Patents

Literature

36results about How to "Realize lean production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

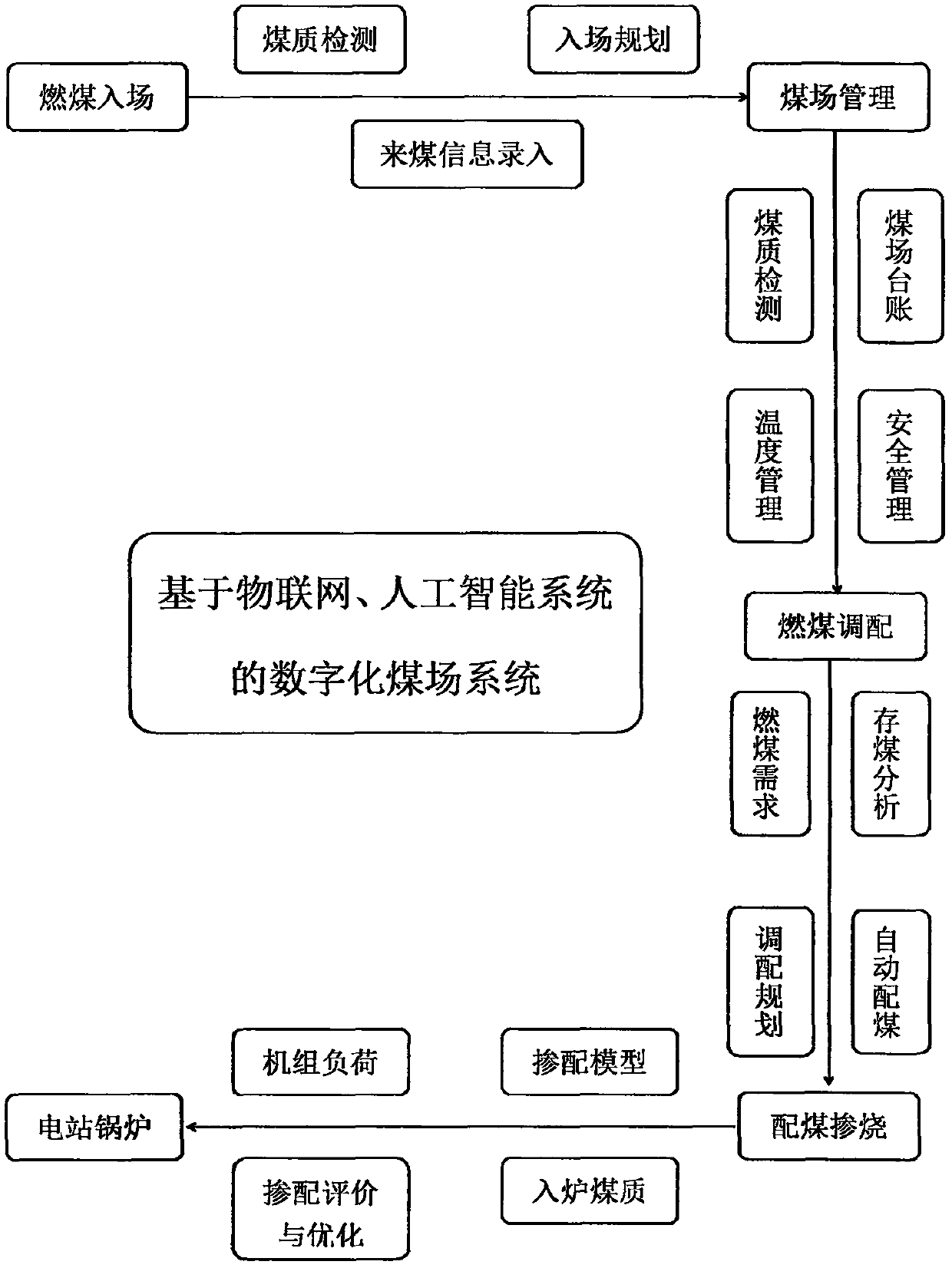

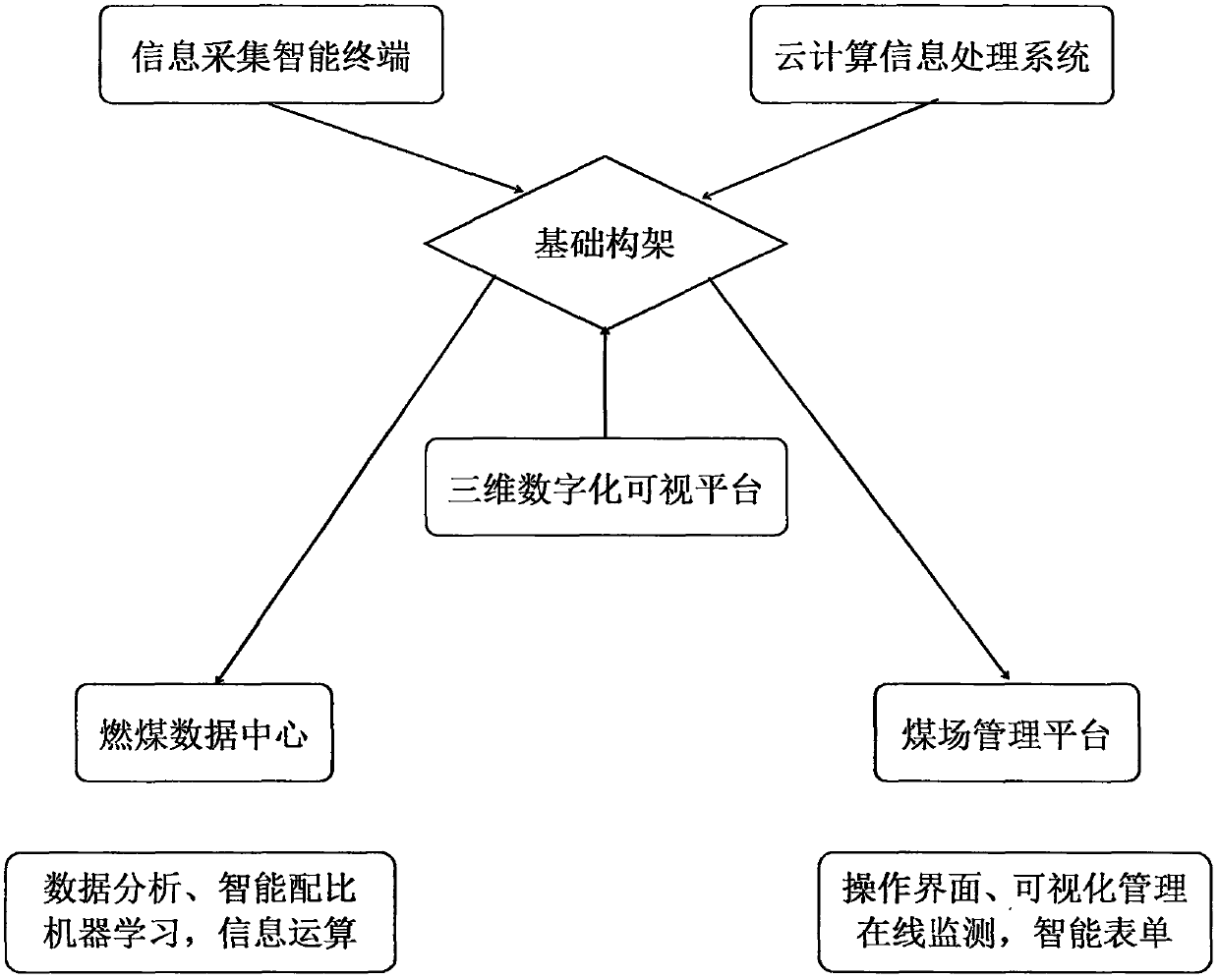

Digitized coal yard system based on Internet of Things and artificial intelligence system

PendingCN109583699AHigh degree of digitizationEasy to deployOffice automationResourcesData centerClosed loop

The invention provides a digitalized coal yard system based on Internet of Things and an artificial intelligence system, relates to the technical field of fuel management, digitalized factories and power generation, and particularly relates to a digitalized management system of a coal yard. The method is based on the Internet of Things. The invention discloses a digital coal yard system of an artificial intelligence system. Digitization and intelligentization of coal yard and fire coal data are achieved by means of an artificial intelligence system, coal quality test equipment and entrance detection equipment are combined by means of coal yard related equipment and an information acquisition intelligent terminal, fire coal digital management is achieved, a data reference basis is providedfor coal blending combustion and fire coal planning, and actual economic benefits are brought to enterprises. According to the invention, a management chain from entry to evaluation is required to beestablished, and closed-loop management of fuel is realized, so that a coal yard management platform and a coal-fired data center are provided on the basis of an overall scheme architecture, and digitalization, visualization and intelligentization of coal yard management of power generation enterprises are realized through construction of the coal yard management platform and the coal-fired data center.

Owner:天津市容创智行节能科技有限公司

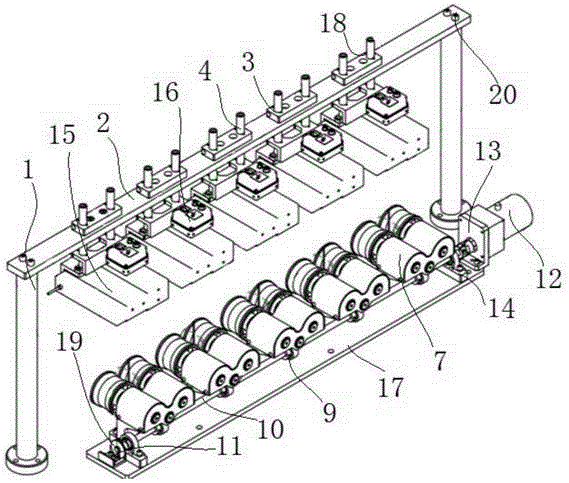

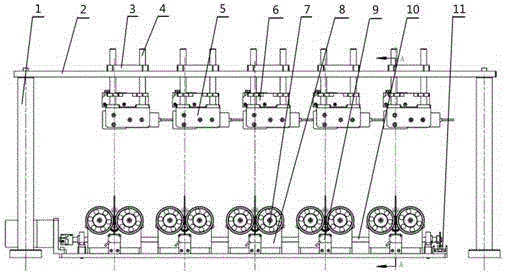

Detection device for piston pin outer circle defects

InactiveCN106290397ARealize quality managementSolve the detection speed is slowMaterial analysis by optical meansVisual recognitionEngineering

The invention provides a detection device for piston pin outer circle defects. The detection device is structurally characterized in that supporting columns and an installing beam are fixed through bolts, fixing plates are arranged on the installing beam, adjusting columns are fixed to the installing beam through the fixing plates, a camera fixing plate and a light source fixing plate are fixed to the corresponding adjusting column, a light source is installed on each light source fixing plate through bolts, a line scanning camera is installed on each camera fixing plate through bolts, and the light sources and the line scanning cameras are located over rolling wheel V-type bases; the rolling wheel V-type bases are installed on a bottom plate, in-place sensors are located below the rolling wheel V-type bases and installed on the bottom plate, and the rolling wheel V-type bases are connected through rolling wheel driving shafts; rolling wheels are arranged on the rolling wheel V-type bases, a rolling rotation driving device is arranged at one side of each rolling wheel, and a shading piece is arranged at the other side of each rolling wheel. The detection device can detect the piston pin outer circle defects, visual recognition is adopted, non-contact dynamic detection is achieved, and the working efficiency is greatly improved while measurement accuracy is ensured.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD

Plant factory

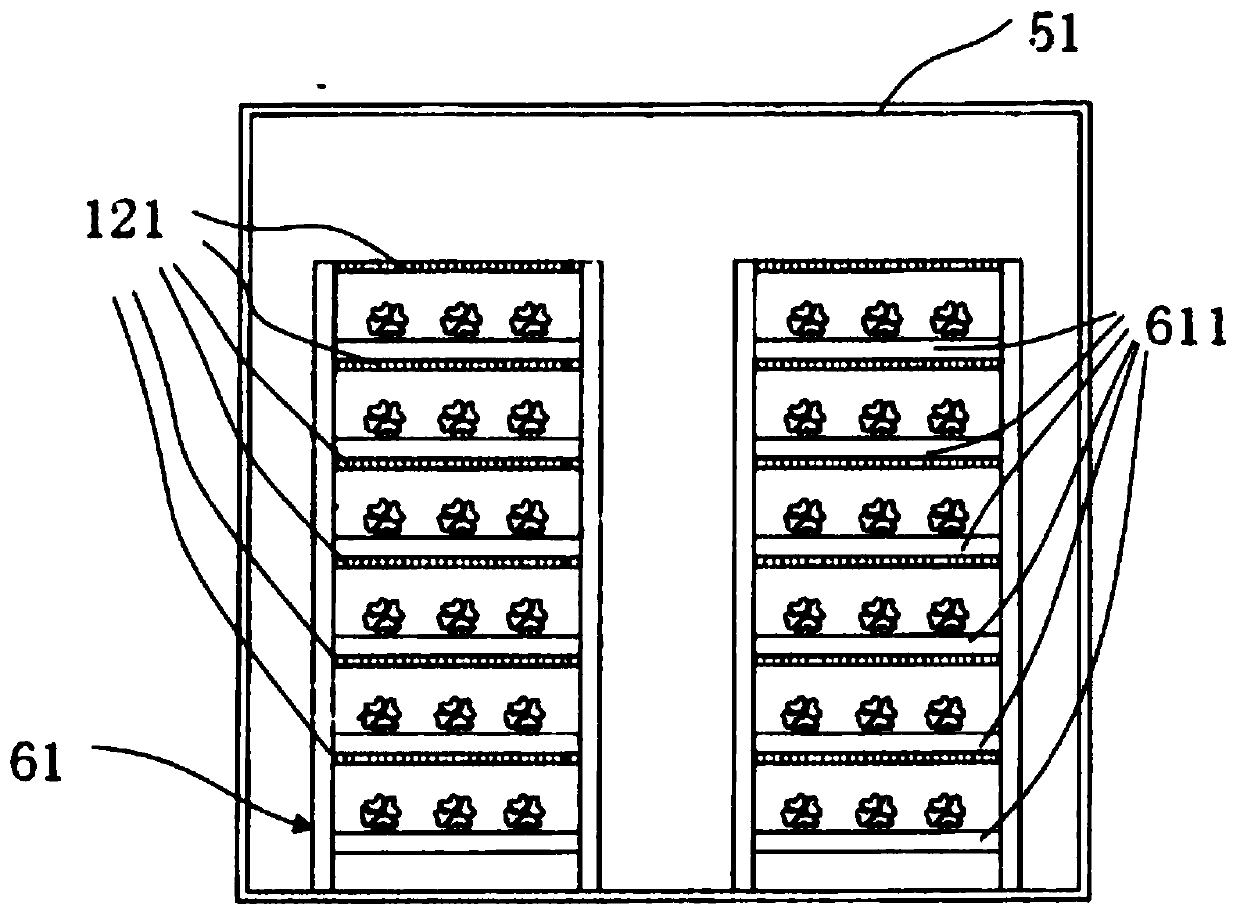

ActiveCN109716953APromote growthImprove planting efficiencyClimate change adaptationGreenhouse cultivationGrowth phasePlant factory

The invention discloses a plant factory which mainly comprises a culture environment room, an illumination assembly, a CO2 concentration generation control module, an air conditioning module, a nutrient supply module and a control module. The plant factory has the advantages that the illumination assembly can be regulated and controlled, the corresponding illumination requirements of different types of plants in each growth phase can be met, the plants can be in the optimal growth statues in each growth phase and can grow according to preset modes which conform to corresponding growth configuration schemes, the plant planting efficiency can be improved, lean production of the plant factory can be implemented, and the zero-inventory purpose which conforms to the production characteristics of the plant factory can be achieved.

