Method and system using one-step method for continuous production of alkyl glycoside

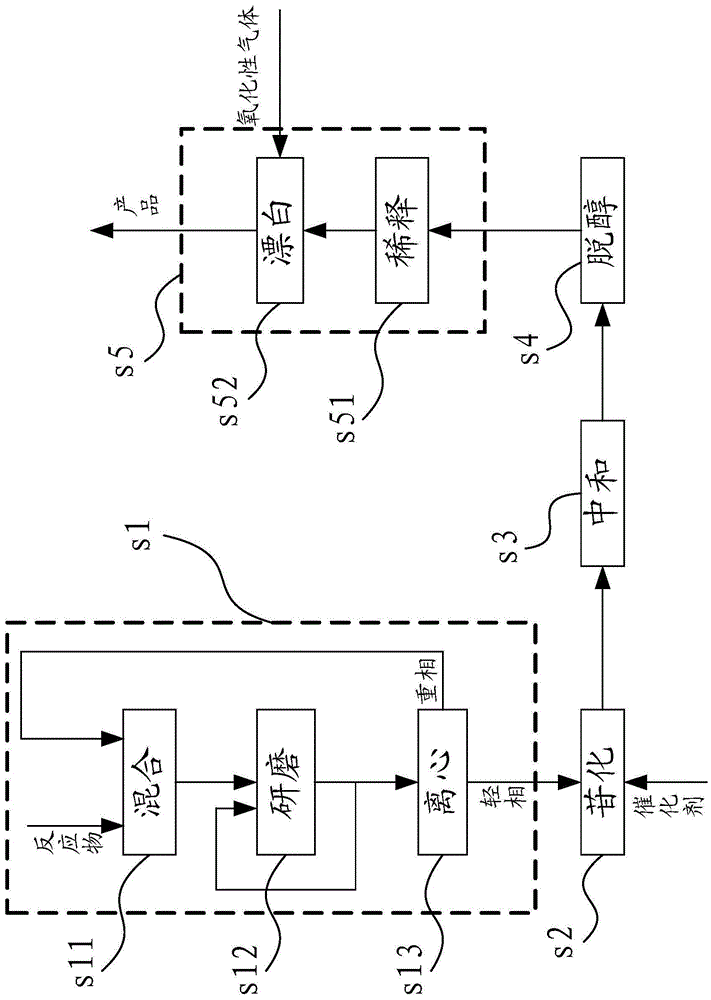

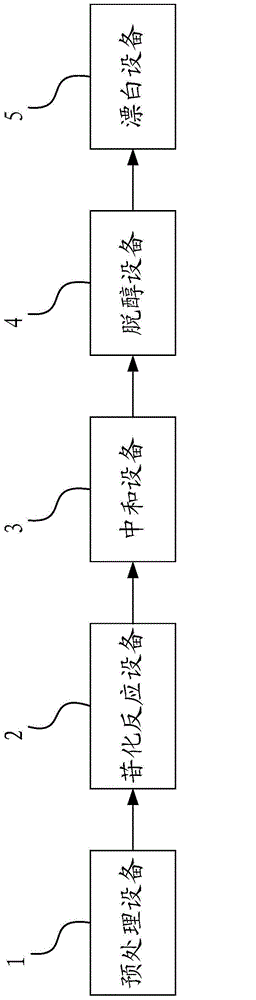

A technology of alkyl glycosides and one-step method is applied in the field of continuous production of alkyl glycosides and systems by one-step method, which can solve the problems of expensive metal borohydride, reduced bleaching efficiency and high production cost, and achieves improved oxidation effect and continuous glycosidation. The effect of response and improvement of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

