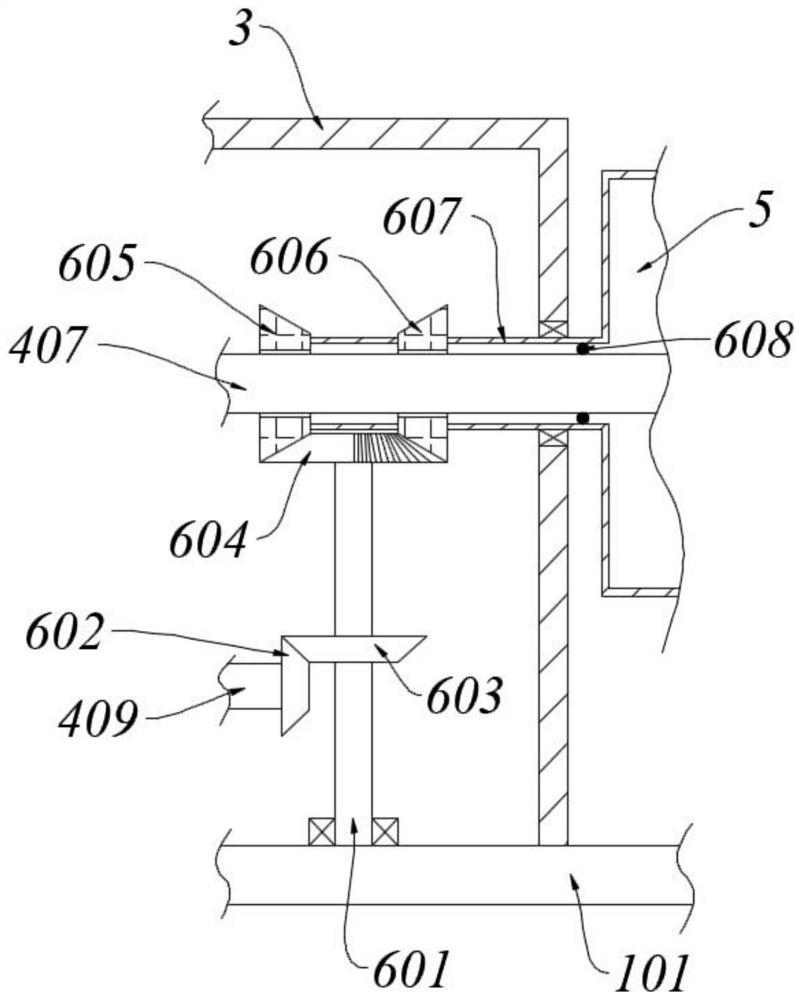

Feeding mechanism for automatic screwing machine of semi-spiral energy-saving lamp tube

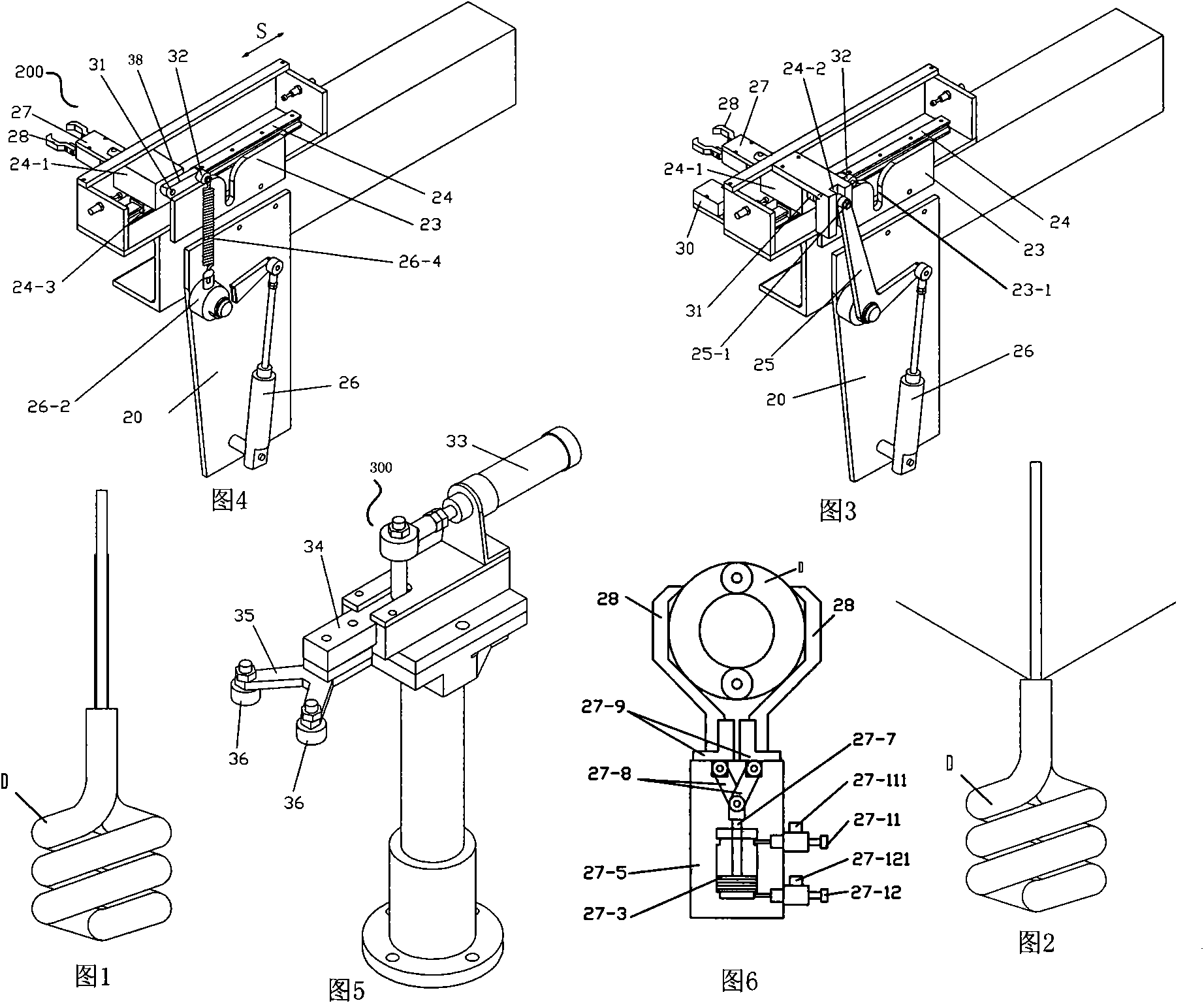

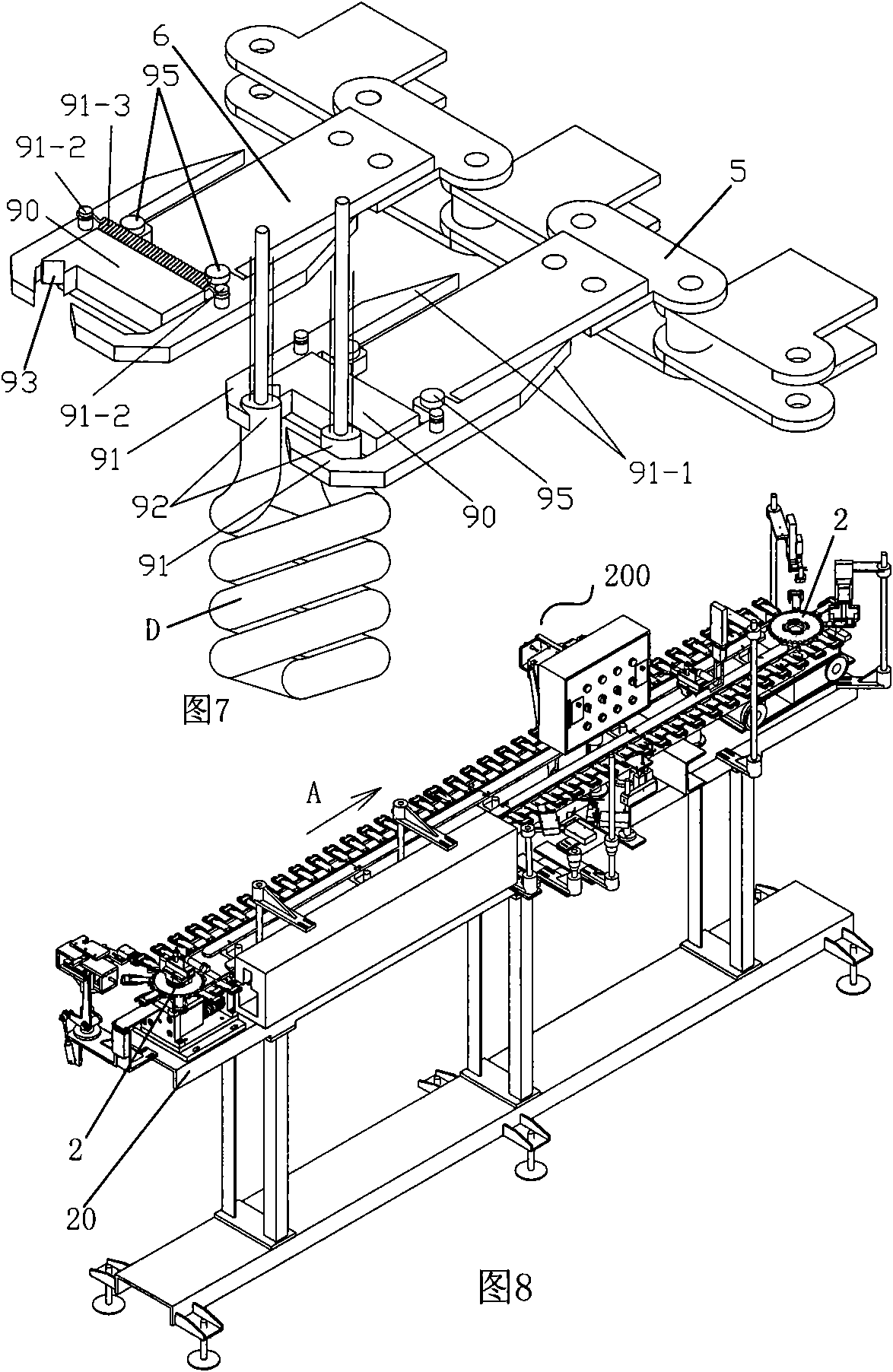

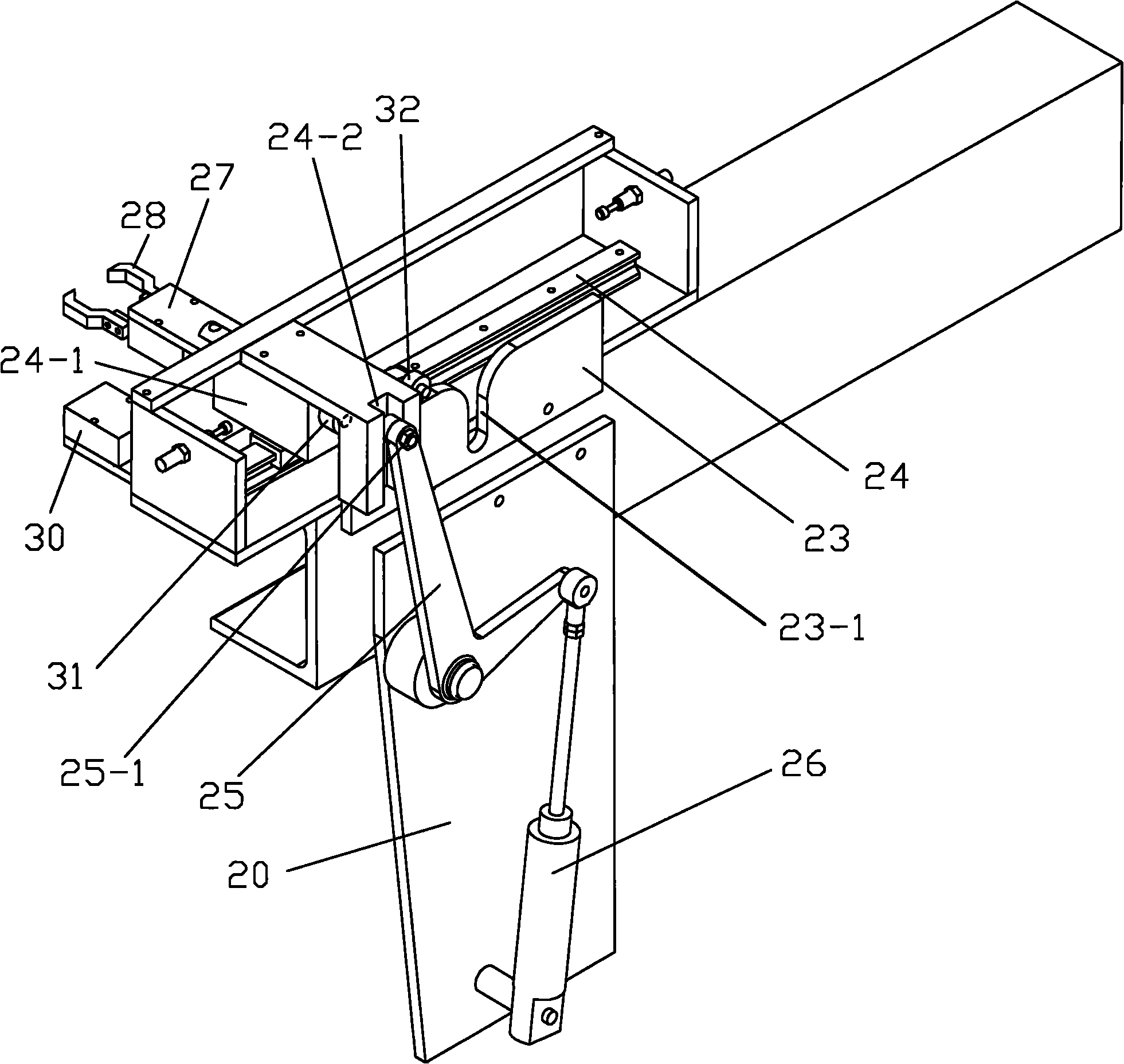

InactiveCN102030188AImprove silk qualityIncrease productivityConveyor partsManipulatorMotion direction

The invention relates to a feeding mechanism for an automatic screwing machine of a semi-spiral energy-saving lamp tube. In order to solve the technical problems, the provided mechanism has the characteristics of accurate transmission and high production efficiency. The technical scheme is that: the feeding mechanism for the automatic screwing machine of the semi-spiral energy-saving lamp tube is arranged on an automatic screwing machine frame and is positioned beside a motion track of a clamp carried by a conveying chain; and the feeding mechanism is characterized by being provided with a tube supply mechanism for transmitting the lamp tube to the clamp and an opening mechanism for opening a clamping jaw of the clamp, wherein the tube supply mechanism comprises a mechanical arm for clamping the lamp tube, a linear motion mechanism which drives the mechanical arm to move horizontally and of which the motion direction is orthogonal to the motion track of the clamp, and an overturning mechanism for driving the mechanical arm to rotate 180 degrees; and the opening mechanism is provided with a linear mechanism driven by a cylinder, and a shifting fork which is arranged at the front end of the linear mechanism and is in opening / closing fit with the clamping jaw of the clamp.