Owner:HUIZHOU CONET HARNESS CO LTD

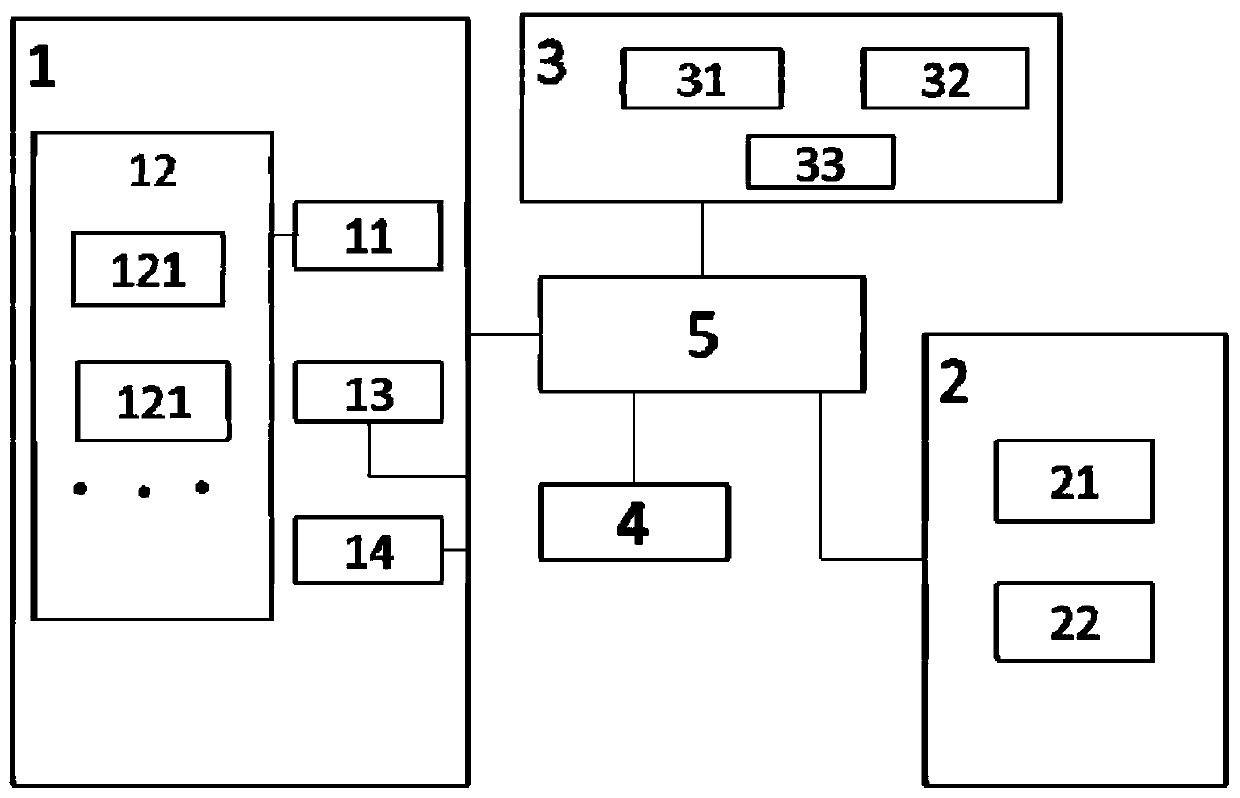

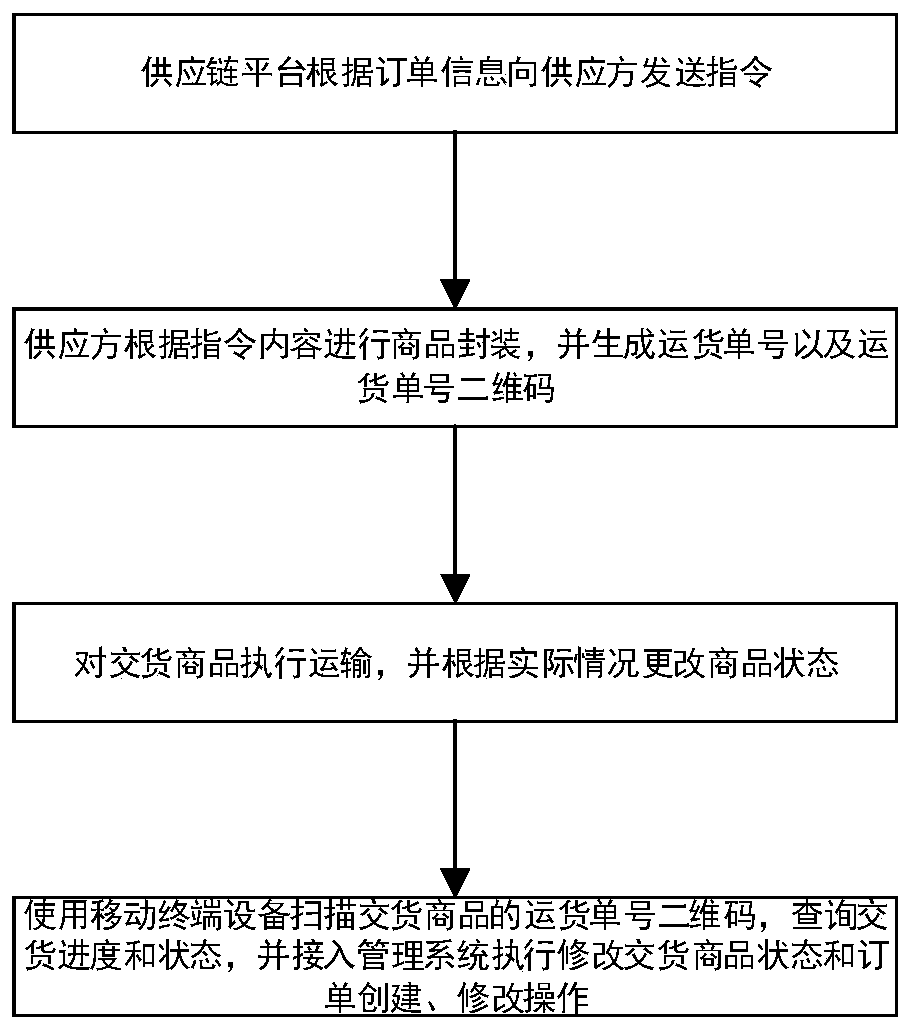

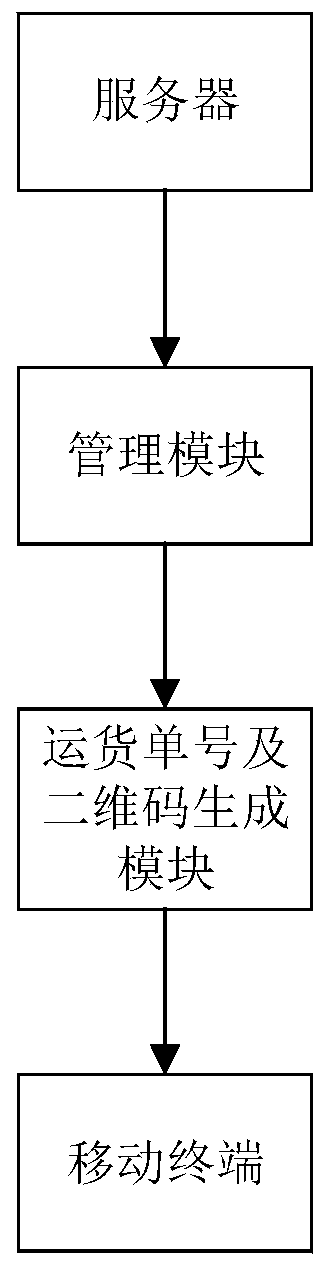

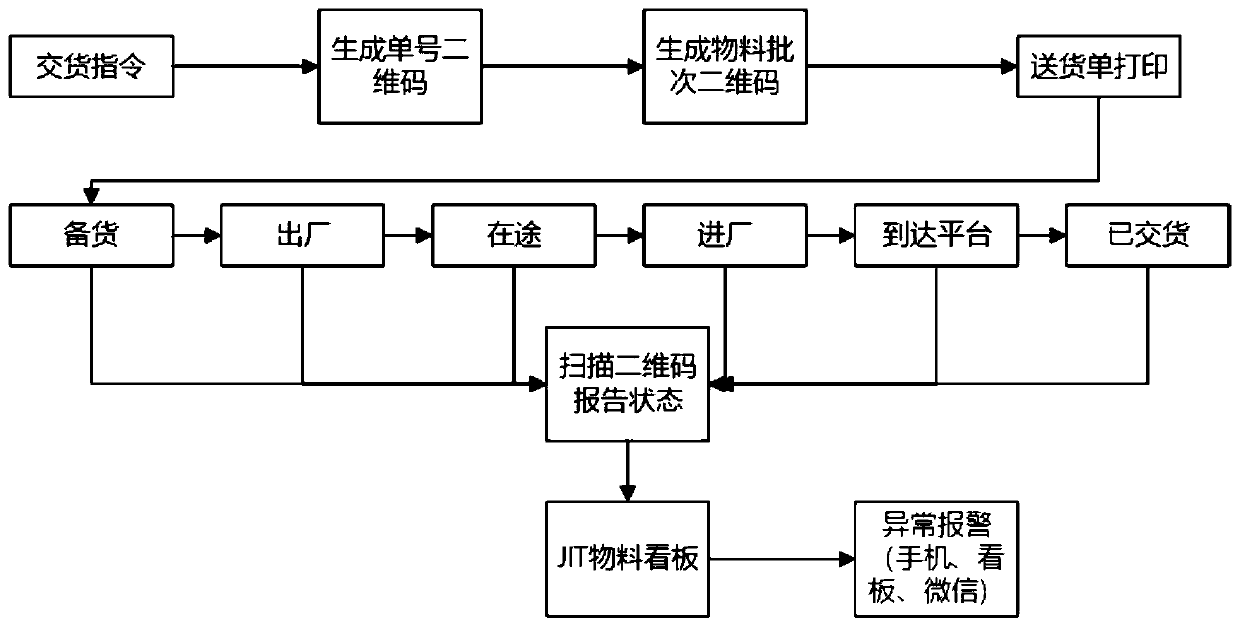

A supply chain platform management method and system

PendingCN109886622AGet delivery information in real timeAchieve delivery deliveryLogisticsTerminal equipmentComputer science

According to the technical scheme, a supply chain platform management method and system is used for achieving the purposes that a two-dimensional code is printed through a delivery list through a supply chain in combination with a mobile internet and a two-dimensional code application method, and the data and the states are collected at all nodes of delivery of a supplier. The supply chain platform sends an instruction to the supplier according to the order information, wherein the instruction content comprises the type of the delivered goods, the quantity of the goods, the earliest delivery time and the latest delivery time; the supplier packages the goods according to the instruction content, generates a waybill number and a waybill number two-dimensional code to transport the deliveredgoods, and changes the state of the goods according to actual conditions; and the mobile terminal equipment is used for scanning the freight note number two-dimensional code of the delivery commodity,inquiring the delivery progress and state, and accessing the management system to execute the operation of modifying the delivery commodity state and order creation and modification. The method has the advantages that the supplier delivery information is obtained in real time, the JIT delivery is achieved, the inventory is reduced, and the lean production is achieved.

Owner:珠海腾飞科技有限公司

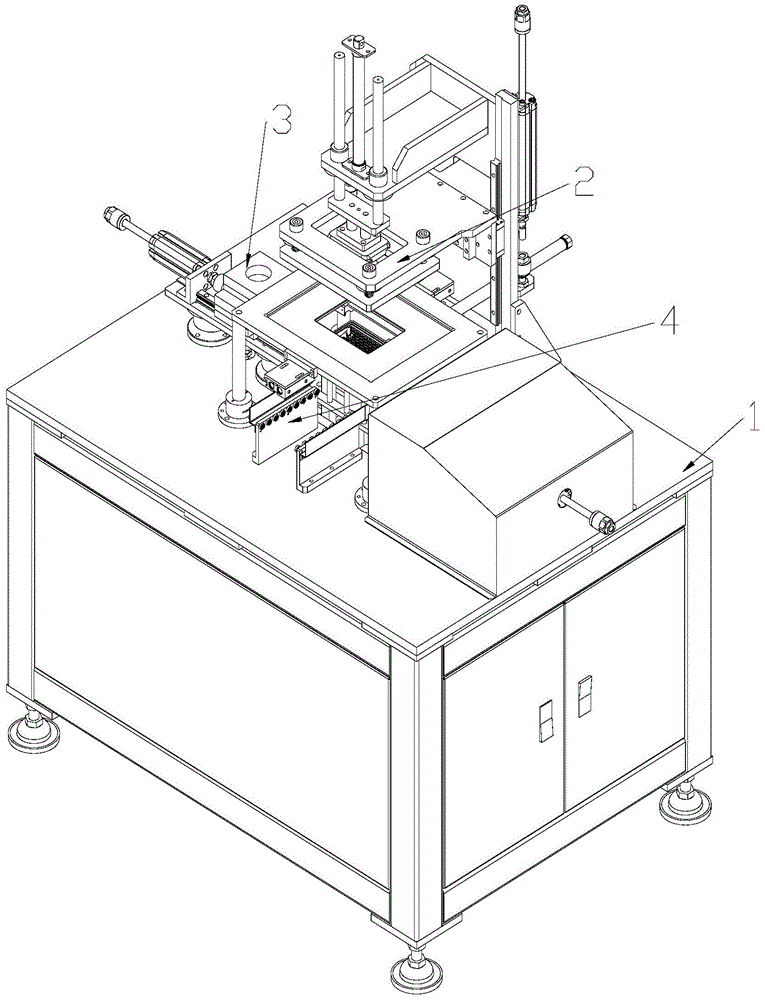

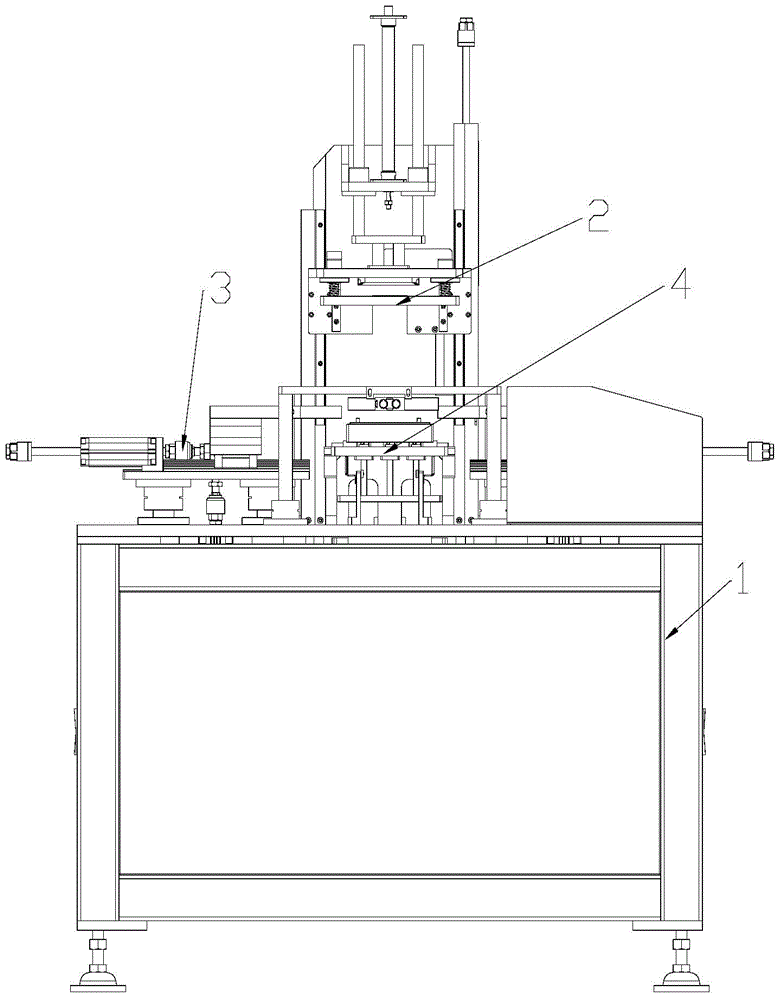

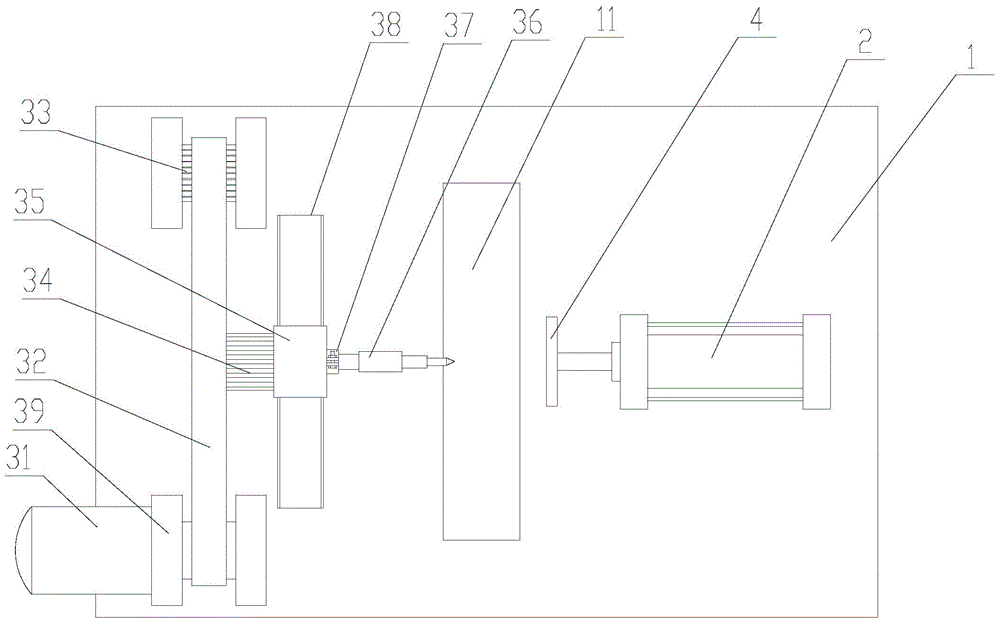

Automatic mesh covering device

ActiveCN104093117ARealize lean productionReduce manual operationsElectrical transducersEngineeringCooperative work

The invention relates to an automatic mesh covering device which comprises a worktable, a mesh tensioning assembly arranged above the worktable, mesh hot iron assembly arranged on the side edge of the mesh tensioning assembly and a discharging assembly arranged below the mesh tensioning assembly. According to the automatic mesh covering device, mesh covering, burning, melting and discharging actions can be automatically achieved through cooperative work of the mesh tensioning assembly, the mesh hot iron assembly and the discharging assembly, only feeding and taking need to be conducted manually, manual operation processes can be reduced, manual operation can be reduced, multiple actions can be completed on one station, the production field and space are reduced, and the purpose of lean production is achieved.

Owner:GUOGUANG ELECTRIC +1

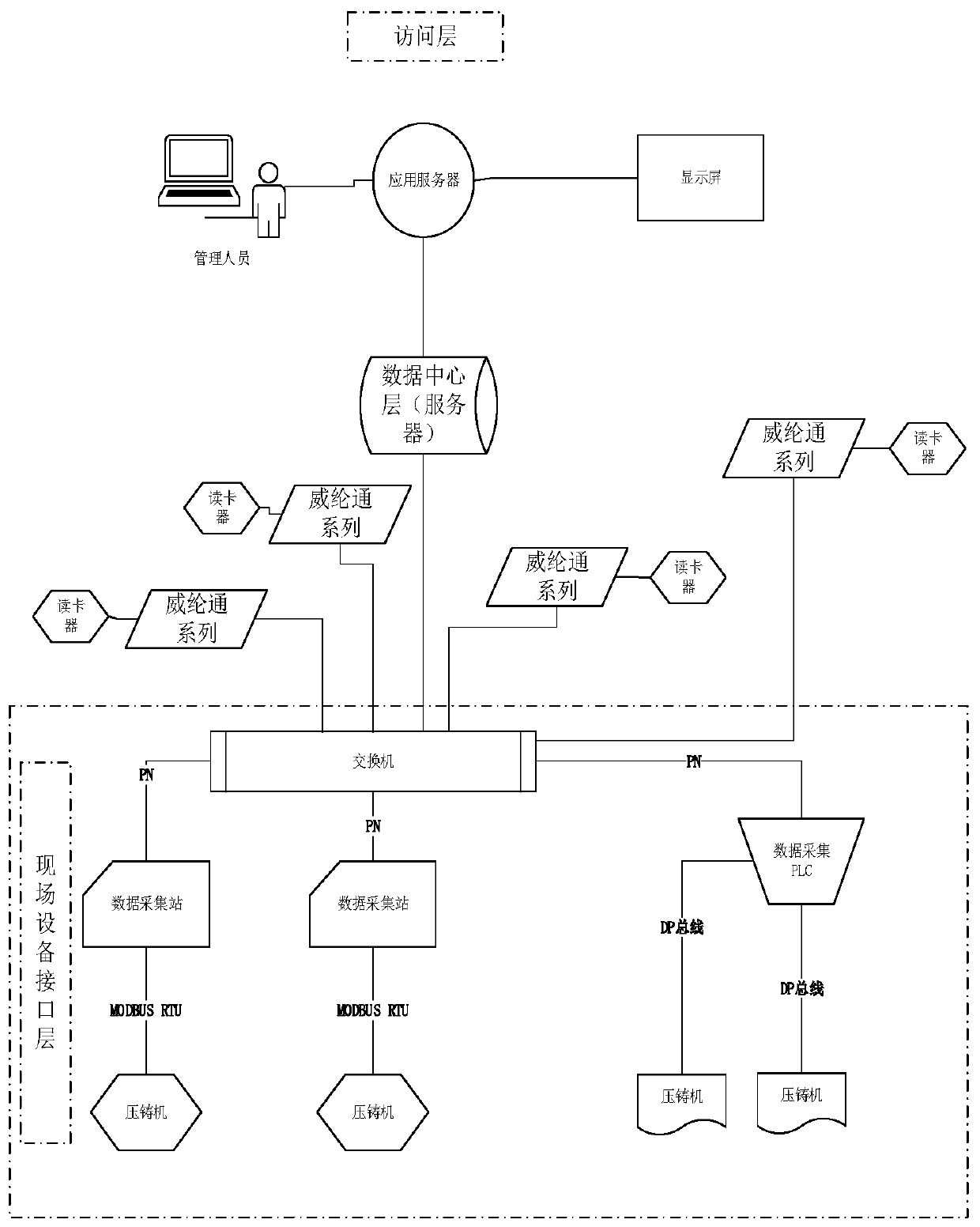

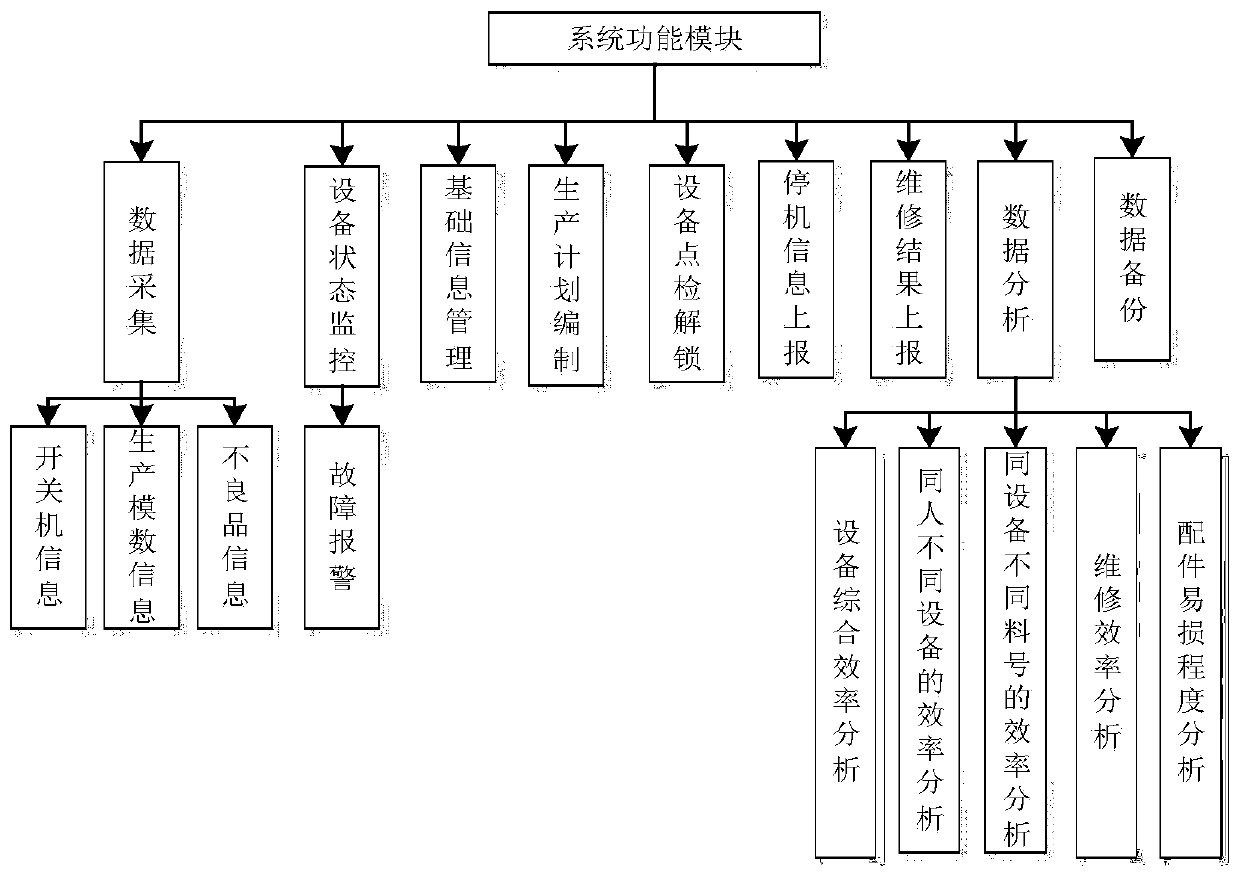

Production management and control method

PendingCN111125235AImprove the level of intelligenceRealize informatizationVisual data miningStructured data browsingIndustrial siteSystems engineering

Disclosed is a production management and control method. First, a production management and control system is established, the production management and control system comprises an access layer, a data center layer and a field device interface layer. The production management and control system is used for production management and control, a data center layer adopts a mainstream force control SCADA industrial configuration software system to collect and display real-time data, real-time management and control of an industrial site can be achieved, and then data is dumped to a relational database through a built-in data dump function of SCADA. By the information management system, production plans are carried out to process and analyze field production data.. The visual data is obtained, the important decision support is provided for the factory production process, the intelligent level of a production workshop is greatly improved through transformation, the informatization of production management is further realized, the production efficiency, the technical level and the product quality are improved, the transparent production and lean production are realized, and the managementlevel of the intelligent workshop is effectively improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