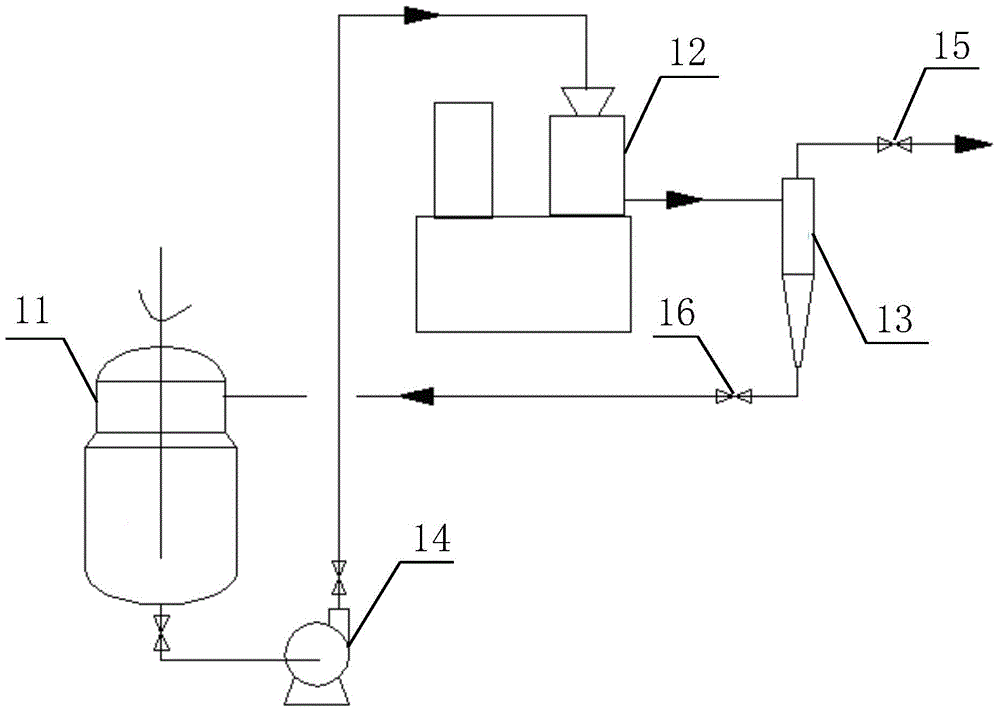

[0096] Specific Example 1: Mix C8-C10 mixed fatty alcohols (each accounting for about 50%) and anhydrous glucose in a mass ratio of 1:1 in a stirred tank and stir evenly, and mix the uniformly mixed mixture in a 0.5m 3 The flow rate per hour is sent to the colloid mill for grinding, the liquid from the colloid mill is sent to the hydrocyclone particle size separator, and the discharge speed of the light phase control valve and the heavy phase control valve is adjusted to make the hydrocyclone The mass ratio of the inner light phase to the heavy phase is 1:7, and the quasi-colloidal light phase is obtained. Observing the light phase with a microscope, it is found that the particle diameter in the light phase is up to 2.5 microns, and the average particle diameter in the field of view is about 1 micron. Put it in a graduated cylinder and observe that the sedimentation distance is less than 3.5 cm in 30 minutes. Add mixed alcohol to the light phase to make the alcohol-sugar ratio ...

specific Embodiment 2

[0099] Specific embodiment 2: after getting decyl alcohol and glucose and mix by the ratio of 2:1, put into stirring tank 1 and mix evenly, with 0.5m per hour 3 The flow rate is sent to the colloid mill 2 for grinding, and the liquid from the colloid mill 2 is sent to the hydrocyclone particle separator 3, and the discharge speed of the valve 5 and valve 4 is adjusted to make the liquid in the hydrocyclone particle separator 3 The mass ratio of the light phase to the heavy phase is 1:10 (the mass ratio of 1:10 is the mass inside the particle size separator), and the quasi-colloidal light phase is obtained. Observe with a microscope, the diameter of the particles in the light phase is less than 2.5 microns, and the average particle diameter in the field of view is about 0.8 microns. Put it in a graduated cylinder for observation, and the sedimentation distance in 30 minutes is less than 3.5 cm. The light phase material coming out from the top or central discharge port of the li...

specific Embodiment 3

[0100] Specific embodiment 3: get decyl alcohol and glucose and mix by the ratio of 0.5:1 and put into stirring tank 1 and mix evenly, with 0.5m per hour 3 The flow rate is sent to the colloid mill 2 for grinding, and the liquid from the colloid mill 2 is sent to the hydrocyclone particle separator 3, and the discharge speed of the valve 5 and valve 4 is adjusted to make the liquid in the hydrocyclone particle separator 3 The mass ratio of the light phase to the heavy phase is 1:1, and the quasi-colloidal light phase is obtained. Observe with a microscope, the particle diameter in the light phase is up to 1 micron, and the average particle diameter in the field of view is about 0.5 micron. Put it in a graduated cylinder for observation, and the sedimentation distance is less than 2 cm in 30 minutes. Add decyl alcohol to the light phase material coming out of the top outlet of the liquid cyclone particle size separator 3 to make the mass ratio of alcohol to sugar reach 5:1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com