Automatic mesh covering device

An automatic, mesh technology, applied in the direction of electrical components, sensors, etc., can solve the problems of operator's fixture stabbing, low production efficiency, etc., and achieve the effect of reducing manual operation, reducing production site and space, and saving manual operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

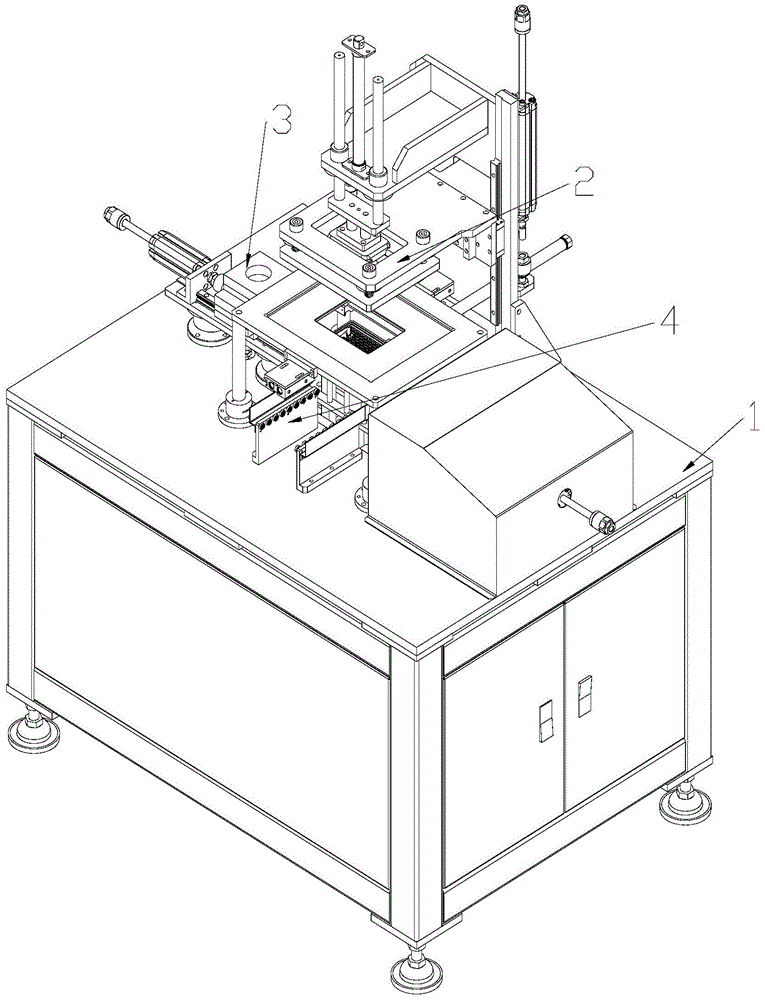

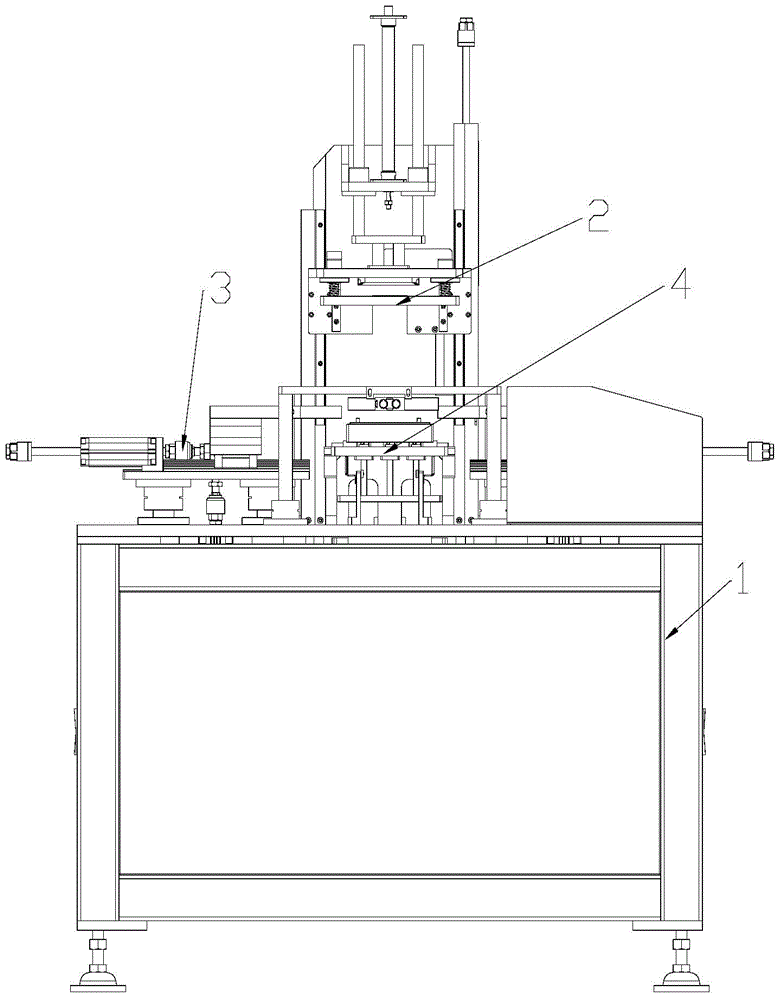

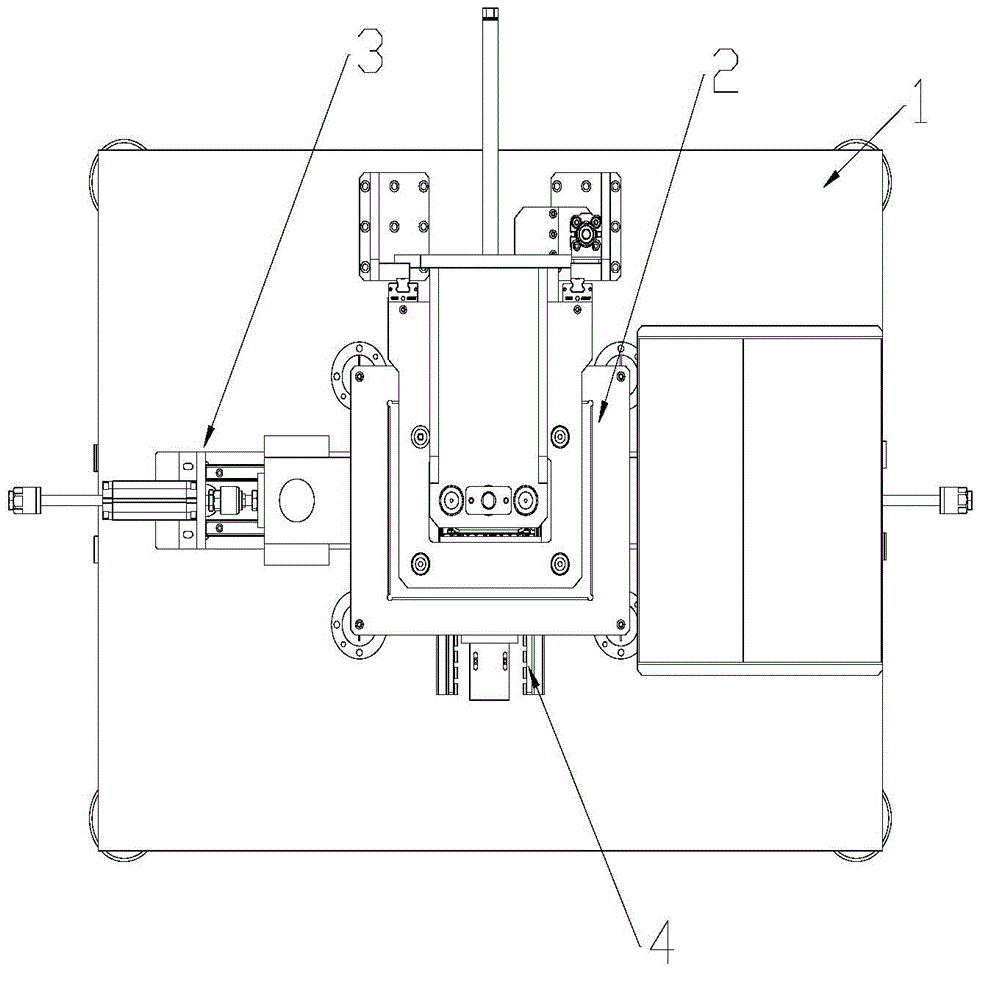

[0028] refer to Figure 1 to Figure 4 The one described in this embodiment includes a workbench 1, a mesh tensioning assembly 2 arranged above the workbench 1, a mesh blanching assembly 3 arranged on the side of the mesh tensioning assembly 2, a mesh blanching assembly 3 arranged on the mesh The discharge assembly 4 below the tension assembly 2.

[0029] Such as Figure 5 As shown, the mesh tensioning assembly 2 includes a cloth pressing plate 21 , an upper pressing die 23 , a cloth placing plate 24 , a cloth pushing plate 26 , a first air cylinder 27 and a guide rail 28 . The cloth pressing plate 21 is installed between the upper pressing die 23 and the distributing plate 24 , and both the cloth pressing plate 21 and the distributing plate 24 are provided with through holes. The cloth pressing plate 21 , the upper pressing die 23 and the cloth pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com