Owner:LINAN NEW SANLIAN LIGHTING ELECTRIC

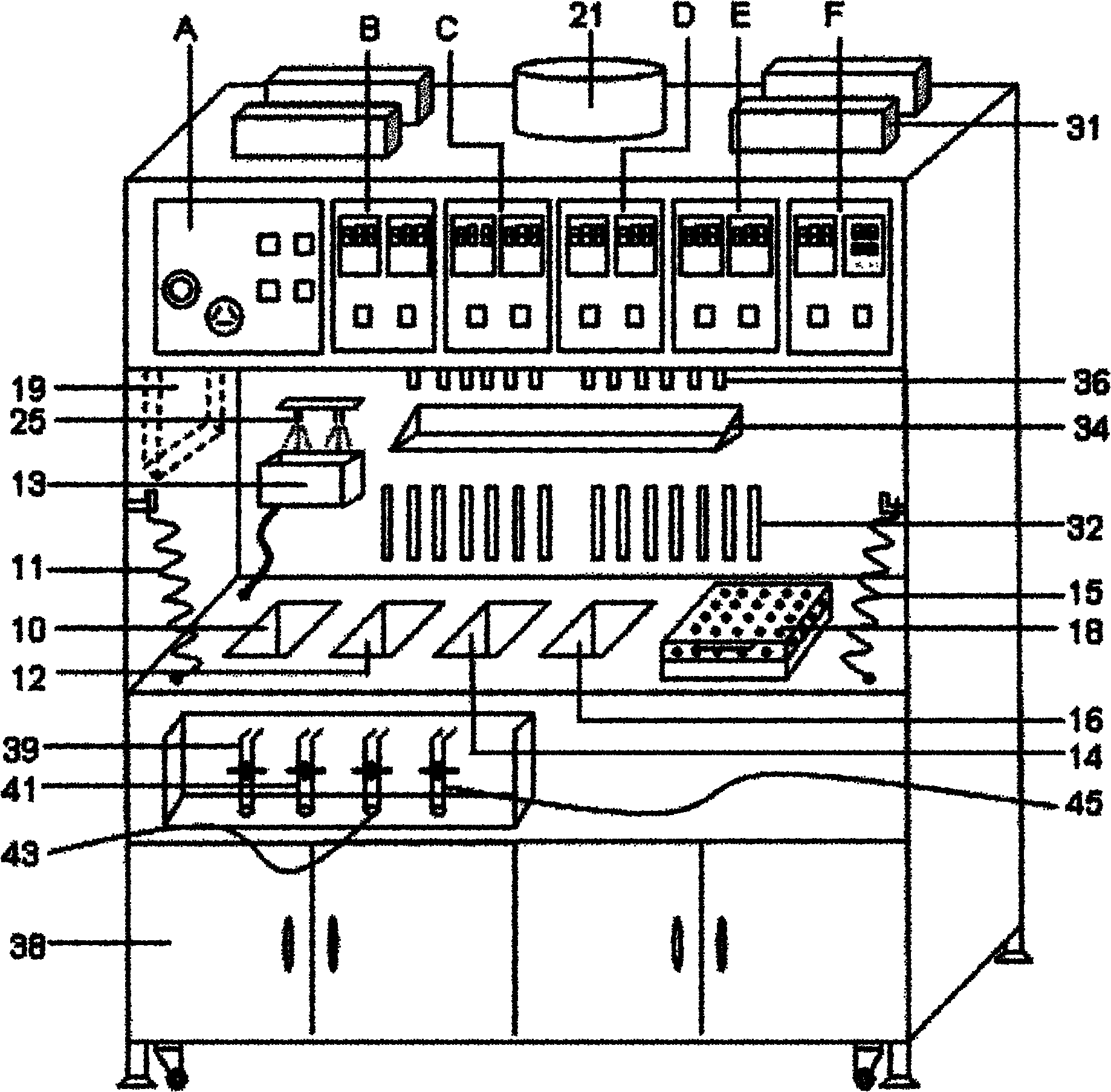

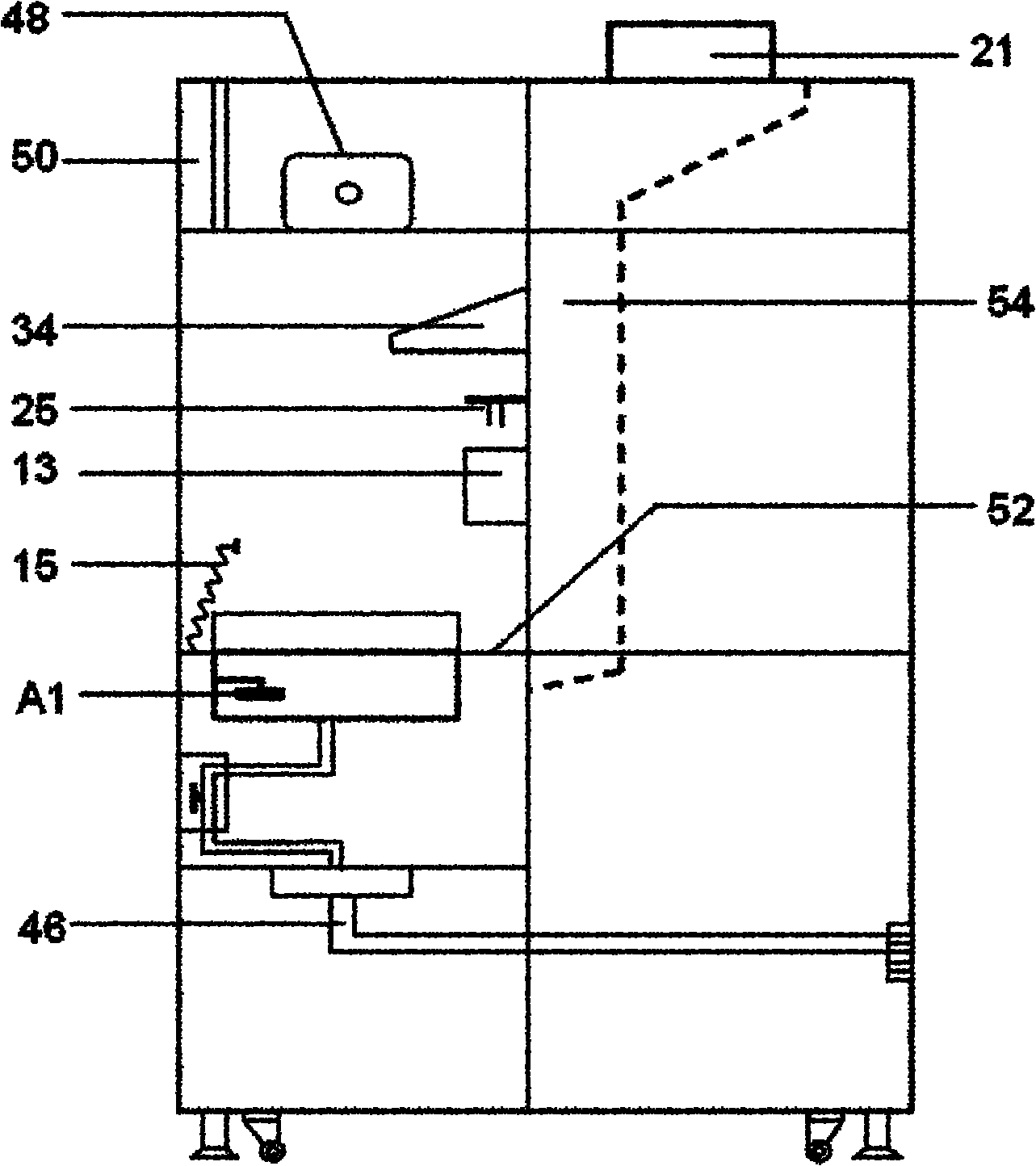

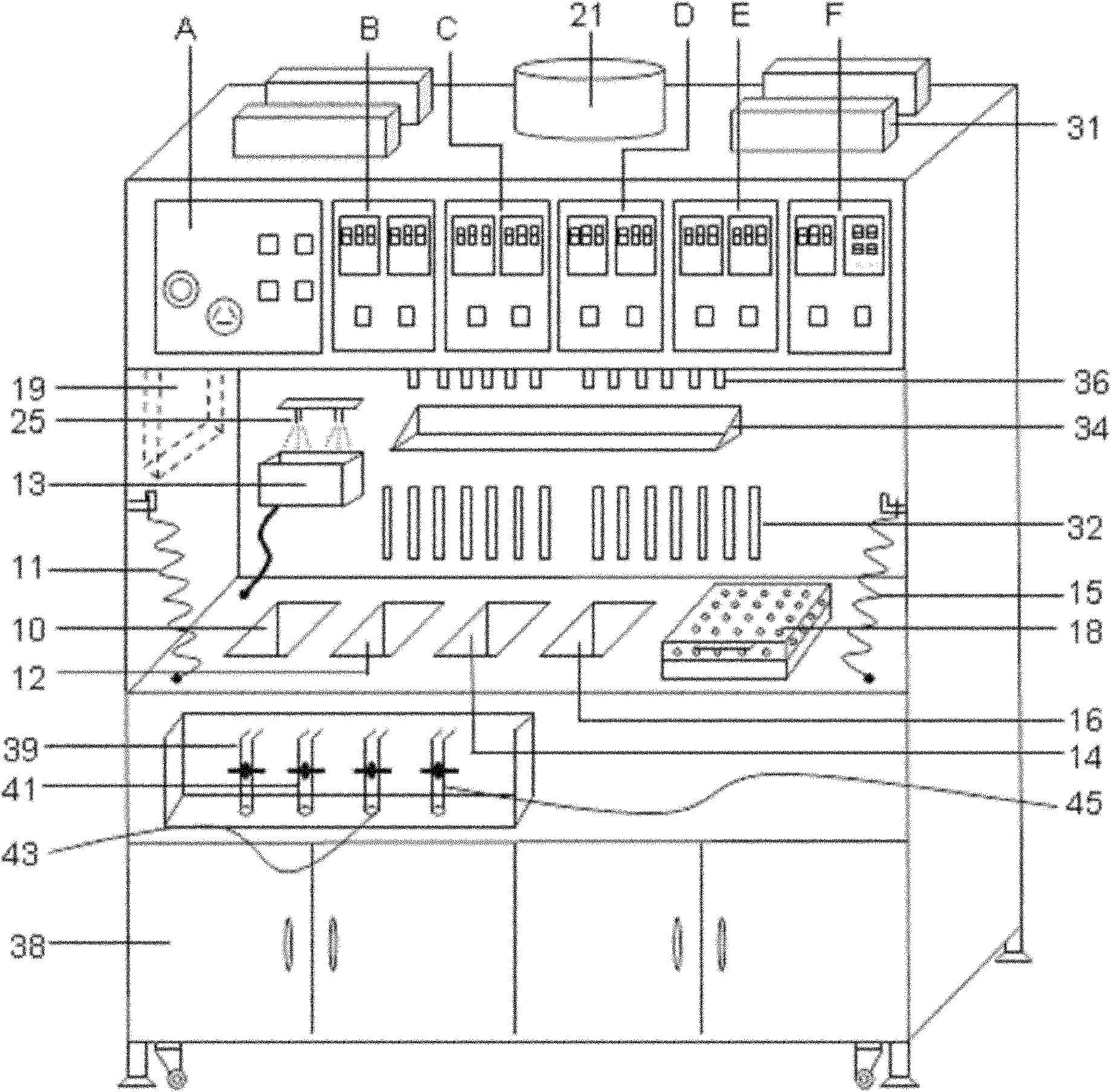

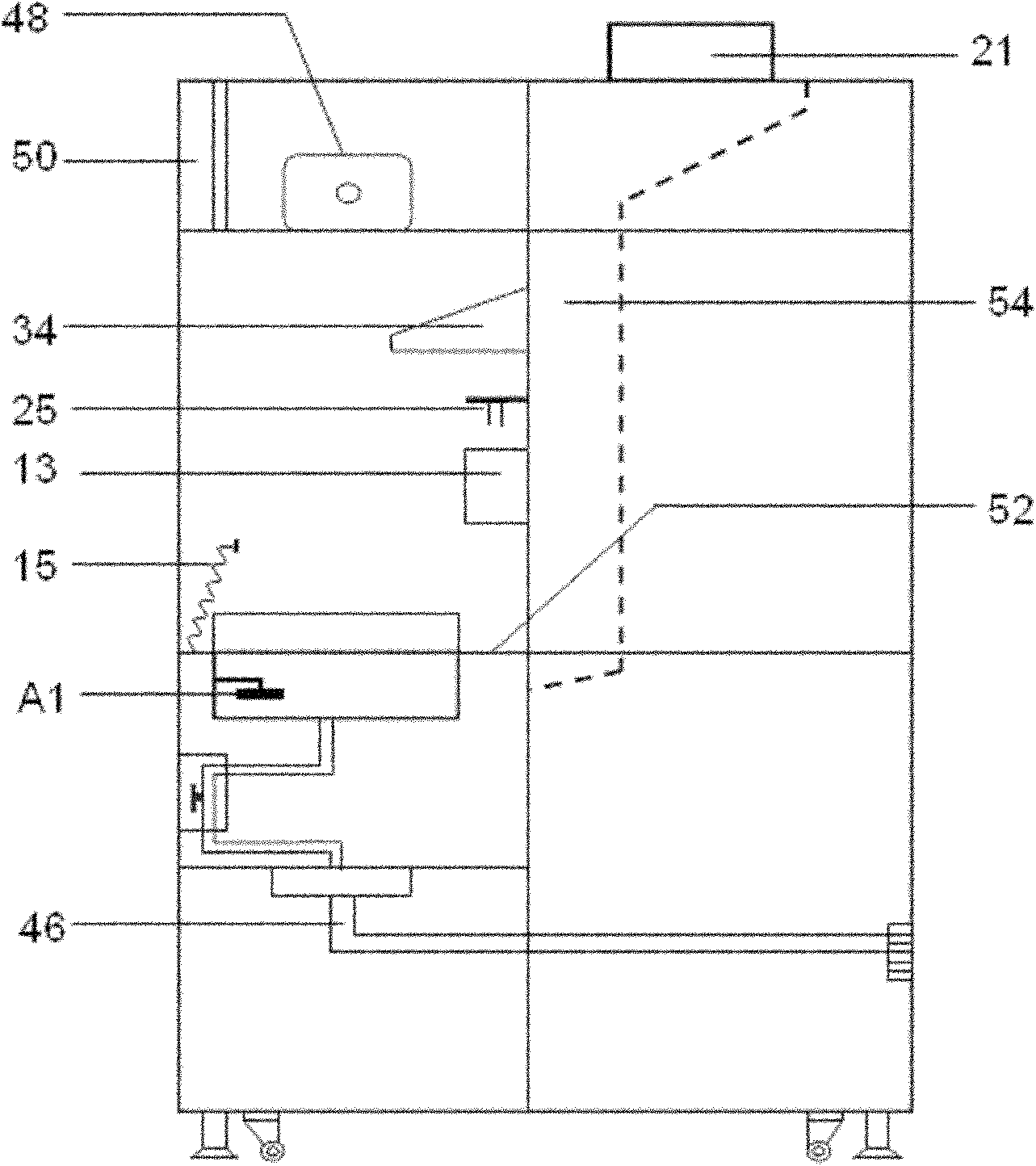

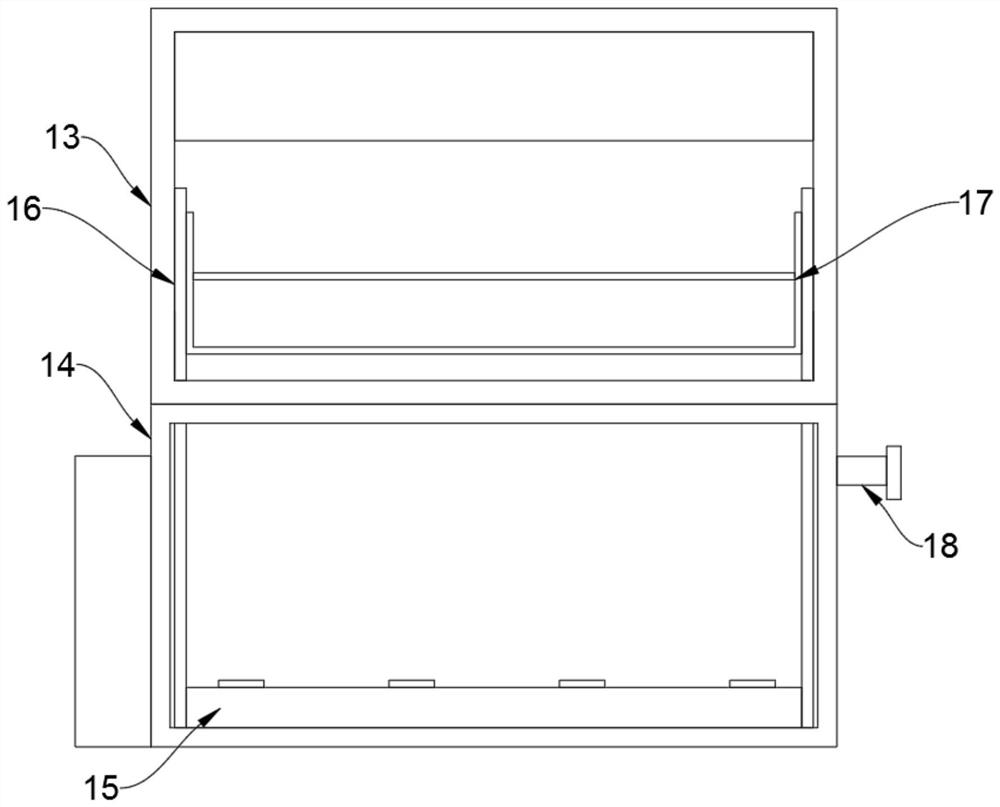

Cleaning machine table for semiconductor package products and cleaning process thereof

ActiveCN102097293AGood cleaning effectImprove cleanlinessSemiconductor/solid-state device manufacturingCleaning using liquidsProcess engineeringProduct function

The invention discloses a cleaning machine table for a semiconductor package products and a cleaning process thereof. The cleaning machine table comprises a control panel, a cleaning operation area and a drying area, wherein the control panel is arranged on the upper part of a front face of the machine table and is used for controlling the cleaning procedure; the cleaning operation area is arranged in the middle of the front face of the machine table, is in a shape of a hollow groove and comprises more than one cleaning slots, and the cleaning machine table is provided with an ultrasonic generation device corresponding to each cleaning slot so that the semiconductor package products in the cleaning slots can be cleaned by the ultrasonic waves; and the drying area is used for drying the cleaned products. The cleaning process comprises the following steps of ultrasonic chemical cleaning, ultrasonic washing in water and drying. After cleaned, the residual glue on the semiconductor package product can be nearly and completely removed so that the product performance is greatly improved and the following product function test is convenient.

Owner:嘉盛半导体(苏州)有限公司

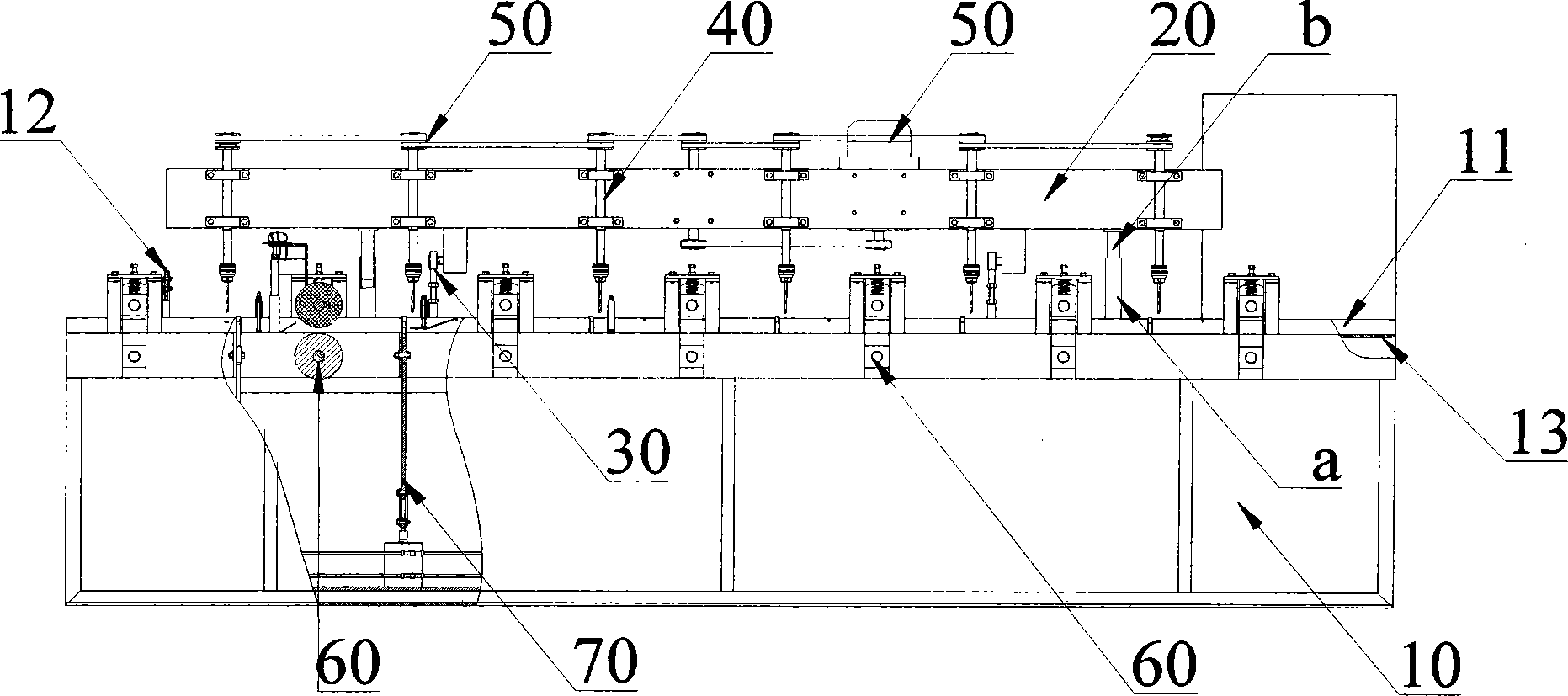

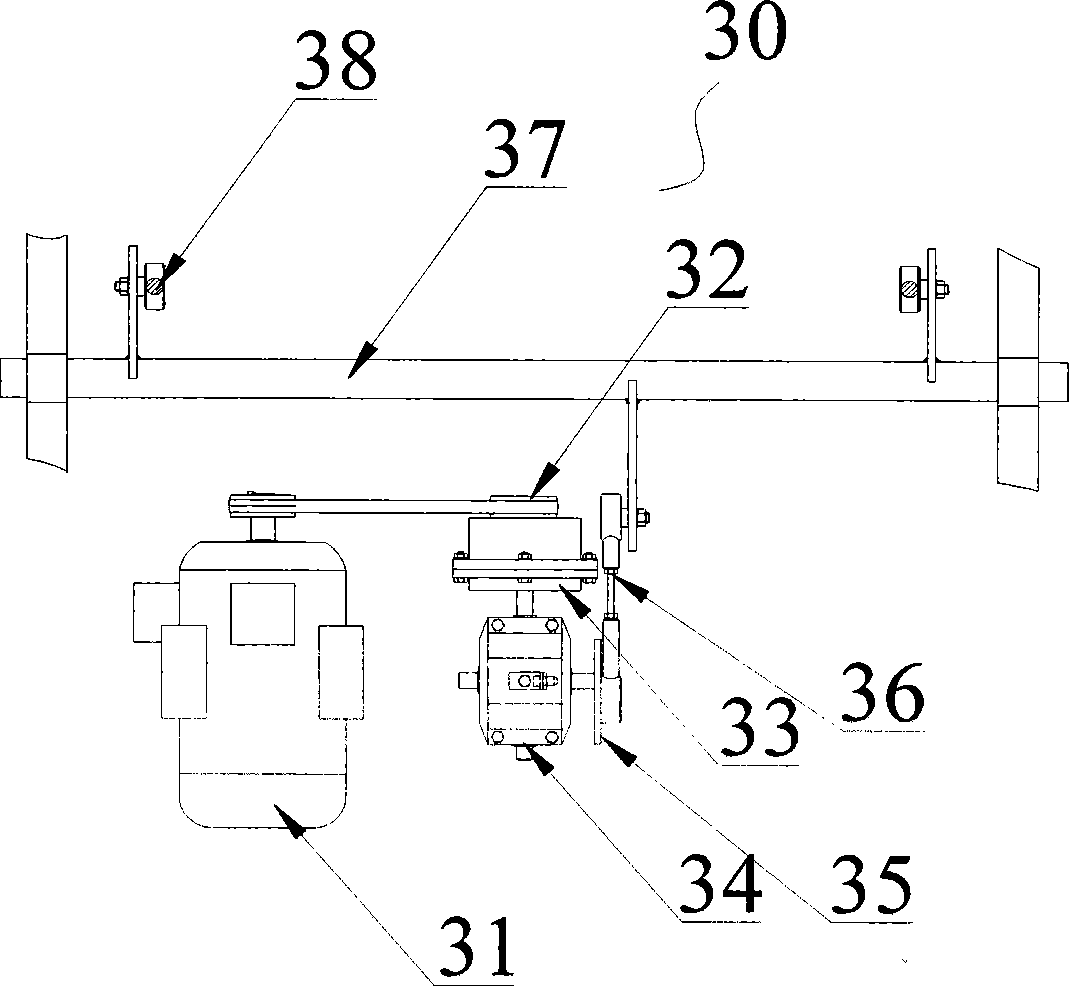

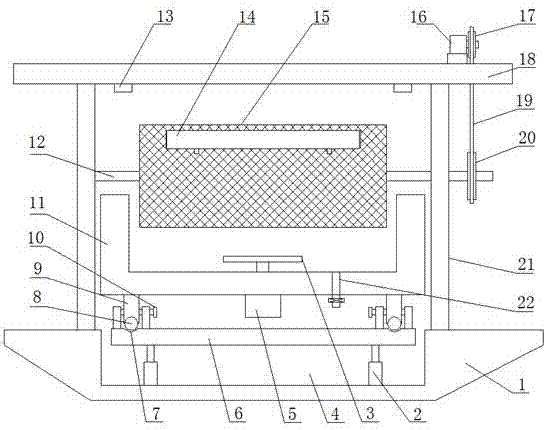

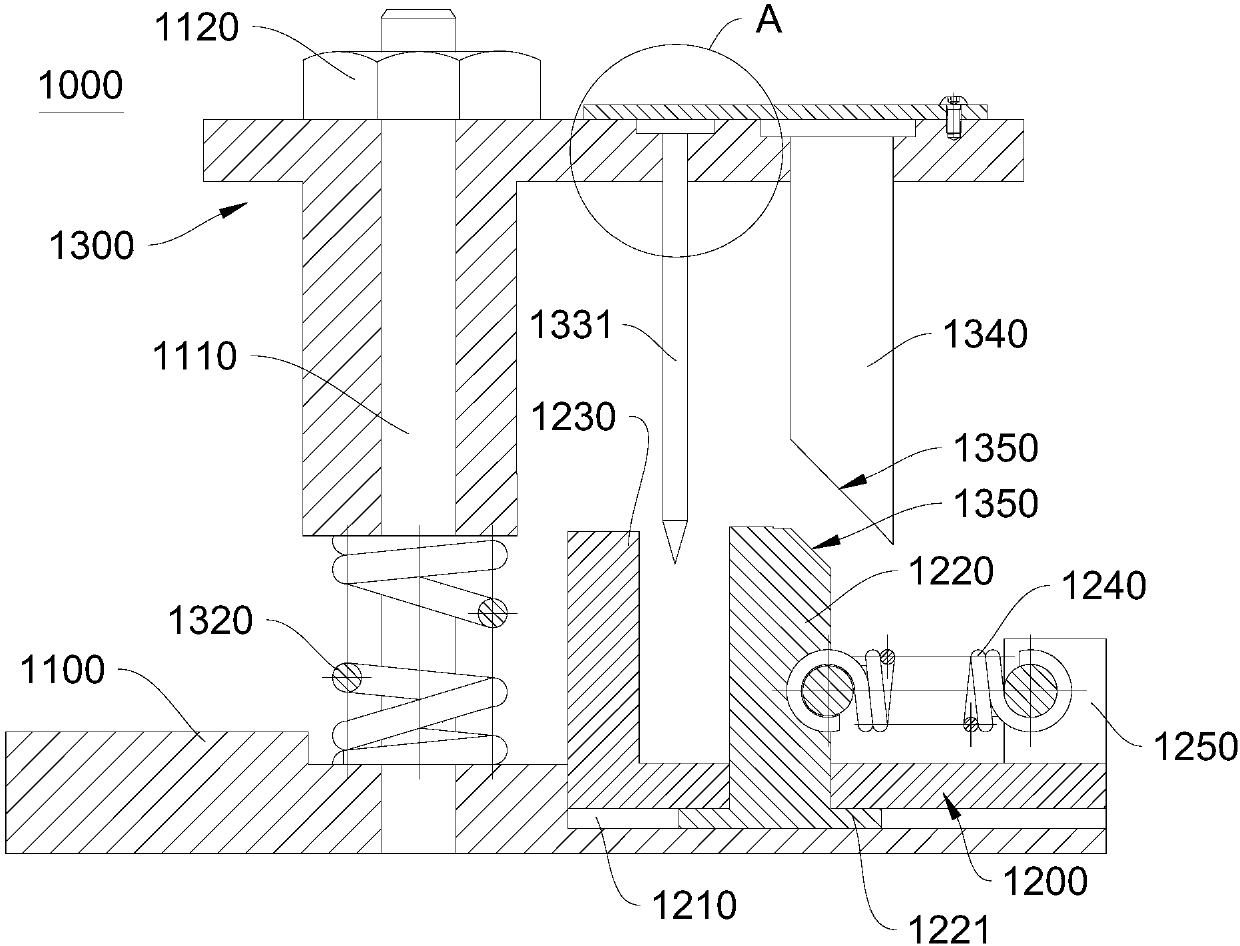

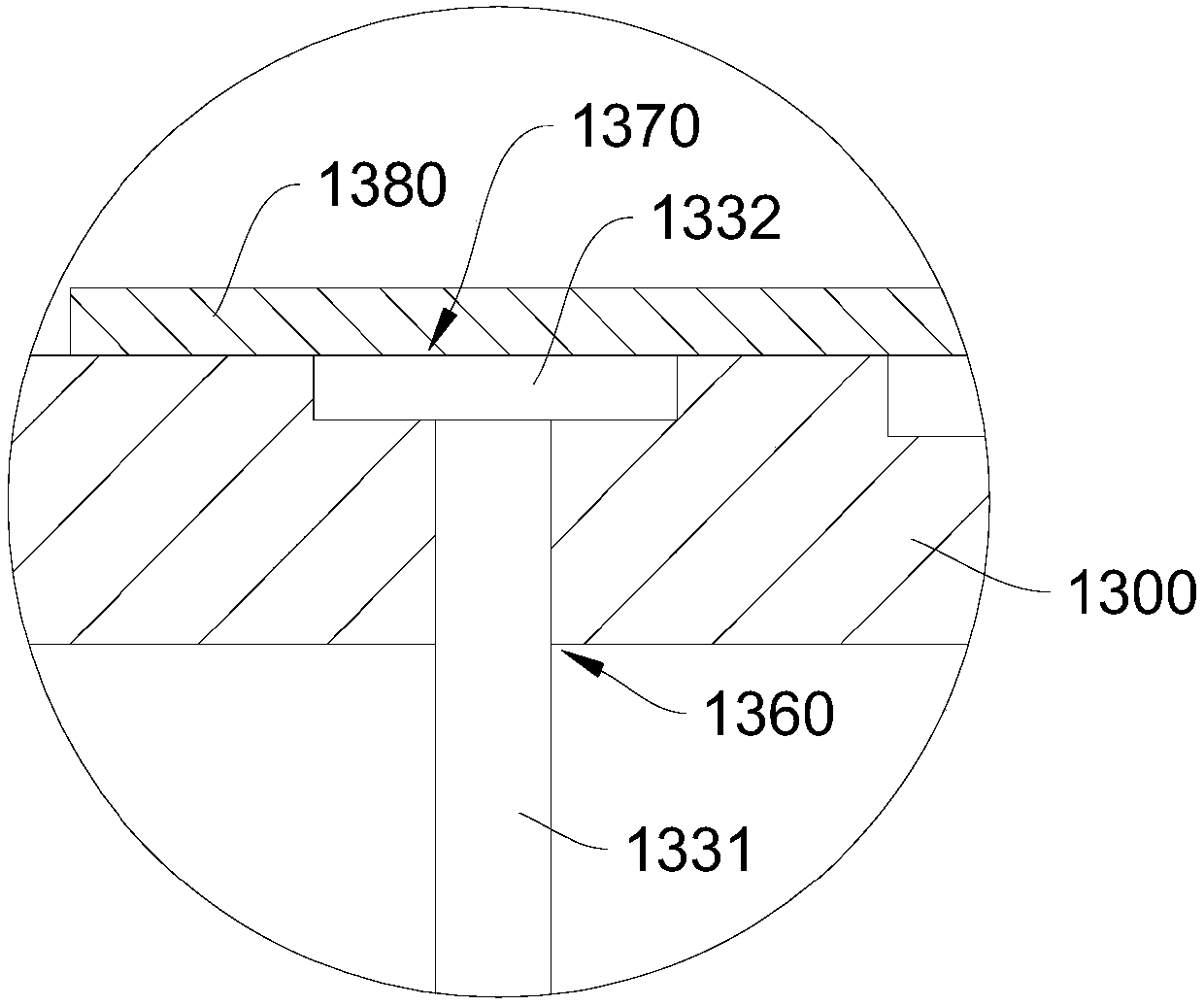

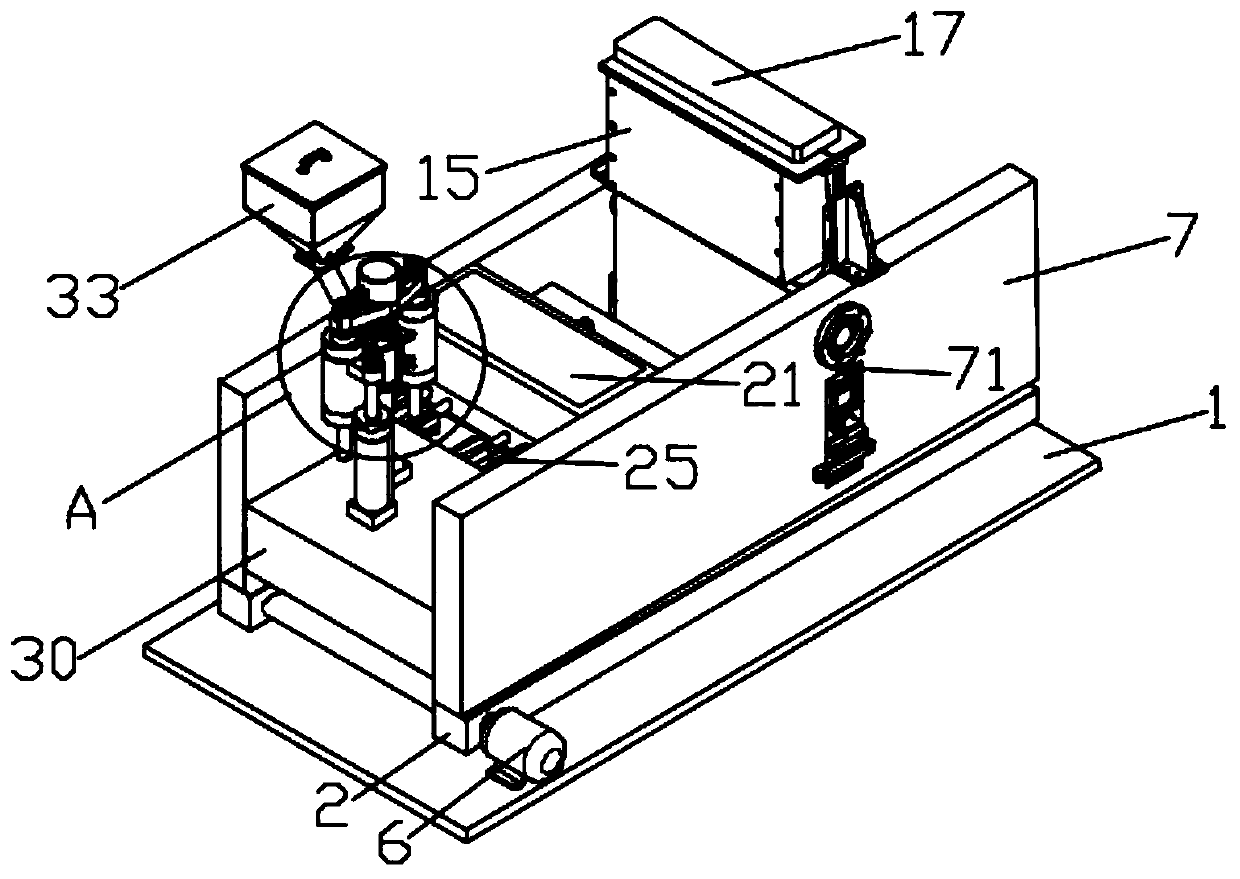

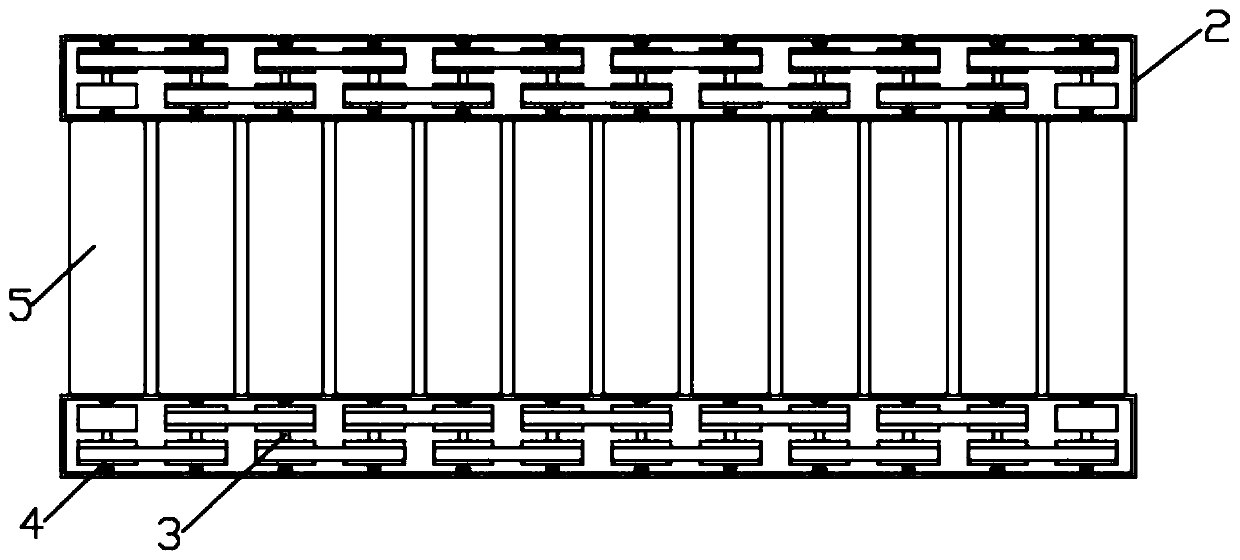

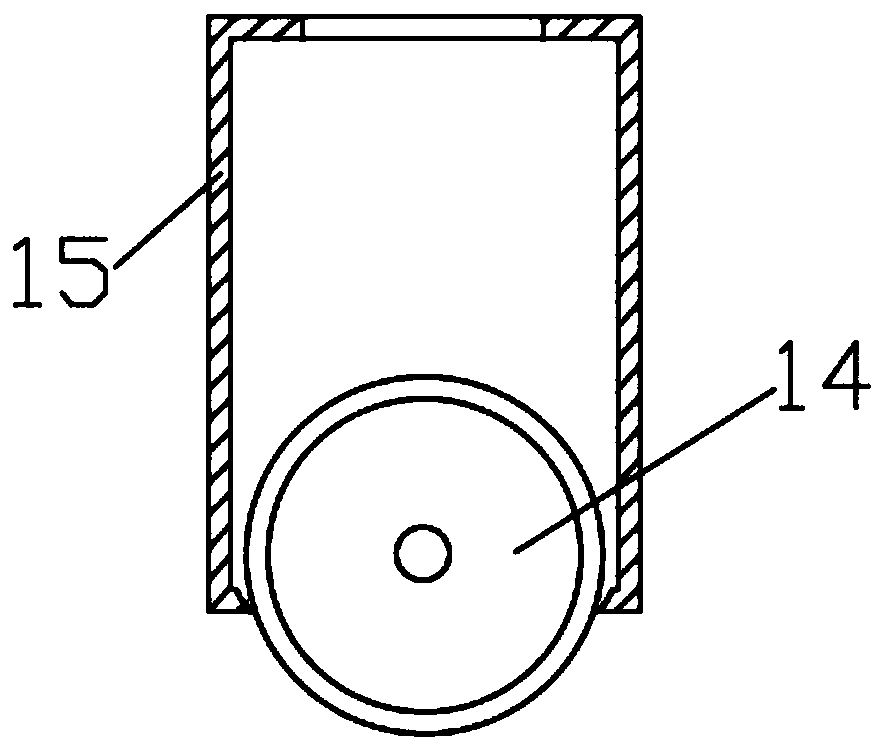

Machine for automatically removing joints of bamboo frame board and drilling holes in bamboo frame board

ActiveCN104029256AConvenience for subsequent useSimple structureStationary drilling machinesIrregularity removal devicesMachine partsEngineering

The invention relates to a machine for automatically removing joints of a bamboo frame board and drilling holes in the bamboo frame board. The machine comprises a worktable, a lifting table, a lifting table rotation mechanism, drill rods, a drill rod transmission mechanism and a machined part transmission mechanism, wherein a machined part feeding opening is formed in one side of the worktable; an opening and closing door is formed in the other side of the worktable; a joint removing cutter is arranged in the machined part feeding opening of the worktable; the lifting table is arranged above the worktable and located between the machined part feeding opening and the opening and closing door; the lifting table transmission mechanism is arranged at the bottom of an inner cavity of the worktable; the lifting table transmission mechanism is connected with the lifting table; a plurality of uniformly-arranged drill rods are arranged on the lifting table; the drill rod is vertical and downward and directly faces a table top of the worktable; the drill rod transmission mechanism is arranged on the lifting table; the drill rod transmission mechanism is connected with the drill rods; the machined part transmission mechanism is arranged on the table top of the worktable; the machined part transmission mechanism, the machined part feeding opening and the opening and closing door are arranged on the same straight line; the machined part transmission mechanism is arranged under the drill rods. When the machine is used, the working efficiency can be improved; meanwhile, groups of holes can be conveniently formed.

