Intelligent casting machining system and casting machining method

An intelligent processing and casting technology, applied in the field of casting processing, can solve problems such as poor consistency, achieve the effects of ensuring personal safety, improving the working environment, and realizing lean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

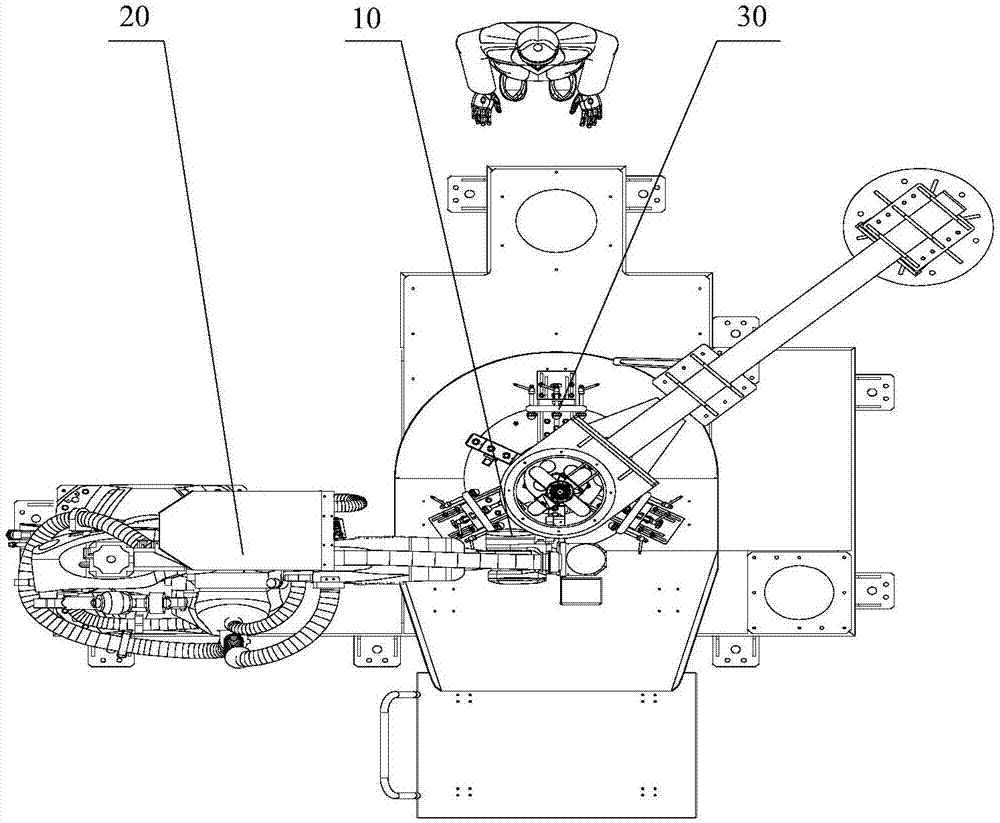

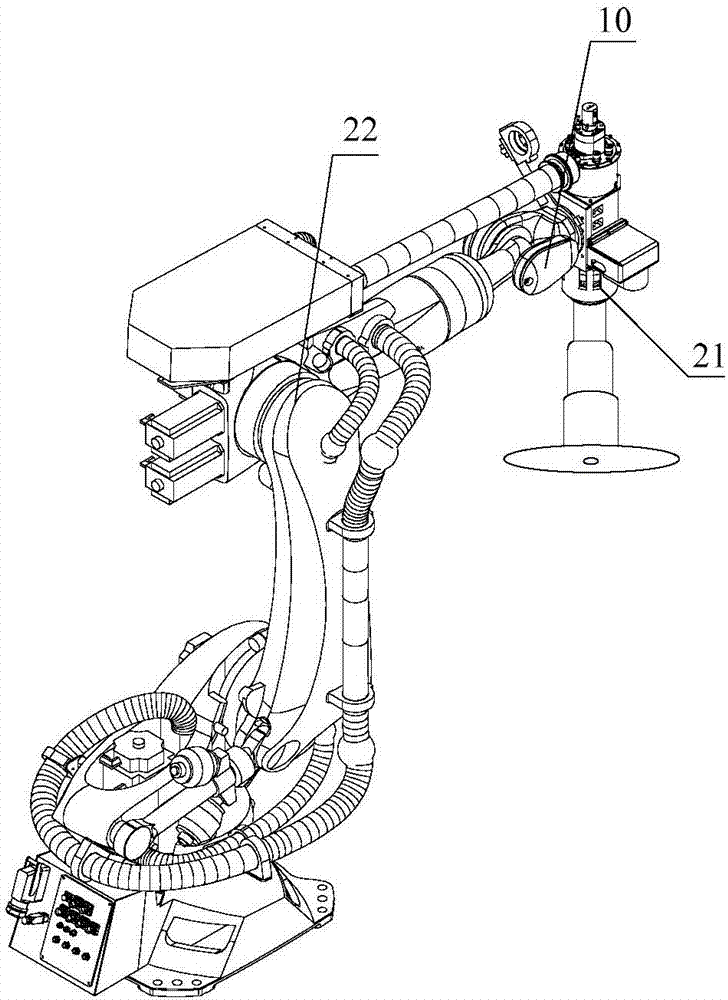

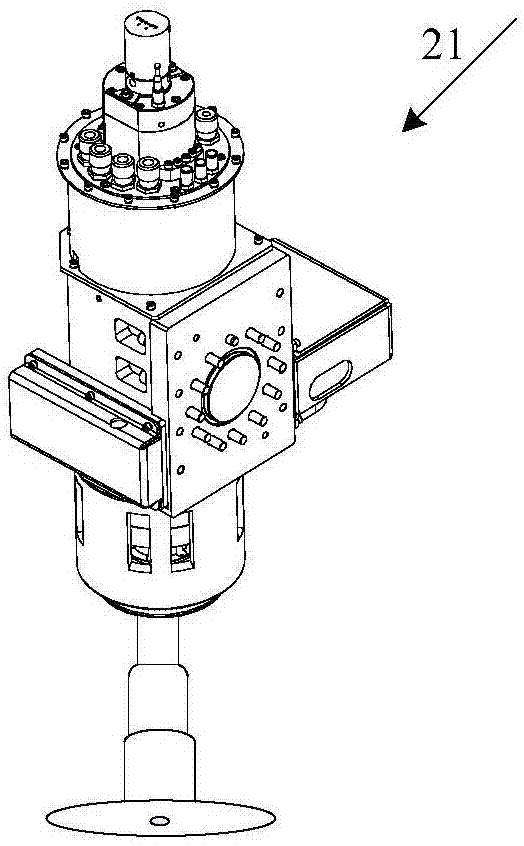

[0038] refer to figure 1 , a preferred embodiment of the present invention provides a casting intelligent processing system, including a smart camera 10, a robot 20 for processing a casting to be processed, a mobile loading and unloading platform 30 for installing a casting to be processed, and a robot for controlling and The controller of the mobile loading and unloading platform 30, the smart camera 10, the robot 20, and the mobile loading and unloading platform 30 are connected to the controller respectively, wherein the smart camera 10 is used to take pictures of the castings to be processed, and determine the pouring gate of the castings to be processed position, and send the determined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com