Plant factory

A plant and factory technology, applied in the field of modern agricultural planting, can solve the problems of unable to adjust the light in real time and meet the light demand, and achieve the effects of lean production, improved planting efficiency, and zero inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

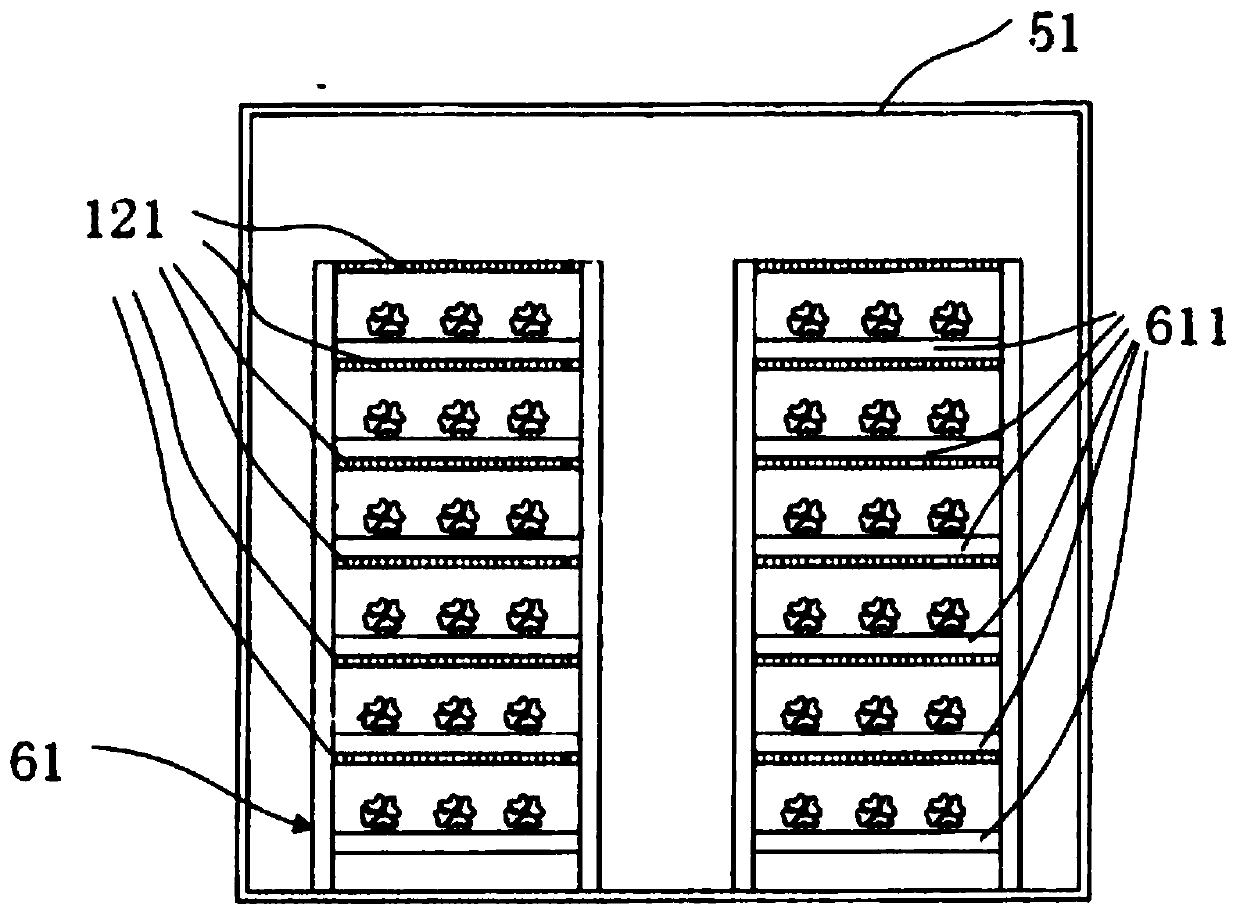

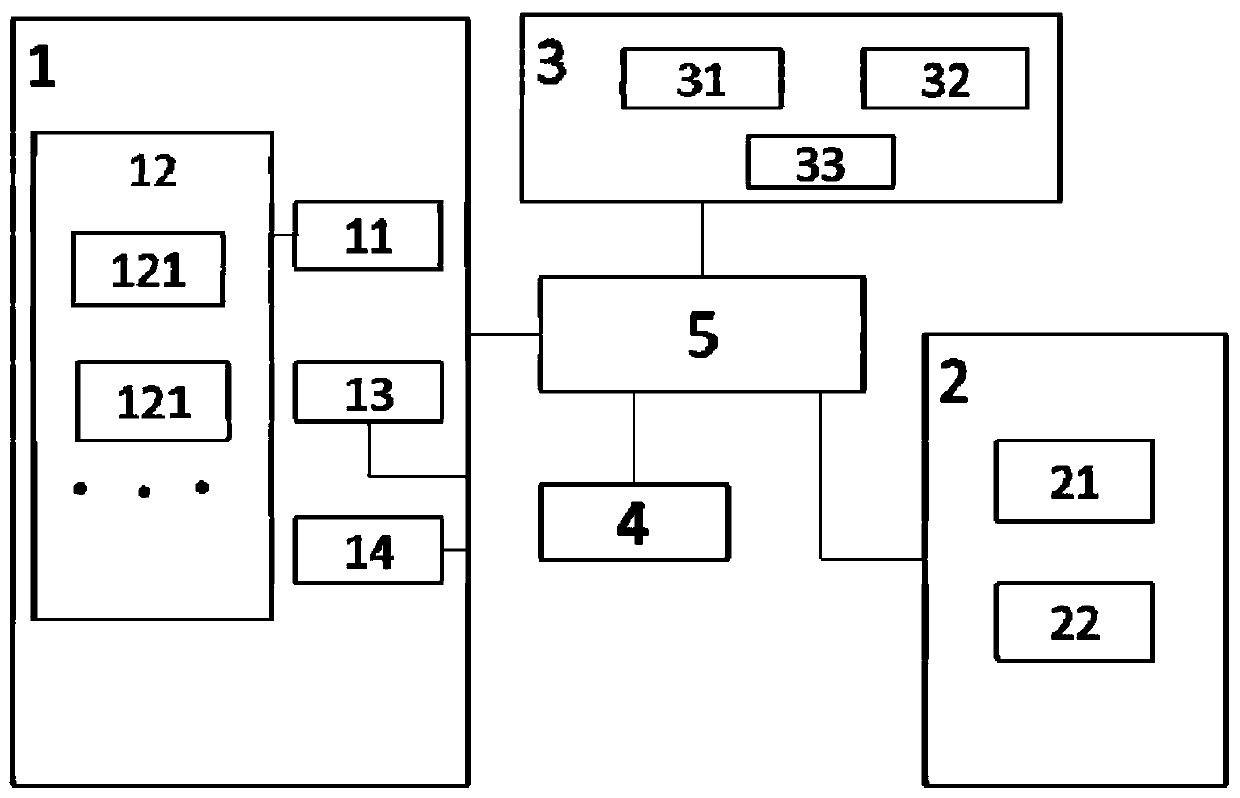

[0037] According to a preferred embodiment of the present invention, see figure 1 with figure 2 The present invention discloses a plant factory, which may include: a cultivation environment chamber 51, a lighting component 1, a CO2 concentration generation control module 2, an air conditioning module 3, a nutrient supply module 4, and a control module 5. The control module 5 selects the growth configuration plan according to the plant type. The control module 5 can control the light component 1, the CO2 concentration generation control module 2, the air conditioning module 3, and the nutrient supply module 4 according to the growth configuration plan to make corresponding adjustments. After the adjustment, the plants of the corresponding type in the plant factory will grow in a predetermined manner that meets the corresponding growth configuration plan. In this way, the corresponding type of plants can reach the growth target manually or automatically set for the plant factory....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com