Owner:桃江县永利竹业机械研发有限公司

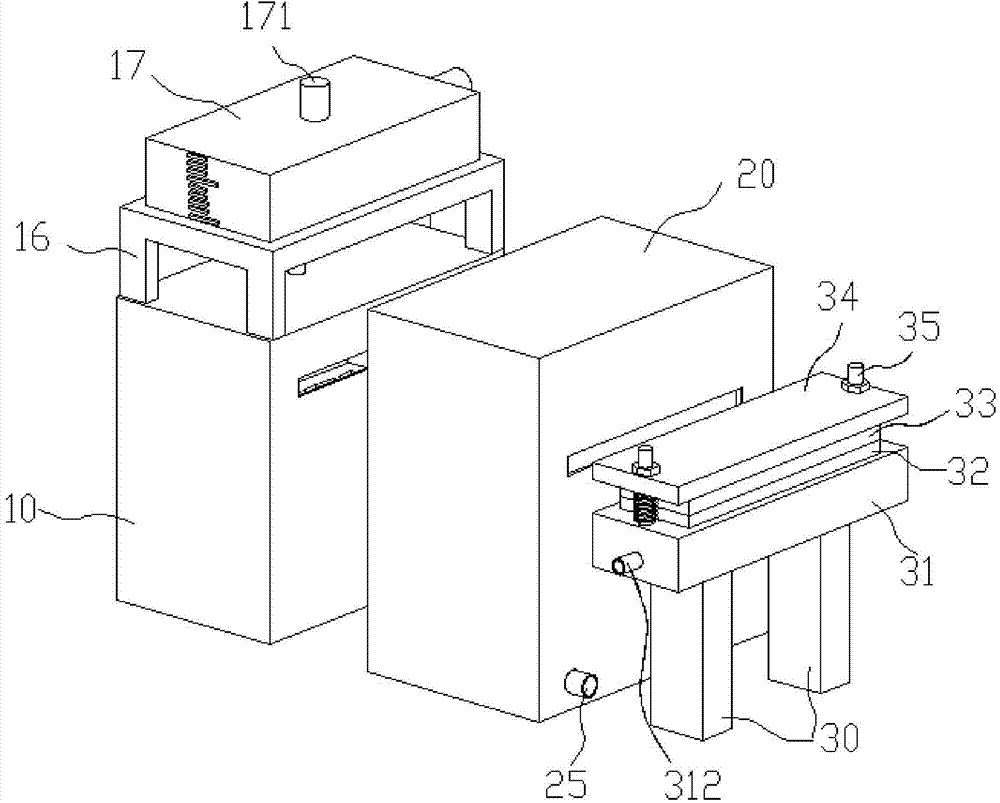

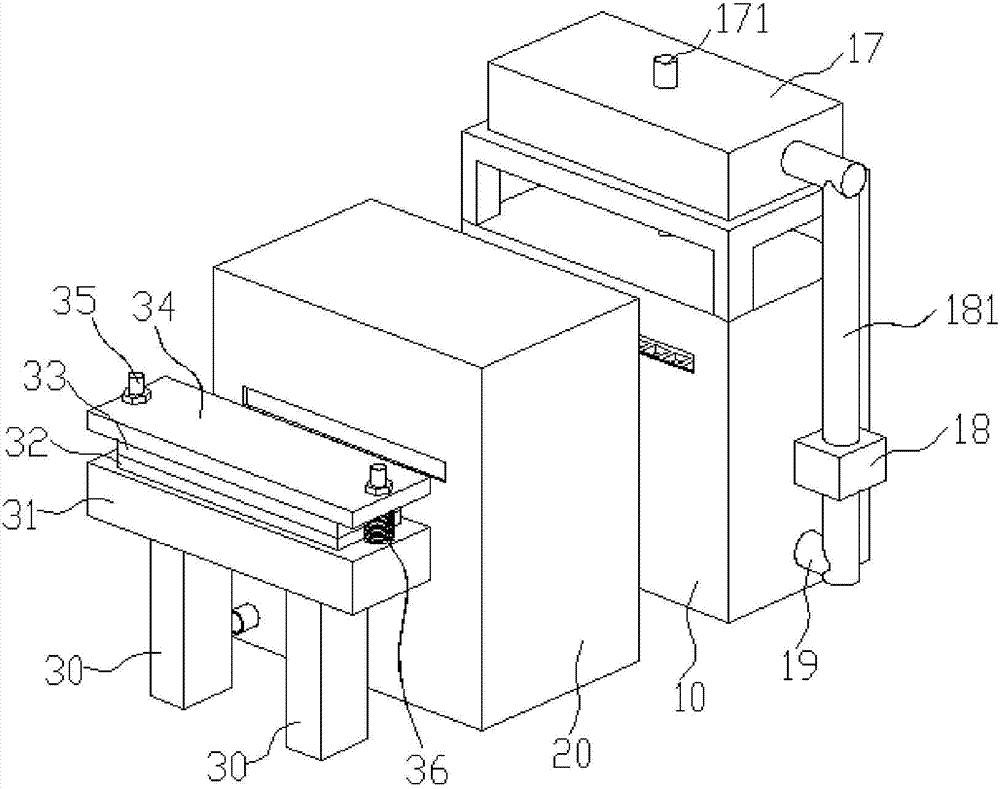

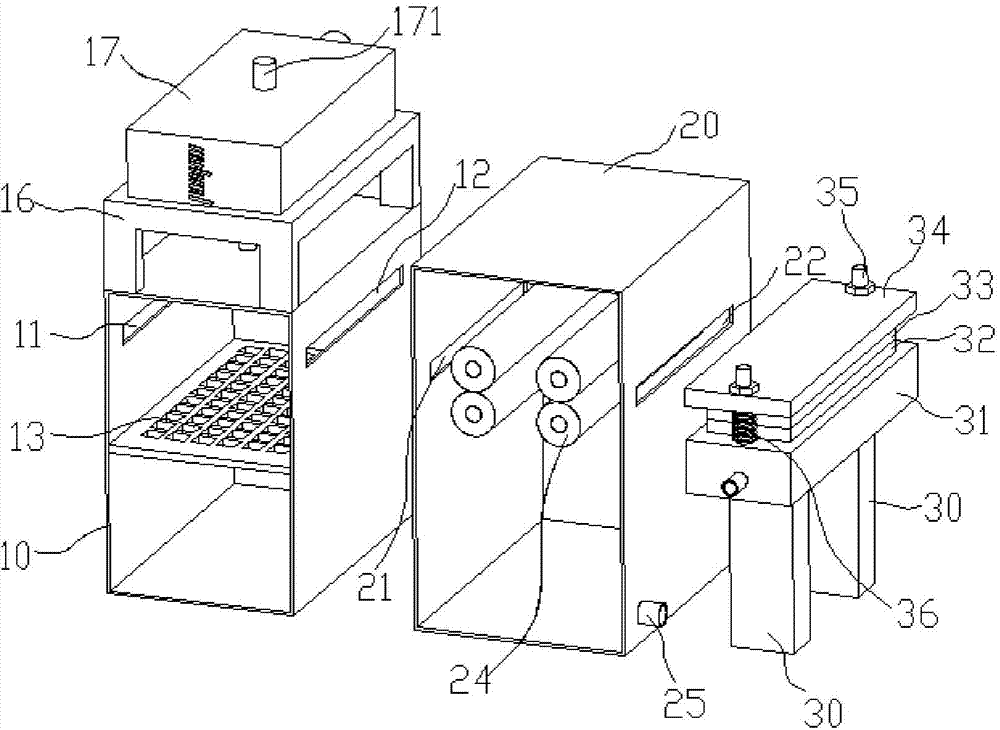

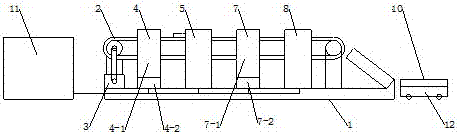

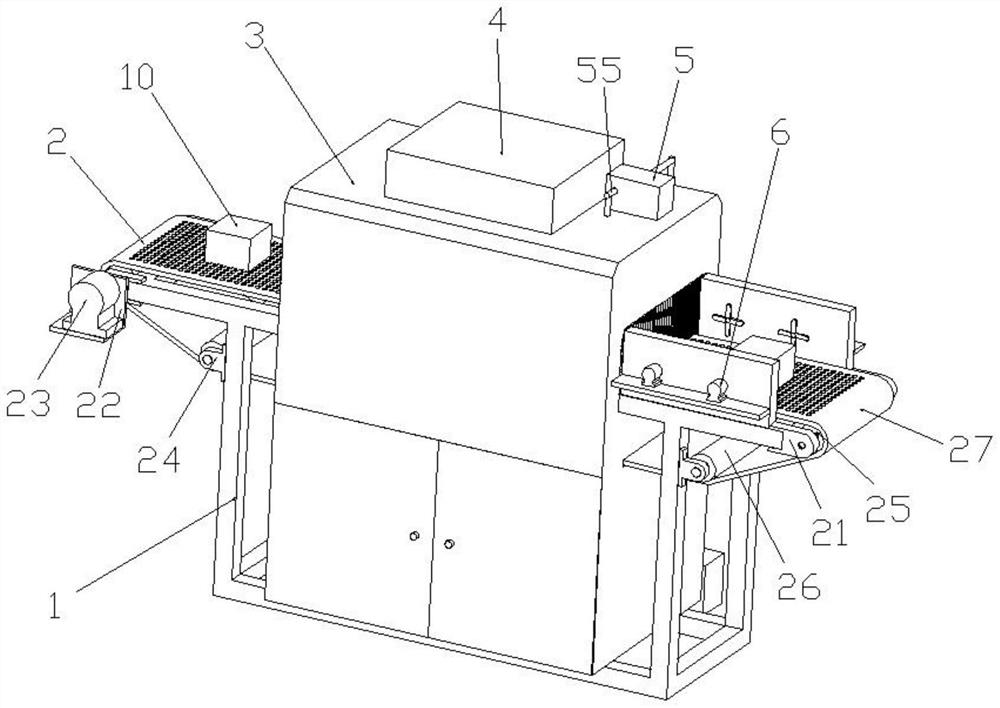

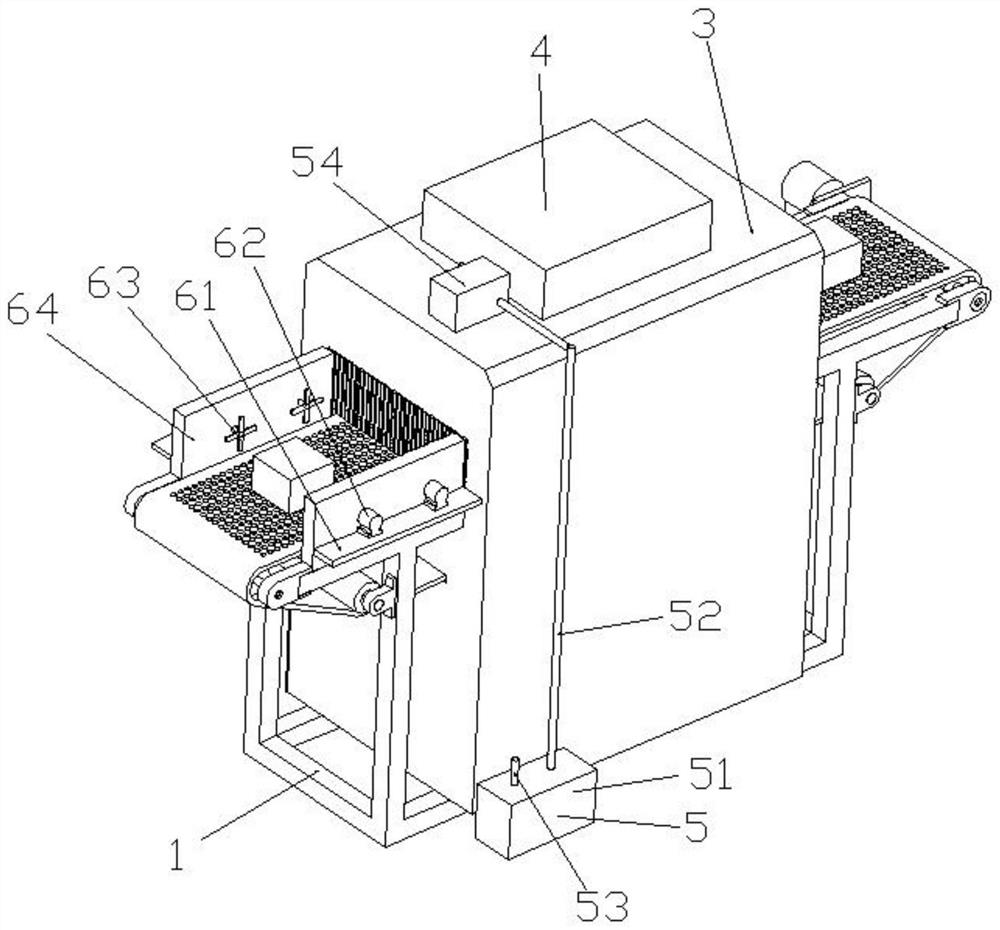

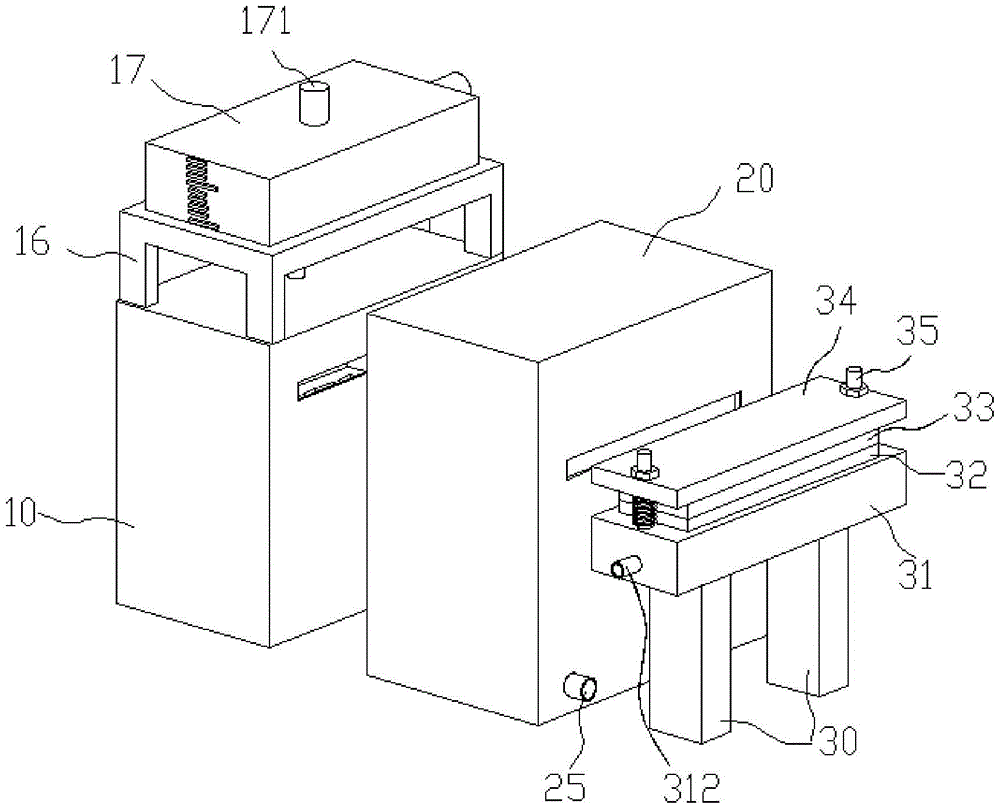

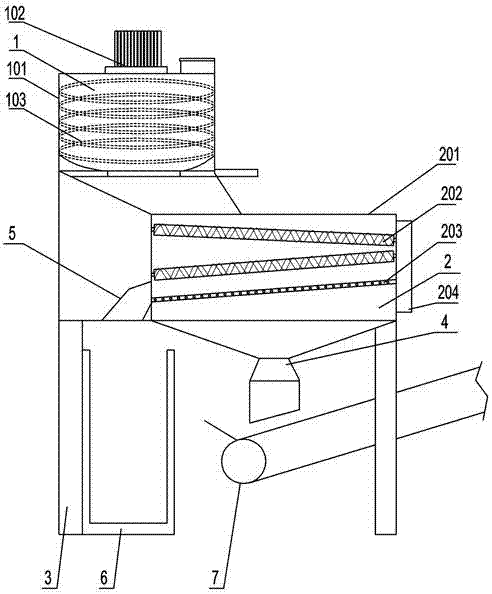

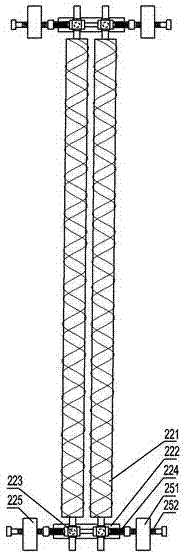

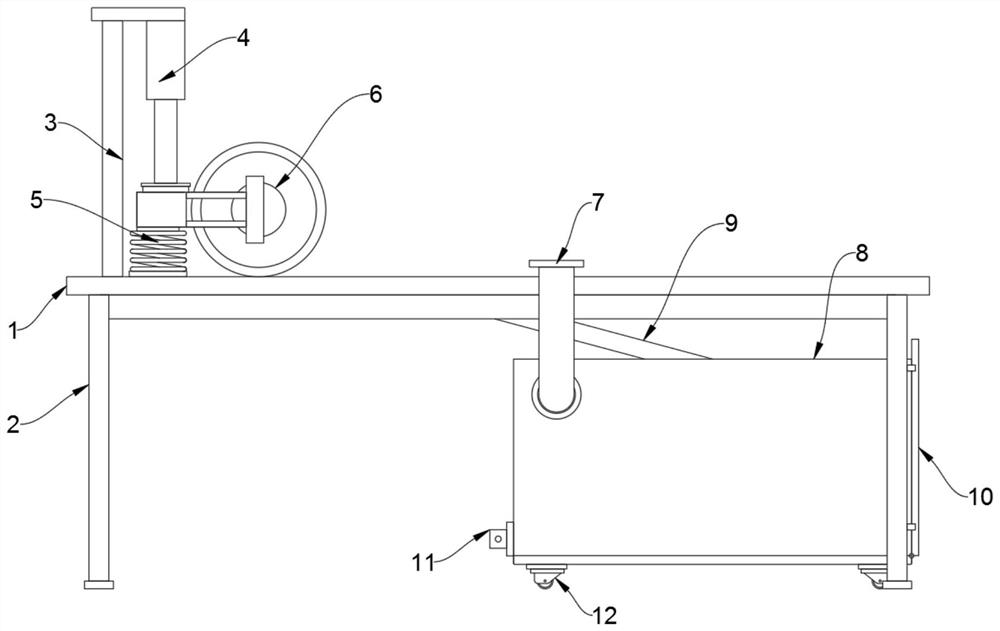

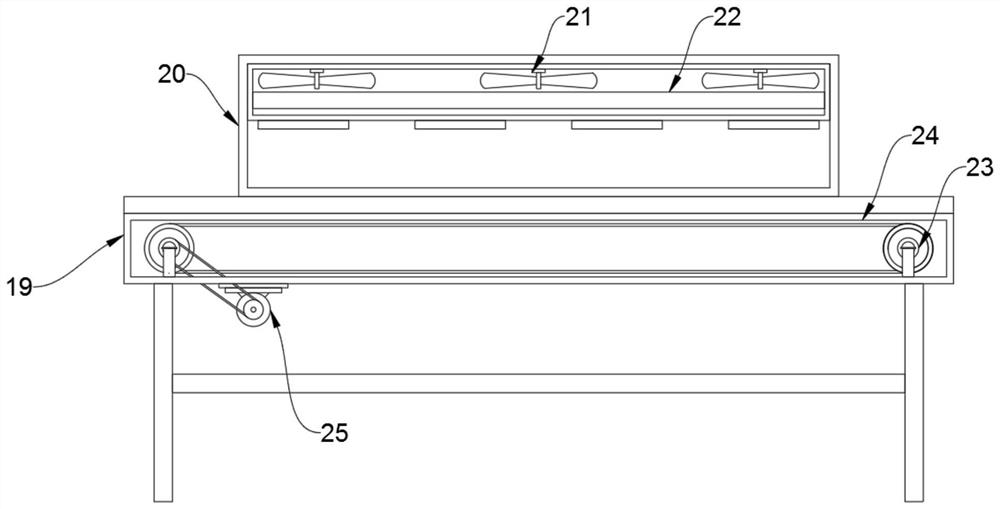

Washing device special for enameled wires

ActiveCN104841670AEfficient decompositionEasy to cleanCleaning using toolsDrying machines with progressive movementsMechanical engineeringWater tanks

The invention discloses a washing device special for enameled wires. The washing device comprises a mist spraying unit, a washing unit and a drying unit, wherein the mist spraying unit comprises a mist spraying box, a mist spraying head arranged at the top of the mist spraying box, a support arranged on the mist spraying box, and a cleaning solution box arranged on the support, the washing unit is arranged at one side of the mist spraying unit and comprises a washing box, spraying heads arranged at the top of the washing box, a washing box drain opening formed in the lower portion of the washing box, and washing roller sets arranged in a containing space of the washing box, and the drying unit is arranged at one side of the washing unit and comprises supporting columns, a water tank arranged at the tops of the supporting columns, a first water absorbing sponge arranged on the water tank, a second water absorbing sponge arranged on the first water absorbing sponge, a pressing plate arranged on the second water absorbing sponge, screw studs connecting the water tank and the pressing plate, and springs arranged on the screw studs in a sleeving mode. The washing device is good in washing effect, and the follow-up working procedures can be carried out conveniently.

