Cooling unit for modification process of long glass fiber reinforced plastic

A technology for reinforced plastics and cooling devices, which is applied in the field of cooling devices for modification process of long glass fiber reinforced plastics, which can solve the problems of fragility, cracking, and brittle products, and achieve the effect of preventing brittleness and sudden cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

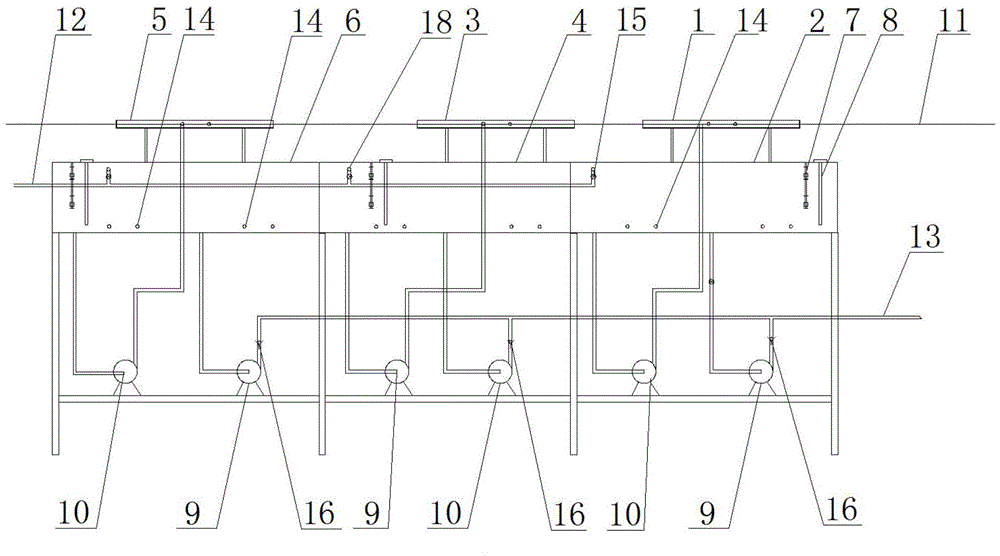

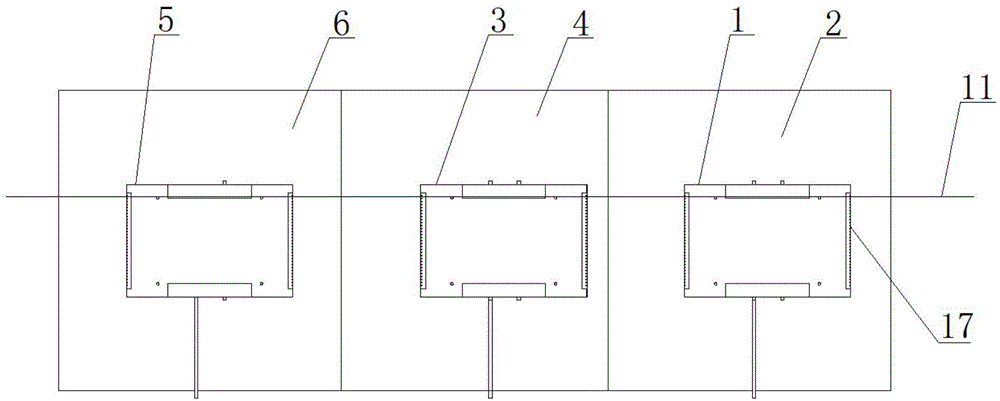

[0022] Such as figure 1 , figure 2 In the cooling device for modification process of long glass fiber reinforced plastic shown in the figure, the strip 11 formed after mixing glass fiber and molten polymer is pulled into the No. 1 small water tank 1 and No. No. 3 small water tank 3 and No. 3 small water tank 5, the material bar 11 moves horizontally, while the liquid levels of No. 1 small water tank 1, No. 2 small water tank 3, and No. 3 small water tank 5 are higher than the horizontal height of the material bar 11. 11 plays the role of cooling; each small water tank is provided with a grid 17, and the feed bar 11 passes through; No. 1 small water tank 1, No. 2 small water tank 3, and No. Ensure that the liquid level is always higher than the horizontal position of the material bar 11, so that the material bar 11 can be completely submerged in water, and the excess water will flow from the grids at the two ends of the No. 1 small water tank 1, the No. 2 small water tank 3, ...

Embodiment 2

[0025]On the basis of embodiment 1, the material as base material is nylon 6, then the setting of water temperature in No. 1 large water tank 2 is at 60 degrees Celsius, the setting of water temperature in No. 2 large water tank 4 is at 50 degrees Celsius, and in No. 3 large water tank 5 The water temperature can be set to not higher than 40 degrees Celsius.

[0026] Compared with the prior art, the cooling device for the modification process of long glass fiber reinforced plastics of the present invention has the following advantages: 1. The material strip in the high-temperature molten state passes through the cooling water in three different regions of high temperature, medium temperature and low temperature respectively It is cooled, which effectively prevents the phenomenon of sudden cooling, which is beneficial to control the crystallization of materials, and prevents the strips from becoming brittle due to sudden overcooling, resulting in brittleness and cracking during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com