Workshop management and control system

A management and control system and workshop technology, applied in the direction of manufacturing computing systems, closed-circuit television systems, electrical transmission signal systems, etc., can solve problems that cannot be discovered and processed in time, unmanned operations, and installation locations that are not easy to access, etc., to achieve convenient and quick acquisition and Feedback, improving the level of intelligence, and the effect of transparency in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

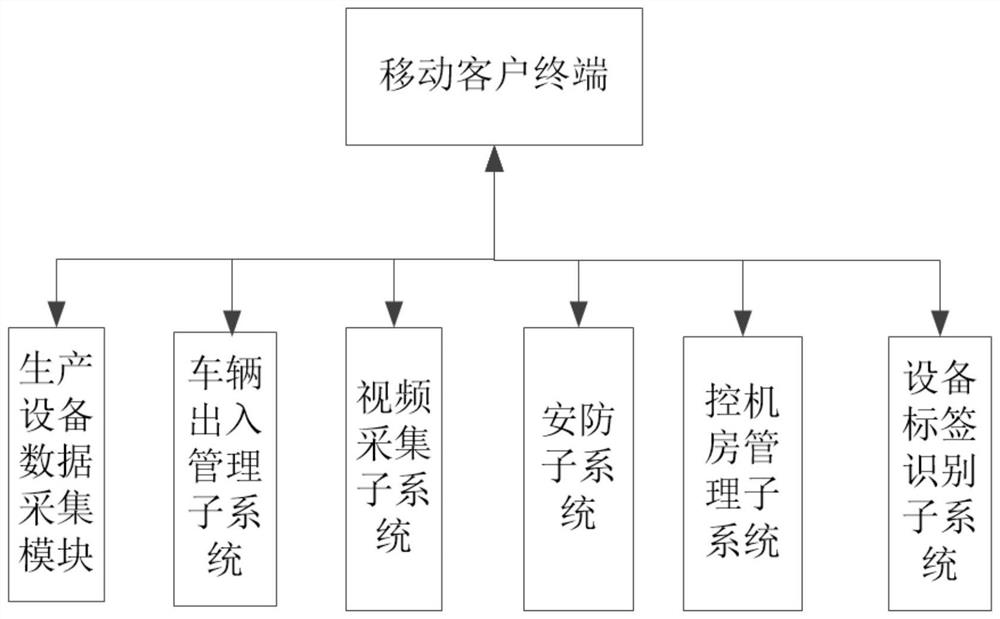

[0023] Please refer to figure 1 , this embodiment provides a workshop management and control system, including a video acquisition subsystem, a production equipment data acquisition module, a security subsystem, an equipment label identification subsystem, a vehicle access management subsystem, and a monitoring machine room management subsystem;

[0024] The video acquisition subsystem includes an image acquisition module, an image transmission module, a local memory and an image processing module, which are used to collect video data from the workshop and transmit them to the monitoring machine room in real time, and compress and package the video data and store them in the local memory. The front-end camera system One or a combination of dome ceiling cameras, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com