Owner:江苏君墨智能装备有限公司

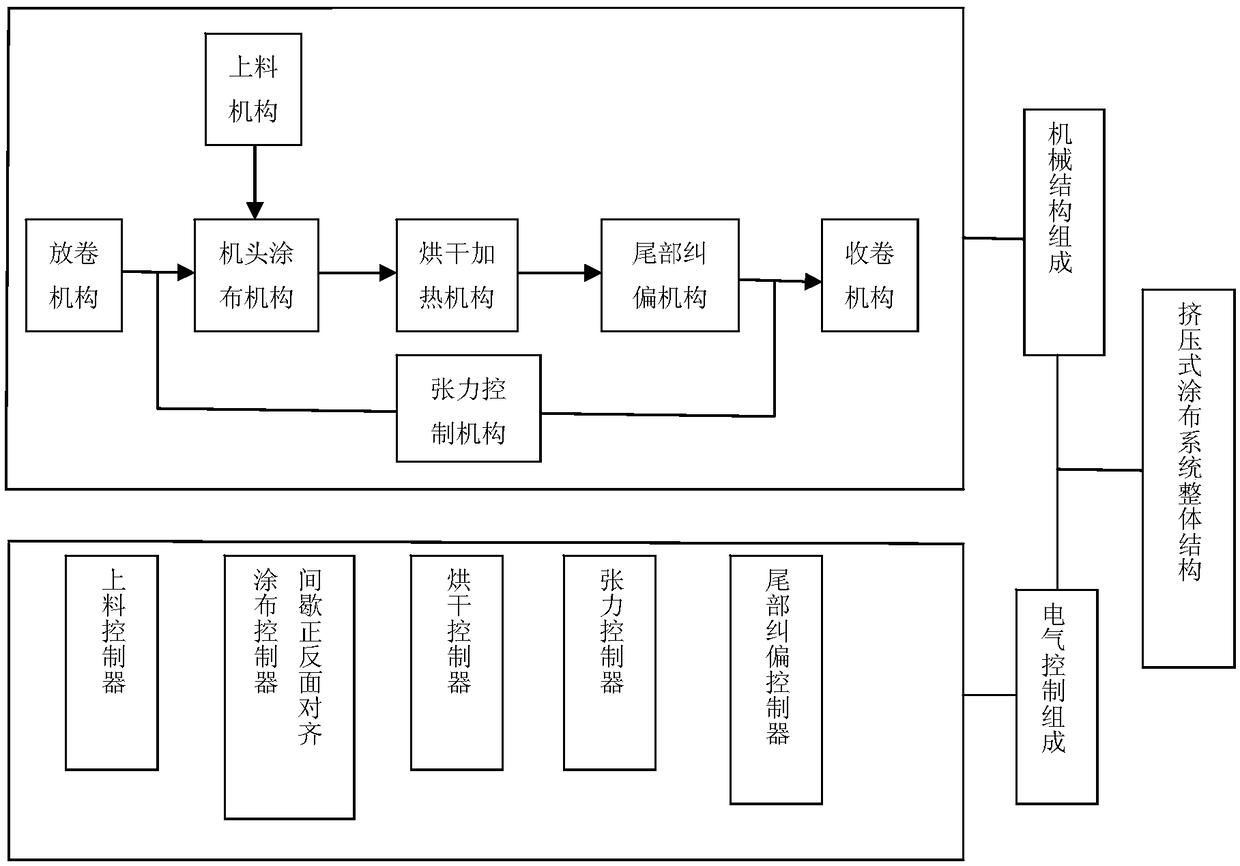

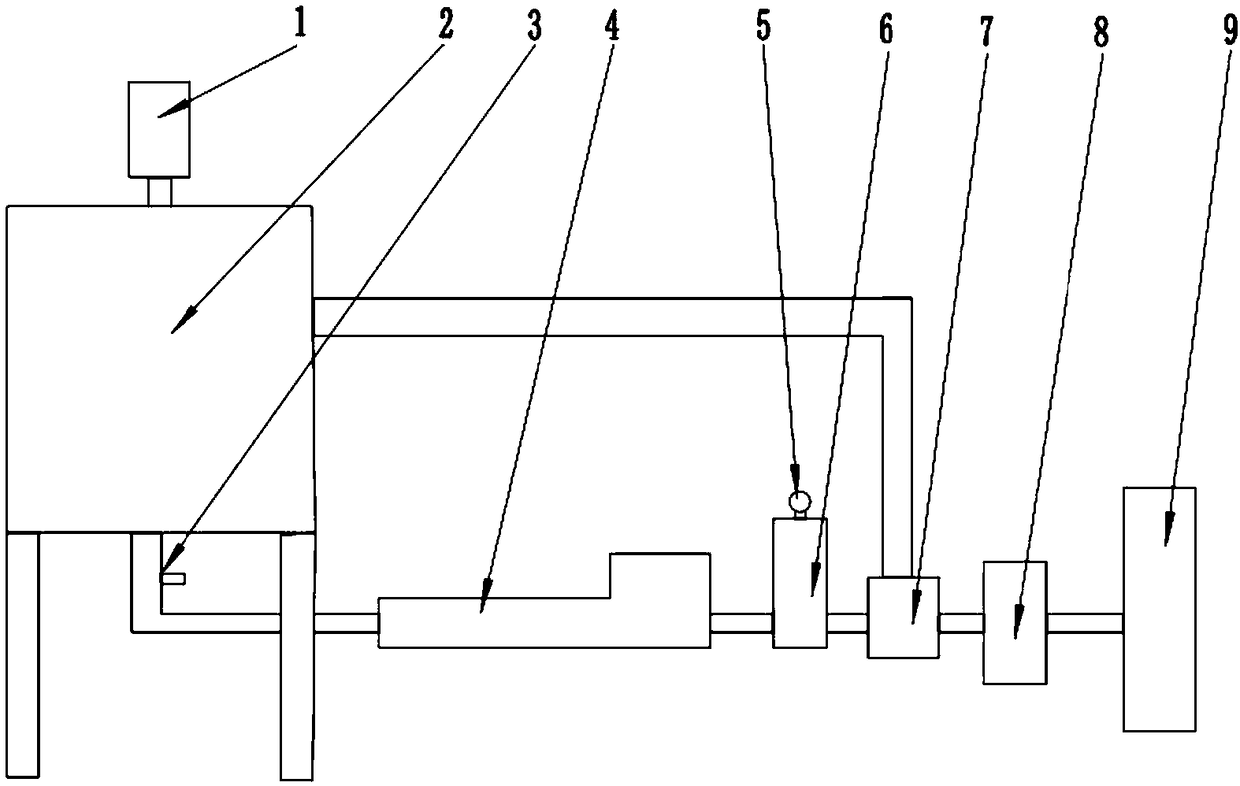

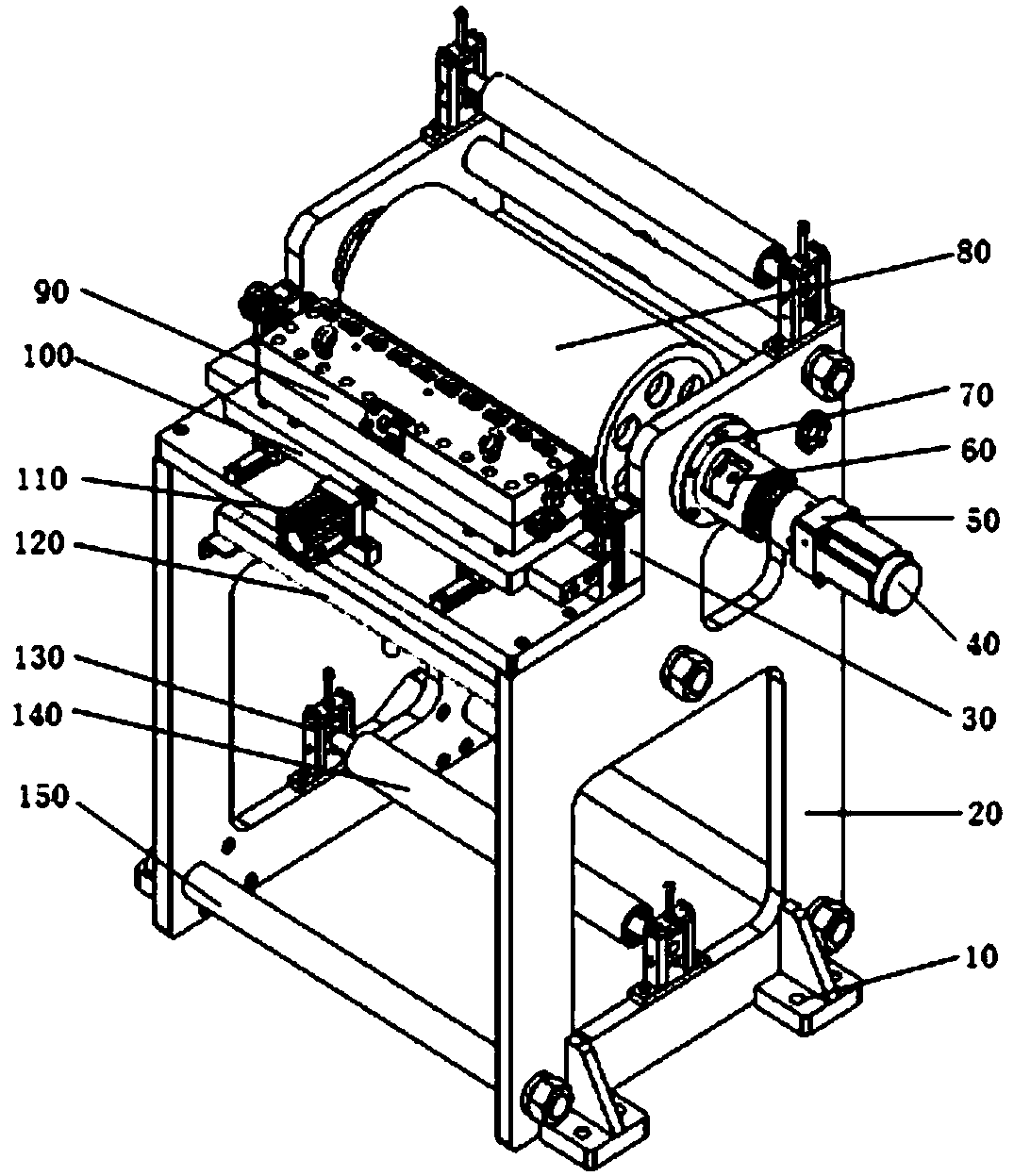

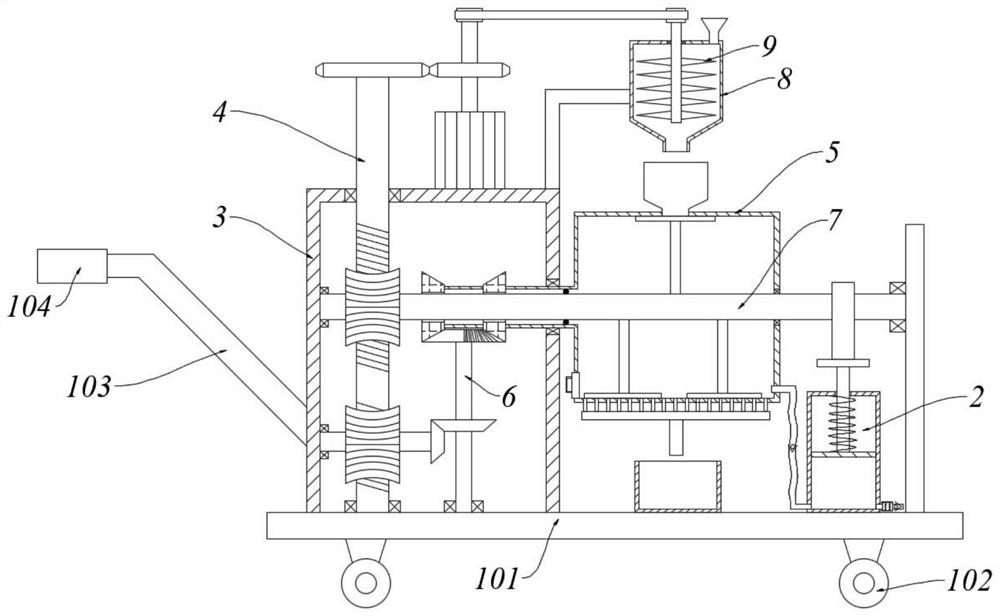

Extrusion type coating system of power lithium battery base band

ActiveCN108816645AFull dispersionFull homogenizationPretreated surfacesCoatingsCoating systemEngineering

The invention discloses an extrusion type coating system of a power lithium battery base band. The extrusion type coating system of the power lithium battery base band comprises an unwinding mechanism, a feeding device, a machine head coating device, a tension control device, a drying heating device, a tail deviation rectifying device and a winding mechanism. The unwinding mechanism releases the base band at a constant speed. The feeding device provides a stable sizing agent. The machine head coating device disperses the sizing agent to be uniform and discharges and coats the sizing agent to the base band along the position of a gap of an outlet of an extrusion mold head. The drying heating device dries the wet sizing agent coated to the base band. The winding mechanism winds the coated and dried base band. The tail deviation rectifying device can guarantee that the base band is tidy during taking up, operation of following working procedures is facilitated, and the tension control device can guarantee the best tension degree of the base band.