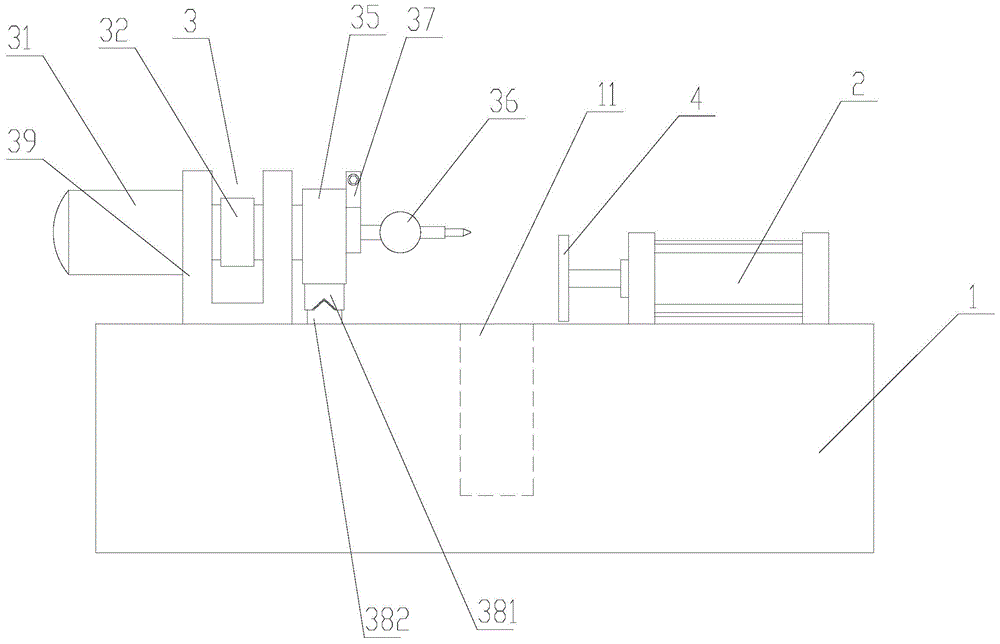

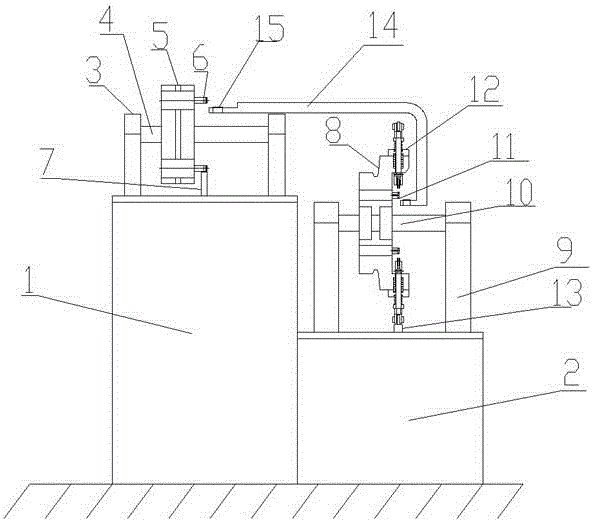

Plane testing tool

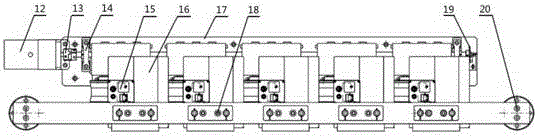

InactiveCN106152920ARealize detectionImplement automatic detectionMechanical roughness/irregularity measurementsTransmission beltElectric machinery

The invention provides a plane testing tool which is convenient in usage and can accurately read testing data and can improve product stability. The plane testing tool comprises a pedestal, a jacking air cylinder and a detection device; the top of the pedestal is provided with a groove; the jacking air cylinder and the detection device are arranged on the pedestal and are arranged on two sides of the groove; the detection device comprises a motor, a transmission belt, a transmission wheel, a moving gear, a fixing seat, a dial indicator, a dial indicator clamping seat, a sliding guiding device and a pair of fixing supports; the pair of fixing supports are arranged on the pedestal; the motor and the transmission wheel are arranged on the pair of fixing supports; the transmission belt is connected between the motor and the transmission wheel; the sliding guiding device is arranged on the pedestal and between the transmission belt and the groove; and the fixing seat is arranged on the sliding guiding device. The plane testing tool realizes automatic detection, easy usage, easy counting, fine production and improved product stability.

Owner:YANGZHOU HONGTIAN MACHINERY

Detection device for end surface defects of piston pin

InactiveCN106290381ARealize quality managementSolve the detection speed is slowOptically investigating flaws/contaminationComputer moduleCcd camera

The invention discloses a detection device for end surface defects of a piston pin. The detection device is provided with two independent detection modules, and the two independent detection modules are used for detecting two end surfaces of the piston pin respectively. The detection device is structurally characterized in that a vertical adjusting pillar is mounted at the top end of a fixed support seat through a plurality of screws and connected with a horizontal adjusting pillar through fixed adjusting blocks, the horizontal adjusting pillar is connected with a mounting plate, the mounting plate is connected with a camera fixing plate through a connecting block, and a lens adjusting block is mounted on the camera fixing plate and connected with a CCD camera through a lens fixing pillar. The end surface defects of the piston pin can be detected, non-contact dynamic detection is realized in a visual identity manner, and the working efficiency is greatly improved while the measurement accuracy is guaranteed.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD +1

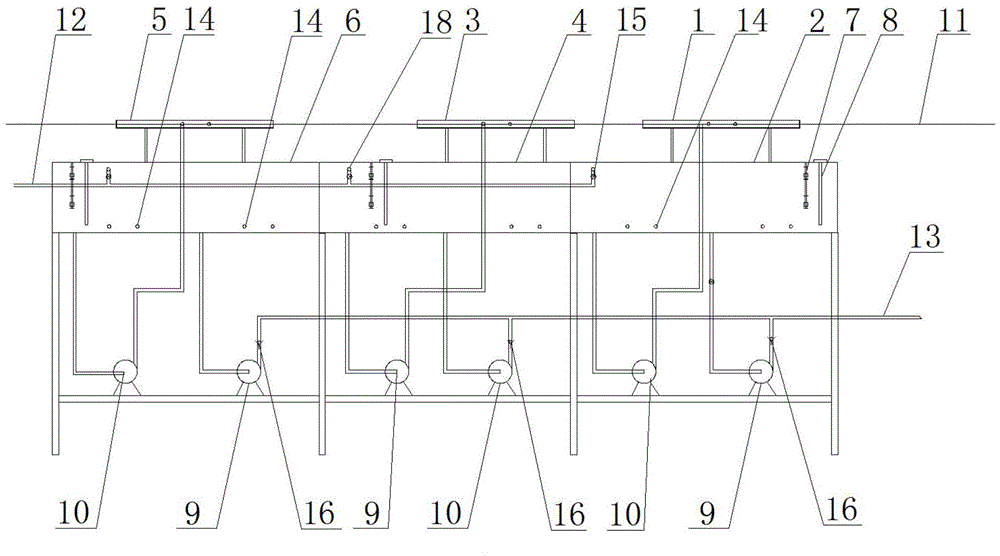

Cooling unit for modification process of long glass fiber reinforced plastic

InactiveCN104827614AReduce usageThe crystallization process is easy to controlGlass fiberWater resources

A cooling unit for a modification process of long glass fiber reinforced plastic comprises a plurality of cooling water tanks arranged in parallel. Each cooling water tank is composed of a small tank and a large tank arranged below the small tank; the temperature of water in the large and small tanks decreases gradually along a moving direction of strips; grilles are disposed at two ends of the top of the small tank and are composed of a plurality of circular columns; a gap between every circular columns is used as a passage allowing passage of the strips; circulating pumps are disposed in the large and small tanks and provide water to the small tank through a pipe, the water in the small tank can flow back into the large tank through the grilles, and the water level of the small tank is lower than the horizontal plane which the strips pass by. The cooling unit has the advantages that the multiple cooling tanks of different temperatures are used to gradually cool the strips, defective rate of the strips can be evidently decreased, lean production is achieved, and waste of cooling water is avoided.

Owner:NANJING JINGJINYUAN TECHN IND

Continuous intelligent flexibility production method for woolen spinning

ActiveCN108803521AHigh sensitivityReduce stackingContinuous processingTotal factory controlProduction lineYarn

The invention provides a continuous intelligent flexibility production method for woolen spinning and relates to an automatic production method. The continuous intelligent flexibility production method comprises a control unit, an oil centralized blending and conveying unit, a plurality of production units and a cone yarn packaging and storing unit, wherein each production unit comprises a cardingsystem, a combined spinning and winding system and a combined winding and twisting system; subsystems in each production unit have no intersection with subsystems in other production units; the control unit controls the oil centralized blending and conveying unit, the production units and the cone yarn packaging and storing unit for production. With the adoption of the method, continuous single-piece lean production is realized, logistics in a workshop is rapid, efficient and punctual, and material inventory of the workshop is reduced greatly. Quality problems are easy to find by single cheese flow in the processing process of the product, anomaly of a production line can be reflected in real time through data monitoring of a production and execution system of the whole production line, and the product can be traced in the whole process. A digital management mode for the workshop is realized, and synchronization and integration of logistics and information flow in the workshop are realized.

Owner:CONSINEE GRP CO LTD

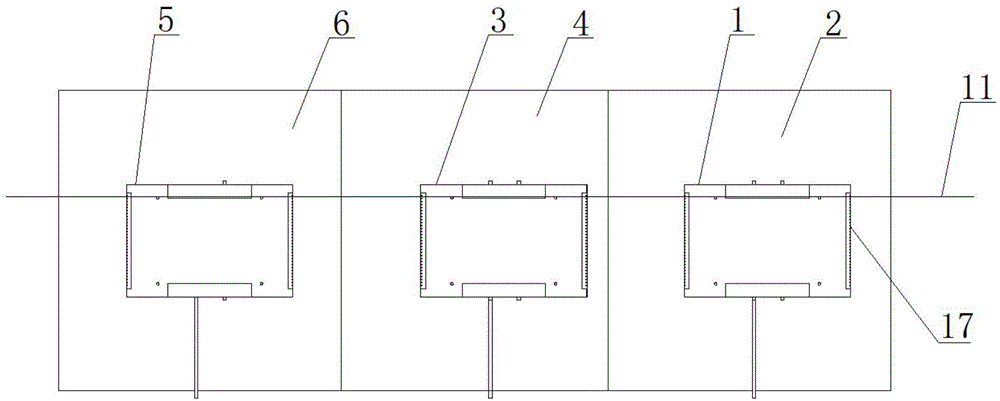

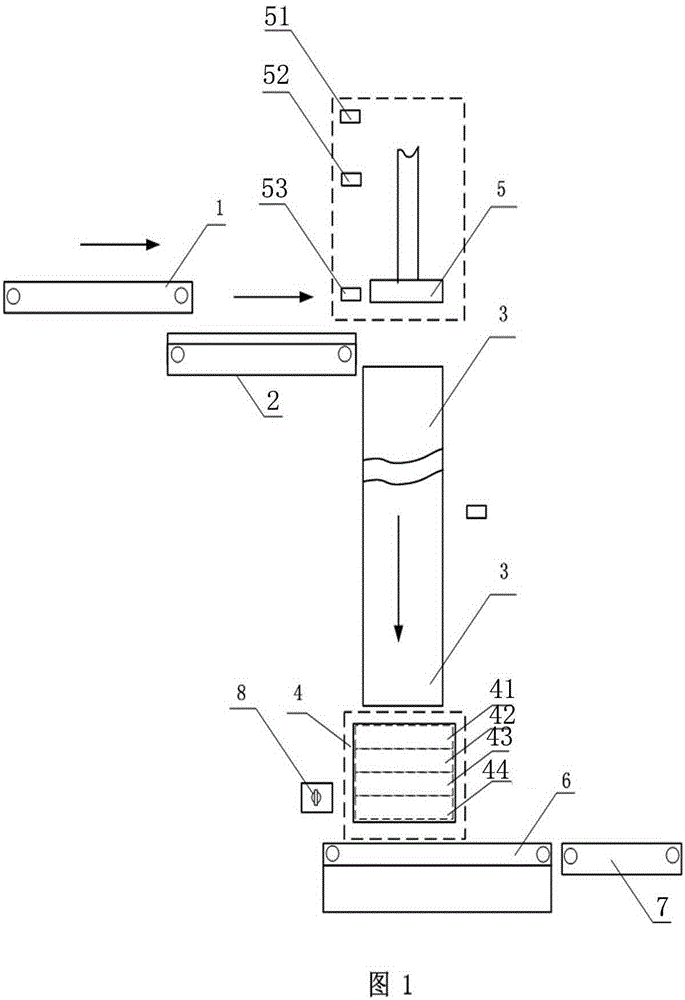

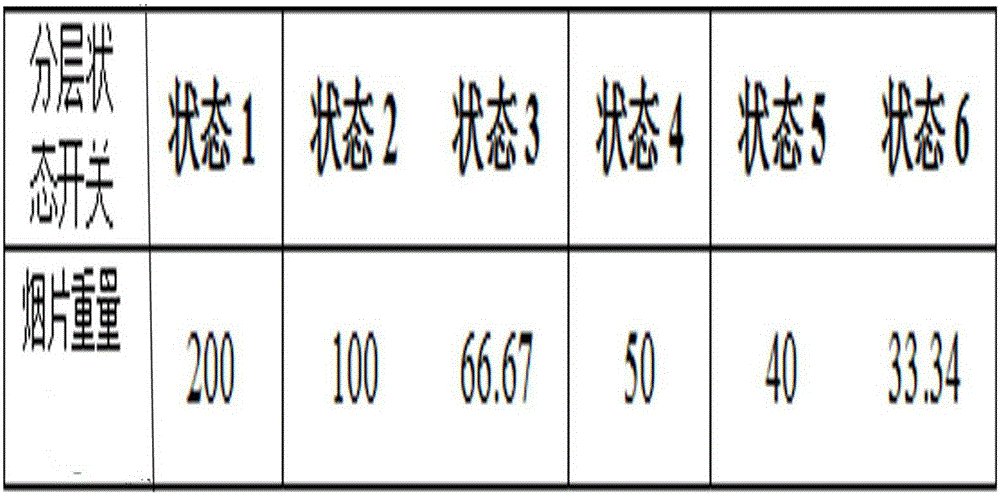

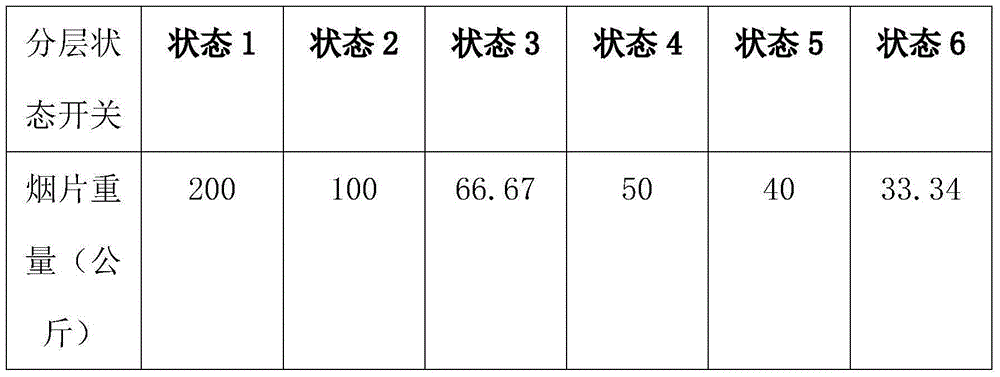

Packaging device and packaging method of finished tobacco flakes

ActiveCN105173268AReduce breakageReduce wastePackaging automatic controlIndividual articlesEngineeringProviding material

The invention discloses a packaging device and packaging method of finished tobacco flakes. An output material conveying roller way is arranged below a finished cigarette box, and an output material conveying belt is arranged on the right of the output material conveying roller way. The pressing frequency and the pressing depth of a main pressing head of a tobacco flake pre-pressing mechanism are controlled by a PLC through time. An electronic belt scale is arranged on the left of a feed box and the finished cigarette box and between the feed box and the finished cigarette box, and a feed material conveying belt is arranged above the electronic belt scale. According to the invention, the feed box provides materials, the electronic belt scale weighs the materials in a segmented mode, and material feeding stops when the weight of the tobacco flakes reaches the set weight value. The PLC automatically calls stroke control parameters to determine the stroke of the pressing head according to the feed material pressing frequency and the tobacco flakes are pressed to different heights through the control parameters. One-time pre-pressing of 200-kg tobacco flakes in the past is changed to four-time pre-pressing, 50kg tobacco flakes are pre-pressed each time. Therefore slicing is not needed in the shred making step, breakage and waste in the slicing process are reduced, and intensive production is achieved.

Owner:HONGTA TOBACCO GRP

Workshop management and control system

PendingCN112070191AImprove the level of intelligenceImprove management levelDatabase updatingData processing applicationsProduction lineInformatization

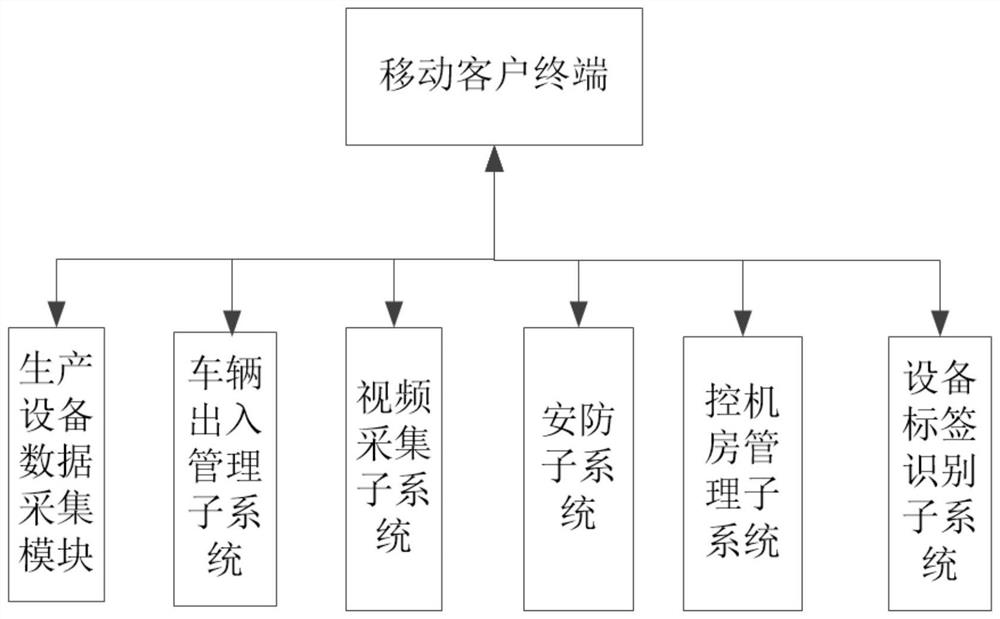

The invention relates to the field of monitoring, and discloses a workshop management and control system, which comprises a video acquisition subsystem, a production equipment data acquisition module,a security subsystem, an equipment label identification subsystem, a vehicle access management subsystem and a monitoring machine room management subsystem. According to the invention, through omnibearing management and control of the workshop, the current operation state of each device of the production line can be displayed, personnel, products and devices in the workshop are managed, the intelligent level of the production workshop is greatly improved, the informatization of production management is further realized, the production efficiency, the technical level and the product quality are improved, transparent production and lean production are realized.

Owner:湖南聚沙信息技术有限公司

A kind of continuous intelligent and flexible production method of carded wool spinning

ActiveCN108803521BReduce labor costsReduce shipping costsContinuous processingTotal factory controlYarnProduction line

The invention provides a continuous intelligent flexibility production method for woolen spinning and relates to an automatic production method. The continuous intelligent flexibility production method comprises a control unit, an oil centralized blending and conveying unit, a plurality of production units and a cone yarn packaging and storing unit, wherein each production unit comprises a cardingsystem, a combined spinning and winding system and a combined winding and twisting system; subsystems in each production unit have no intersection with subsystems in other production units; the control unit controls the oil centralized blending and conveying unit, the production units and the cone yarn packaging and storing unit for production. With the adoption of the method, continuous single-piece lean production is realized, logistics in a workshop is rapid, efficient and punctual, and material inventory of the workshop is reduced greatly. Quality problems are easy to find by single cheese flow in the processing process of the product, anomaly of a production line can be reflected in real time through data monitoring of a production and execution system of the whole production line, and the product can be traced in the whole process. A digital management mode for the workshop is realized, and synchronization and integration of logistics and information flow in the workshop are realized.

