Processing device and method for louver blades

A technology for processing devices and shutters, which is applied in the direction of auxiliary devices, electric processing equipment, metal processing equipment, etc., can solve the problems of process waste, large processing volume, time waste, etc., and achieve cost-saving processing, high-efficiency processing, and consistent accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A processing device for shutter blades.

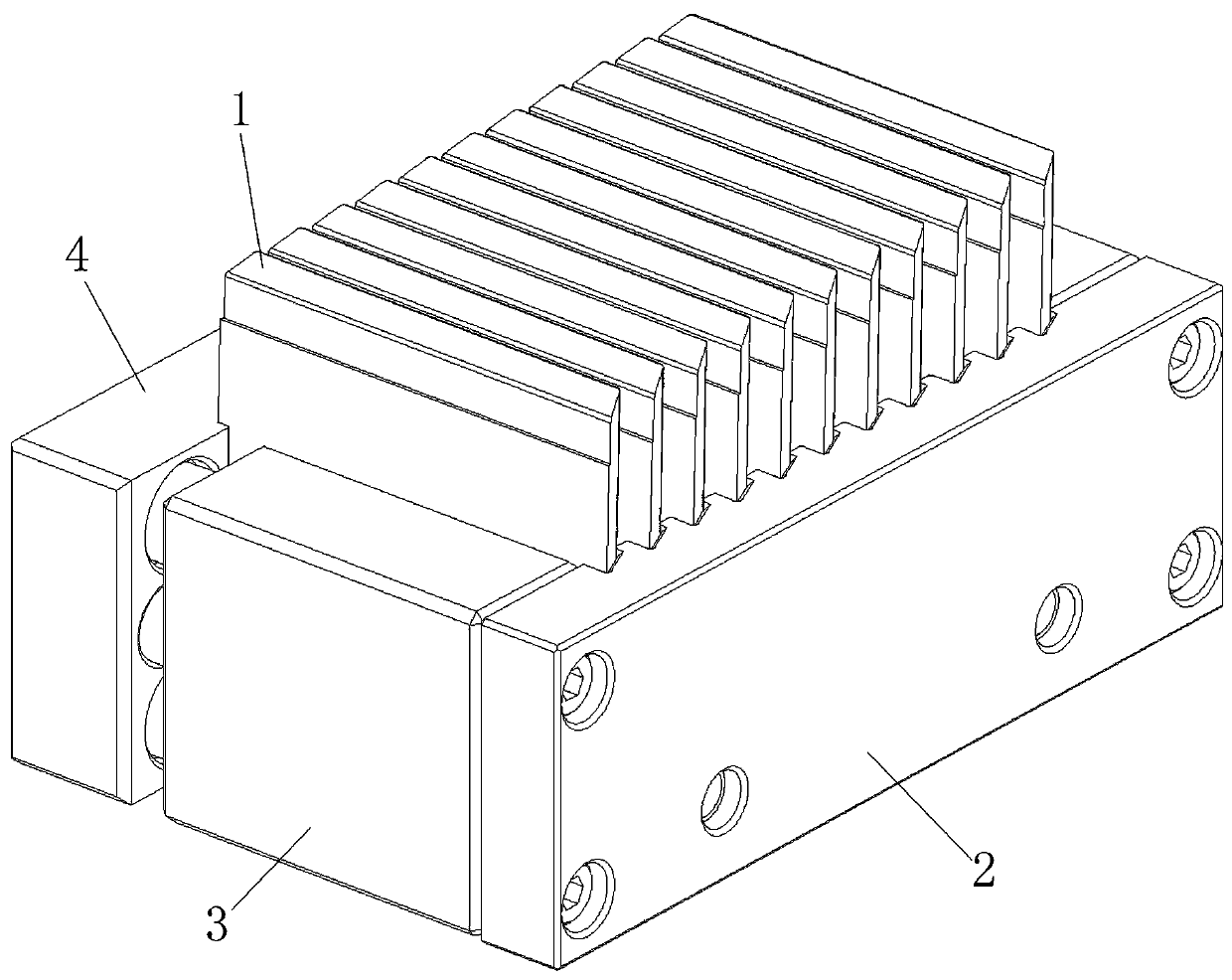

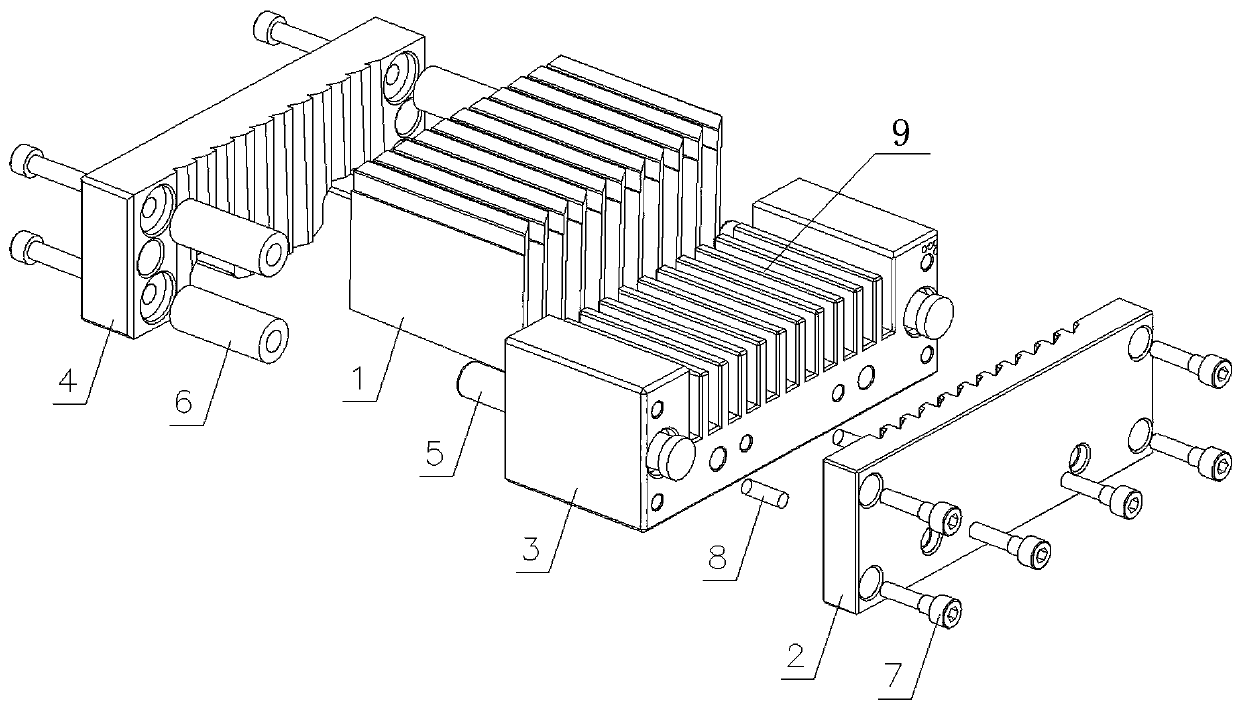

[0022] like image 3 As shown, a processing device for louver blades includes a first clamping plate 2, a second clamping plate 3 and a third clamping plate 4, and the first clamping plate 2, the second clamping plate 3 and the third clamping plate 4 are assembled sequentially from right to left, The second clamping plate 3 is provided with several knife grooves 9, the bottom surface of the knife grooves 9 is provided with an inclination angle, and the knife grooves 9 are used for installing the louver blade 1 to be processed. The first clamping plate 3 and the The third clamping plates 4 are provided with fixing grooves, and the fixing grooves are used for assembling the louver blades 1 to be processed.

[0023] The first splint 2 and the second splint 3 are positioned by the pin 8, and the screw 7 is locked as a whole, and the third splint 4 is guided by the guide post 5, and the screw 7 is locked, and further o...

Embodiment 2

[0028] Embodiment 2: A kind of processing method of louver blade.

[0029] A processing method for a louver blade, using the processing device for a louver blade as described in Embodiment 1, comprising the following steps:

[0030] S1, assemble the first splint 2, the second splint 3, and the third splint 4 in sequence;

[0031] S2, loosen the third clamping plate 4, put the shutter blades 1 to be processed into the knife grooves 9 of the second clamping plate 3 piece by piece, and fix the third clamping plate 4 again;

[0032] S3, the entire processing device is clamped on the wire cutting machine table to perform wire cutting processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com