Owner:SOUTHEAST UNIV

Flanging machine

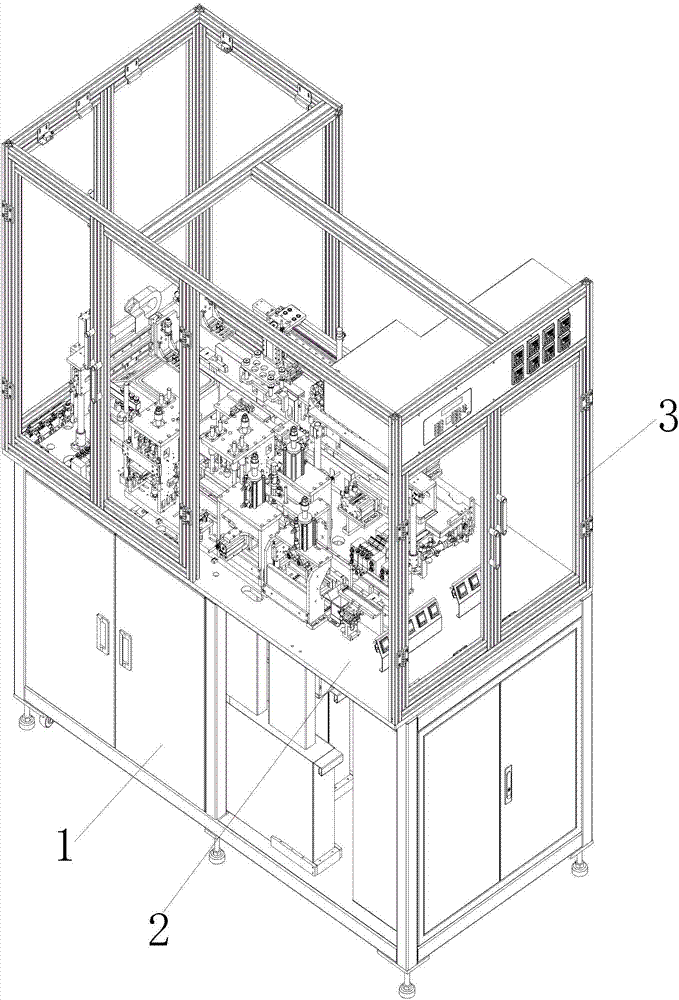

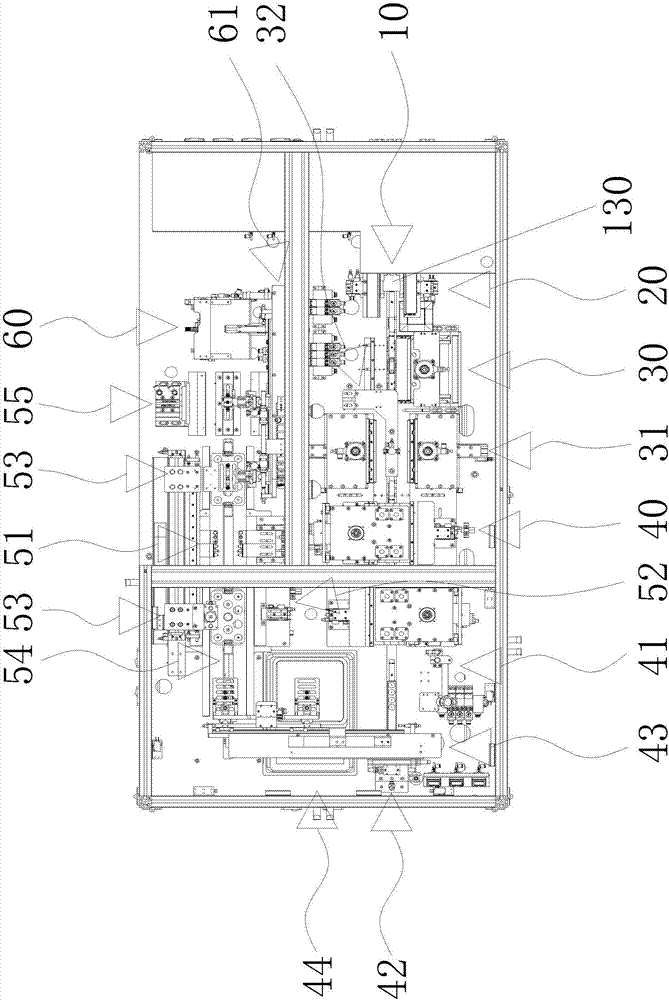

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

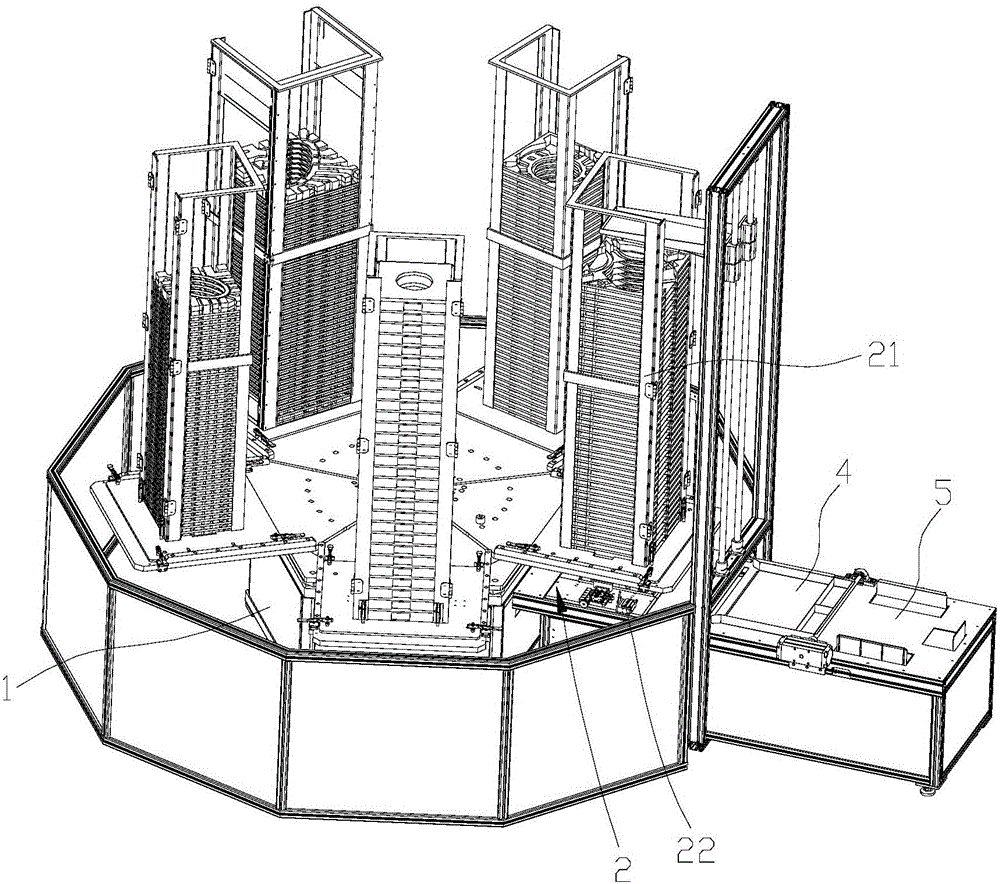

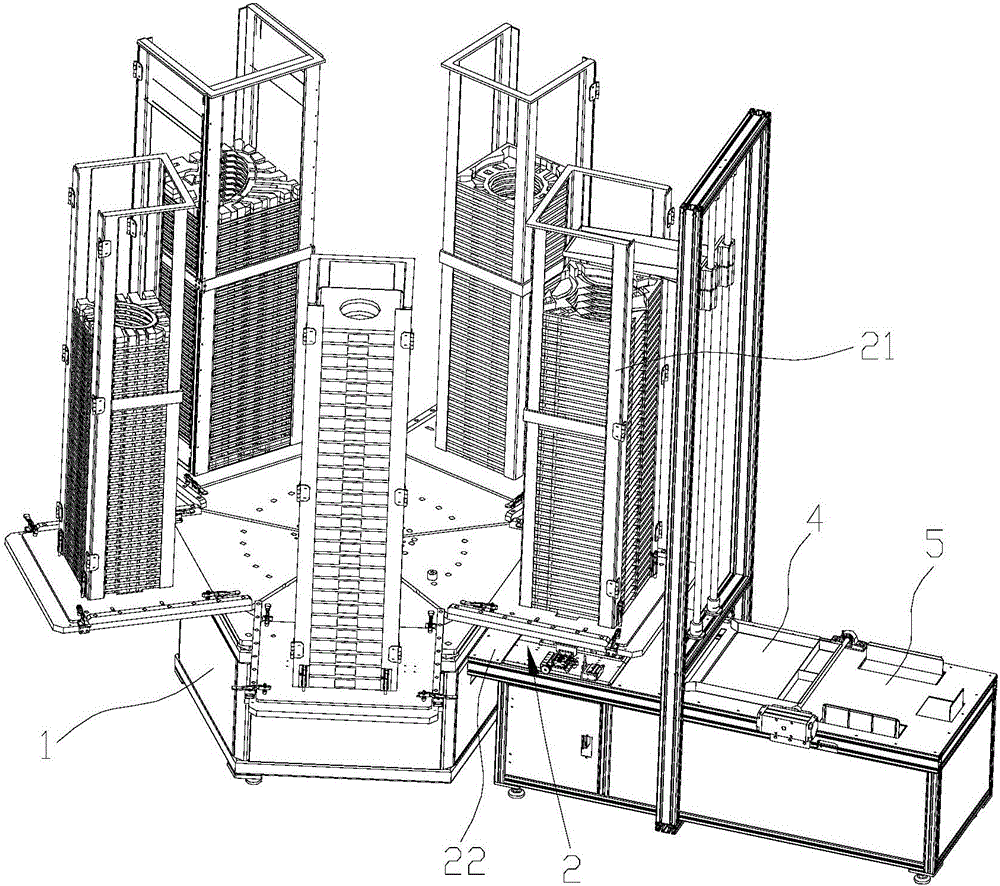

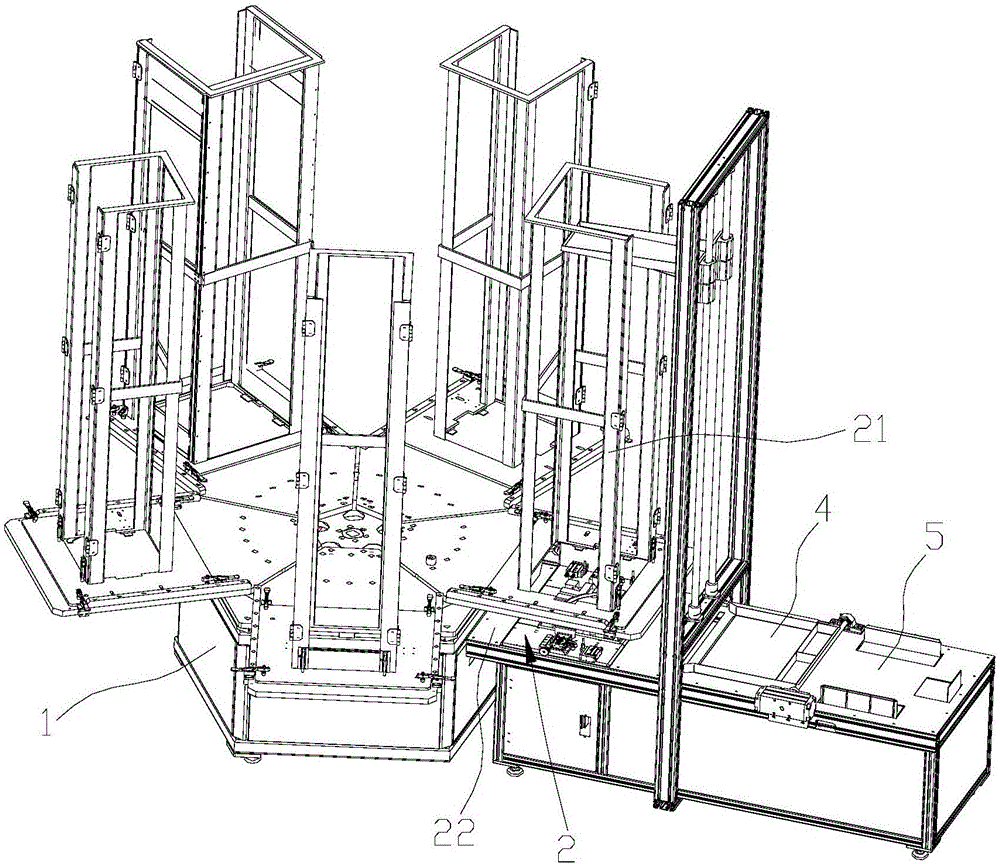

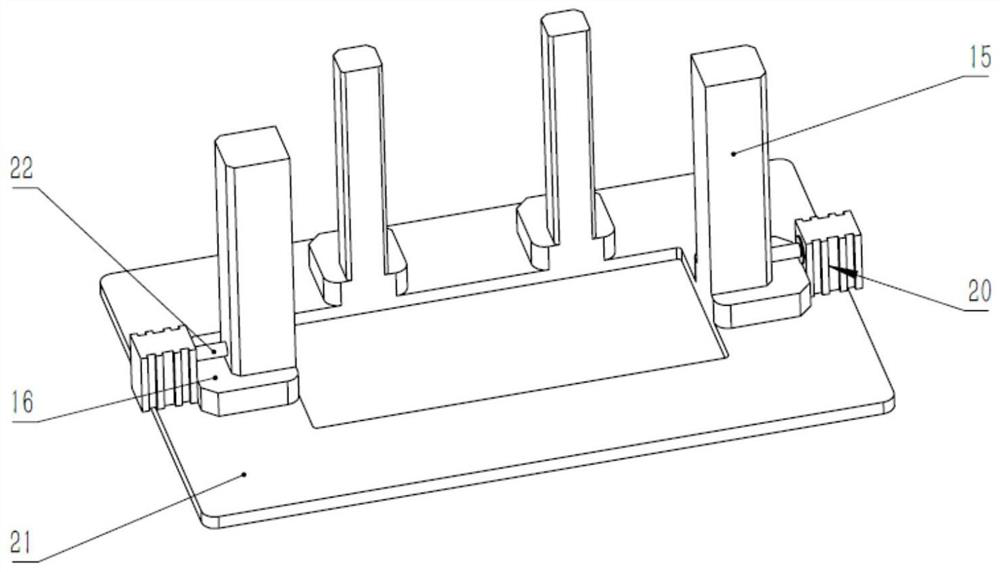

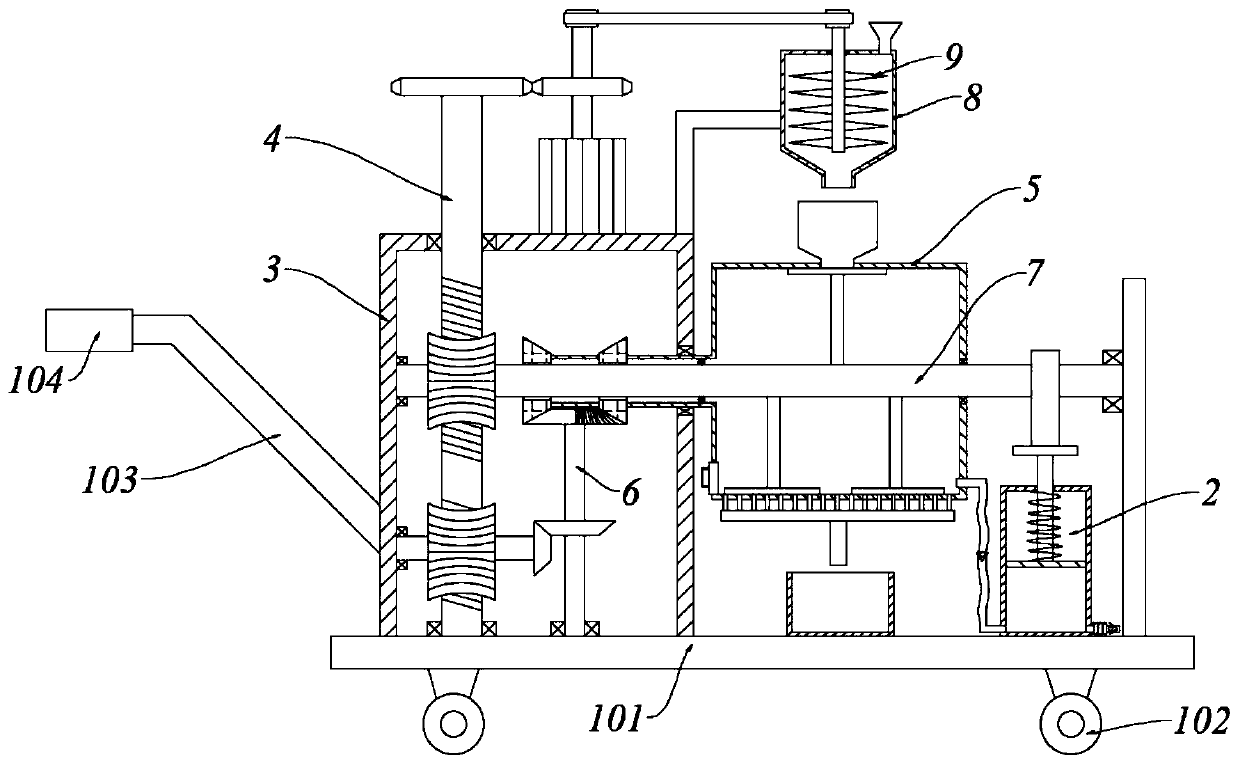

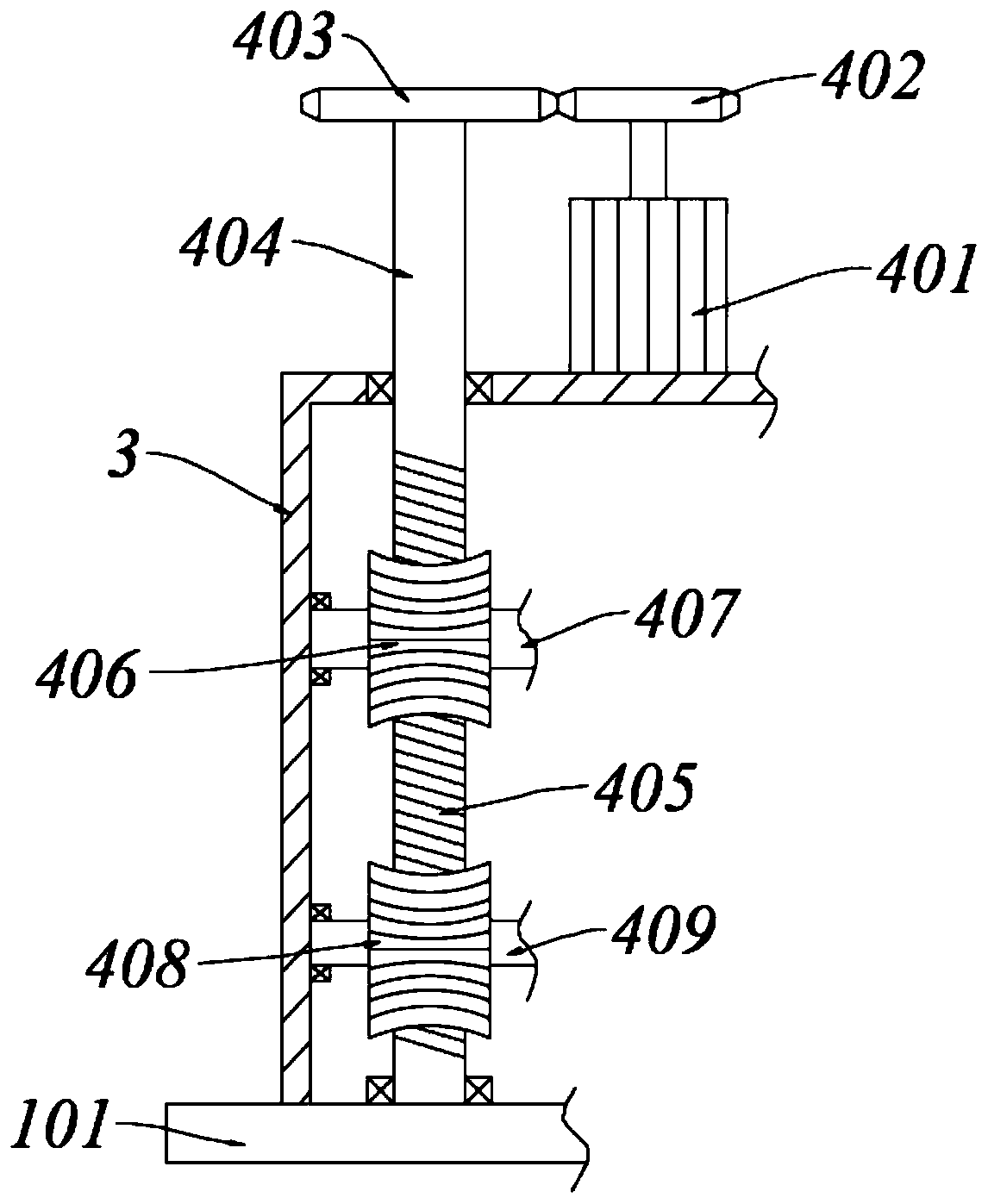

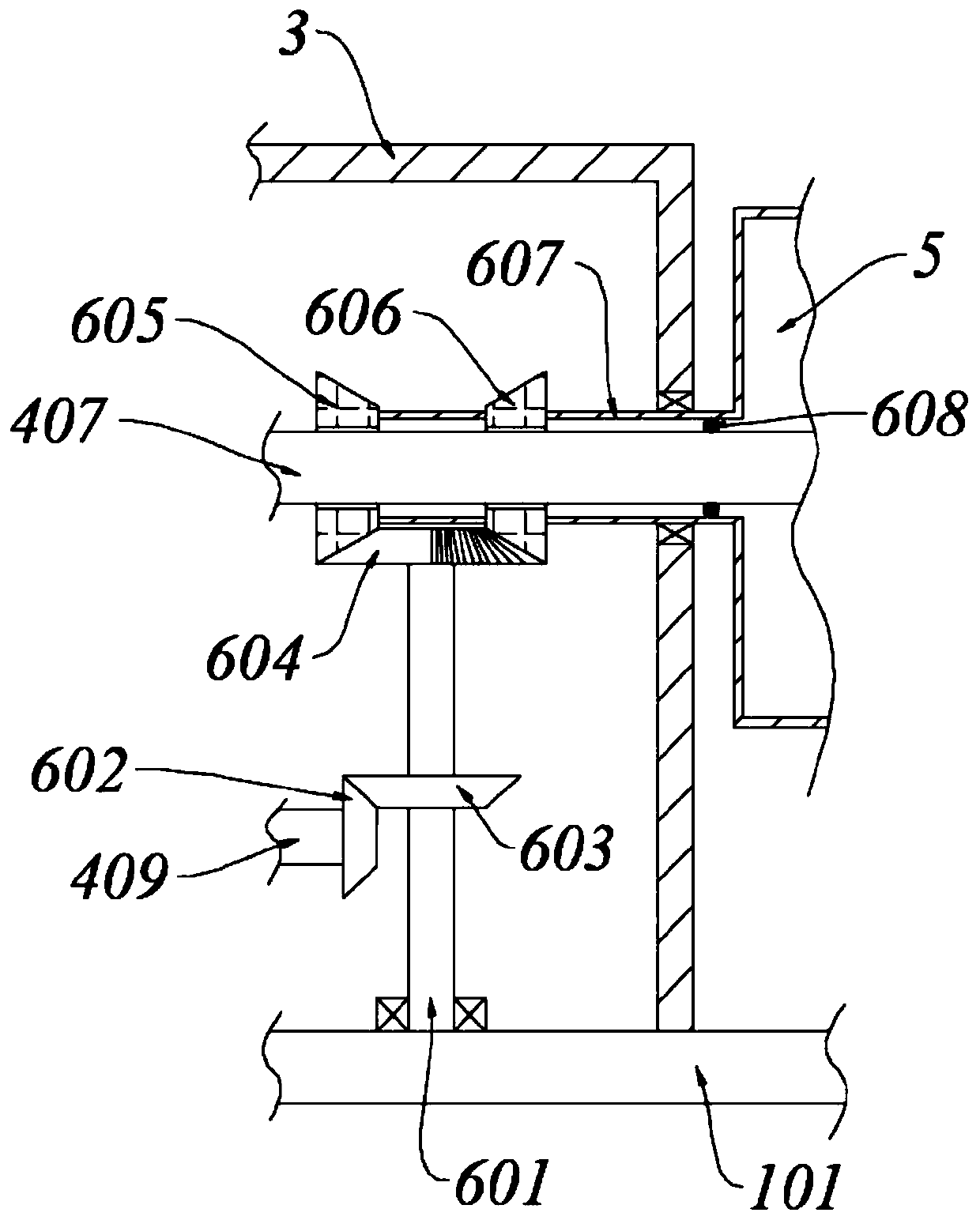

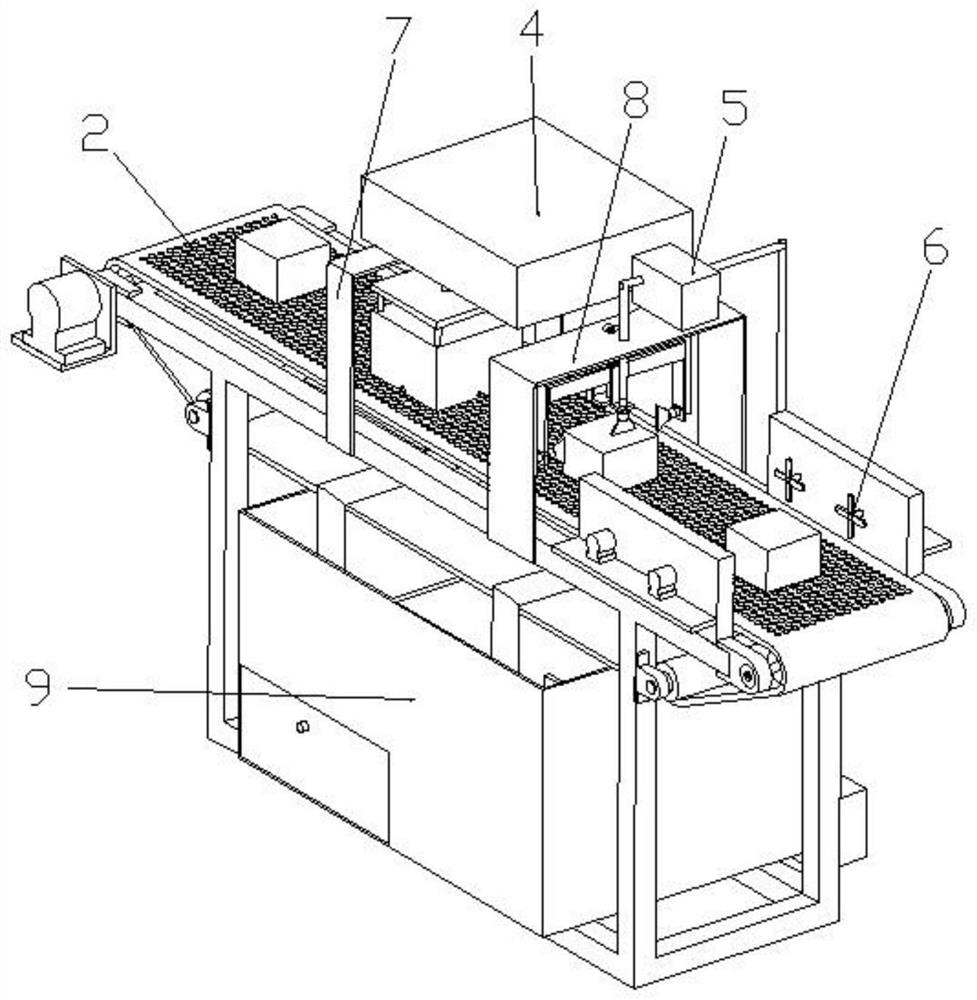

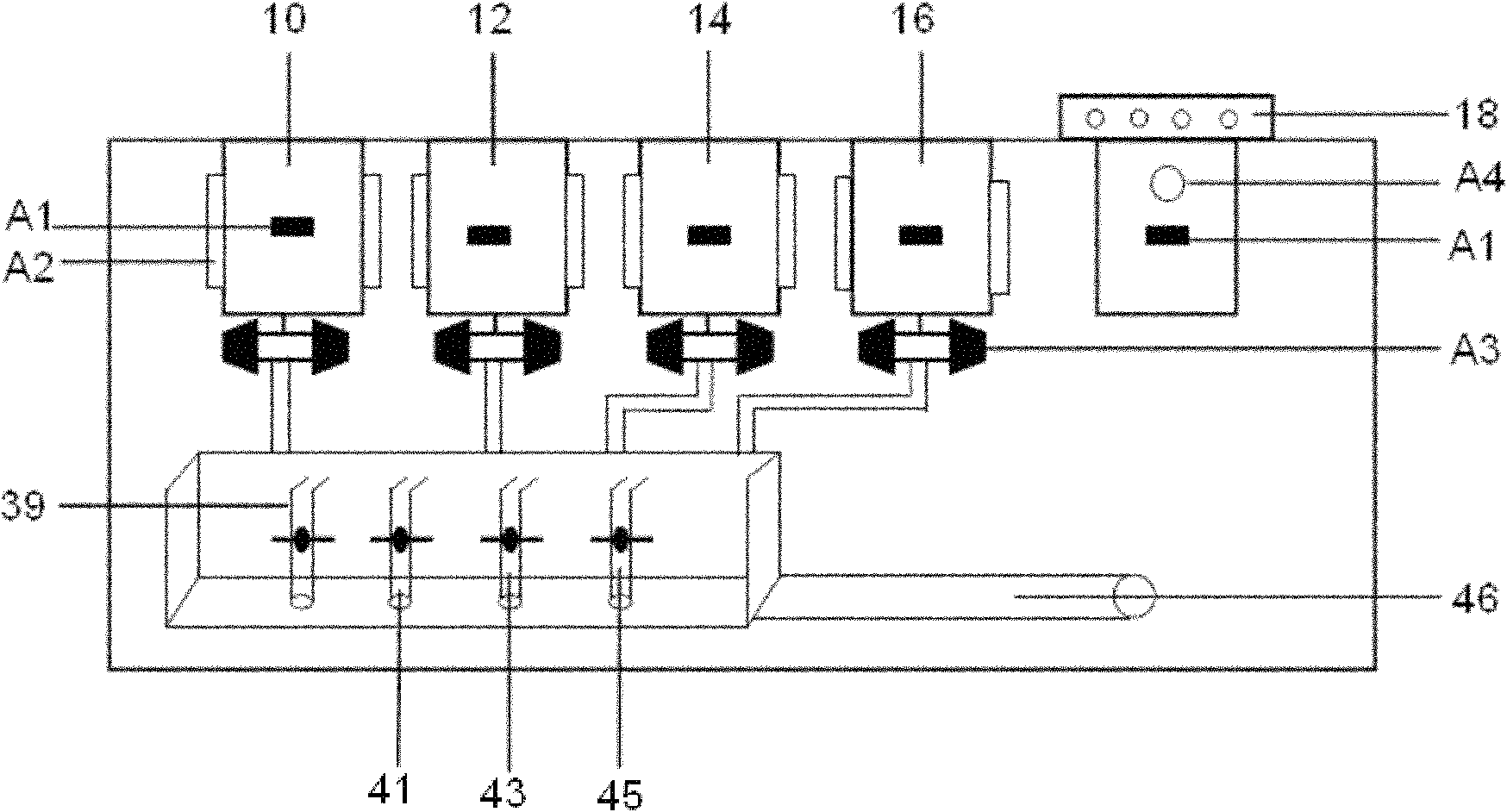

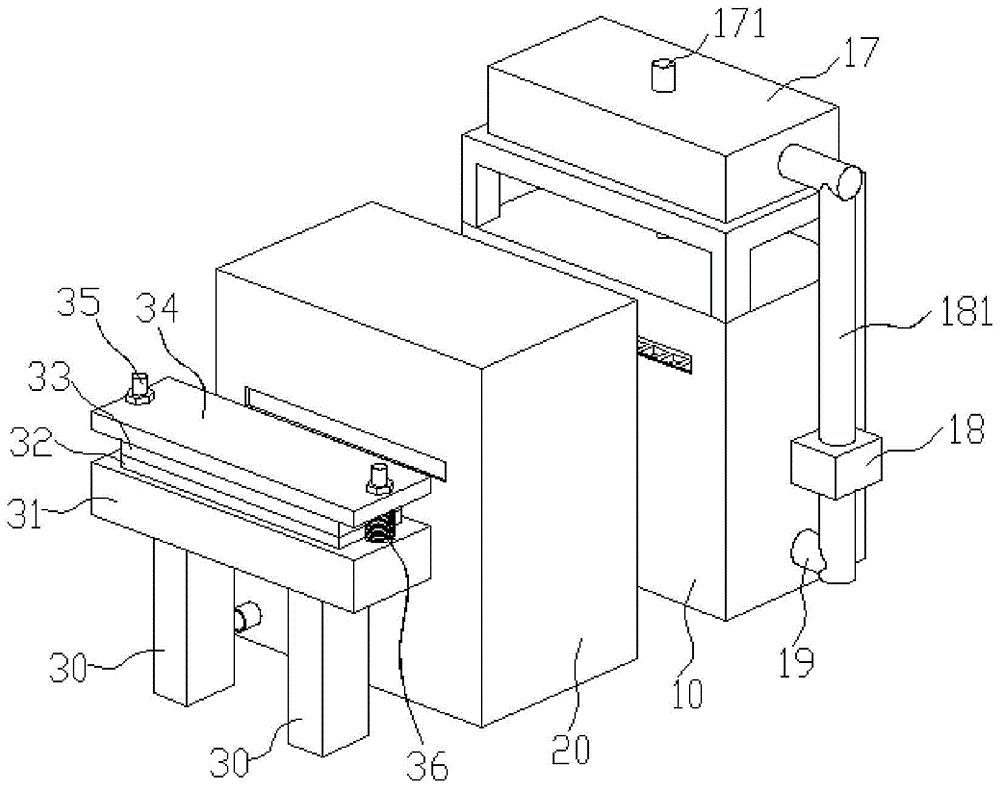

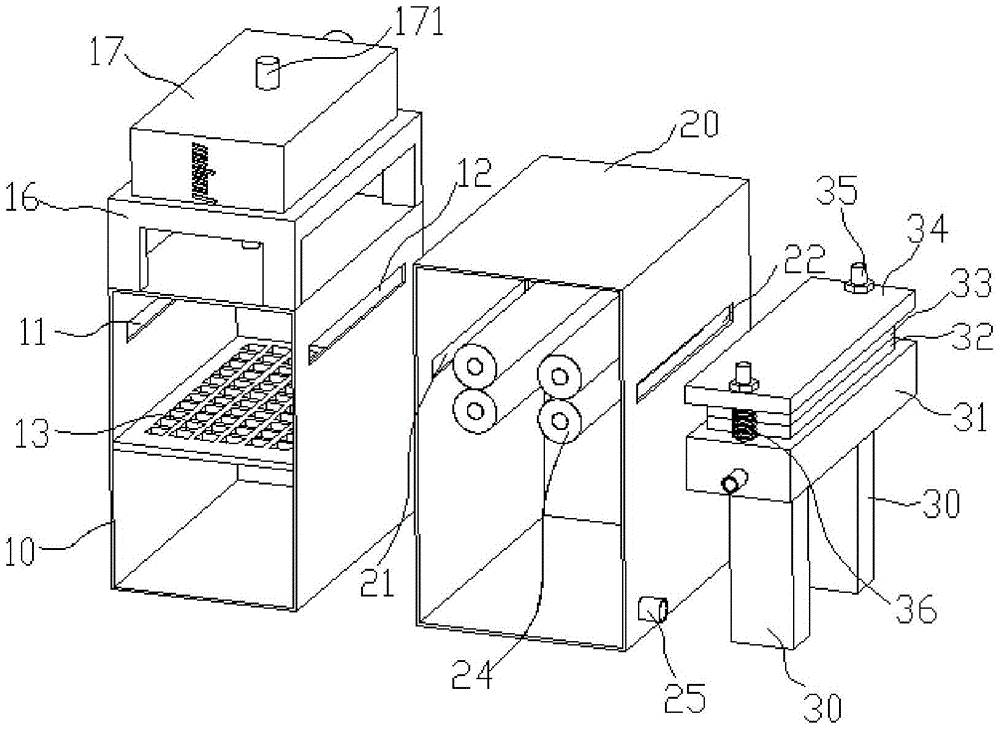

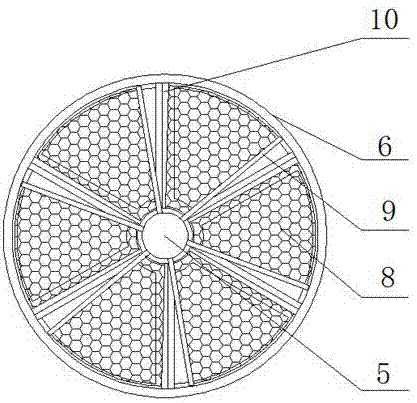

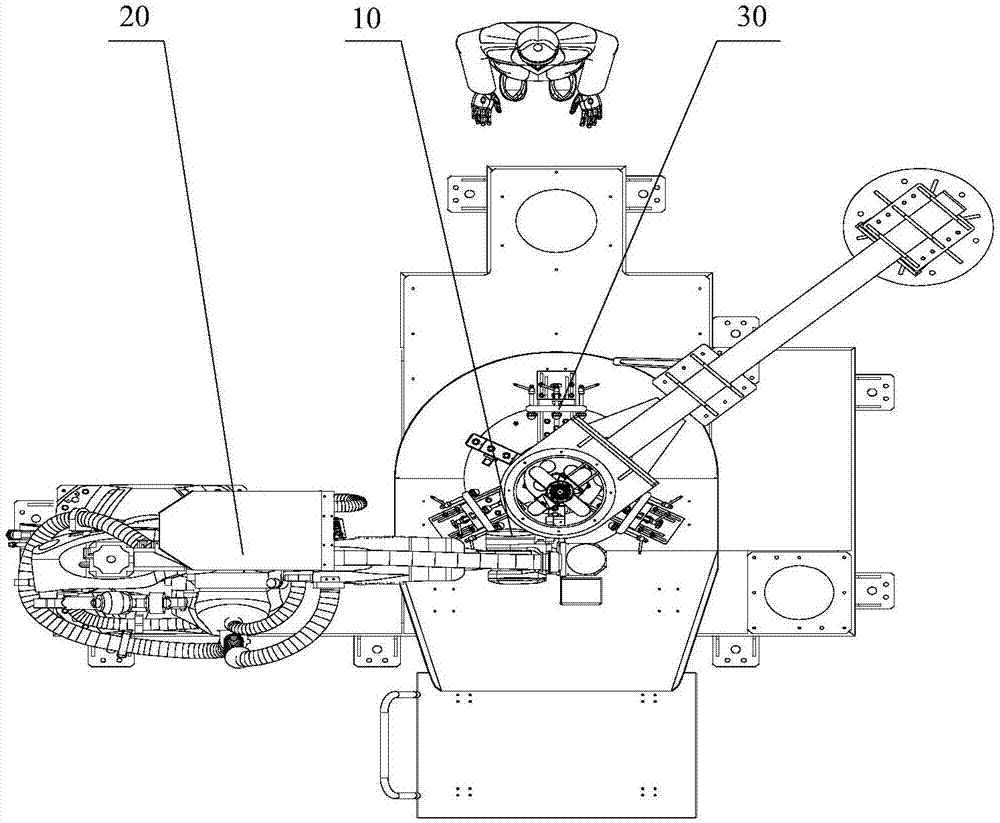

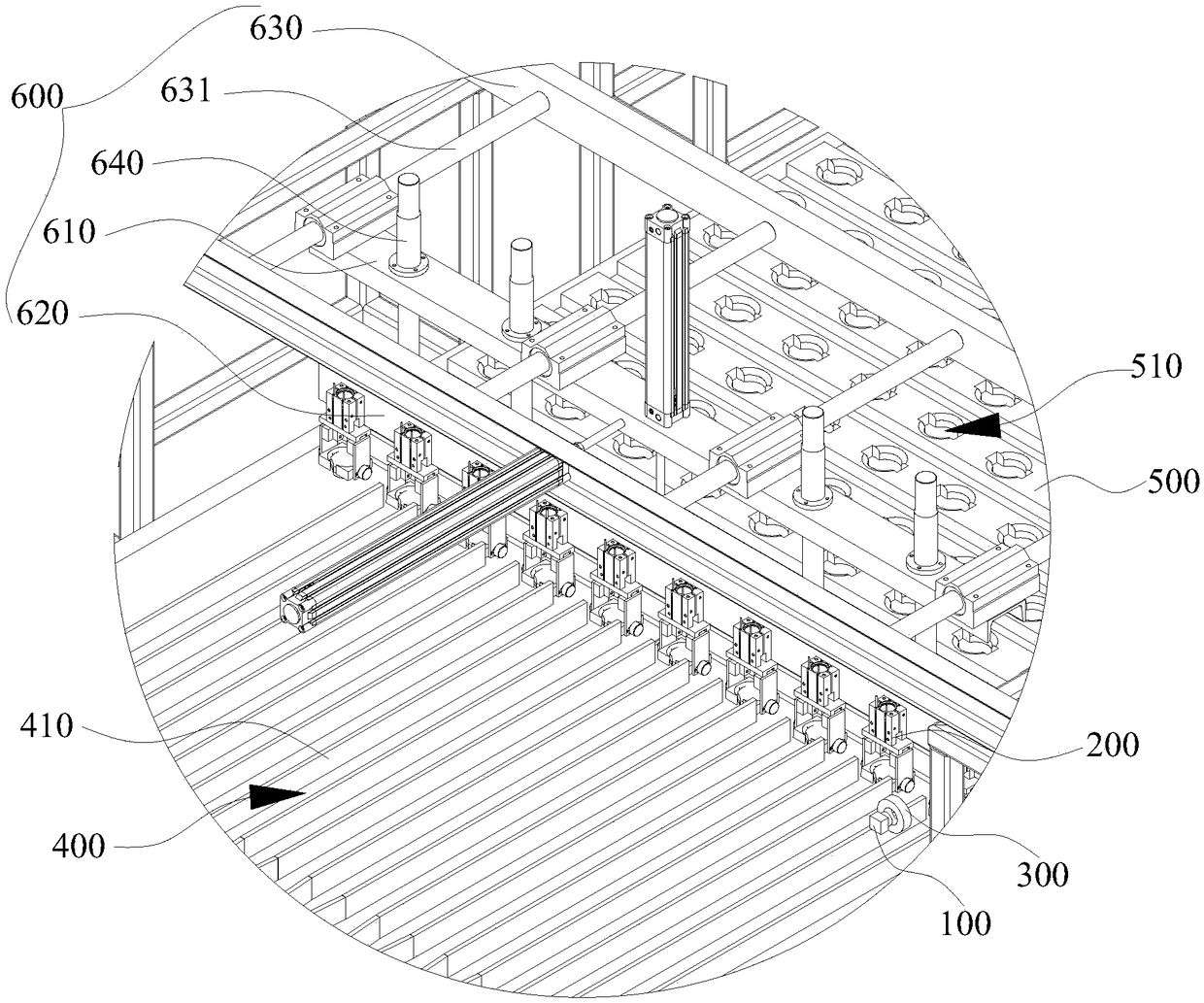

Workpiece separation system

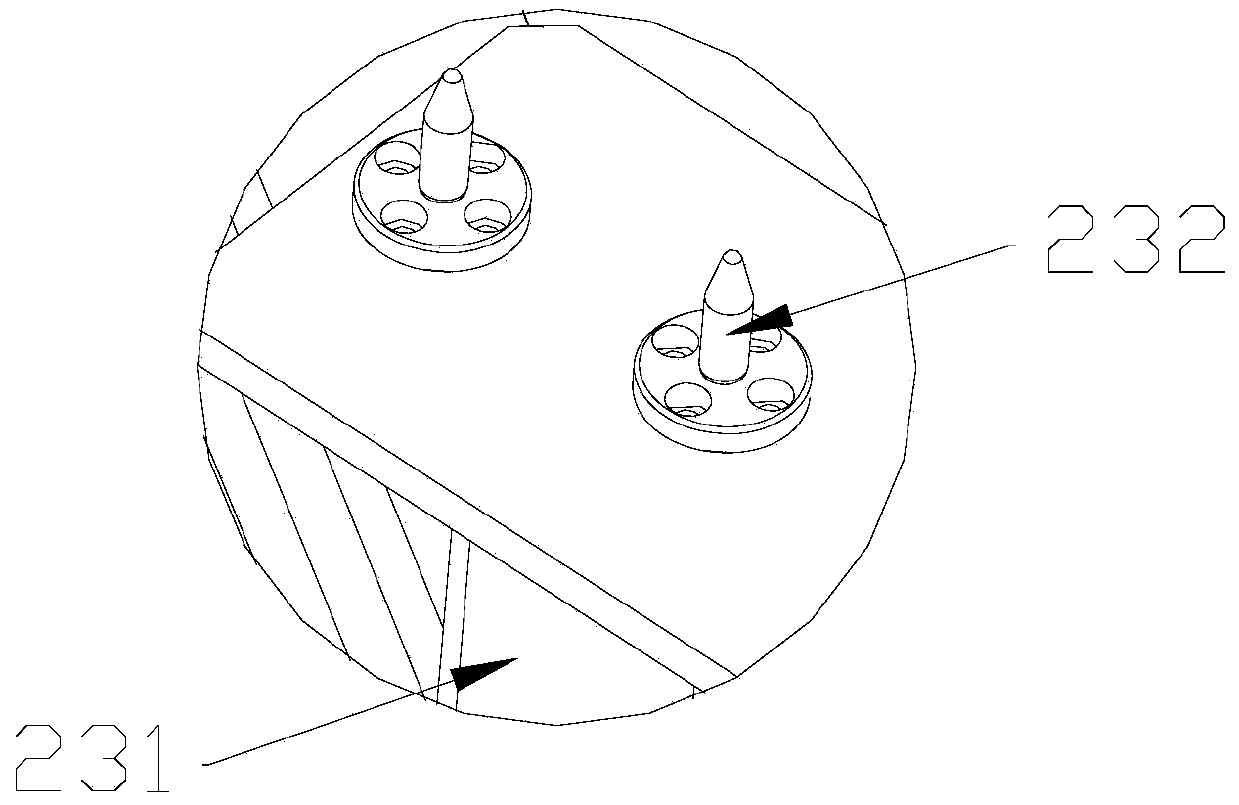

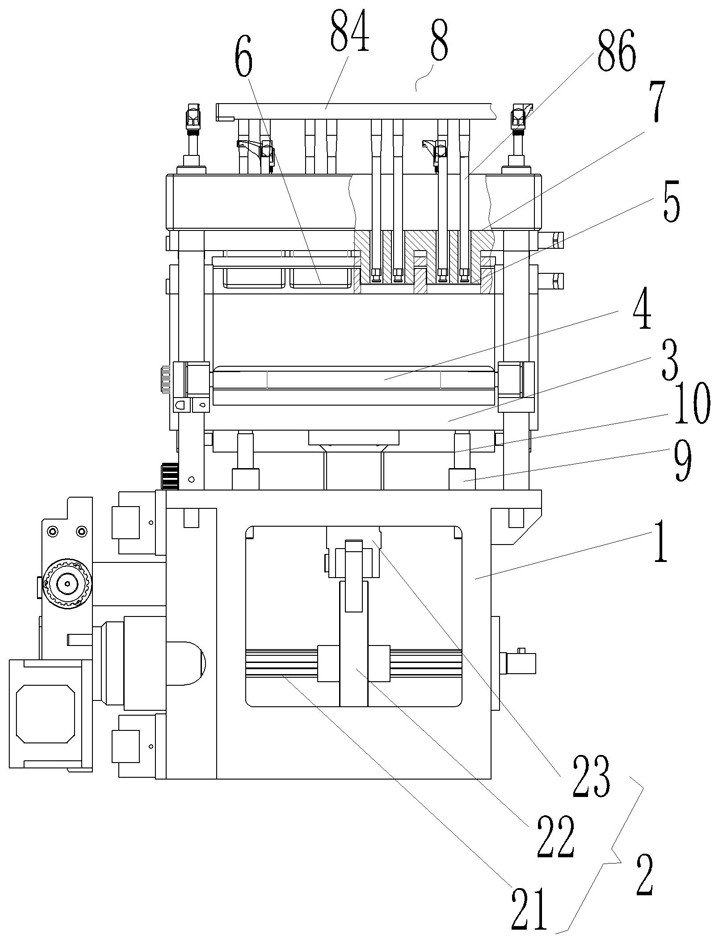

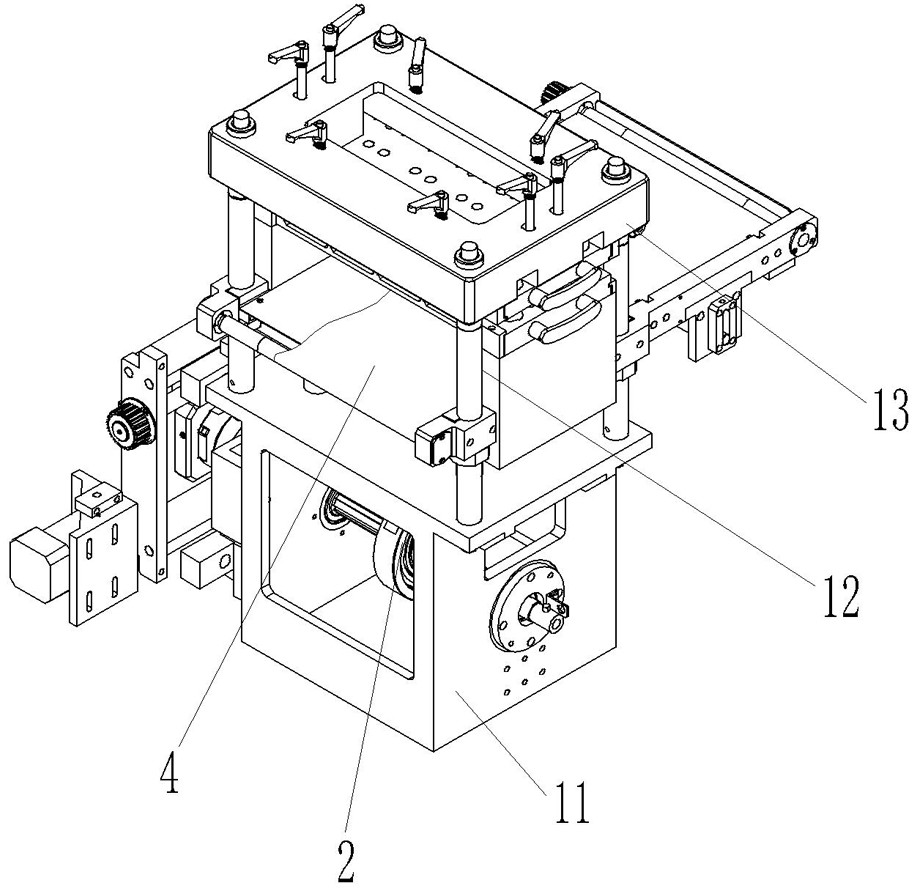

ActiveCN106276281AConvenient follow-up processRealize automatic separationDe-stacking articlesConveyor partsSeparation systemMaterial storage

The invention discloses a workpiece separation system. The workpiece separation system comprises a conveying device, a material dividing device, a pushing device, an overturning device and an adjusting device; the material dividing device comprises a material storage device used for storing stacked workpieces and a separation device used for separating the workpieces on the bottommost layer, and the material storage device is arranged on the conveying device; the conveying device is used for conveying the material storage device to the separation device and enables the separation device to separate the workpieces on the bottommost layer; the pushing device is used for pushing the separated workpieces to the overturning device; the overturning device is used for overturning the separated workpieces; and the adjusting device is used for adjusting the positions of the overturned workpieces. By means of the above structural arrangement, automatic separation of the stacked workpiece and automatic overturning of the separated workpieces are achieved through the separation system, the production automation is further achieved, and the production efficiency is effectively improved.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

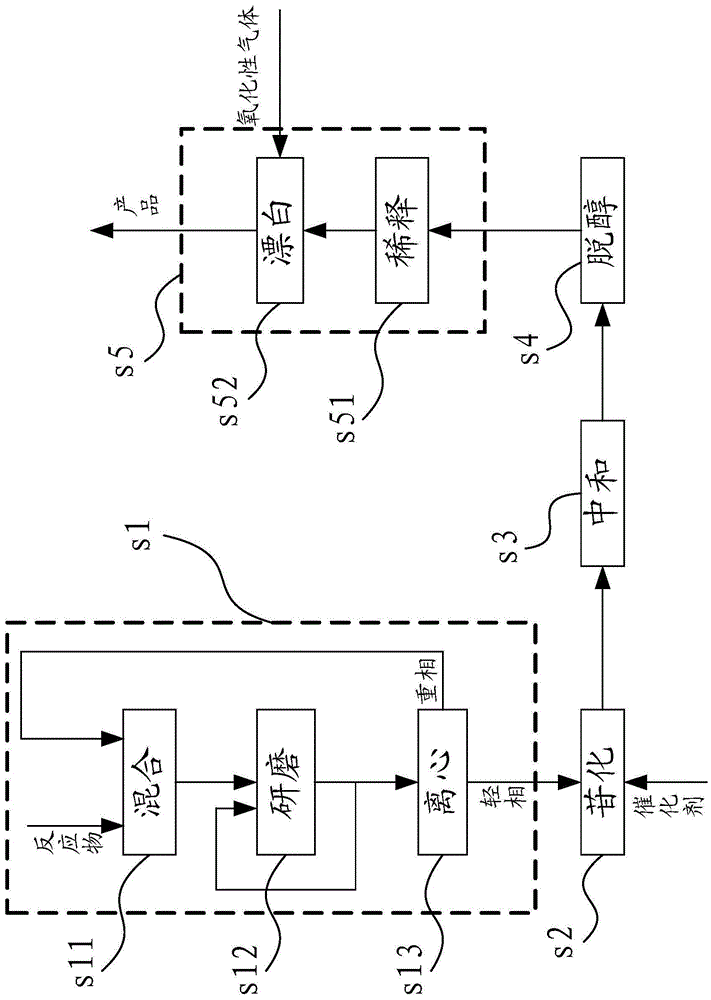

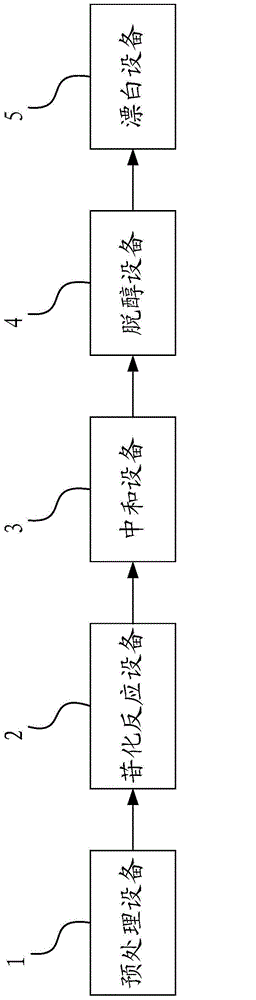

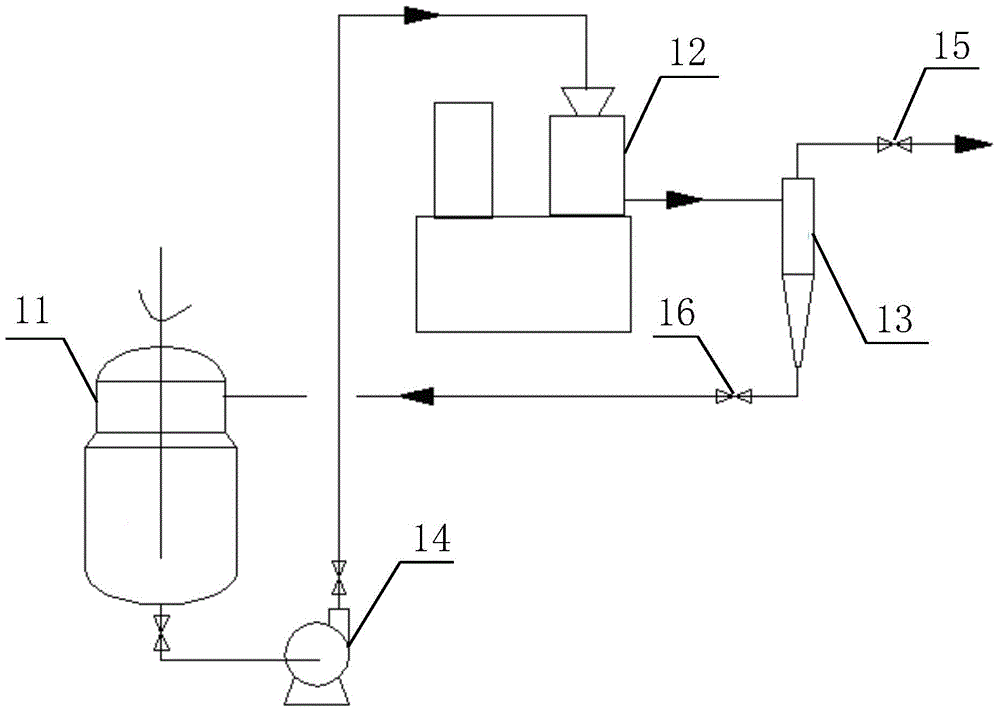

Method and system using one-step method for continuous production of alkyl glycoside

ActiveCN104418920AContinuous glycoside reactionIncrease profitSugar derivativesChemical/physical/physico-chemical stationary reactorsColloid millContinuous production

The invention discloses a method and system using one-step method for continuous production of alkyl glycoside, the system comprises pretreatment equipment, glycosidation reaction equipment and bleaching equipment, the pretreatment equipment comprises a mixing kettle, a colloid mill and a particle fraction separator, the glycosidation reaction equipment is provided with multistage independent reaction units, the bleaching equipment is provided with an overflow wall and a reaction chamber, the method is mainly as follows: before the glycosidation reaction, reactants are mixed by the mixing tank, and ground by the colloid mill for quasi solation treatment to make the glucose particle size not more than 10 mu m to form a stable and uniform sol phase, the stable and uniform sol phase enters into the particle fraction separator for separation of a light phase, the light phase is sent into the a glycosidation reactor for multistage glycosidation reaction for continuous production of an alkyl glycoside crude product, after neutralization and dealcoholization, the alkyl glycoside crude product through the overflow wall overflows into the reaction chamber for the formation of a liquid film, and a finished product is prepared by bleaching after oxidizing gas / liquid film contact. The method can realize the continuous production of the alkyl glycoside by one-step method, and the product quality is stable and uniform.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Oil tea fruit cleaning device

PendingCN107125784AImprove cleaning effectImprove cleaning efficiencyFatty-oils/fats productionFood treatmentEngineeringOil processing

The invention relates to the technical field of tea oil processing, in particular to an oil tea fruit cleaning device. The device comprises a base, wherein a groove is formed at the upper end of the base; support columns are arranged on the two sides of the groove and vertically fixed at the upper end of the base; telescoping mechanisms are arranged at the bottom in the groove; a bearing plate is arranged at the upper ends of the telescoping mechanisms; a cleaning tank is arranged at the upper end of the bearing plate; support legs are arranged at the lower end of the cleaning tank; traveling wheels are arranged at the lower ends of the support legs; limitation grooves corresponding to the traveling wheels in position are formed at the upper end of the bearing plate; limitation plates are arranged on the two sides of the limitation grooves; limitation rods are arranged on the limitation plates in a penetrating manner; hollow clamp grooves corresponding to the limitation rods in position are formed in the support legs; and the limitation rods penetrate through the hollow clamp grooves. The oil tea fruit cleaning device can sufficiently clean oil tea fruits, improves cleaning efficiency and provides great convenience to a subsequent procedure of the tea oil processing.