Owner:CONSINEE GRP CO LTD

Automatic control system for toothpaste production

InactiveCN114661016AImprove qualityRealize quality traceabilityTotal factory controlProgramme total factory controlInformatizationAutomatic control

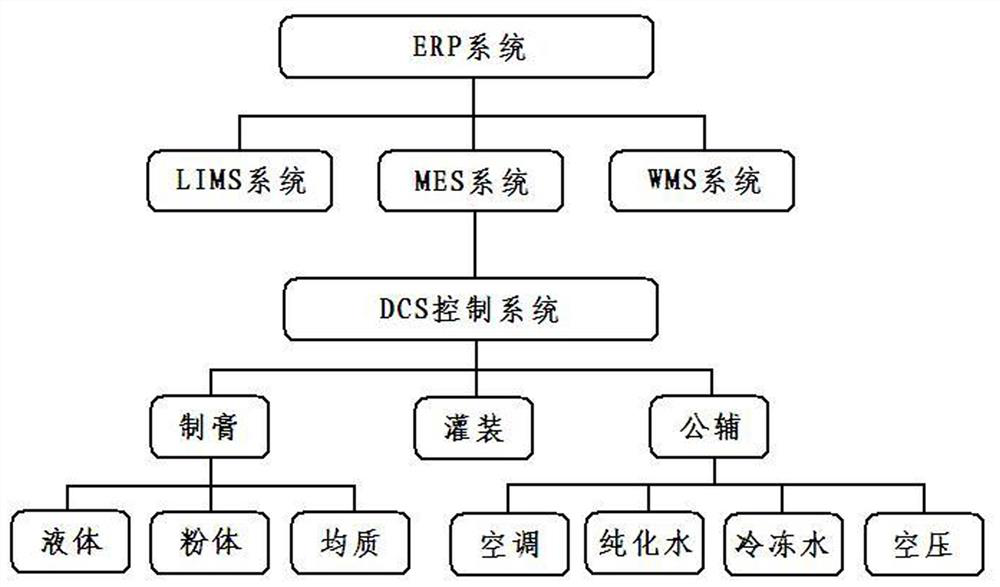

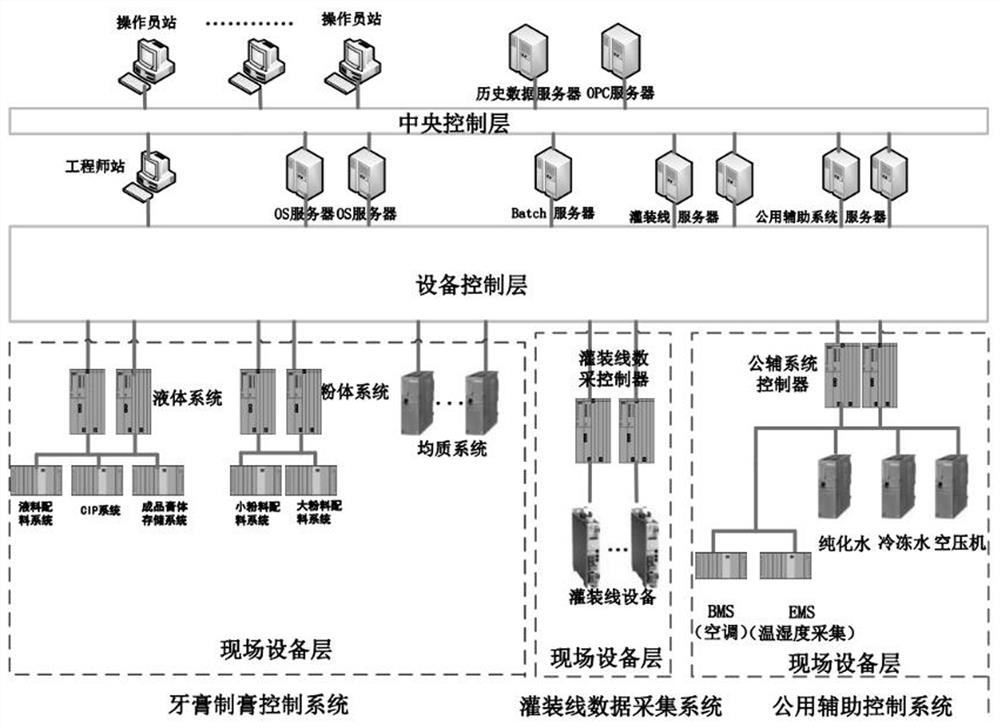

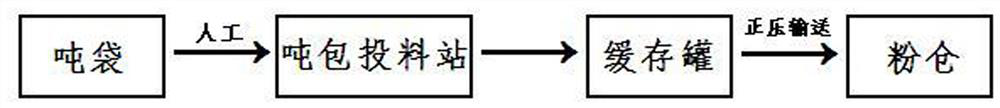

The invention discloses an automatic control system for toothpaste production. The whole production process management and process automatic control are realized through integration of an informatization system and an automation system. The informatization system comprises an ERP system, an MES system, a WMS system and an LIMS system, and the automation system is a DCS control system and comprises a toothpaste preparation control system, a toothpaste filling line data acquisition system and a public auxiliary control system; the production process of the system is divided into three parts of production material management, production process management and production process control. The automatic production level is greatly improved, the production efficiency is improved, the product quality is traced in the whole process, and meanwhile the labor intensity is reduced.

Owner:YUNNAN BAIYAO GROUP

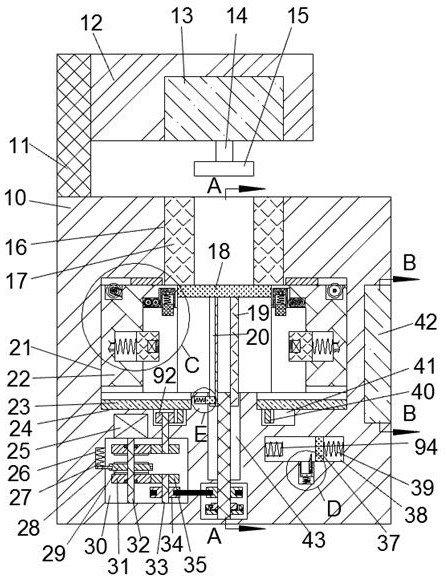

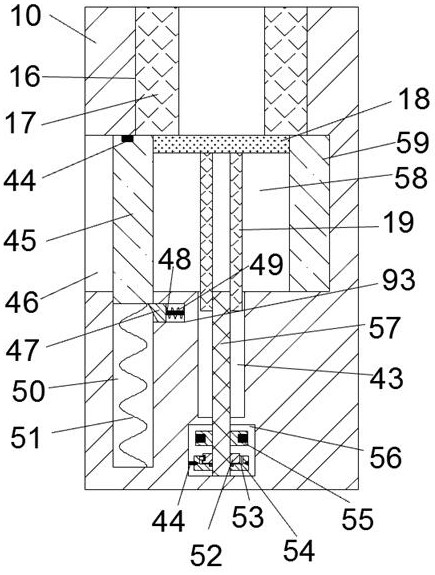

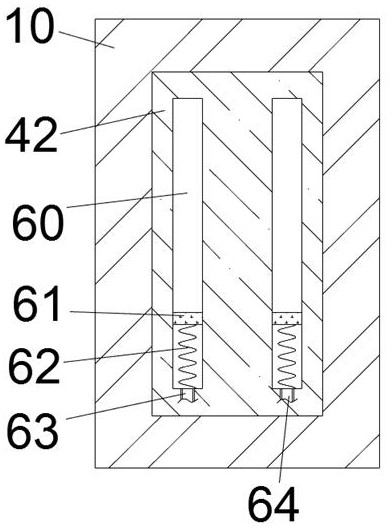

Blank die-casting device with preheating and detecting functions

InactiveCN112123665ARealize lean productionReduce investmentThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermistor

The invention discloses a blank die-casting device with preheating and detecting functions. The blank die-casting device comprises a working box, a die-casting mechanism is fixedly arranged on the endface of the top of the working box, a die-casting cavity with an upward opening is formed in the end face of the top of the working box, a die-casting die is assembled in the die-casting cavity, anda heating cavity with an upward opening is formed in the inner bottom wall of the die-casting cavity. A shaft sleeve cavity with an upward opening is formed in the inner bottom wall of the heating cavity, a transmission cavity is formed in the inner wall of the left side of the shaft sleeve cavity, a power mechanism is arranged in the transmission cavity, a magnet sliding groove is formed in the inner wall of the right side of the shaft sleeve cavity, and a detection plate is fixedly arranged on the right side end face of the working box. According to the blank die-casting device, automatic die-casting of a blank of phenolic resin is achieved, subsequent outer diameter and height detection and preheating of the blank are integrated, multiple functions are achieved, the preheating temperature of the blank is accurately controlled by using a semiconductor thermistor, lean production is achieved, the equipment investment is greatly reduced, and the production cost is reduced.

Owner:SHENGZHOU RUNYA ELECTRONICS TECH CO LTD

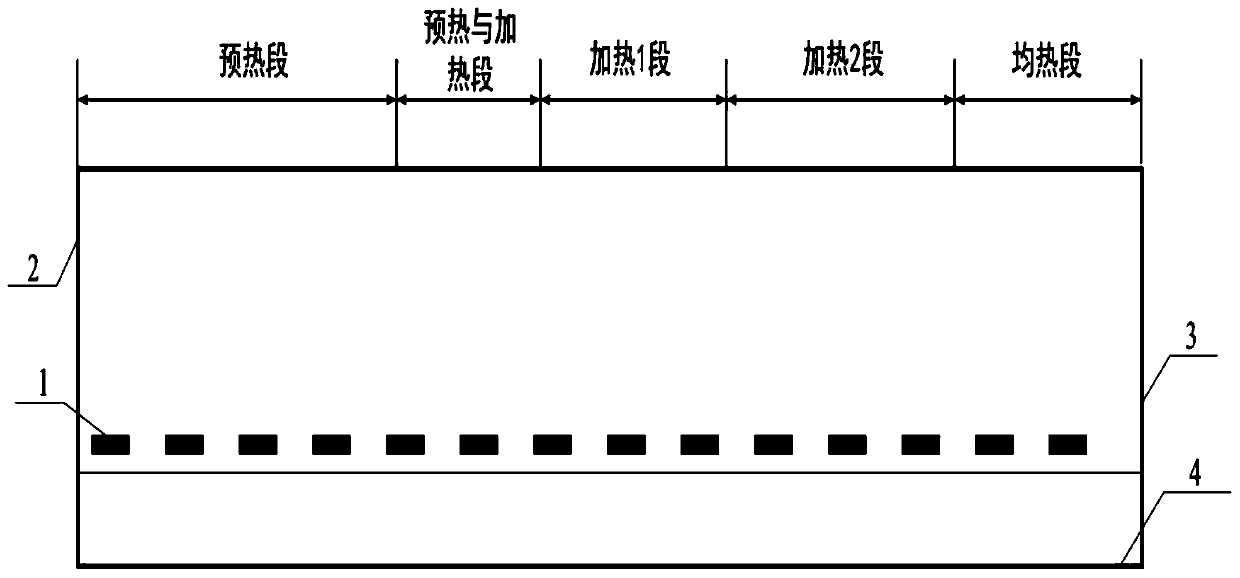

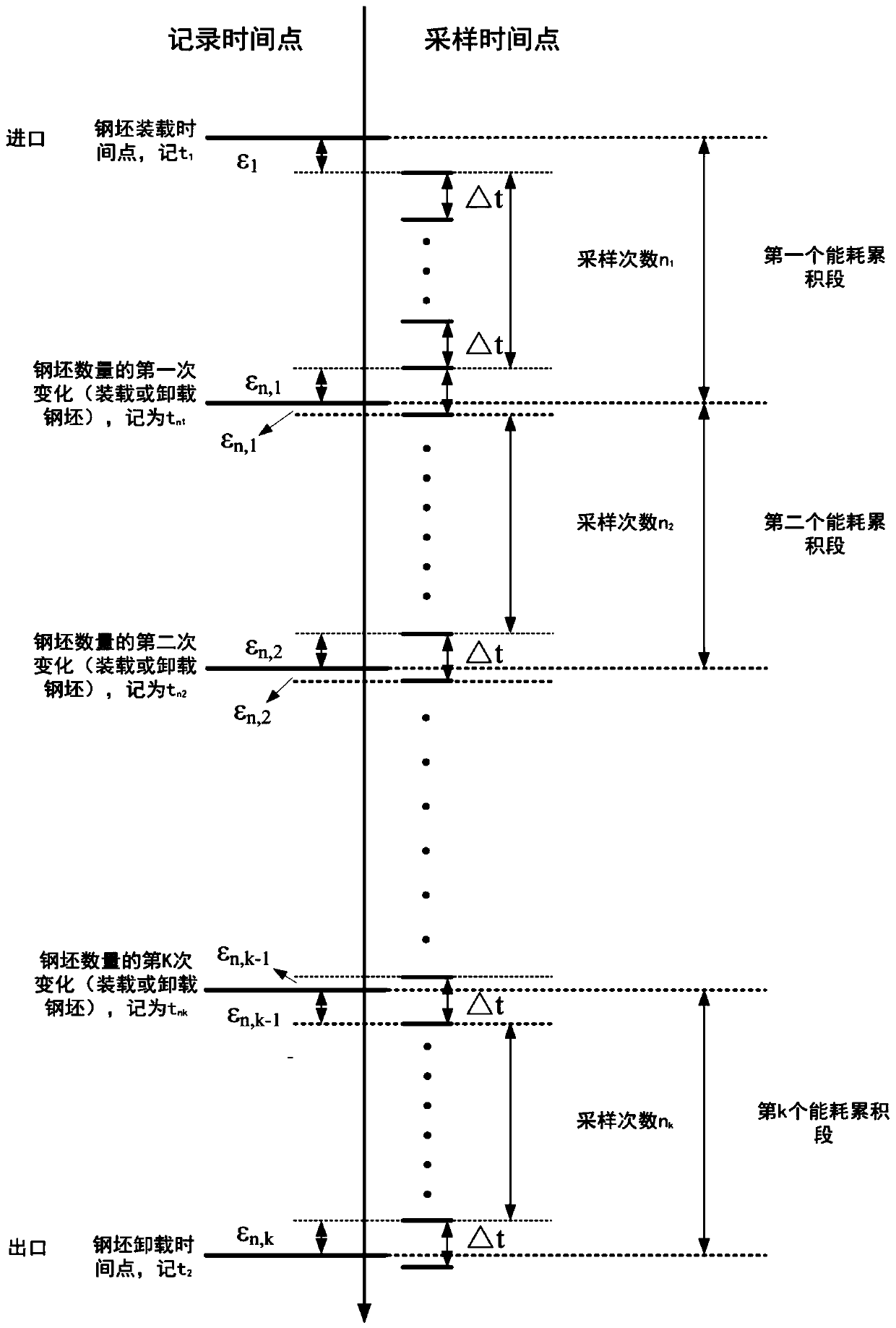

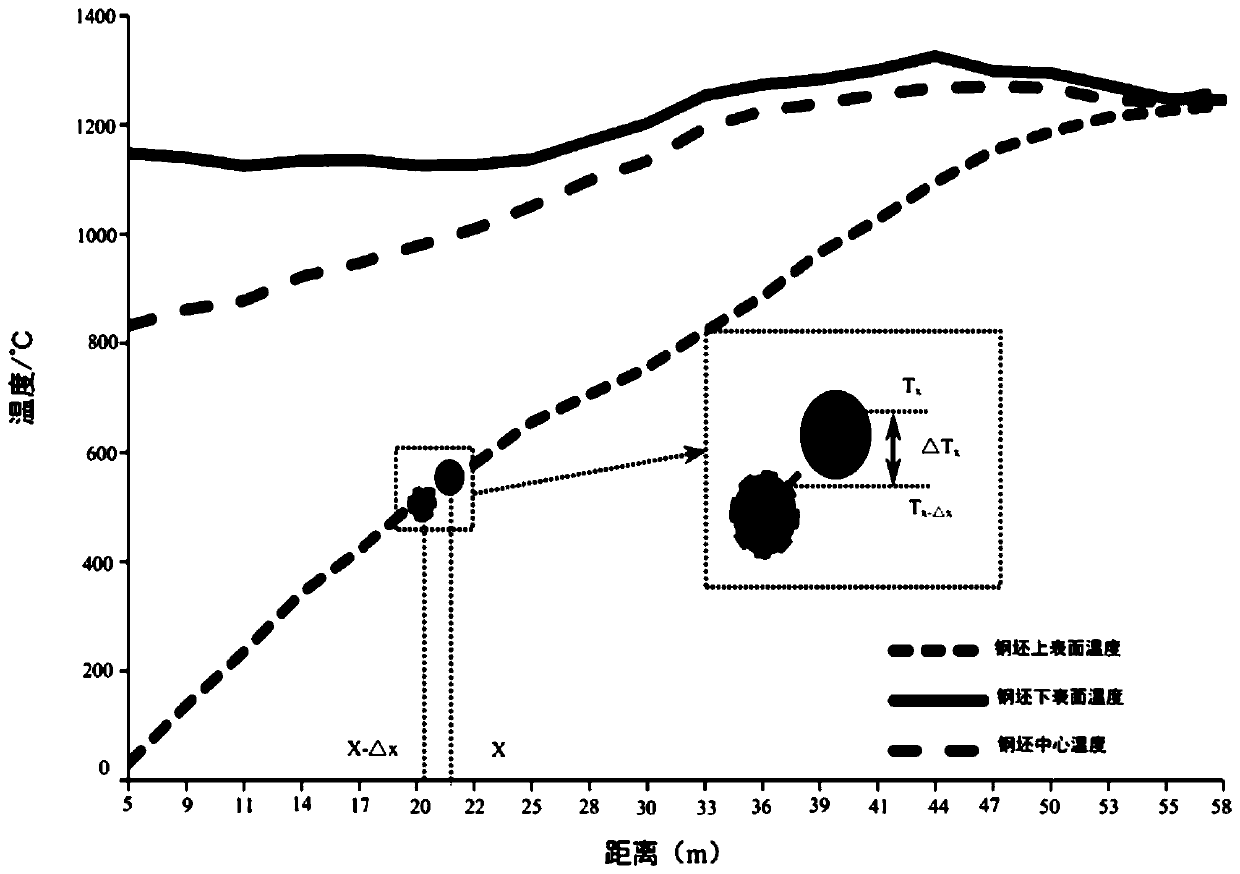

Method for measuring heating furnace energy consumption apportionment

PendingCN111159919APromote energy saving and emission reductionSolving costing challengesDesign optimisation/simulationResourcesHeating furnaceEnergy consumption

The invention discloses a method for measuring heating furnace energy consumption apportionment, and belongs to the field of steel production. The method comprises the following steps: S1, dividing the whole heating furnace into k energy consumption accumulation sections, and carrying out discrete processing of energy consumption accumulation; s2, determining an energy consumption accumulation proportion of a single steel billet; and S3, calculating the energy consumption of a single billet of the heating furnace to obtain the energy consumption required for heating the single billet and the effective absorption heat of the billet, and exploring the influence of factors such as different billet widths, production rhythms and grades on billet production of the heating furnace. The blank ofcalculation of energy consumption and cost of single steel billet production in the steel billet production process of the heating furnace in the existing algorithm is overcome, and the heating furnace energy consumption apportionment amount under different factor conditions in the heating furnace production process can be effectively explored.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

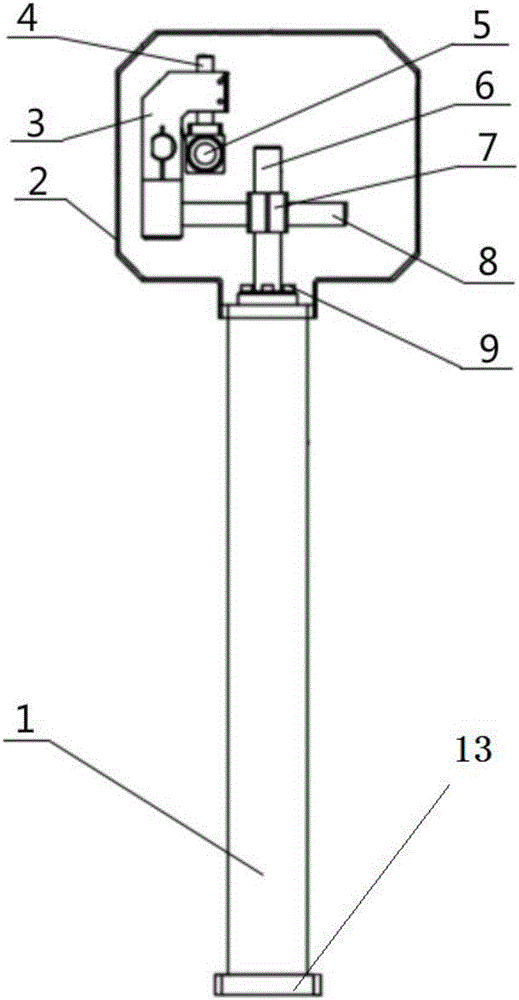

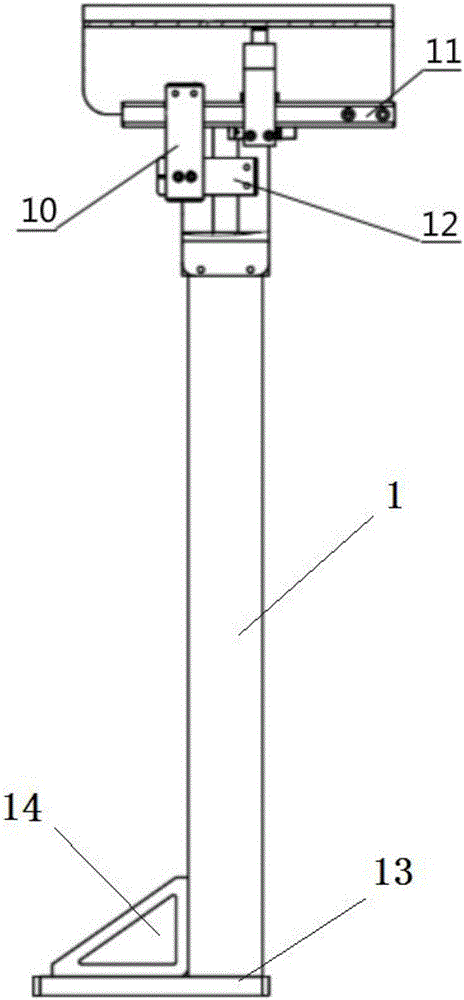

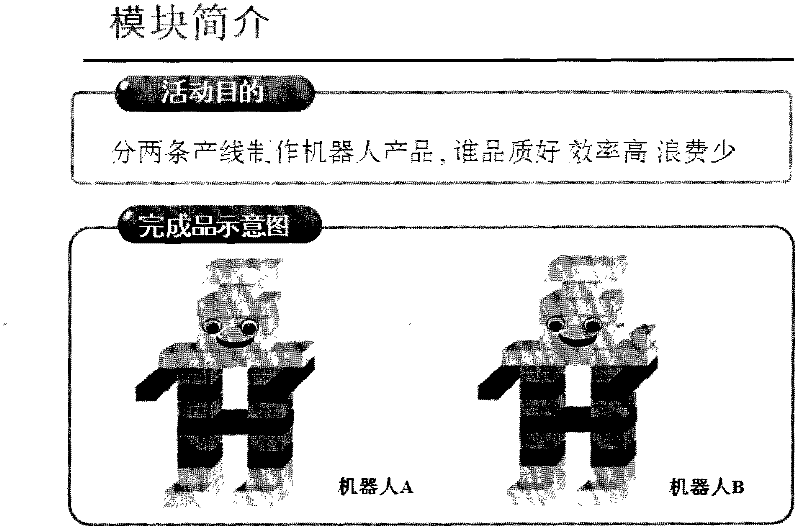

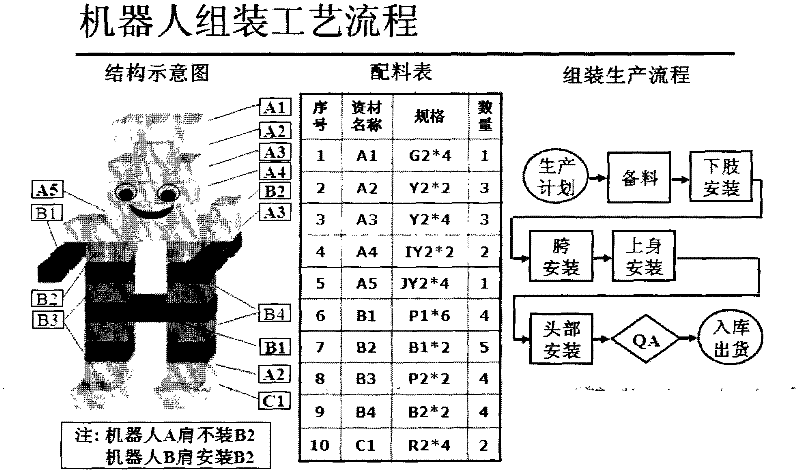

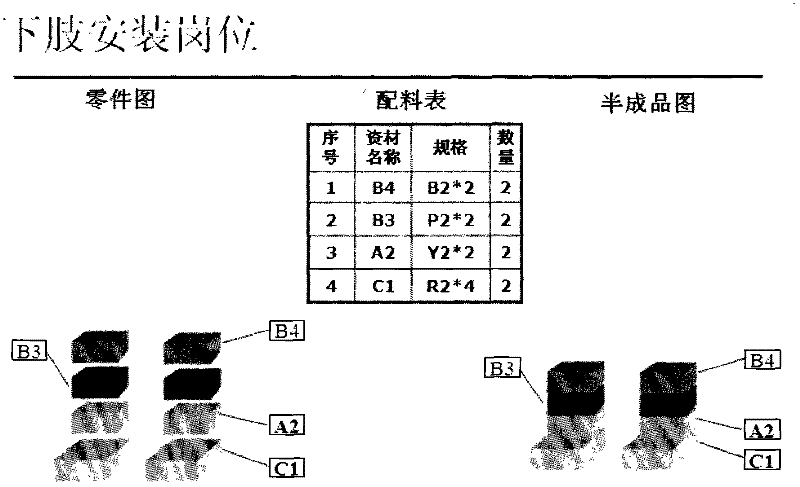

Situation training module and method for lean production line

InactiveCN102254478AImprove efficiencyEliminate bad wasteEducational modelsProduction lineCountermeasure

