Method for measuring heating furnace energy consumption apportionment

A heating furnace and energy consumption technology, which is applied in the field of measuring the energy consumption allocation of heating furnaces, achieves the effects of broad application prospects, lean energy production, and effective absorption heat calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

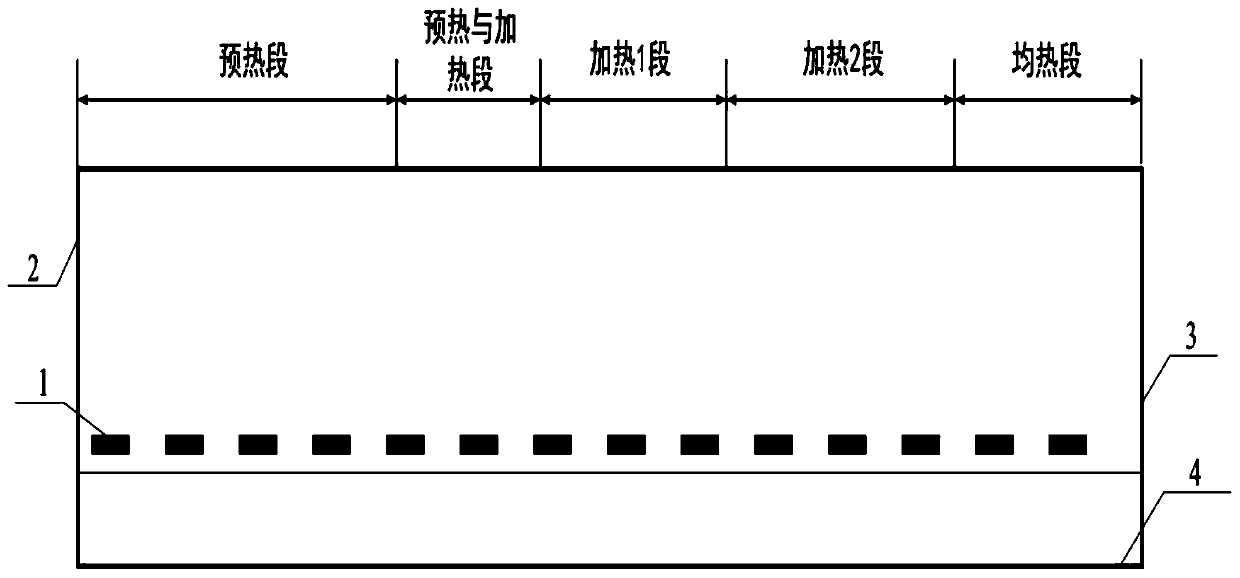

[0076] like figure 1 The schematic diagram of the ordinary heating furnace model structure is shown, including the heating furnace body 4, the front and rear ends are respectively provided with the heating furnace inlet 2 and the heating furnace outlet 3, after the billet 1 is loaded into the heating furnace inlet 2, it passes through the preheating section in turn , preheating and heating section, heating section 1, heating section 2 and soaking section, and then unloaded from the furnace through outlet 3 of the heating furnace.

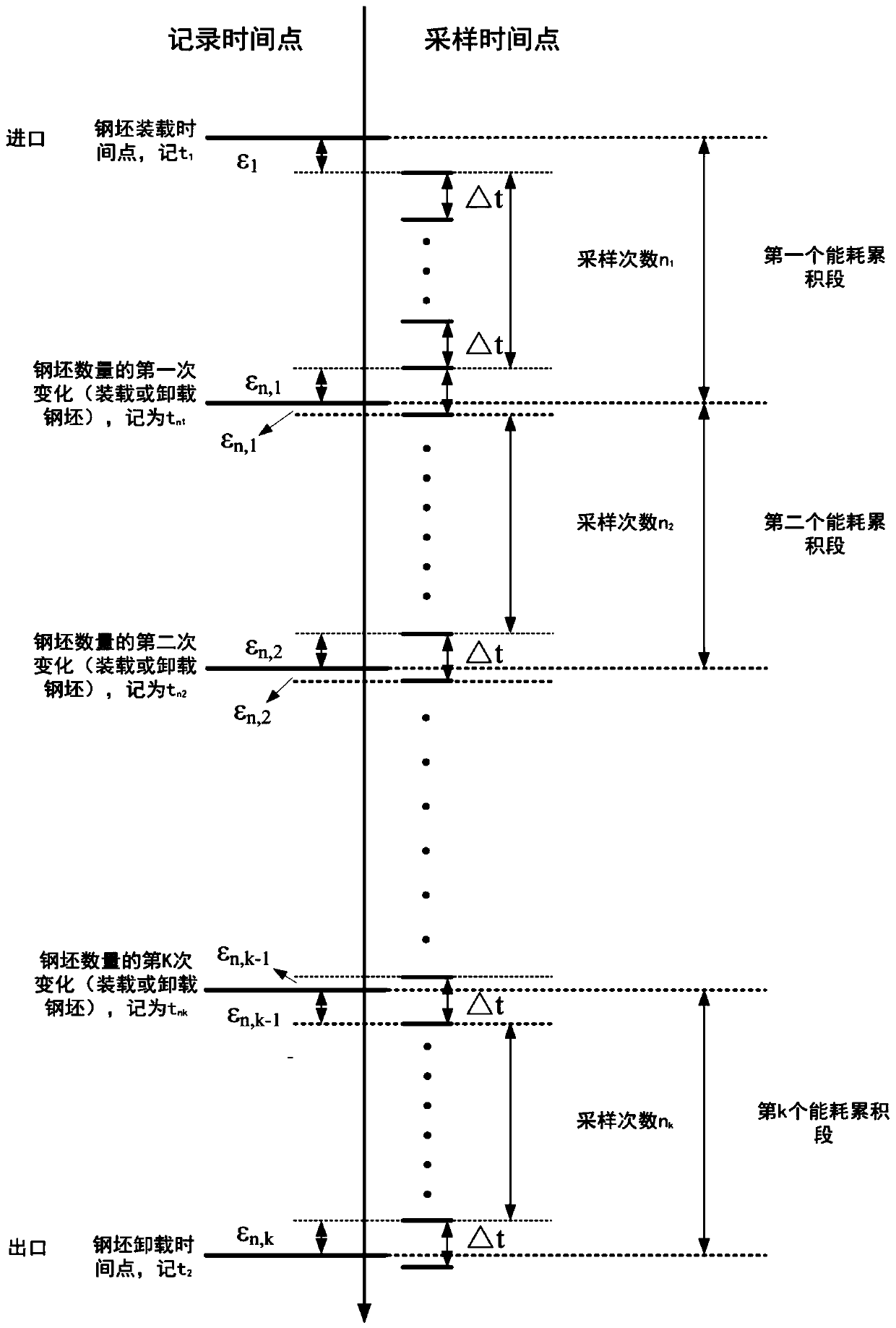

[0077] like figure 2 As shown, a method for measuring the energy consumption allocation of the heating furnace in this embodiment includes the following steps:

[0078] S1. Discrete processing of energy consumption accumulation;

[0079] Each time period when the number of steel billets in the heating furnace is constant is recorded as an energy consumption accumulation period, and the time period during which the steel billet stays in the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com