Owner:湖南神农国油生态农业发展有限公司

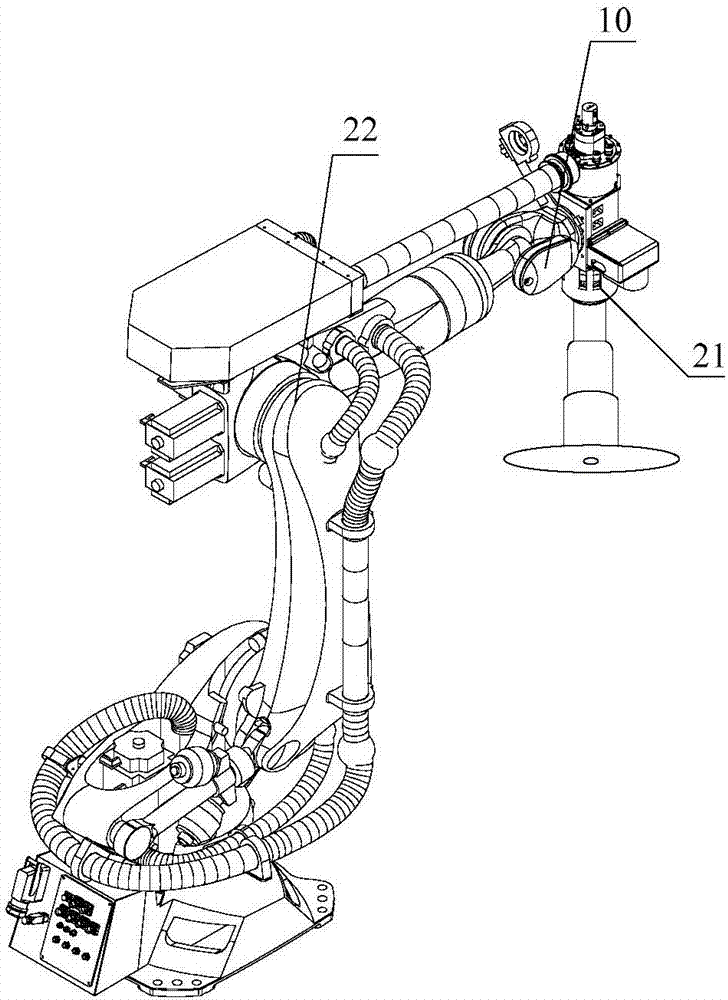

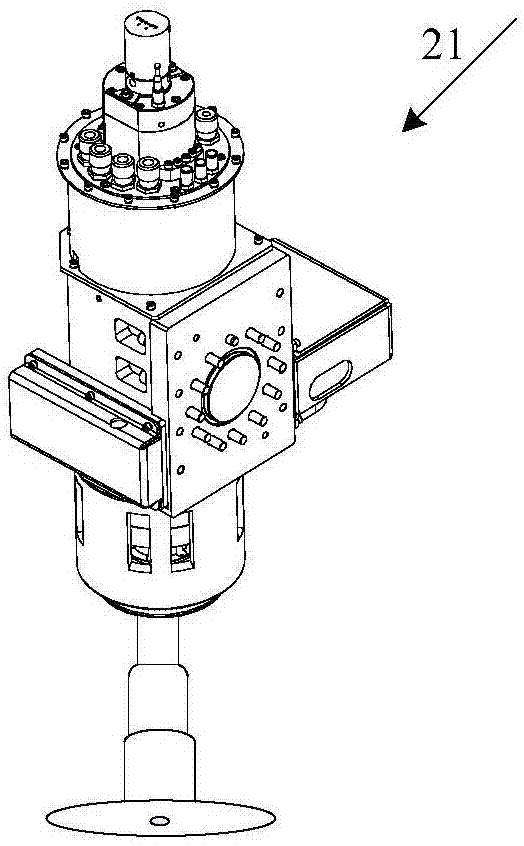

Automatic gluing equipment for shoemaking

ActiveCN110916295AGuaranteed stabilityGuaranteed repeat positioning accuracyShoe gluingRobot handLaser scanning

The invention provides automatic gluing equipment for shoemaking. The invention belongs to the field of shoemaking equipment, the equipment comprises a tray bottom plate, and a six-axis manipulator, agluing assembly, a dispensing assembly and a laser scanning assembly which are arranged on the tray bottom plate, the six-axis manipulator clamps the shoe tree to move through the clamping assembly;wherein the gluing assembly comprises a gluing machine and a gluing spray head which are integrally arranged, the dispensing assembly comprises an automatic dispensing machine and a bottom plate assembly, the bottom plate assembly is arranged on a station of the automatic dispensing machine, the number of the laser scanning assemblies is two, one laser scanning assembly is directly arranged on thetray bottom plate, and the other laser scanning assembly is arranged at the end, close to the bottom plate assembly side, of the automatic dispensing machine. According to the invention, the dispensing and gluing requirements of different positions of the vamp are met, and the gluing quality is improved.

Owner:FUDAN UNIV

Blanking device of bubble cap packaging machine

PendingCN112093173AConvenient follow-up processIncrease productivityPackagingConveyor partsStructural engineeringBlister pack

The embodiment of the invention provides a blanking device of a bubble cap packaging machine. The blanking device comprises an installation frame, a first driving mechanism, a lower die base, a conveying belt, a lower die, an upper die, and a material pressing stable-discharging device; the first driving mechanism is arranged on the installation frame and is rotationally connected with the installation frame; the lower die base is arranged on the installation frame and is located above the first driving mechanism; the lower die base is connected with the installation frame in a sliding mode and is fixedly connected with the first driving mechanism; the first driving mechanism is used for driving the lower die base to move along the vertical direction; the conveying belt is fixed on the lower die base; the lower die is fixed on the lower die base and is located above the conveying belt; a bubble cap channel is formed in the lower die; the upper die is fixed on the installation frame andis located above the lower die; and the material pressing stable-discharging device is arranged on the upper die, is in sliding connection with the upper die and is fixedly connected with the installation frame. The blanking device of the bubble cap packaging machine provided by the embodiment of the invention can enable blanked bubble caps to fall onto the conveying belt in order.

Owner:浙江海晨机械有限公司

Board detecting mechanism for wood packing box

InactiveCN107537786AQuick checkImprove detection efficiencyCounting objects on conveyorsSortingCrateConveyor belt

The invention relates to a wooden board sorting mechanism for wooden packaging boxes, which belongs to the field of wooden packaging box production. It includes a frame and a conveyor belt, the conveyor belt is connected with a stepping motor, a first detection mechanism is provided on one side of the conveyor belt, and the detection mechanism is fixed on the machine side along the direction of the conveyor belt. The first pushing device on the frame, the first pushing device is provided with a receiving device at a symmetrical position along the conveyor belt, and the first pushing device is provided with a second detection device along one side of the conveyor belt direction, so One side of the second detection device is provided with a second pushing device. The advantage of the present invention is that it can realize rapid detection of wooden packing boxes, improve the detection efficiency and detection accuracy, and complete the sorting of different types of wooden boards at the same time as the detection, which is convenient for the subsequent process and is automated. The degree is high; it is equipped with a counter, which can automatically count qualified products, making the whole production process more orderly.