The invention discloses a situation training module and a situation training method for a lean production line. The situation training module is used for simulating the actual manufacturing production line to improve the skill of a site manager for lean management, constantly find eight waste points by comparing training groups and make improvement. The situation training module is a building block model toy which can be assembled or disassembled. The situation training method for the lean production line by the situation training module comprises the following steps of: 1, establishing teams; 2, delivering a production plan; 3, organizing 2 to 3 production lines for mass production; 4, recording production data and analyzing financial performance of all production lines; 5, discussing and analyzing waste and problems of the production line, and providing improvement suggestion; and 6, performing training again or for multiple times, and making constant improvement. By the invention, the traditional mode of orally imparting knowledge is changed, the training efficiency is higher, the method is effective, and a trainee can easily master the method.

Owner:陆忠

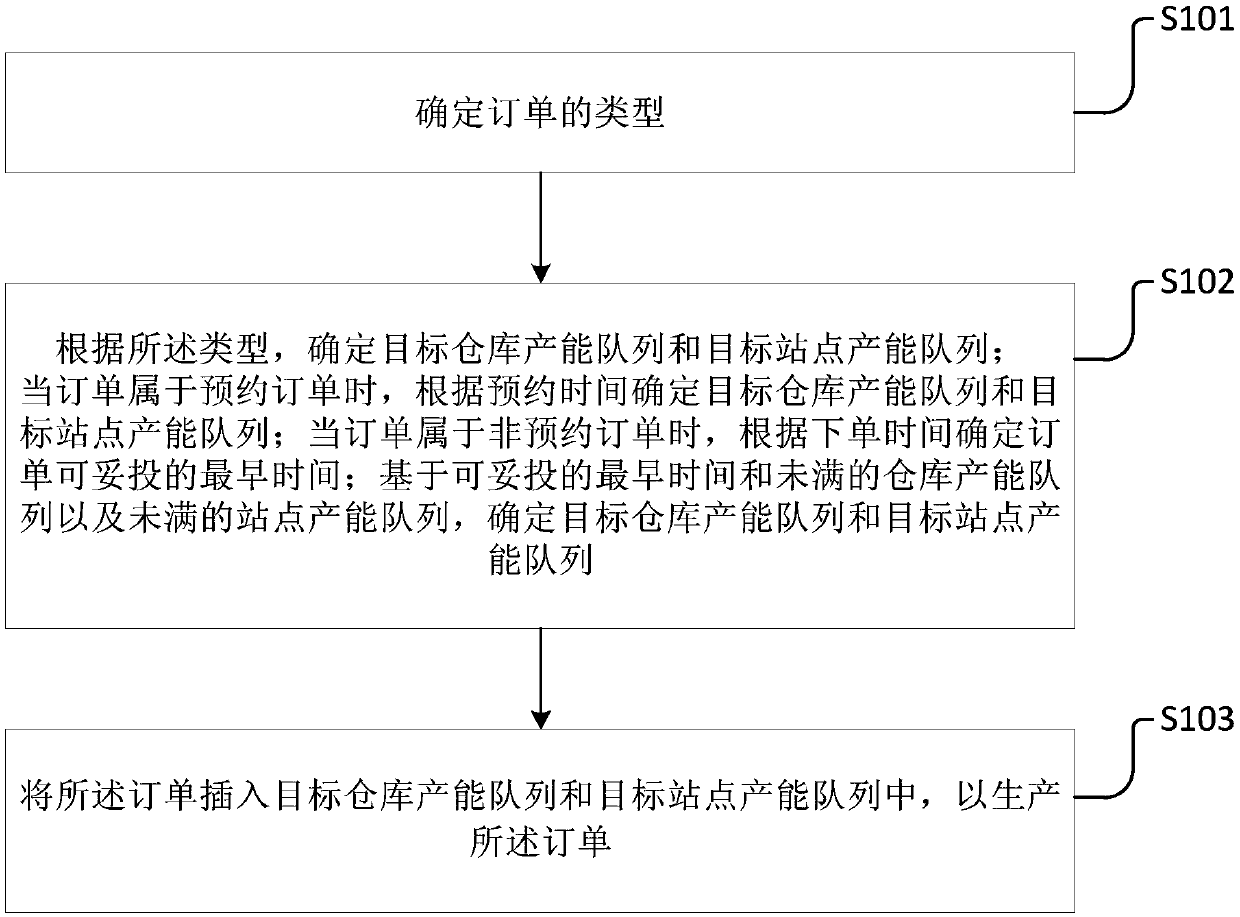

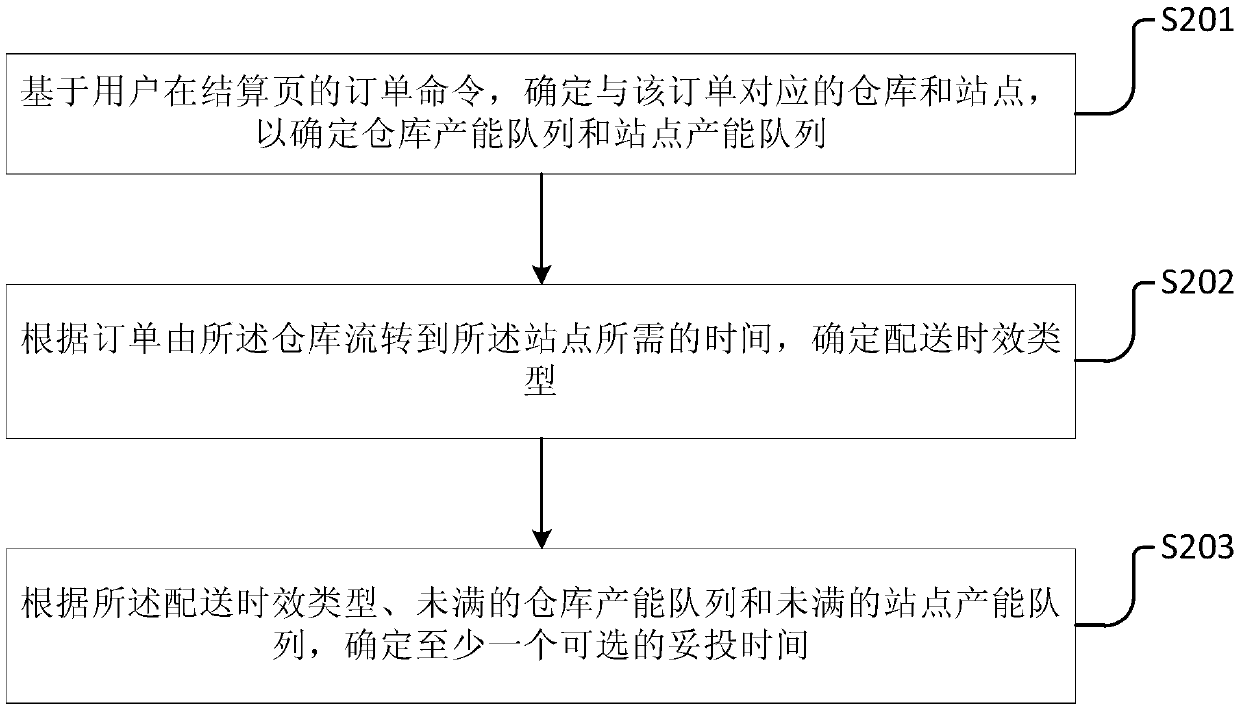

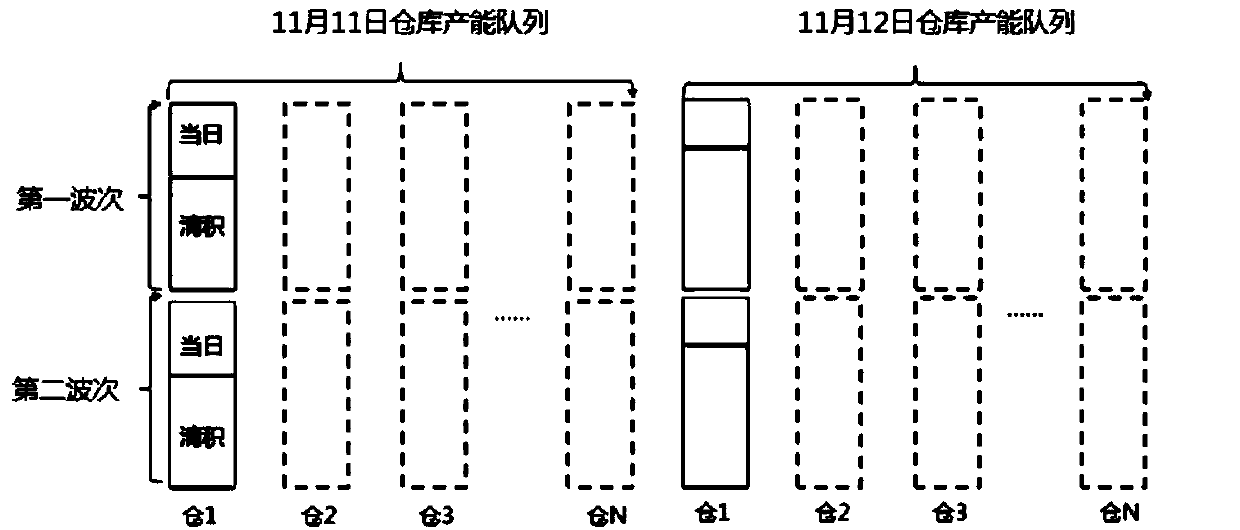

Order production method and device

PendingCN110858332AReduce reminder rateImprove experienceReservationsBuying/selling/leasing transactionsLogistics managementOrder form

The invention discloses an order production method and device, and relates to the technical field of logistics storage. A specific embodiment of the method comprises the steps of determining the typeof an order; determining a target warehouse capacity queue and a target station capacity queue according to the type; inserting the order into a target warehouse capacity queue and a target station capacity queue to produce the order; wherein when the order belongs to a reservation order, a target warehouse capacity queue and a target station capacity queue are determined according to reservationtime; when the order belongs to a non-reservation order, determining the earliest available time of the order according to the order placing time; and determining a target warehouse capacity queue anda target station capacity queue based on the earliest available time, the insufficient warehouse capacity queue and the insufficient station capacity queue. According to the embodiment, smooth production can be achieved, the capacity is utilized to the maximum extent, more accurate logistics services are provided for users, the performance rate is improved, the user order urging rate is reduced,and the user experience is improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

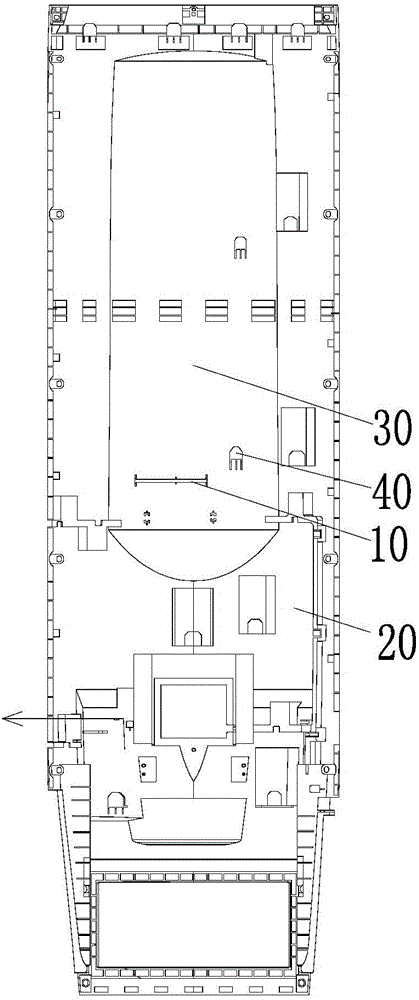

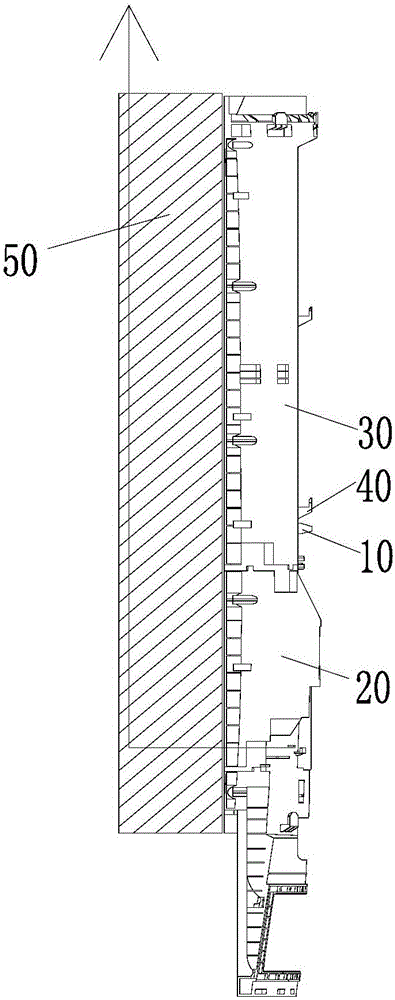

Air conditioner

InactiveCN106091304AAvoid wastingReduce operational complexityLighting and heating apparatusSpace heating and ventilation detailsEngineeringMotherboard

Owner:GREE ELECTRIC APPLIANCES INC

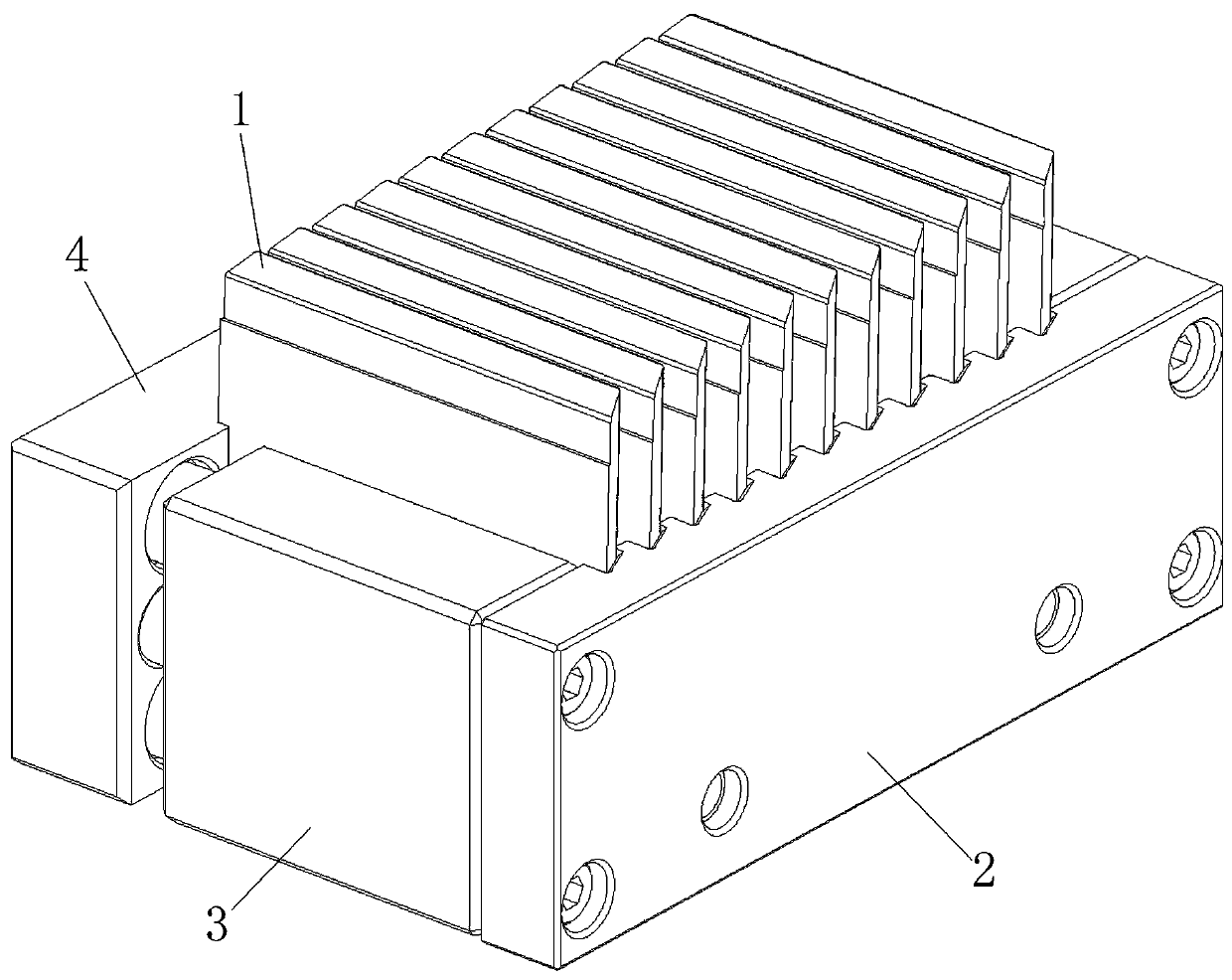

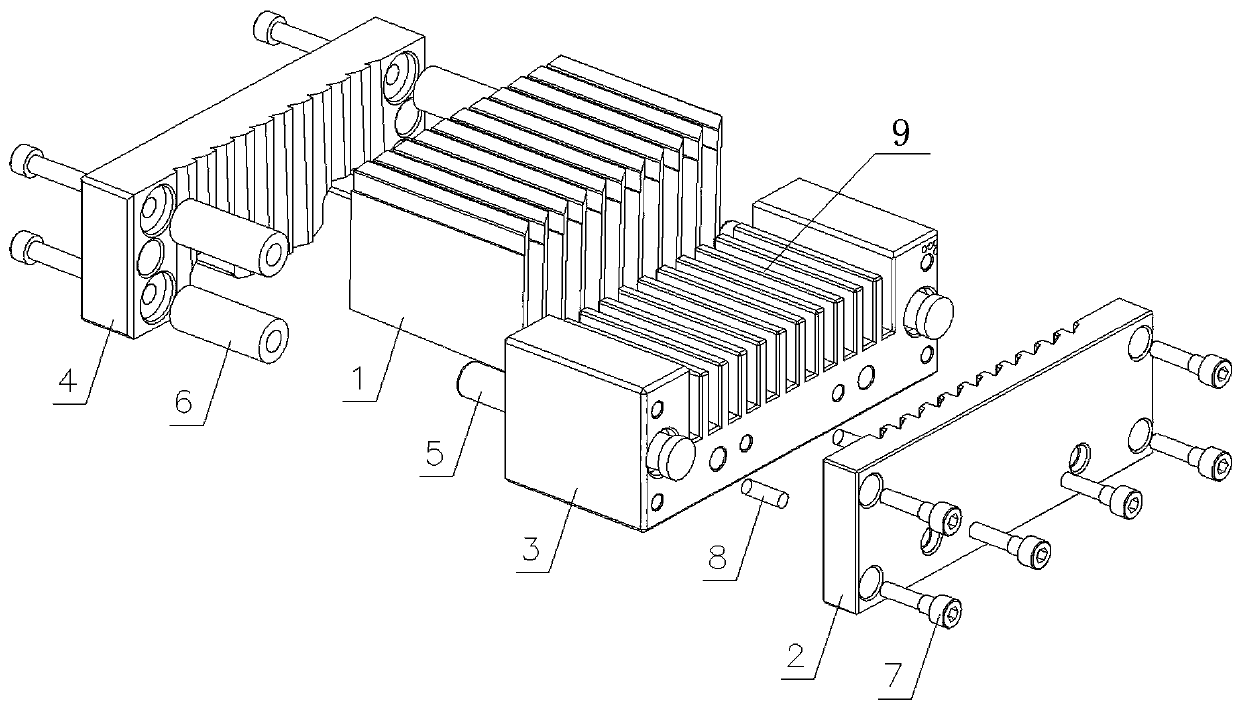

Processing device and method for louver blades

PendingCN111203601AFast processingEfficient processingElectrical-based auxillary apparatusStructural engineeringKnife blades

