Plane testing tool

A tooling and plane technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve problems such as difficulty in obtaining accurate inspection data or deviation values, hidden dangers of product quality stability, and difficulty in achieving lean production, so as to achieve lean production. , Improve stability and facilitate the effect of data statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

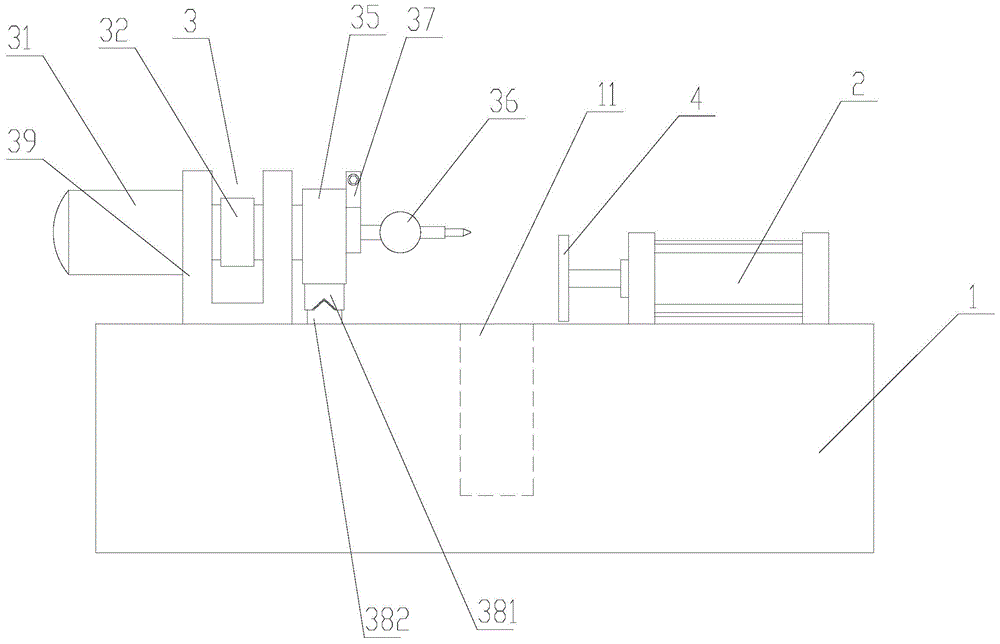

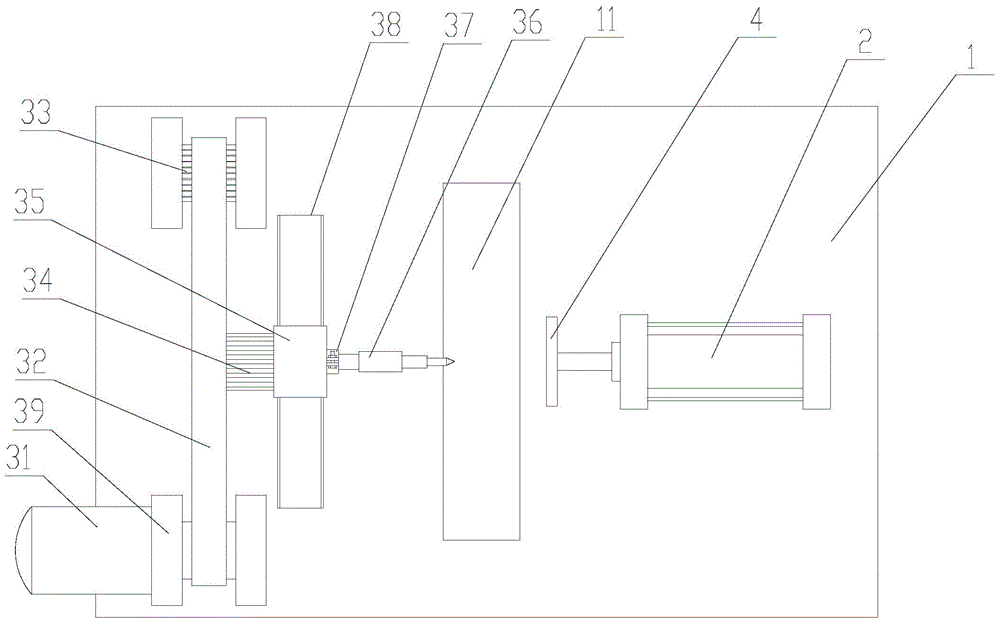

[0012] The present invention as Figure 1-2 As shown, it includes a base 1, a clamping cylinder 2 and a detection device 3. The top surface of the base 1 is provided with a groove 11 for accommodating workpieces to be inspected. The clamping cylinder 2 and the detection device 3 are all located on on the base 1 and respectively located on both sides of the groove 11;

[0013] The detection device 3 includes a motor 31, a transmission belt 32, a transmission wheel 33, a moving gear 34, a fixed seat 35, a dial indicator 36, a dial indicator clamping seat 37, a sliding guide 38 and a pair of fixed mounts 39. A pair of fixed mounts 39 are arranged on the base 1, the motor 31 and the transmission wheel 33 are respectively provided on the pair of fixed mounts 39, the transmission belt 32 is connected between the motor 31 and the transmission wheel 33, The sliding guiding device 38 is arranged on the base 1 and is located between the transmission belt 32 and the groove 11, the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com