Owner:苏州卫刚木包装制品有限公司

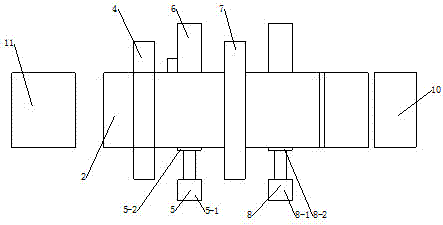

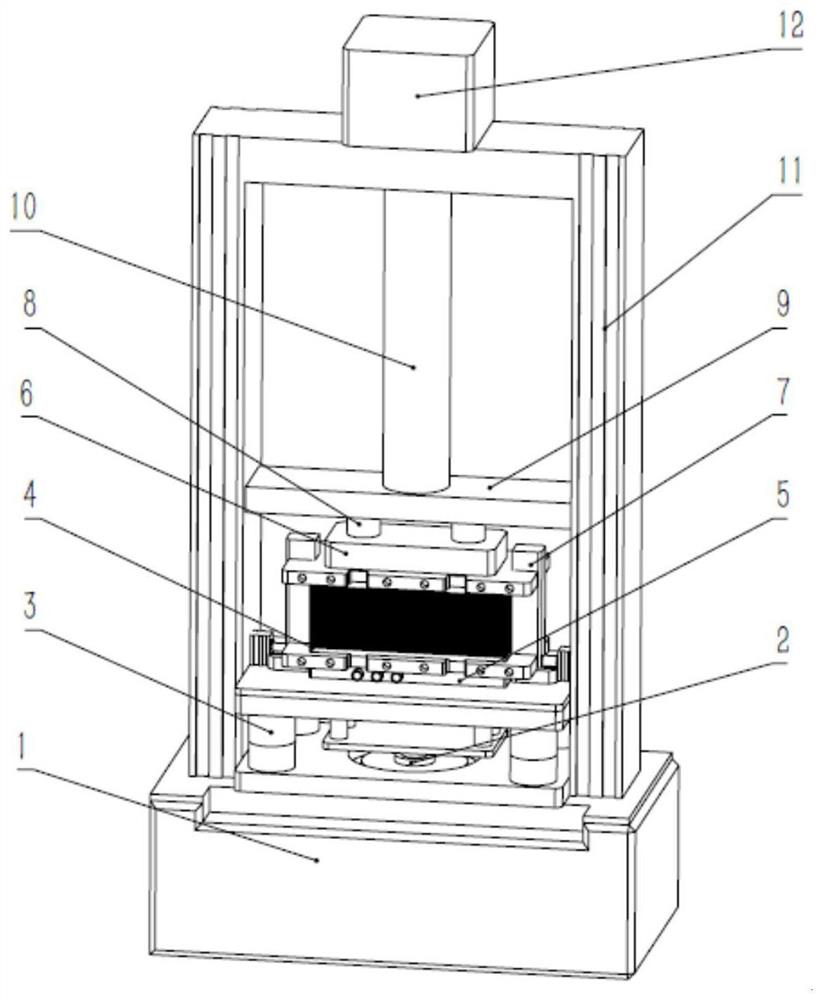

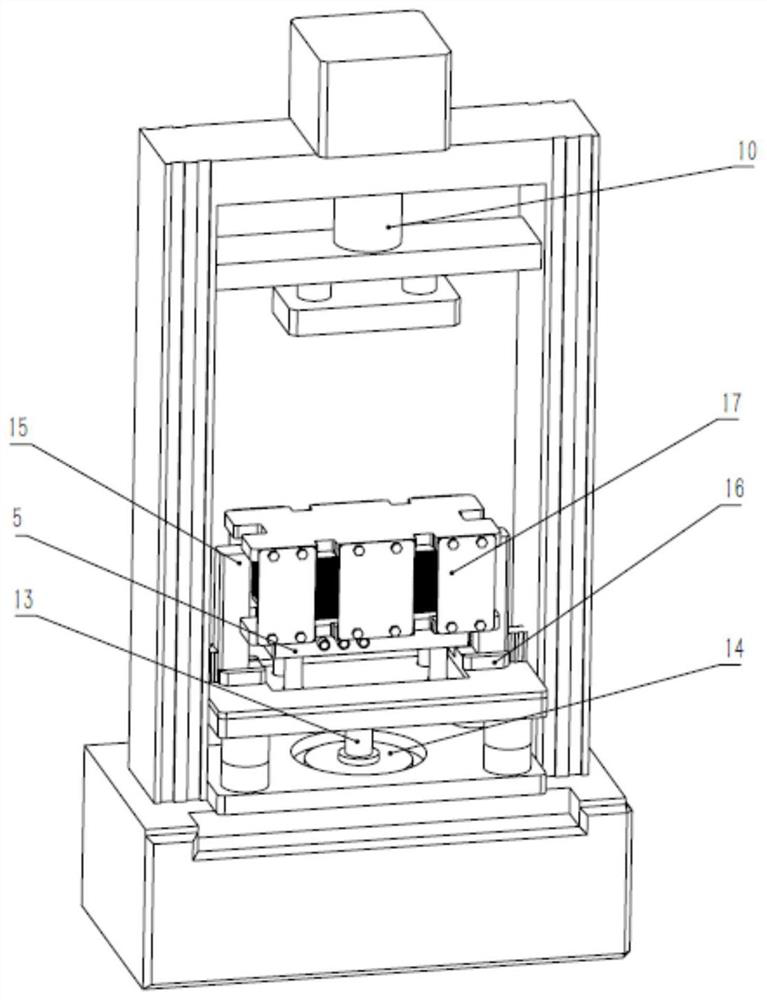

Fuel cell stacking leakage detection equipment

PendingCN112326144AAir tightness effectAvoid increased workloadMeasurement of fluid loss/gain rateFuel cellsFuel cellsElectric machinery

The invention relates to fuel cell stacking leakage detection equipment, which mainly comprises a lifting mechanism, a positioning mechanism, a pressure mechanism, an air tightness detection mechanismand the like; the pressure mechanism comprises an equipment rack, and other mechanisms are respectively arranged in the mechanism. The mechanisms are matched with each other to jointly assist in completing the procedures of electric pile stacking and air tightness detection. The pressure mechanism comprises a press base, a pressure sensor, a press outer frame, a pressure motor, a pressure guide column, a press stand column, a pressure rod, a press support, a pressure contact plate and a pressure sensor. The press base is arranged on the horizontal ground, the press outer frame is erected on the press base, the pressure motor is arranged at the top of the press outer frame and controls the pressure rod to stretch out and draw back, the tail end of the pressure rod is connected with the pressure connecting plate, and the pressure is transmitted to the pressure contact plate through the pressure guide column. In order to monitor the pressure of the pressing machine in real time, the pressure sensor and the press stand column are connected to be arranged on a press base platform and connected with the press support.

Owner:BEIJING NOWOGEN TECH CO LTD

Drying device for resin waste recycling

ActiveCN110542291AAvoid sticking to the wallEasy to throw inDrying solid materials with heatDrying solid materials without heatWater dischargeWaste product

The invention relates to the technical field of resin waste recycling equipment, in particular to a drying device for resin waste recycling. A servo motor is adopted as drive powder, a first rotatingshaft is driven to rotate through gear transmission, so that a worm is driven to rotate. The worm drives a first worm wheel and a second worm wheel to rotate, and an upper rotating shaft and a lower rotating shaft are both made to rotate. For the upper rotating shaft, a stirring rod rotates along with the upper rotating shaft, on one hand, materials are stirred and scattered; and on the other side, scraper blades prevent materials from adhering to the wall; in cooperation air intake on the right side, the materials are in full contact with the dry air, so that moisture is taken away. For the lower rotating shaft, the lower rotating shaft drives a first bevel gear to rotate, a second rotating shaft is made to rotate through transmission of the bevel gear, an incomplete bevel gear rotates along with the rotating shaft and is sequentially meshed with a left bevel gear and a right bevel gear, so that a shaft sleeve generates reciprocating rotation, then a dissolution tank is driven to swing in a reciprocating manner, a shaking function is generated on the materials in the dissolution tank, centrifugal force is generated, and then moisture can be conveniently thrown into a water discharge pipe and discharged into a water collecting tank.

Owner:阜阳市鑫格特机电设备有限公司

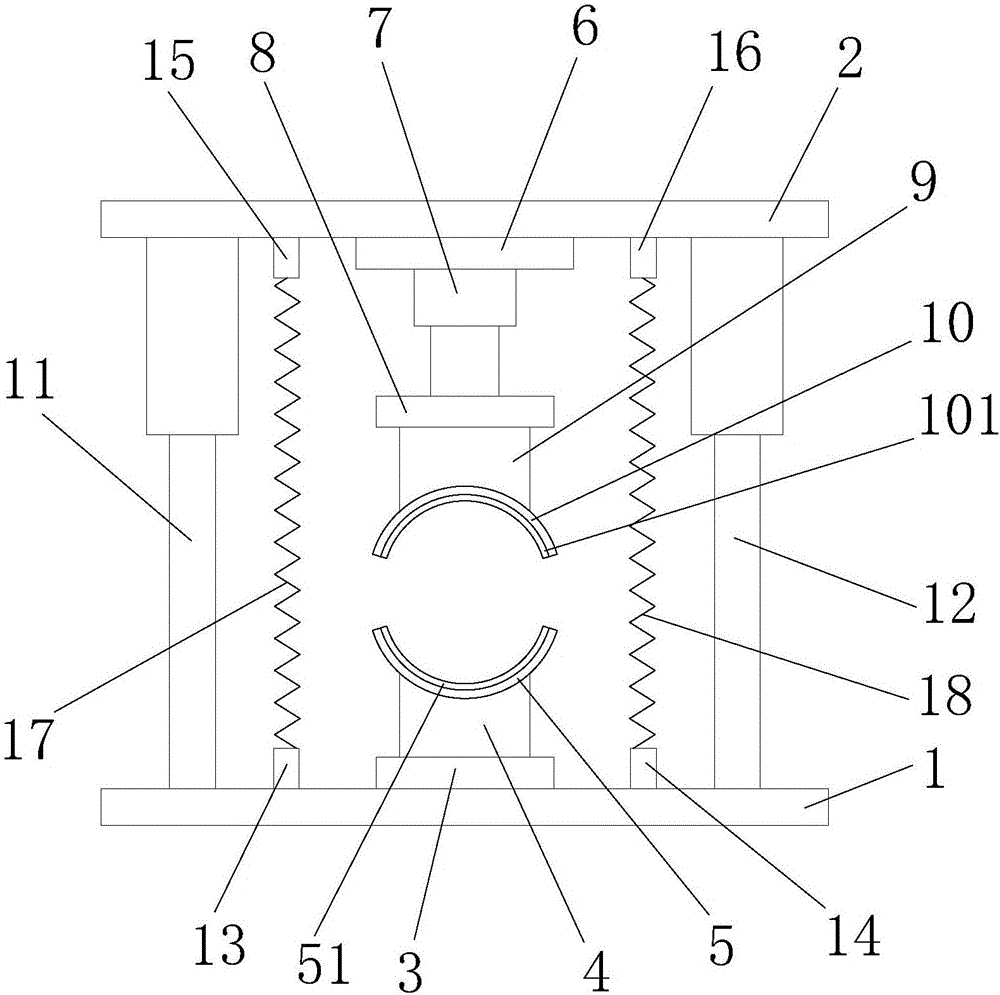

High-precision clamper

InactiveCN106695611AEasy clampingImprove securityWork holdersHydraulic cylinderArchitectural engineering

The invention discloses a high-precision clamper comprising a base and a top seat. A supporting seat is installed on the base. A fixed column A is perpendicularly installed on the supporting seat. A clamping head A is installed at the upper end of the fixed column A. An air cylinder fixing seat is installed at the lower end of the top seat. An air cylinder is installed at the lower end of the air cylinder fixing seat. A supporting plate is installed at the lower end of an air cylinder rod of the air cylinder. The lower end of the supporting seat is perpendicularly provided with a fixed column B. A clamping head B is installed at the lower end of the fixed column B. The clamping head B is located over the clamping head A and identical with the clamping head A in size. A hydraulic cylinder A is installed between the base and the left side of the top seat. A hydraulic cylinder B is installed between the base and the right side of the top seat. The high-precision clamper can conveniently clamp large-diameter steel tubes, follow-up work can be conveniently conducted, and the high-precision clamper is simple in structure, practical and effective and greatly improves the safety of the steel tube during finished product detection.

Owner:黄斌

Dust removal device for recycling waste lead-acid storage batteries

InactiveCN112354919AEasy to collectImprove transmission efficiencySievingFinal product manufactureDust controlEnvironmental engineering

The invention discloses a dust removal device for recycling waste lead-acid storage batteries. A transmission mechanism is mounted at the top of a supporting frame; a protective shell is arranged in the middle of the supporting frame; the transmission mechanism penetrates through the protective shell; an air drying mechanism is arranged on one side of the top of the transmission mechanism; a dustremoval mechanism and a cleaning mechanism are arranged in the middle of the top of the transmission mechanism; the cleaning mechanism is located between the air drying mechanism and the dust removalmechanism; a collecting box is arranged below the transmission mechanism; the collecting box is located inside the protective shell; a dust collector and a water circulation system are arranged at thetop of the protective shell; and the water circulation system is located on the side, close to the air drying mechanism, of the protective shell. By the adoption of the structure, dust removal can befully carried out on the recycled waste lead-acid storage batteries, the influence of floating dust, impurities and waste chips on subsequent procedures is avoided, meanwhile, dust removal and cleaning are integrated, the working efficiency is improved, and time is saved.

Owner:骆驼集团(安徽)再生资源有限公司

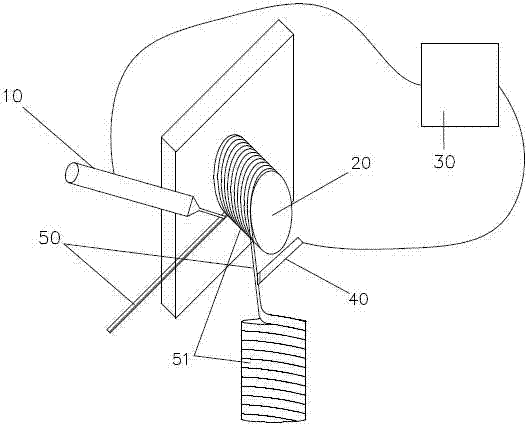

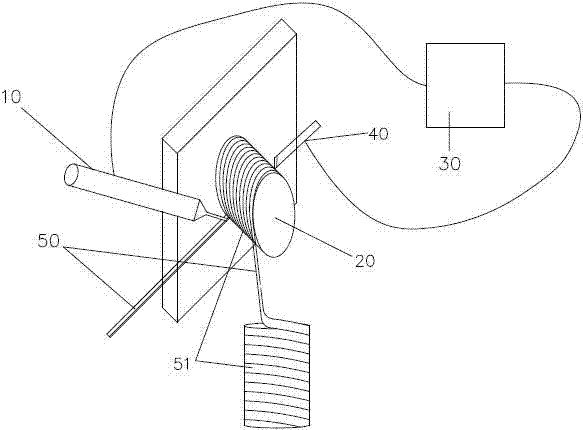

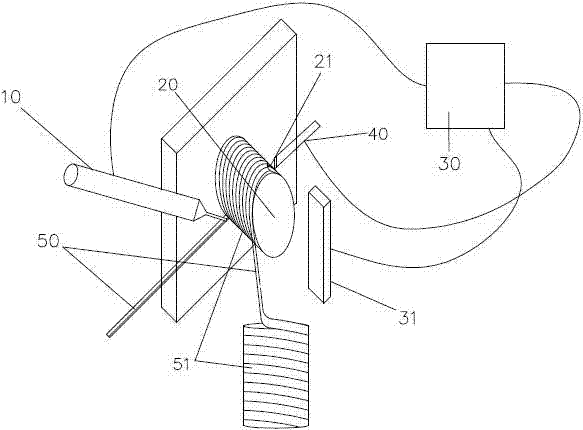

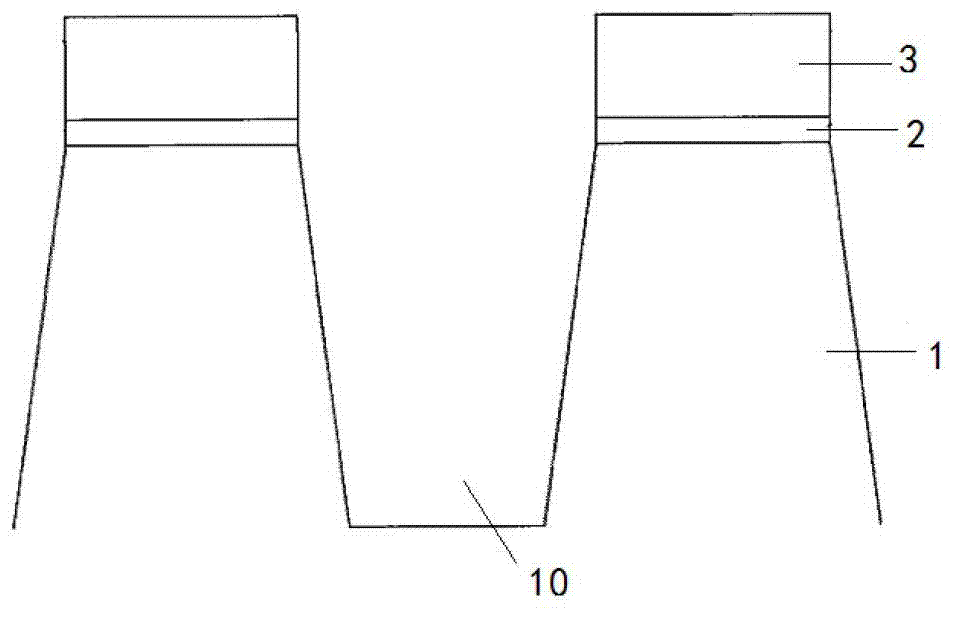

Production method of support tubes and production system adopting method

ActiveCN103112174ALow costAutomate operationTubular articlesManufacturing engineeringMethod of support

The invention discloses a production method of support tubes. When the support tubes are produced to a specific length, the welding of support bars is suspended, so that the support bars can not be bonded to one other, subsequent process steps are facilitated, and production costs are saved. The invention also discloses a production system adopting the support tube production method. The system comprises a mold shaft, a heating and welding device, and a control terminal capable of controlling the work of the heating and welding device, so that automated operation is achieved in the whole production process, and manpower costs are greatly saved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Water-based anti-rusting liquid and preparation method thereof

InactiveCN106191841AWill not polluteAnti-rustMetallic material coating processesWater basedDistillation

The invention discloses water-based anti-rusting liquid. The water-based anti-rusting liquid comprises raw materials of, by weight, 15-25 parts of isopropanolamine, 3.1-5.2 parts of boric acid, 25-30 parts of dimethyl dodecanedioate, 2-5 parts of a rare earth corrosion inhibitor, 1-2 parts of sodium molybdate, 4-6 parts of tartaric acid, 0.1-0.3 part of a defoaming agent, 0.1-0.2 part of a surfactant, 0.1-0.3 part of a sterilizing agent and 42-52 parts of water. The invention further discloses a preparation method of the water-based anti-rusting liquid. The preparation method includes the following steps that the raw materials are weighed according to the weight parts, the boric acid, the isopropanolamine and xylene are evenly mixed, and backflow, reduced pressure distillation and vacuum drying are conducted to obtain a material A; the material A and the dimethyl dodecanedioate are evenly mixed, heated and stirred, and then vacuum drying is conducted to obtain a material B; and the material B, the rare earth corrosion inhibitor, the sodium molybdate, the tartaric acid, the defoaming agent, the surfactant and the sterilizing agent are evenly mixed and then stirred after water is added, so that the water-based anti-rusting liquid is obtained. The water-based anti-rusting liquid is good in anti-rusting performance and free of environment pollution.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Hollow channel isolation region preparation method

InactiveCN103247567AImprove performanceGood lookingSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a hollow channel isolation region preparation method which comprises the following steps: providing a supporting base; sequentially depositing buffering oxide layers and nitride layers on the supporting base; etching a hollow channel by utilizing the shallow trench isolation (STI) manufacturing technique; etching buffering oxide layer cuts on two sides of the shallow channel to form a groove; performing the first etching on the nitride layers on two sides of the shallow channel; growing a layer of oxidation film on the surface of the supporting base; and performing the second etching on the nitride layers on two sides of the shallow channel. The method starts from morphology of nitrides and realizes performance improvement of devices through modification of fewer craft processes, and utilizes twice etching to improve morphology of silicon nitride, so that the problem that the shallow channel isolation top edge lacks corners or hollows after the silicon nitride is removed is solved; and at the same time, the outline of corners of the shallow channel isolation region can be improved, so that the subsequent handling is facilitated.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Cleaning machine table for semiconductor package products and cleaning process thereof

ActiveCN102097293BConsistent cleanlinessKeep drySemiconductor/solid-state device manufacturingCleaning using liquidsSemiconductor packageProcess engineering

The invention discloses a cleaning machine table for a semiconductor package products and a cleaning process thereof. The cleaning machine table comprises a control panel, a cleaning operation area and a drying area, wherein the control panel is arranged on the upper part of a front face of the machine table and is used for controlling the cleaning procedure; the cleaning operation area is arranged in the middle of the front face of the machine table, is in a shape of a hollow groove and comprises more than one cleaning slots, and the cleaning machine table is provided with an ultrasonic generation device corresponding to each cleaning slot so that the semiconductor package products in the cleaning slots can be cleaned by the ultrasonic waves; and the drying area is used for drying the cleaned products. The cleaning process comprises the following steps of ultrasonic chemical cleaning, ultrasonic washing in water and drying. After cleaned, the residual glue on the semiconductor package product can be nearly and completely removed so that the product performance is greatly improved and the following product function test is convenient.

Owner:嘉盛半导体(苏州)有限公司

Fish splitting machine

PendingCN107788088AAvoid scratchesReduce operational burdenFish work-tablesFish processing hand toolsFisheryEngineering

The invention discloses a fish splitting machine, and relates to the technical field of food production. The fish splitting machine comprises a base, a fish splitting table and a knife holder, whereinthe fish splitting table is arranged on the base and is provided with a slide rail, a first stopper and a second stopper; the first stopper cooperates with the slide rail in a sliding manner; the second stopper is arranged at one end part of the slide rail; the first stopper and the end part away from the second stopper, of the slide rail are connected through first elastic parts; the base is provided with a vertical column; a through hole is formed in the knife holder; the knife holder is arranged on the vertical column through the through hole in a sleeving manner; in the axial direction ofthe vertical column, the vertical column is movably connected with the knife holder; second elastic parts are arranged between the base and the knife holder; the knife holder is provided with a splitting knife and a pressure block which are arranged towards the fish splitting table; the first stopper and / or the pressure block are / is provided with a wedge surface, so that when the knife holder ispressed towards the base, the pressure block can push the first stopper towards the second stopper by using the wedge surface to clamp the fish, and splitting of fish is facilitated. The fish splitting machine is simple in structure and convenient to use, the efficiency of splitting fish can be greatly improved, and realization of the assembly line production is facilitated.

Owner:CHENGDU TEXTILE COLLEGE

A special cleaning device for enameled wire

ActiveCN104841670BEfficient decompositionEasy to cleanDrying machines with progressive movementsCleaning using toolsWaste managementWater tanks

The invention discloses a special cleaning device for enameled wires, which includes: a spray unit, which includes a spray box, a spray head arranged on the top of the spray box, a bracket arranged above the spray box, and a cleaning device arranged on the bracket. liquid tank; a cleaning unit, which is arranged on one side of the spray unit and includes a cleaning box, a sprinkler head arranged on the top of the cleaning box, a cleaning box drain outlet arranged at the lower part of the cleaning box, and a cleaning box drain outlet arranged on the bottom of the cleaning box. A cleaning roller group in the accommodation space of the cleaning box; a drying unit, which is arranged on one side of the cleaning unit and includes a support column, a water tank provided on the top of the support column, and a first absorbent sponge provided on the upper part of the water tank , a second absorbent sponge disposed above the first absorbent sponge, a pressure plate disposed above the second absorbent sponge, a threaded column connecting the water tank and the pressure plate, and a spring sleeved on the threaded column . The invention has good cleaning effect and facilitates subsequent processes.

Owner:江苏君墨智能装备有限公司

Automatic shelling device of camellia oleifera fruits

InactiveCN107411109APrevent ruptureQuality improvementFatty-oils/fats productionHuskingEngineeringCamellia oleifera

The invention relates to the technical field of processing of camellia oleifera, in particular to an automatic shelling device of camellia oleifera fruits. The automatic shelling device comprises a heating mechanism, a shelling mechanism and a supporting frame, wherein the heating mechanism is fixedly arranged above the shelling mechanism; a discharge end of the heating mechanism communicates with an inner chamber of the shelling mechanism; a discharge opening is formed below the shelling mechanism; the supporting frame is fixedly arranged at the bottom of the shelling mechanism; the shelling mechanism comprises a shelling box body, shelling double-roll mechanisms, a multi-aperture screen mesh and a power mechanism; incline directions of the adjacent two groups of shelling double-roll mechanisms are opposite; the multi-aperture screen mesh is fixedly and obliquely arranged in the shelling box below the bottommost shelling double-roll mechanism; and the power mechanism drives the shelling double-roll mechanisms to rotate. According to the automatic shelling device of camellia oleifera fruits disclosed by the invention, when the camellia oleifera fruits are squeezed out, camellia oleifera seeds cannot burst, so that burst of camellia oleifera seeds during the shelling process of the camellia oleifera fruits can be effectively avoided, and the quality of camellia oleifera products can be greatly improved.