The invention provides a processing device and method for louver blades. The processing device includes a first clamp plate, a second clamp plate and a third clamp plate, the first clamp plate, the second clamp plate and the third clamp plate are assembled in sequence from right to left, the second clamp plate is provided with a plurality of blade grooves, an inclination angle is arranged on the bottom surface of each blade groove, the blade grooves are used for installing the louver blades to be processed, the first clamp plate and the third clamp plate are each provided with fixing grooves,and the fixing grooves are used for assembling the louver blades to be processed. The multiple louver blades to be processed are assembled at the same time through the multiple blade grooves, the problem of wasted time of multiple times of clamping in a single time of processing of the blades is solved, meanwhile, the problems of waste and large processing volume of multiple accurate grinding processes are solved, high-efficiency batch processing which can be completed by one-time clamping and one line cutting is realized, and the production and processing efficiency is greatly improved.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

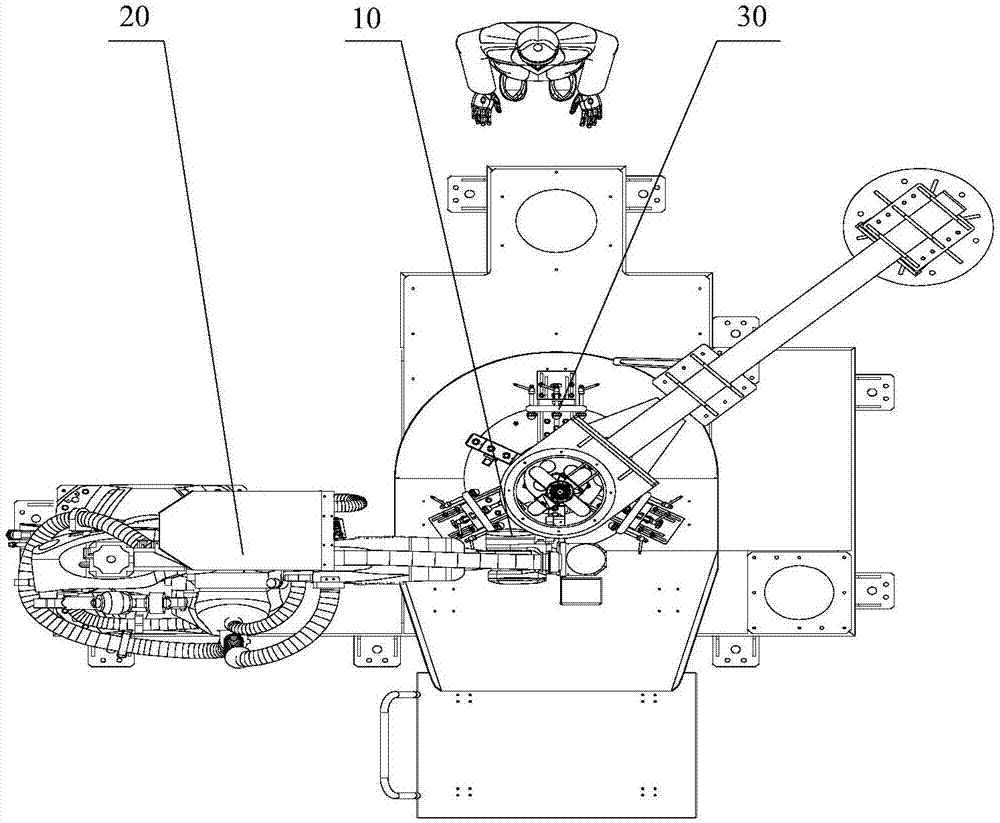

Intelligent casting machining system and casting machining method

The invention discloses an intelligent casting machining system and a casting machining method. The intelligent casting machining system comprises an intelligent camera, a robot, a mobile loading / unloading platform and a controller; the controller is respectively connected with the intelligent camera, the robot and the mobile loading / unloading platform, wherein the intelligent camera is used for shooting pictures of castings to be machined, determining the positions of casting ports of the castings to be machined and sending the position data of the determined casting port positions to the controller; and the controller is used for controlling the mobile loading / unloading platform to move according to the position data sent by the intelligent camera to correct the castings to be machined according to the casting machining positions determined by the intelligent camera and controlling the robot to use a cutting tool to cut the corrected castings to be machined. The intelligent casting machining system and the casting machining method realize lean production in the war industry, greatly improve the manual working environment, guarantee the personal safety, and improve the working efficiency.

Owner:CHANGSHA CTR ROBOTICS

Method for processing composite product with through holes

ActiveCN113103366AImprove water cutting processing efficiencyAvoid damageMetal working apparatusWater jet cutterHigh pressure water

The invention discloses a method for processing composite product with through holes, and belongs to the field of composite material processing. According to the method, before the composite material product is machined through a high-pressure water cutting method, a through hole meeting the requirements is drilled in the position, needing to be fed, of a composite material blank, in this way, when high-pressure water cutting machining is conducted, a water jet cutter is fed from the position where a hole is formed in advance, and then cutting machining of the composite material product is completed in sequence, so that product damages caused by layering of the composite material are effectively prevented. The method is convenient and simple to operate and easy to control, the damages to the laminated composite material plate are small, the layering risk of the laminated composite material product is reduced to the maximum extent, and the qualified rate of the product is high, so that the water cutting processing efficiency of the composite material product is greatly improved, and lean production can be realized.