Owner:HUNAN SHENNONG CAMELLIA OLEIFERA TECH DEV

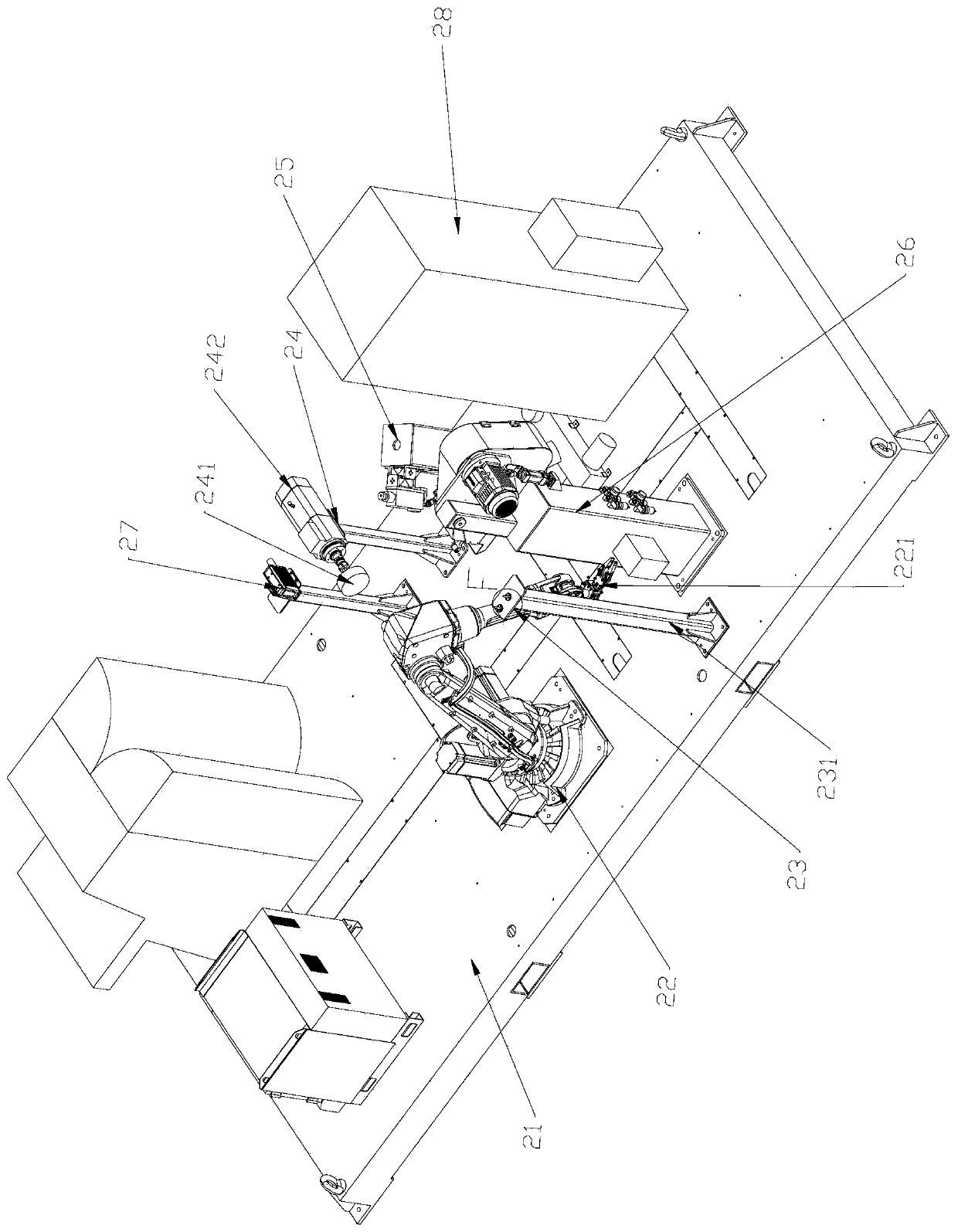

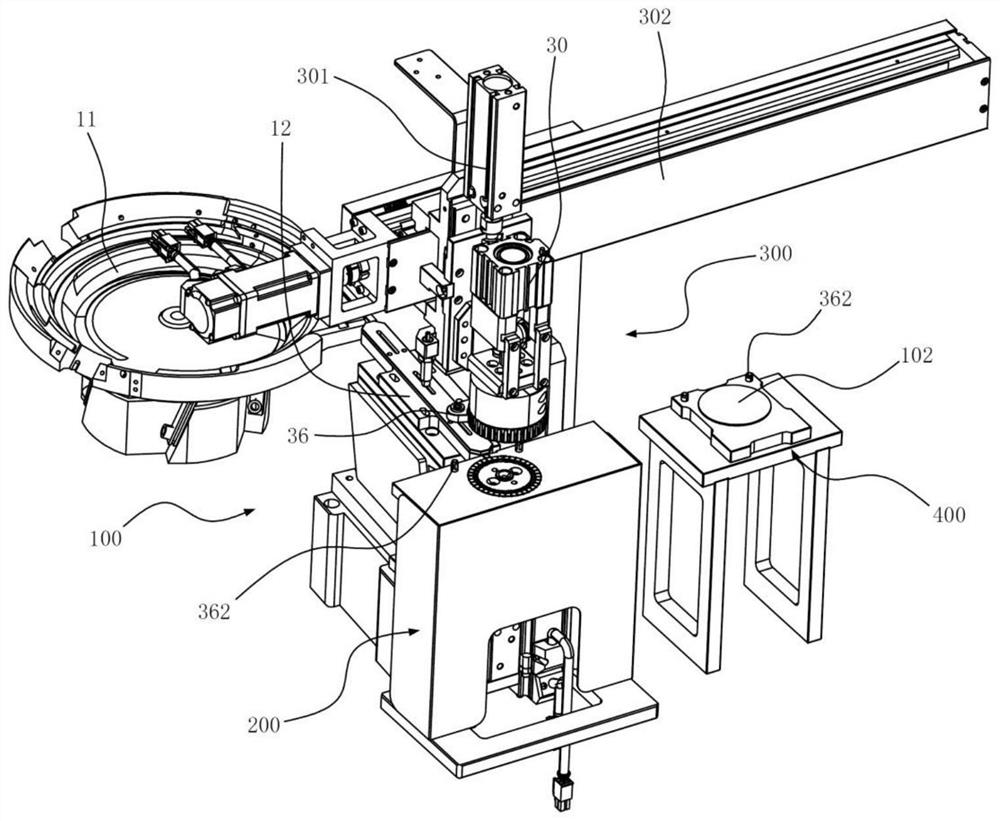

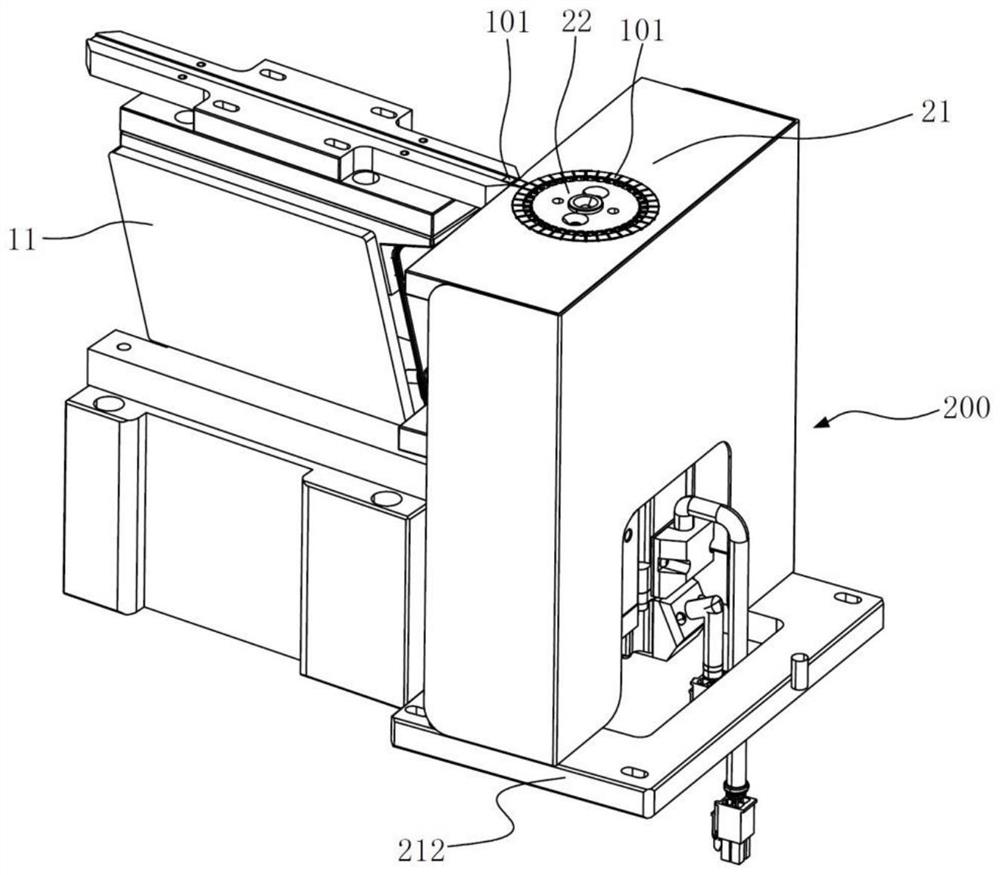

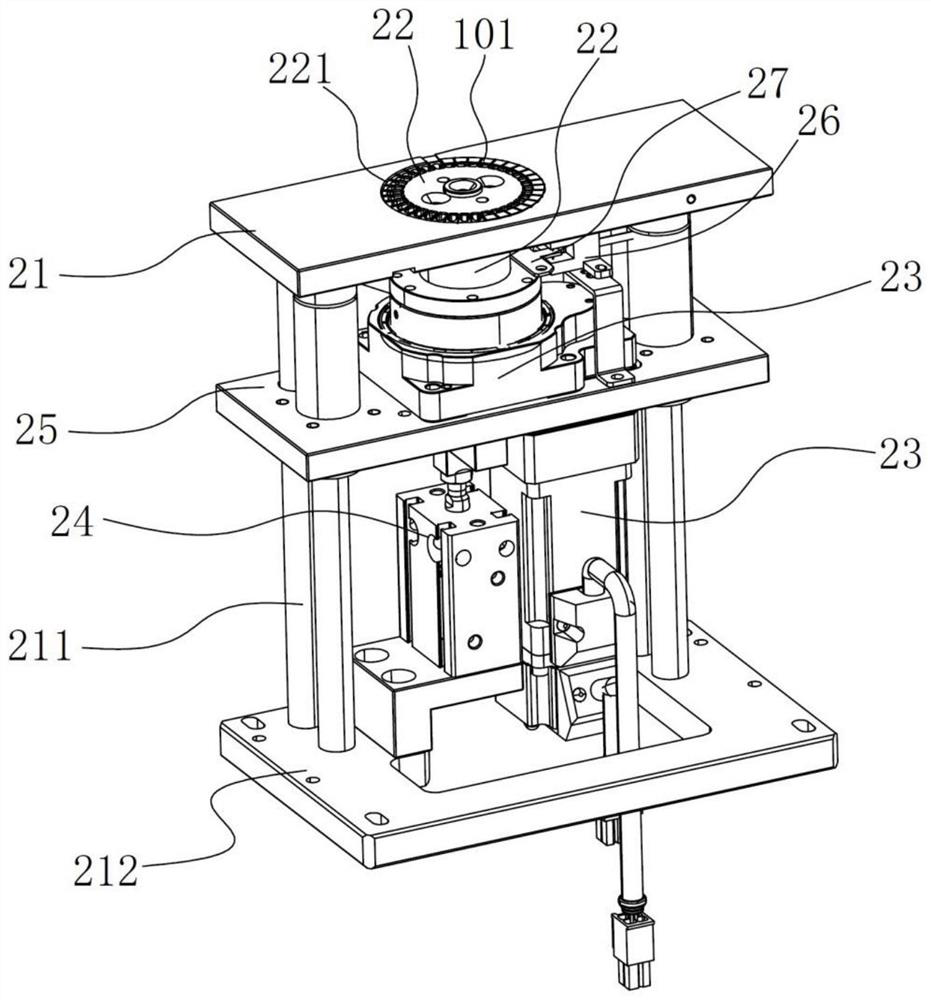

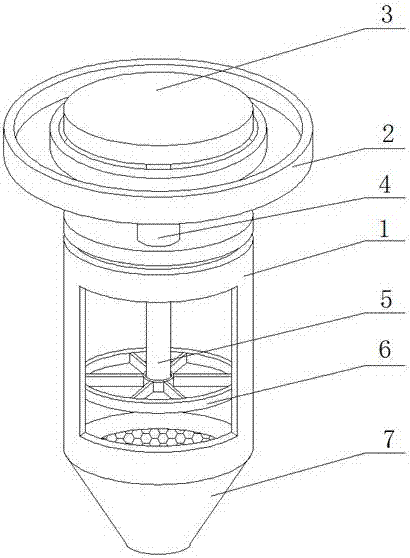

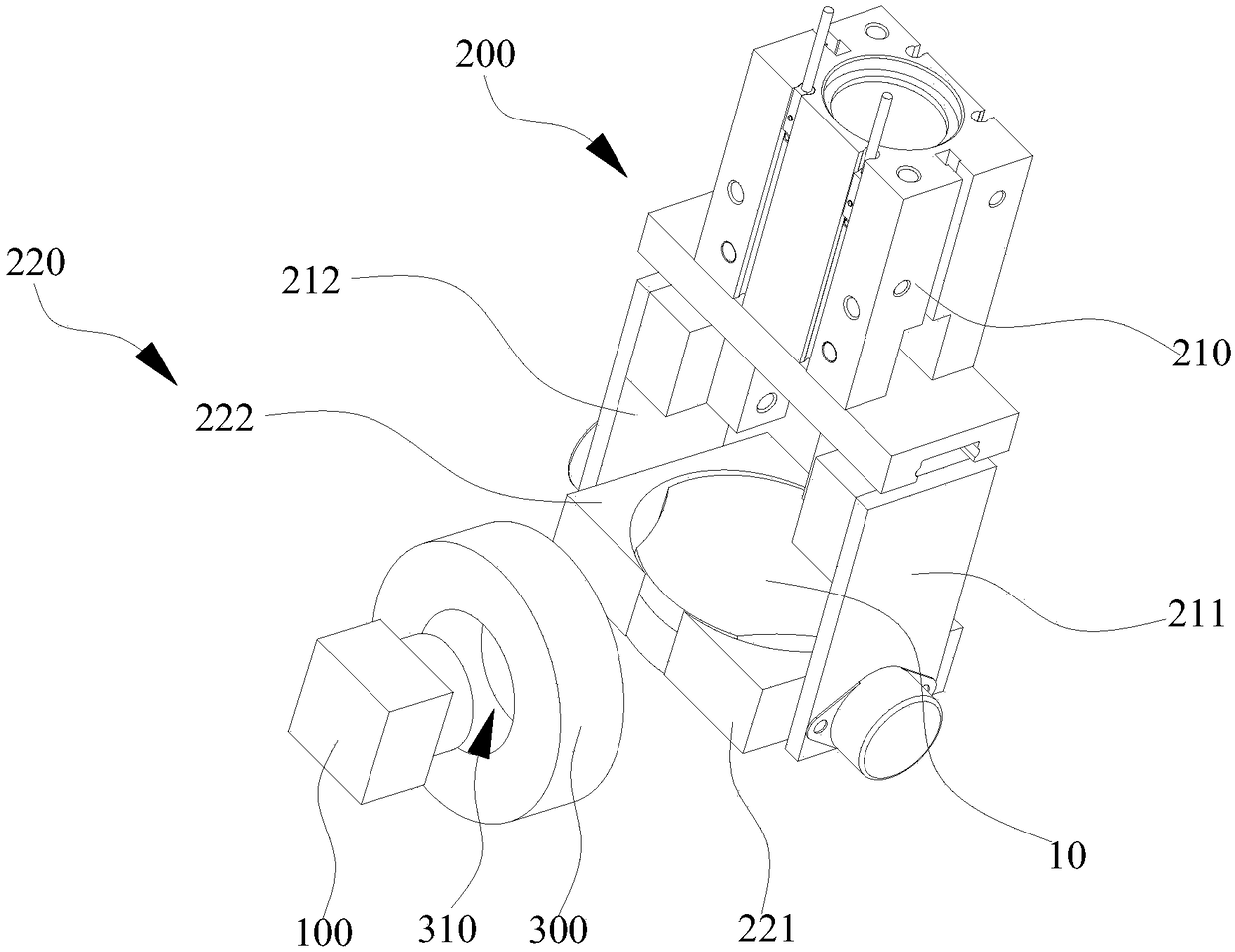

Wireless charging annular magnet assembling device

ActiveCN114799859AEasy to assembleReduce labor intensityMaterial gluingAssembly machinesEngineeringVertical axis

The invention relates to automatic production assembly equipment, in particular to a wireless charging annular magnet assembly device. A wireless charging annular magnet assembling device is characterized in that the wireless charging annular magnet assembling device comprises a feeding assembly, a positioning assembly, a grabbing assembly and a workbench, the feeding assembly comprises a conveying rail, the grabbing assembly comprises a clamping jaw, the clamping jaw can move between the positioning assembly and the workbench, the positioning assembly comprises a fixing plate and a rotating driver, and the rotating driver is arranged on the fixing plate. A containing groove with an upward opening is formed in the fixing plate, an inner positioning piece is arranged in the containing groove, the inner positioning piece is provided with a plurality of positioning grooves with lateral openings, the positioning grooves are evenly distributed in the inner positioning piece with the vertical axis as the center, and the fixing plate is provided with a feeding guide groove which is provided with a lateral opening and enables the positioning grooves to be communicated with the conveying rail. The device has the advantages that the production and assembly efficiency can be improved, the labor intensity of workers is reduced, the consumable cost is reduced, and follow-up procedures are facilitated.

Owner:浙江英洛华引力科技有限公司

Tea oil filtering device

InactiveCN107057851AQuick filterQuick collectionFatty-oils/fats refiningOil processingDouble filtration

The invention relates to the technical field of camellia oil processing, in particular to a tea oil filtering device, which includes a filter shell, an opening is provided at one end of the filter shell, a cover plate is connected to the opening, and a mounting plate is installed in the middle of the cover plate. A rotating rod is inserted into the installation port. One end of the rotating rod passes through the installation port and extends into the filter housing. One end of the rotating rod located in the filter housing is connected with a fixed ring. The outer side of the fixed ring A stirring frame is sleeved, the fixed ring and the stirring frame are connected by a second connecting rod, one side of the rotating rod is connected with a first connecting rod, and the fixed ring is provided with a ring for clamping the first connecting rod sliding port, one side of the first connecting rod and one side of the second connecting rod are connected through the first filter screen, the tea oil filtering device of the present invention can perform double filtering, so that the tea oil in the tea oil Impurities can be fully filtered, which provides great convenience for the subsequent process of tea oil processing.

Owner:湖南神农国油生态农业发展有限公司

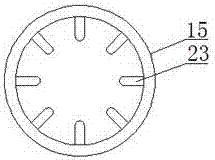

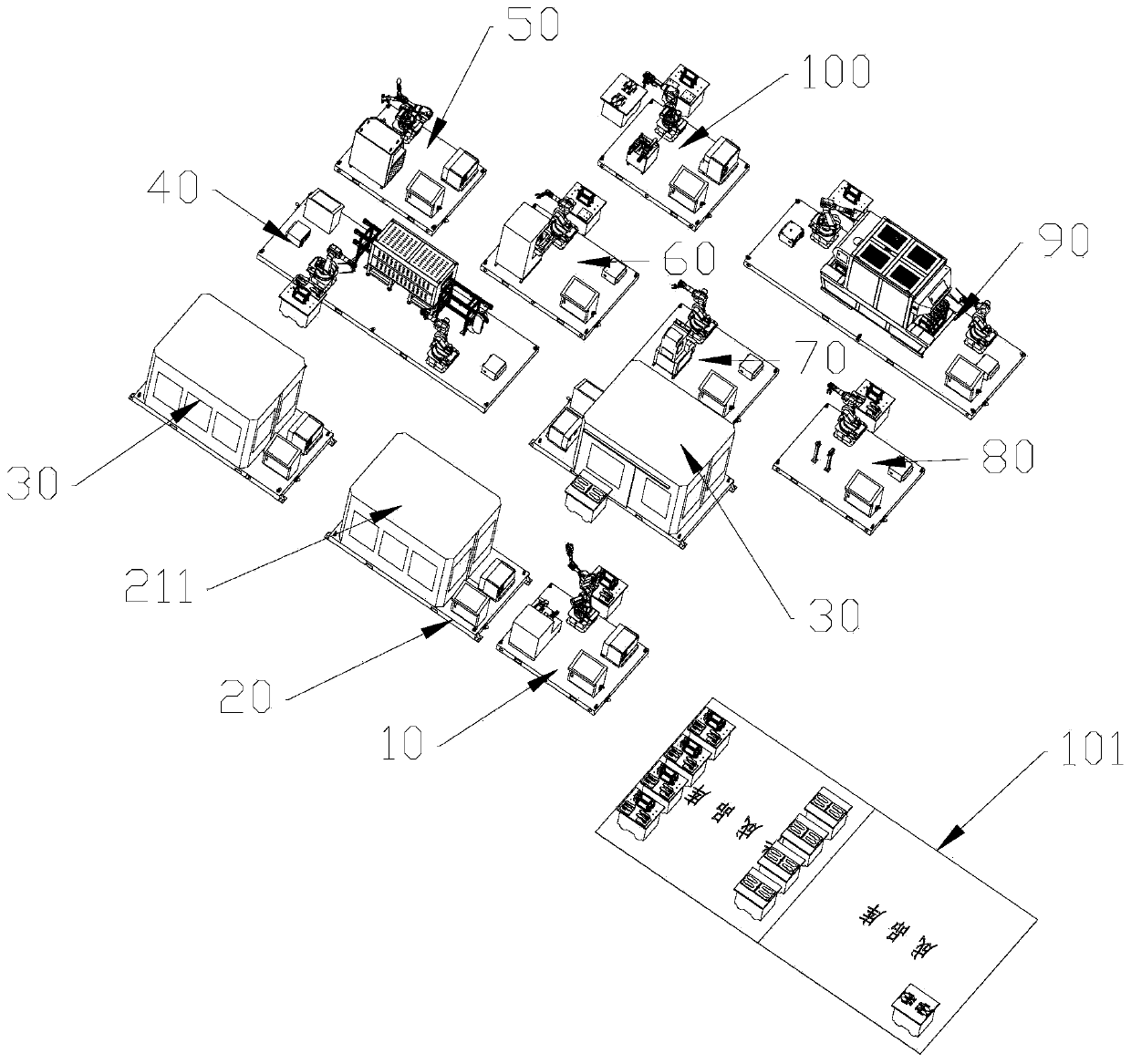

Intelligent casting machining system and casting machining method

The invention discloses an intelligent casting machining system and a casting machining method. The intelligent casting machining system comprises an intelligent camera, a robot, a mobile loading / unloading platform and a controller; the controller is respectively connected with the intelligent camera, the robot and the mobile loading / unloading platform, wherein the intelligent camera is used for shooting pictures of castings to be machined, determining the positions of casting ports of the castings to be machined and sending the position data of the determined casting port positions to the controller; and the controller is used for controlling the mobile loading / unloading platform to move according to the position data sent by the intelligent camera to correct the castings to be machined according to the casting machining positions determined by the intelligent camera and controlling the robot to use a cutting tool to cut the corrected castings to be machined. The intelligent casting machining system and the casting machining method realize lean production in the war industry, greatly improve the manual working environment, guarantee the personal safety, and improve the working efficiency.

Owner:CHANGSHA CTR ROBOTICS

Processing device for increasing strength of aluminum-plastic composite panel

ActiveCN110936699AHigh strengthUniform coatingLaminationLamination apparatusAdhesive beltEngineering

The invention discloses a processing device for increasing strength of an aluminum-plastic composite panel. The device includes a support plate, wherein a transmission rack is installed on the top ofthe support plate. A plurality of conveying rollers are arranged on the conveying frame at equal intervals. Two side plates are installed on both sides of the top of the conveying rack, and a first driving roller is arranged between the two side plates. A second drive roller is provided above the first drive roller, which is the main drive roller. The second driving roller is connected to the first driving roller through an adhesive tape transmission, and a glue coating roller is provided above the second driving roller. The glue coating roller is driven by a piston rod of a third air cylinderand pushes out a steel plate from the bottom of a plate accommodating box via a plate in / out port, then a piston rod of a third air cylinder pushes a pressing plate to move down so as to push the steel plate, delivered from the plate in / out port, onto the plastic core plate, so that the plastic core plate is attached to the steel plate via glue. The invention solves the problems that in processing of the aluminum-plastic composite panel in the prior art, the steel plate cannot be attached to the plastic core plate well, and the attachment of the steel panel is inconvenient.

Owner:ANHUI FENGHUI METAL

A drying device for resin waste recycling

ActiveCN110542291BAvoid sticking to the wallEasy to throw inDrying solid materials with heatDrying solid materials without heatGear driveGear wheel

Owner:阜阳市鑫格特机电设备有限公司

High-oxidation-resistance bamboo product manufacturing process

InactiveCN111605018AEasy to controlImprove toughnessWood treatment detailsCane mechanical workingPulp and paper industryIndustrial engineering

The invention discloses a high-oxidation-resistance bamboo product manufacturing process, relates to the field of bamboo product processing, and aims to solve the problem that normal use is affected by oxidation of an existing bamboo product in the prior art. The high-oxidation-resistance bamboo product manufacturing process comprises the following steps that firstly, a bamboo product raw materialis placed on the upper end face of a cutting table top, the bamboo product raw material is cut into strips through a cutting tool, and the strip-shaped bamboo product raw material slides into a spraying box through a discharging plate; secondly, an electric spray head is opened, the electric spray head flushes the strip-shaped bamboo product raw material in the flushing box, water obtained afterflushing is discharged to the lower portion of the interior of the flushing box through a filter plate, and the water can be discharged through a water outlet; and thirdly, the strip-shaped bamboo product raw material flushed in the flushing box is taken out and placed above a feeding plate, the strip-shaped bamboo product raw material is moved and conveyed through the feeding plate, and the strip-shaped bamboo product raw material is dried through a drying box above the feeding plate.

Owner:河源盛宴竹业科技有限公司

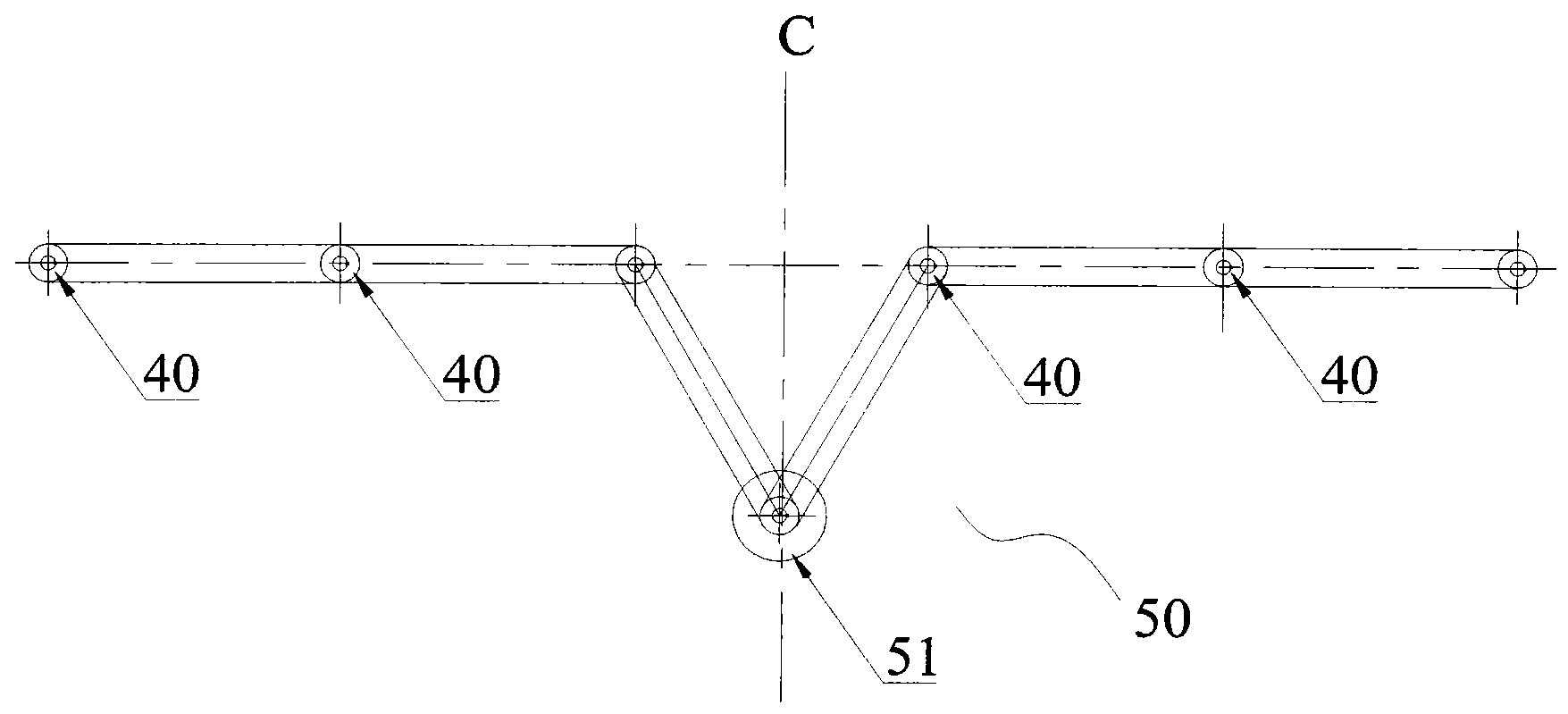

Sponge part adjusting assembly, sponge part adjusting method and sponge part transporting system

InactiveCN108217175AConvenient follow-up processImprove work efficiencyConveyor partsTransport systemEngineering

The invention discloses a sponge part adjusting assembly, a sponge part adjusting method and a sponge part transporting system. The sponge part transporting system comprises a transporting assembly and a sponge part adjusting assembly. The sponge part adjusting assembly comprises a camera and an adjusting mechanism. The camera and the adjusting mechanism are correspondingly arranged. The adjustingmechanism comprises a body and a clamping part. The clamping part is rotationally mounted on the body, and is used for clamping a sponge part. The camera is used for inputting a side face image of the sponge part, the body is arranged on the transporting assembly, and the transporting assembly is used for driving the body to move. According to the sponge part transporting system, the sponge partis clamped by the clamping part through the adjusting mechanism, the transporting assembly is used for driving the adjusting mechanism to move the sponge part to the position of the camera, the position of the sponge part is recognized through the camera, if the requirement is not met, the clamping part is turned over, compared with manual operation, the overall working efficiency is higher, and meanwhile the human cost is lower.

Owner:GUANGZHOU YONGHEXIANG AUTOMATION EQUIP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com