Owner:SHANDONG NON METALLIC MATERIAL RES INST +1

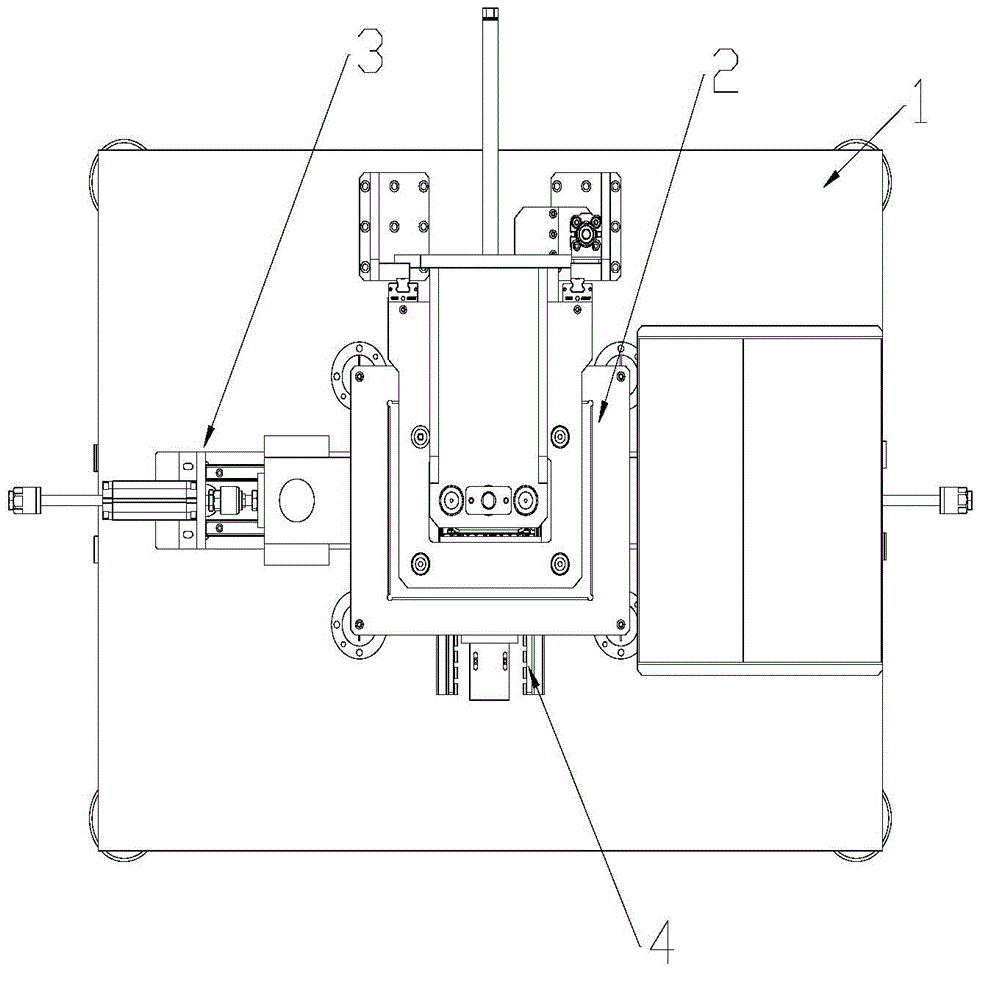

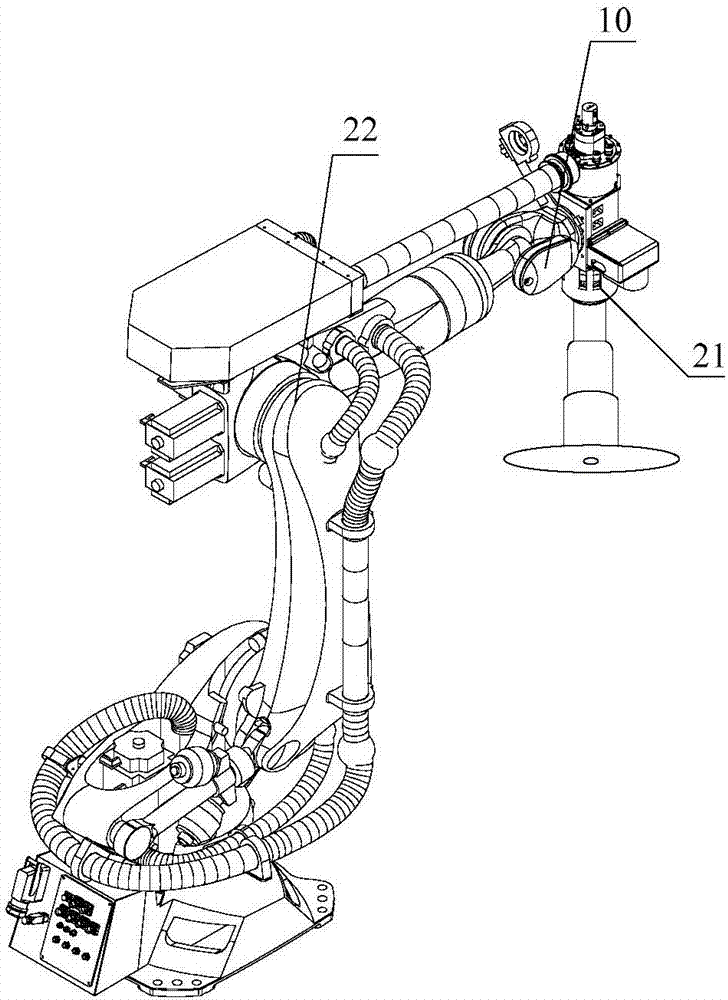

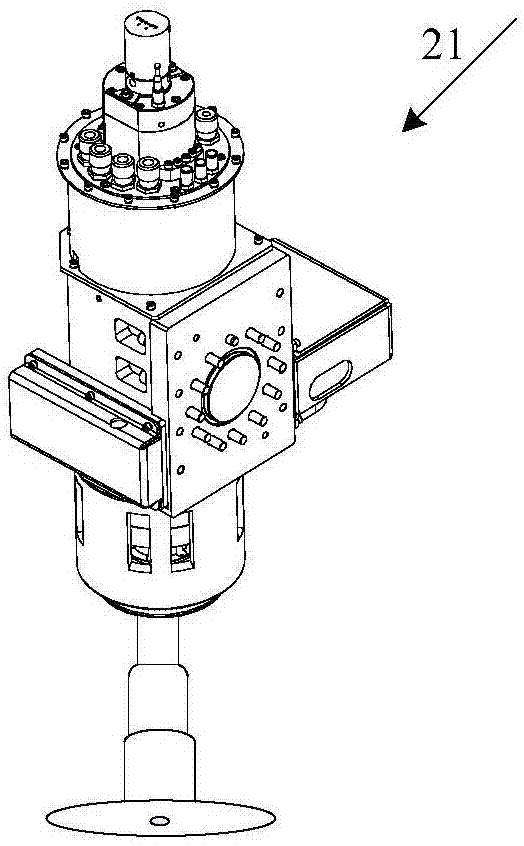

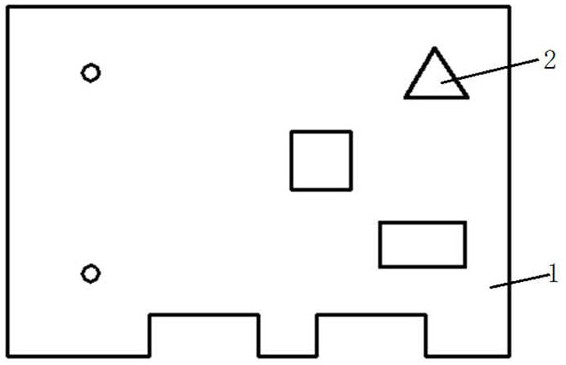

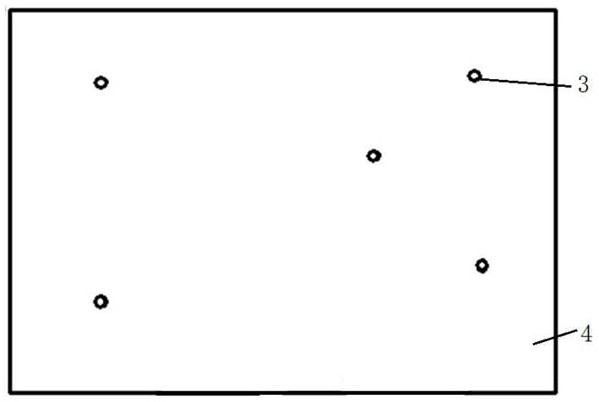

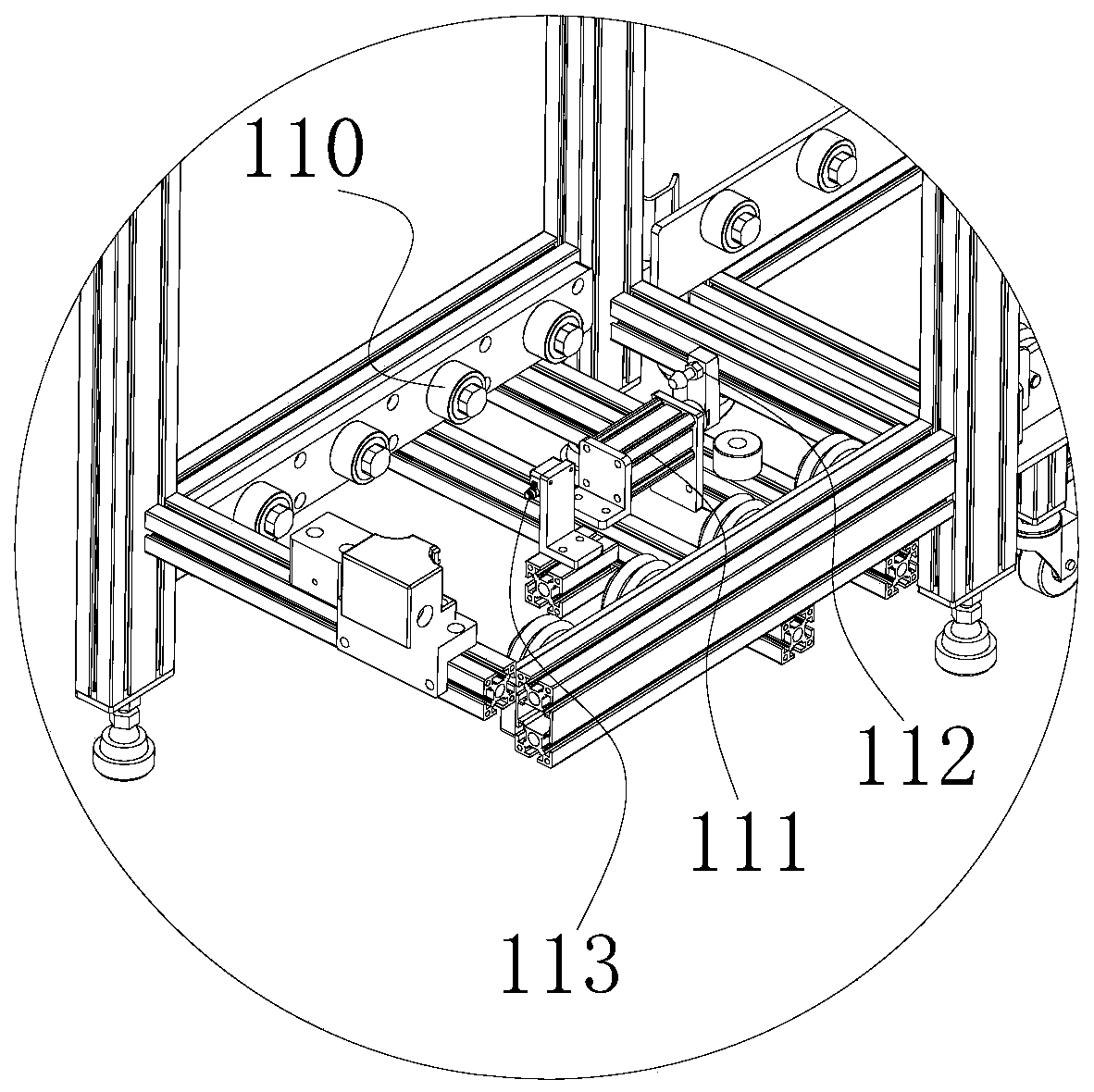

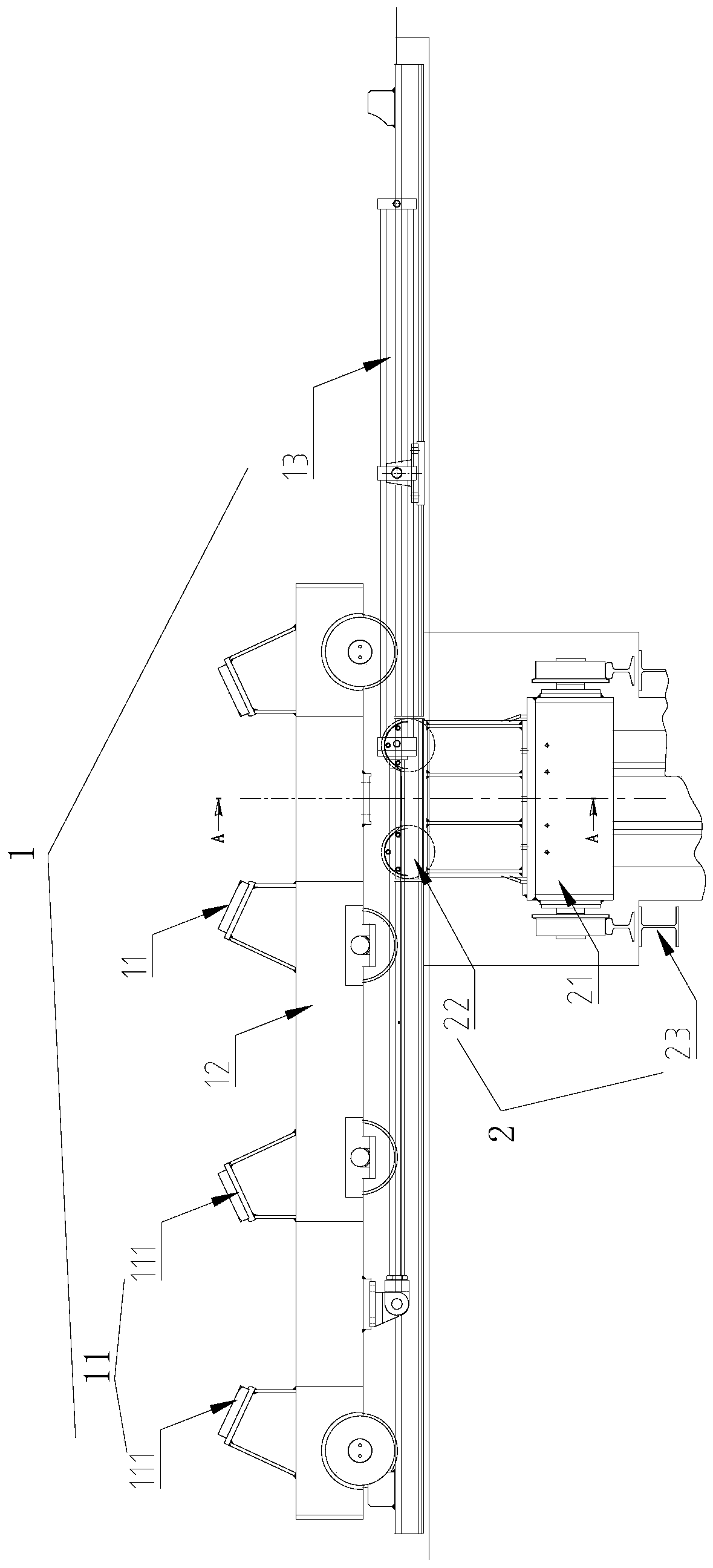

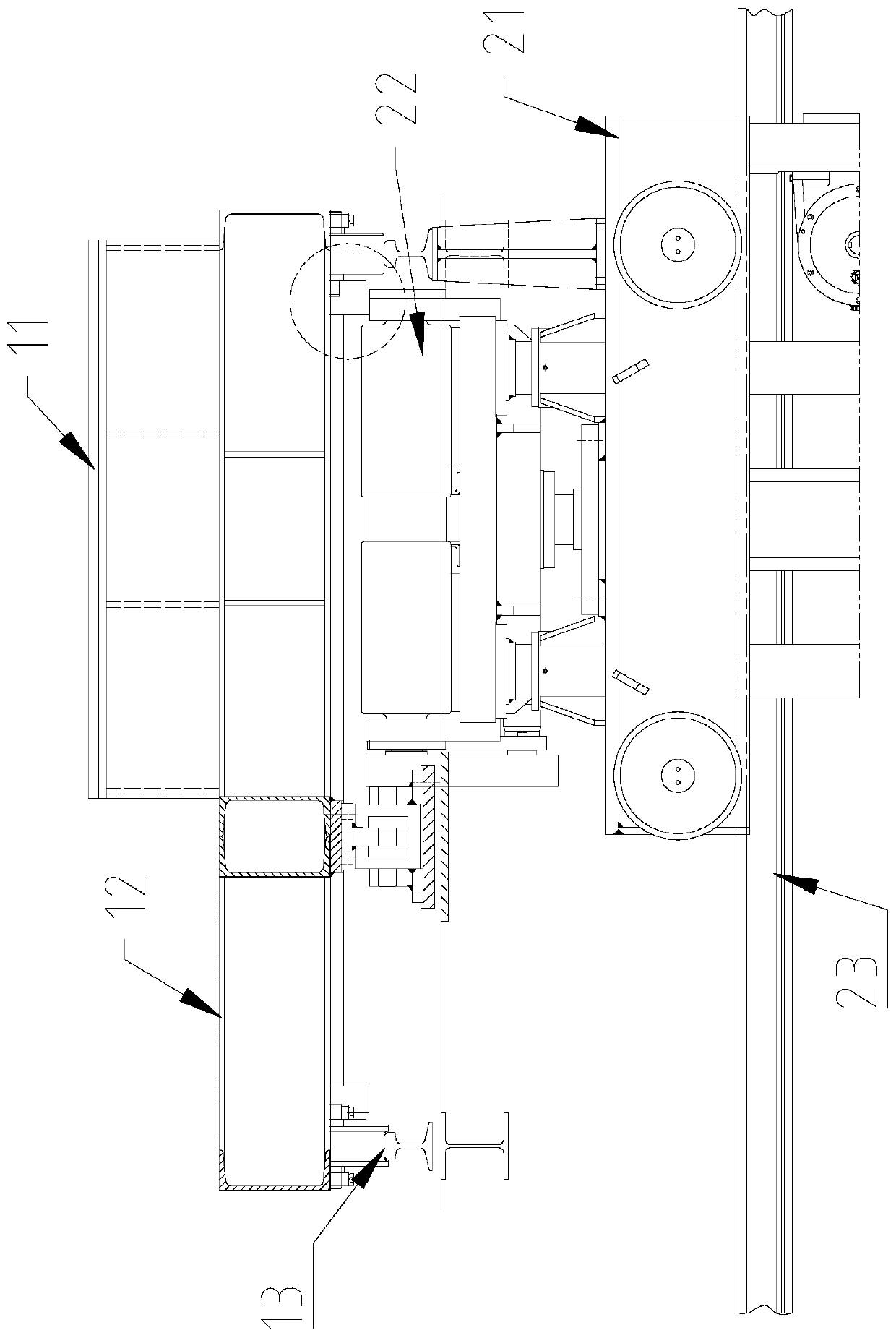

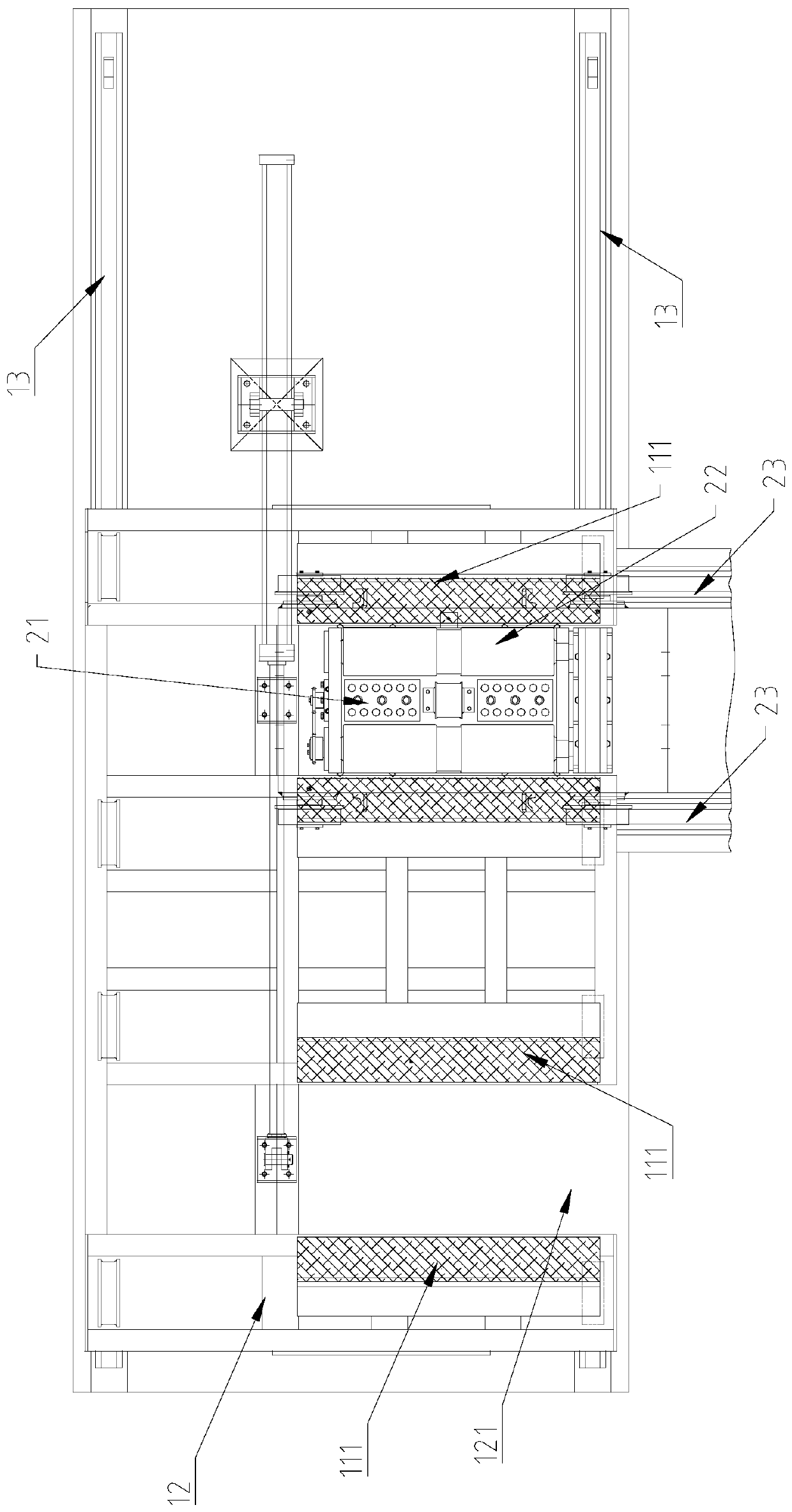

Fabric positioning conveying equipment used for inlaying injection molding and fabric positioning method

The invention discloses fabric positioning conveying equipment used for inlaying injection molding and a fabric positioning method. A fabric storage unit, a fabric grabbing unit and a fabric positioning unit are included. The fabric storage unit comprises a fabric transportation trolley and a frame which are symmetric left and right. The fabric grabbing unit comprises two parallel first sliding rails. A first moving plate and a second moving plate which are parallel and are matched through first sliding blocks pass through the first sliding rails. A clamping air cylinder and a guiding column fixed through a shaft sleeve are fixed to the middle portion of the first moving plate. The fabric positioning unit comprises a conveying module, a fabric base, a brush positioning mechanism and a pressing mechanism, and the brush positioning mechanism is arranged between the pressing mechanism and a clamping claw. Since leather fabric has certain ductility, the leather fabric is in a hook face shape after being grabbed. The brush positioning mechanism is adopted for conducting stepping type beating on the fabric, accordingly, accurate fabric positioning is achieved, and the high-precision leather fabric inlaying injection molding production technology requirement is met.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Multi-head knurling and easy-pulling machine

InactiveCN105817885ARealize lean productionShorten process production timeOther manufacturing equipments/toolsPunch pressKnurling

A multi-head knurling tearing machine, which divides the tearing aluminum cover knurling, rolling tearing wire, rubber plug padding line and punch into two sets of independent operating mechanisms, and is matched with multiple heads, and the processing time of a single aluminum cover is equal to The knurling disc rotates once, and the simultaneous operation of the knurling mechanism and the punching mechanism can greatly shorten the production time. Theoretically, it can meet the production capacity of the knurled punching punch for tearing the aluminum cover of the punching machine. In this way, the online lean production of tearing knurling and punching is realized, and the production cost is reduced.

Owner:重庆正川永成医药材料有限公司

An automatic pressing equipment

ActiveCN105365252BImprove inner qualityGuaranteed temperaturePressesCompression moldingAutomatic test equipment

Owner:HUARUI ELECTRICAL APPLIANCE

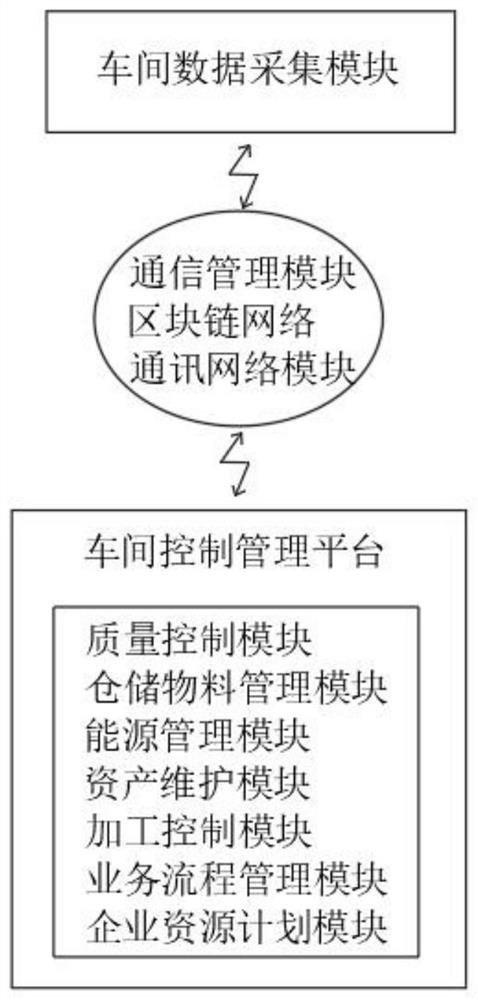

Intelligent data management and control system for block chain production workshop

PendingCN114859837AIncrease authenticityRealize transparent productionEnergy industryProgramme total factory controlData acquisitionEnterprise resource planning

The invention discloses a block chain production workshop intelligent data management and control system, which comprises a workshop data acquisition module and a workshop control management platform, and is characterized in that the workshop data acquisition module is connected with the workshop control management platform through a communication management module, a block chain network and a communication network module; the workshop control management platform comprises a quality control module, a warehouse material management module, an energy management module, an asset maintenance module, a processing control module, a business process management module and an enterprise resource planning module, and the workshop data acquisition module comprises a data acquisition sensor and a data management module. The data acquisition sensor is mounted in a workshop and used for acquiring instruments, working conditions and output rate data in the workshop; the intelligent data management and control system for the block chain production workshop can realize control and management of the whole workshop production process.

Owner:苏州川力软件有限公司

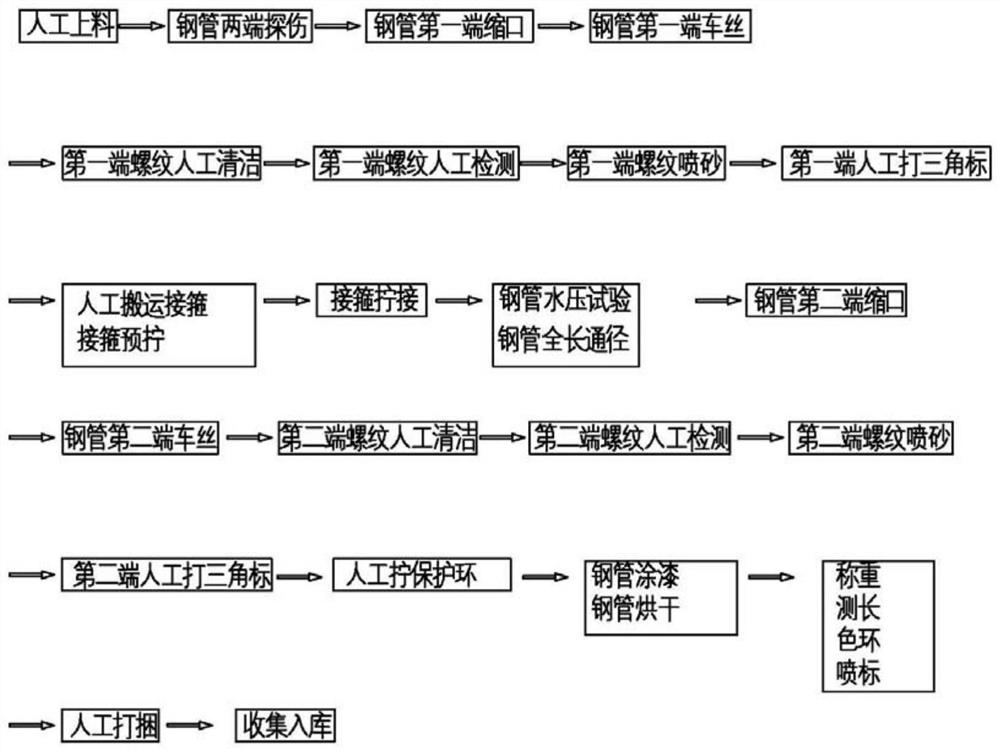

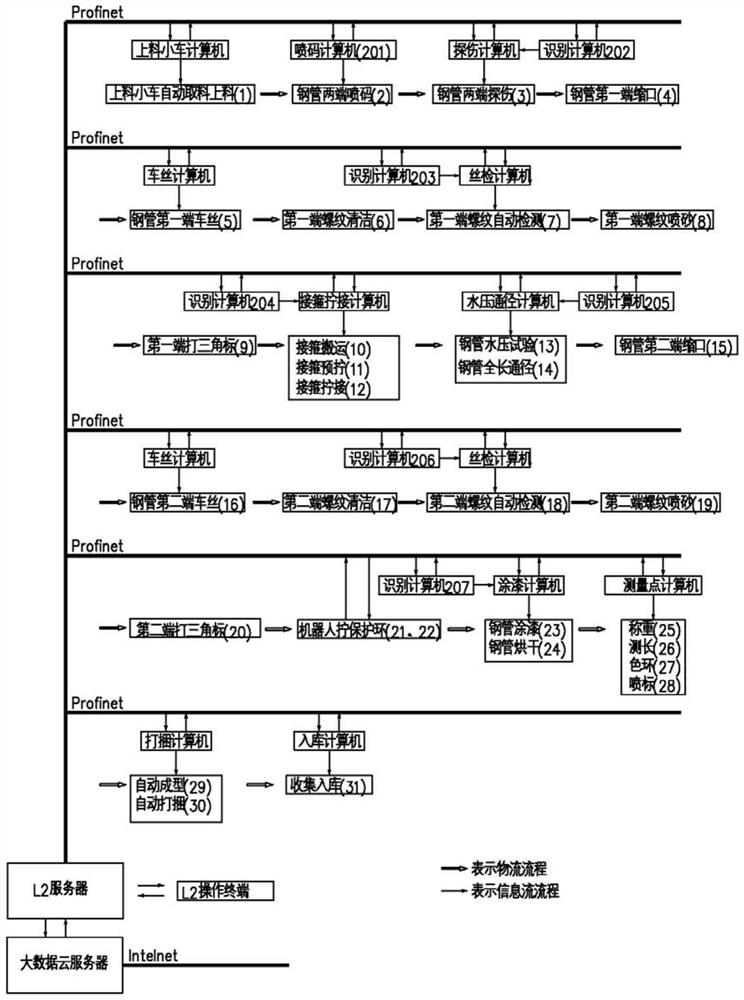

An intelligent petroleum oil casing processing production system and production method

ActiveCN111596634BRealize lean productionSmall number of postsTotal factory controlProgramme total factory controlPetroleum oilSteel tube

The intelligent petroleum oil casing processing production system of the present invention includes: an oil casing processing production quality management unit and an oil casing processing inspection unit, and the production quality management unit includes: a big data cloud server, a secondary server, and an identification device, The secondary server communicates with the big data cloud server, obtains steel pipe raw material information from the big data cloud server, and communicates with the identification device through the local area network, and the identification identification device transmits the identified steel pipe identity code information to the oil casing processing inspection unit , the oil casing processing inspection unit receives the processing inspection parameters from the secondary server and performs processing inspection on the steel pipe, and uploads the identity code information of the steel pipe and the actual processing inspection production data to the secondary server correspondingly, and the secondary server processes the actual steel pipe The inspection production data and raw material information are edited into a database corresponding to the identity code information of the steel pipe, and uploaded to the big data cloud server. In this way, the processing and inspection data of oil and casing can be tracked one by one.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

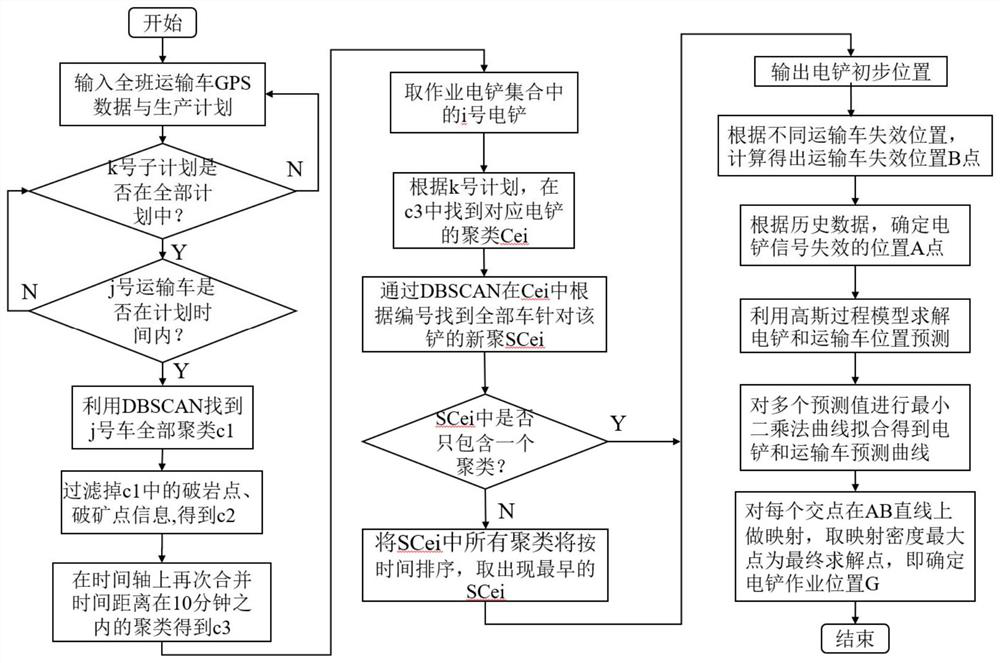

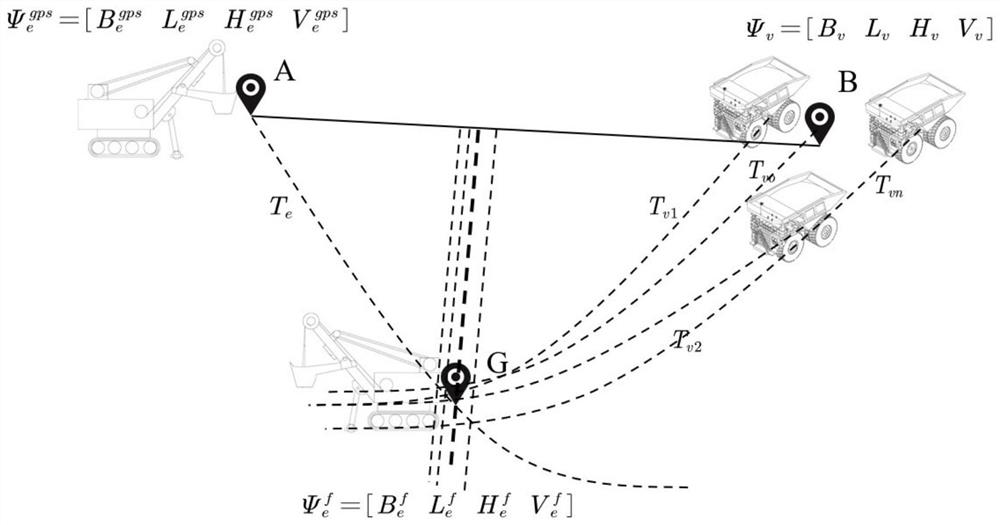

Electric shovel positioning method based on density clustering

PendingCN114818922ARealize lean productionCharacter and pattern recognitionSatellite radio beaconingLean manufacturingAutomotive engineering

The invention belongs to the technical field of strip mine production, and particularly relates to a density clustering-based electric shovel positioning method, which comprises the following steps of: calculating a vehicle-shovel corresponding relation by utilizing a scheduling operation plan of each shift and GPS (Global Positioning System) dynamic positioning data according to operation time and tracks of a shovel where a transport vehicle is located, a rock crushing turnover point and an ore crushing turnover point; and the preliminary positioning information of the electric shovel is obtained by using a DBSCAND algorithm. Performing trajectory prediction on the failure positions of the electric shovel and the transport vehicle by using a GPR algorithm, analyzing data of a signal vanishing point of the electric shovel and a signal vanishing point of the transport vehicle, performing least square method curve fitting on a plurality of predicted values, and performing mapping on each intersection point of the predicted trajectory on a connecting line of the failure positions of the electric shovel and the transport vehicle; and taking the point with the maximum mapping density as the accurate operation position of the electric shovel. According to the method, on the basis of existing equipment, a proper algorithm is used for calculation, the accurate position of the electric shovel can be obtained without re-investment of the equipment, reference data is provided for production scheduling, and lean production of mines is further achieved.

Owner:ANSTEEL GRP MINING CO LTD

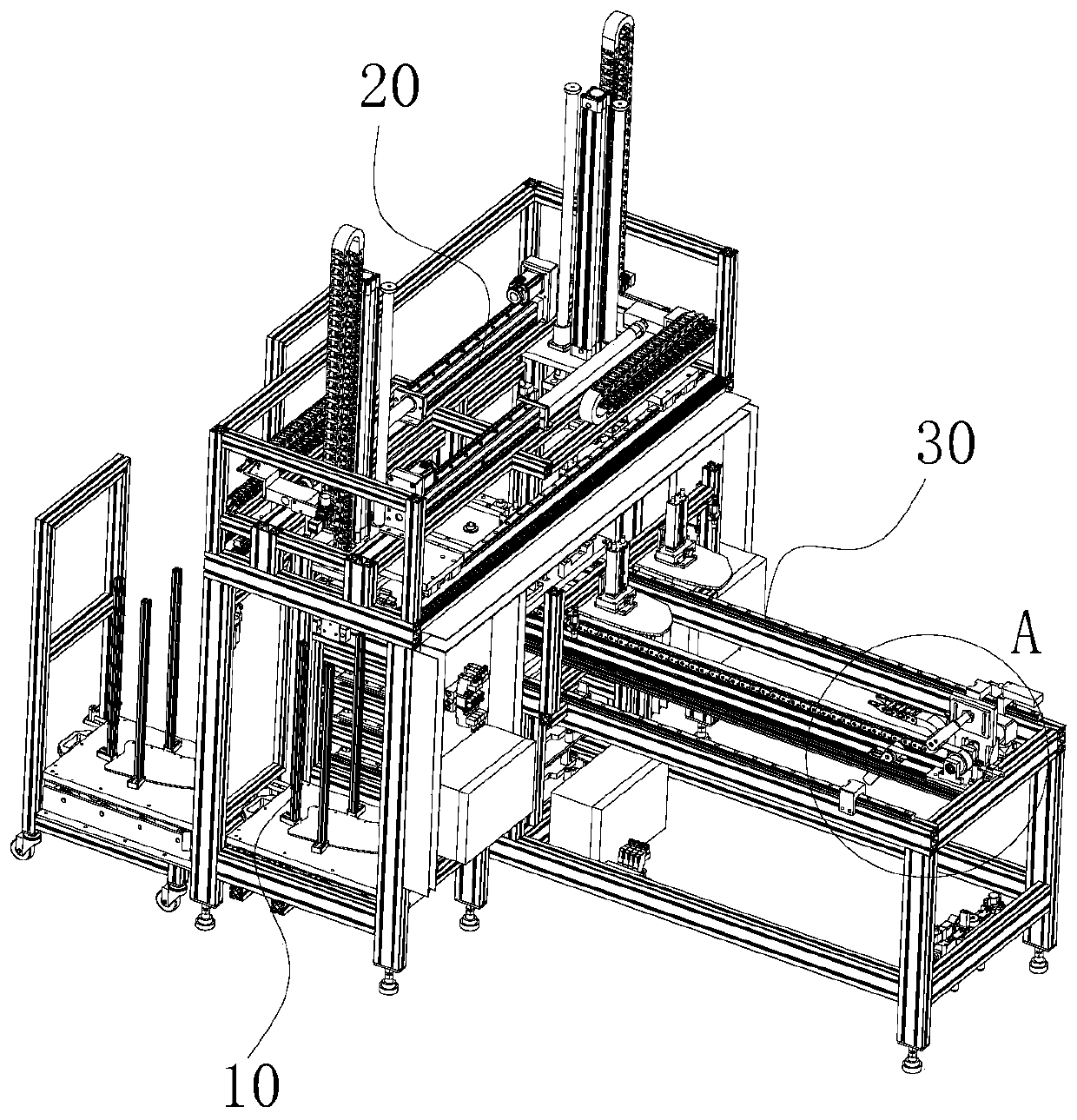

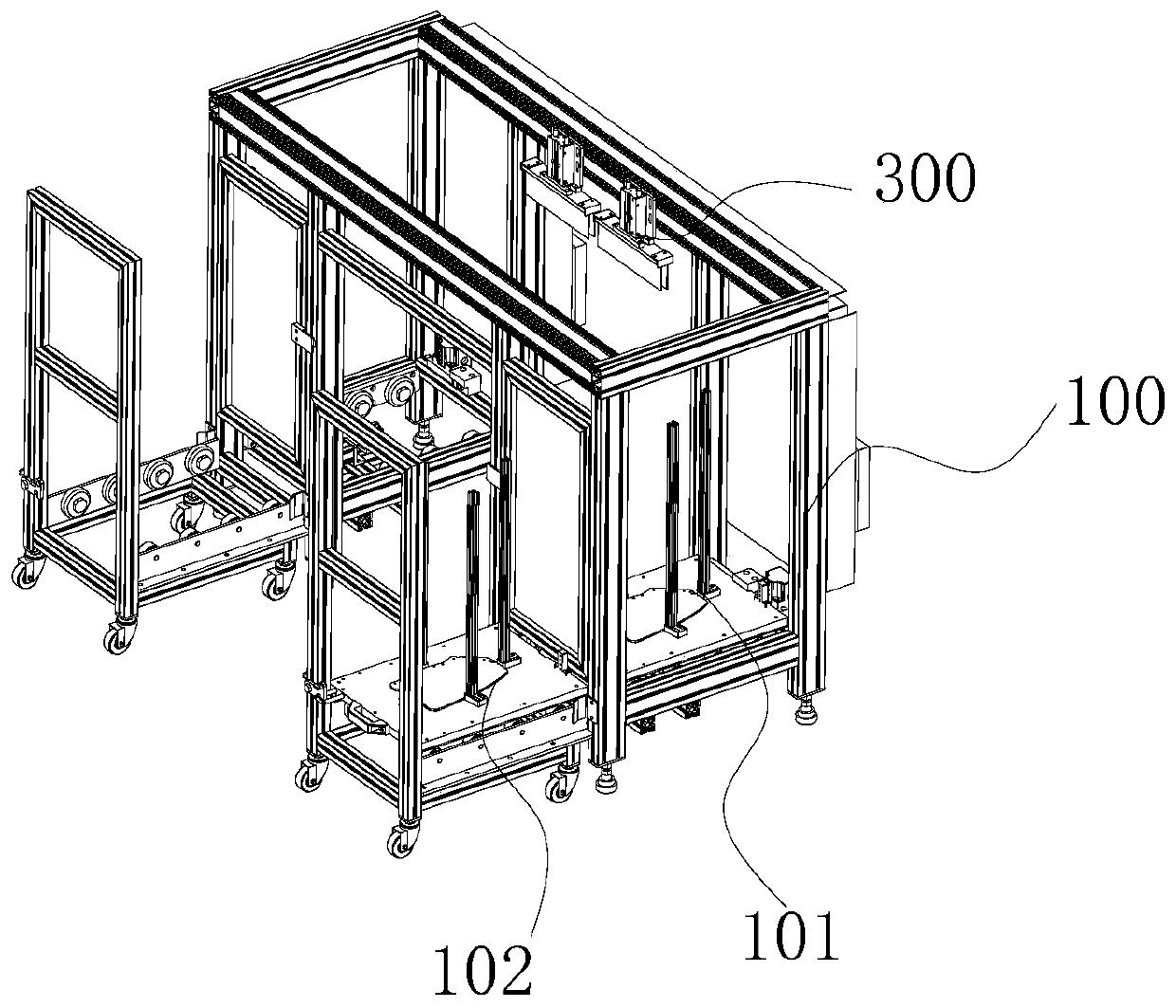

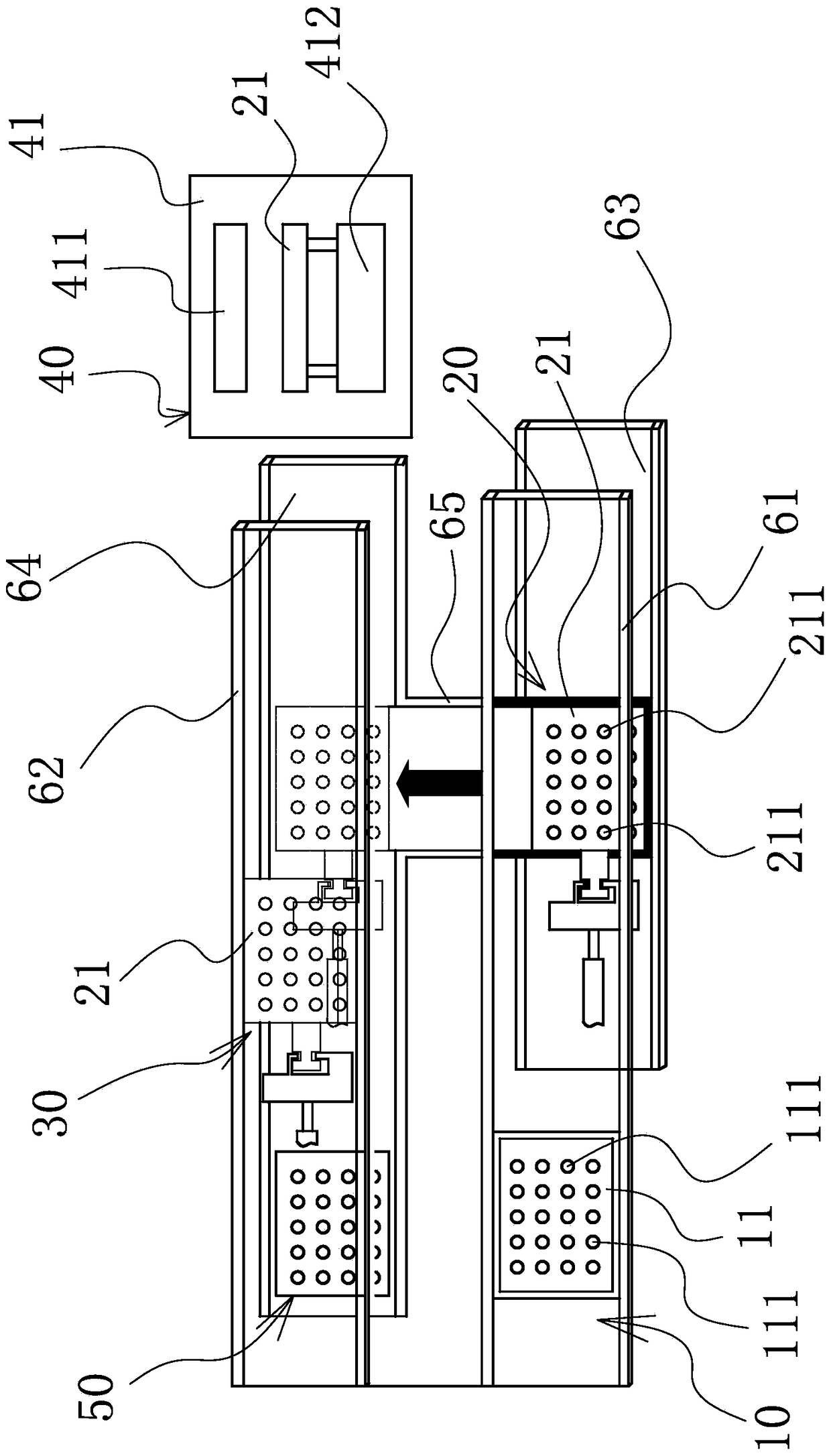

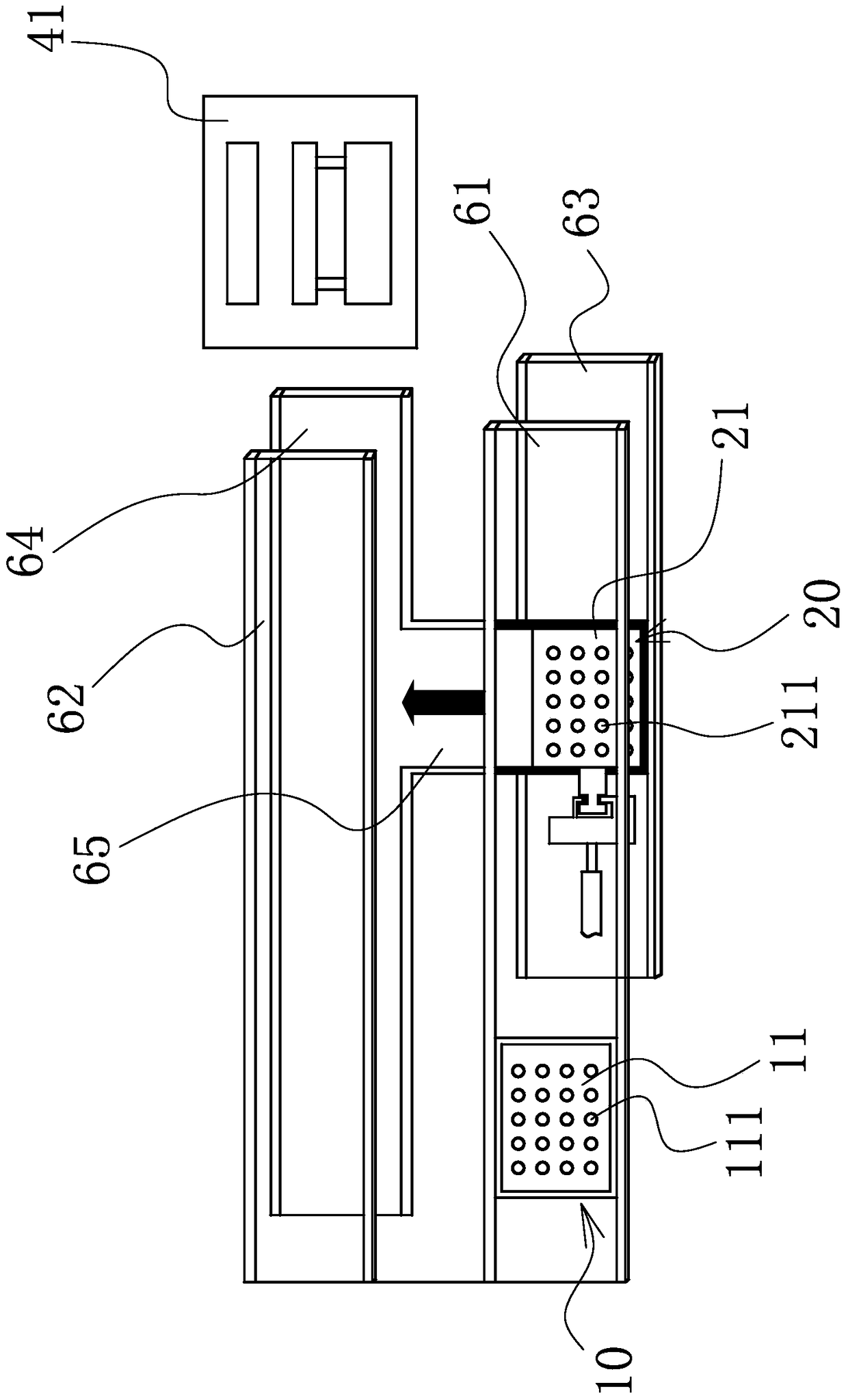

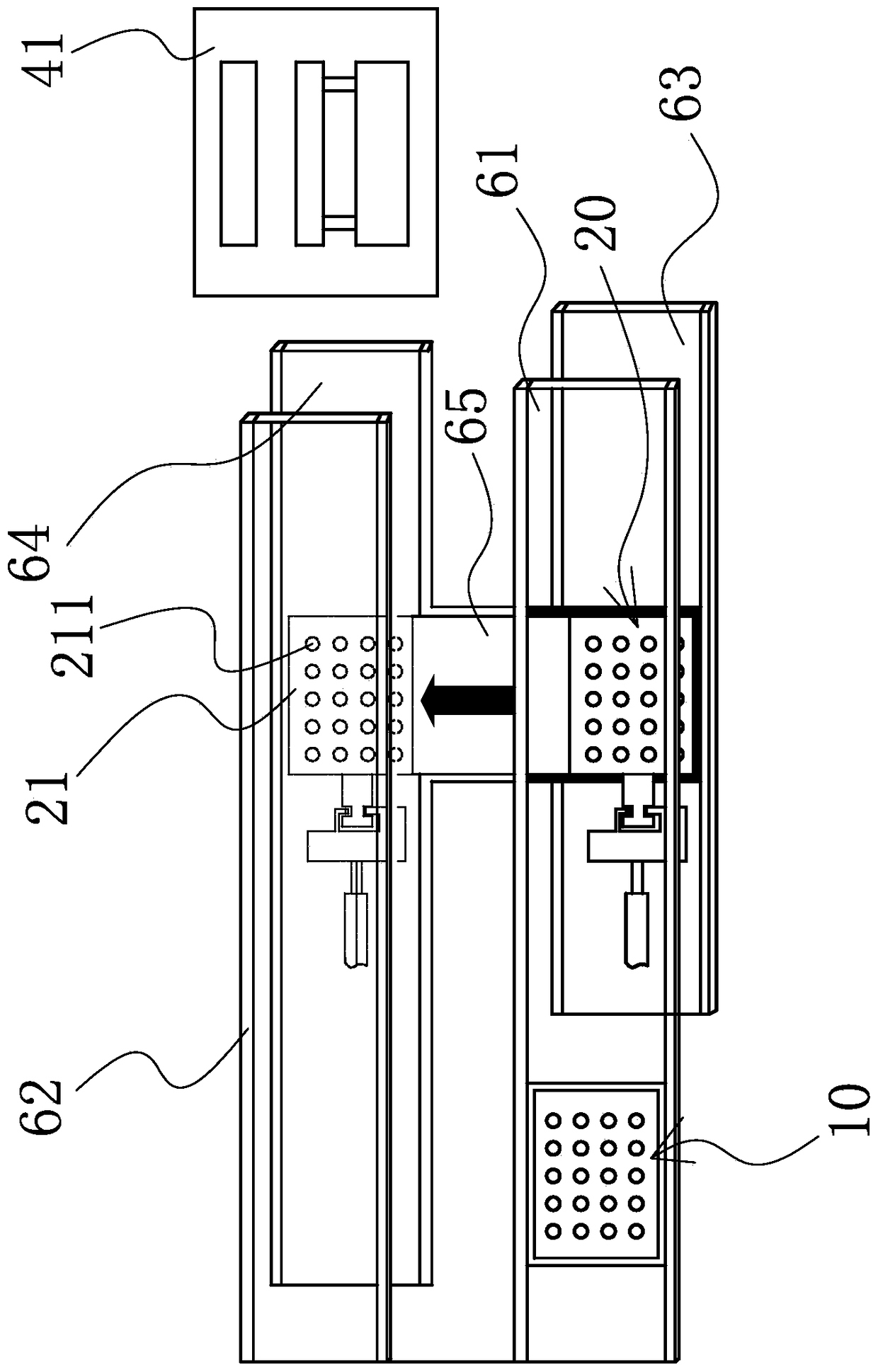

Material storage and feeding device, production equipment and control method for operating production equipment

The invention provides a material storage and feeding device, production equipment and a control method for operating the production equipment and relates to the technical field of cross cut shears. By means of the material storage and feeding device, the production equipment and the control method for operating the production equipment, the technical problems that when a singular material storageand feeding structure is adopted, time is wasted in the material switching process, and the production efficiency is low are solved. The material storage and feeding device comprises a material storage module and a feeding module. One end of the feeding module is linked with the material storage module, and the other end of the feeding module is linked with a feeding opening of next procedure equipment. The material storage module is provided with two material storage portions. The material storage module can move relative to the feeding module, and thus, the two material storage portions arealigned with the feeding module alternately. The production equipment is a cross cut shear. According to the material storage and feeding device, the production equipment and the control method for operating the production equipment, a sideway-moving type double-position material storage table is arranged, the mode that a to-be-switched roll material is put into the standby material storage portion in advance is adopted, and the material switching time is shortened; the material switching action is directly completed through sideway-moving type material storage sliding rails, and the production efficiency is improved; procedural bottleneck points in the feeding link are eliminated; the time, wasted in waiting, of workers is shortened; and the lean production is achieved.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

Process for coating automobile axle

ActiveCN101954349BReduce investmentReduce manufacturing costPretreated surfacesSpecial surfacesProduction lineCoating system

The invention discloses a process for coating an automobile axle. Main coating flow of the automobile axle comprises the following steps of: degreasing, hot water rinsing, antirust water rinsing, water blowing shielding, drying, forced cooling, primer spraying, finish paint spraying, leveling, drying and forced cooling. Compared with the conventional process in China, a primer drying process and a corresponding primer drying chamber are eliminated. Due to the adoption of a new material, a new process and an advanced 2C1B coating system, the process has the advantages of improving the quality of a product coating, eliminating a process, reducing the investment in fixed assets and saving the production and operating costs of a production line compared with the same industry.

Owner:ANHUI HUALING AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com