Feeding mechanism for automatic screwing machine of semi-spiral energy-saving lamp tube

An energy-saving lamp, semi-spiral technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of affecting exhaust quality, more personnel, and increase production costs, so as to improve production efficiency, reduce production costs, The effect of improving silk quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

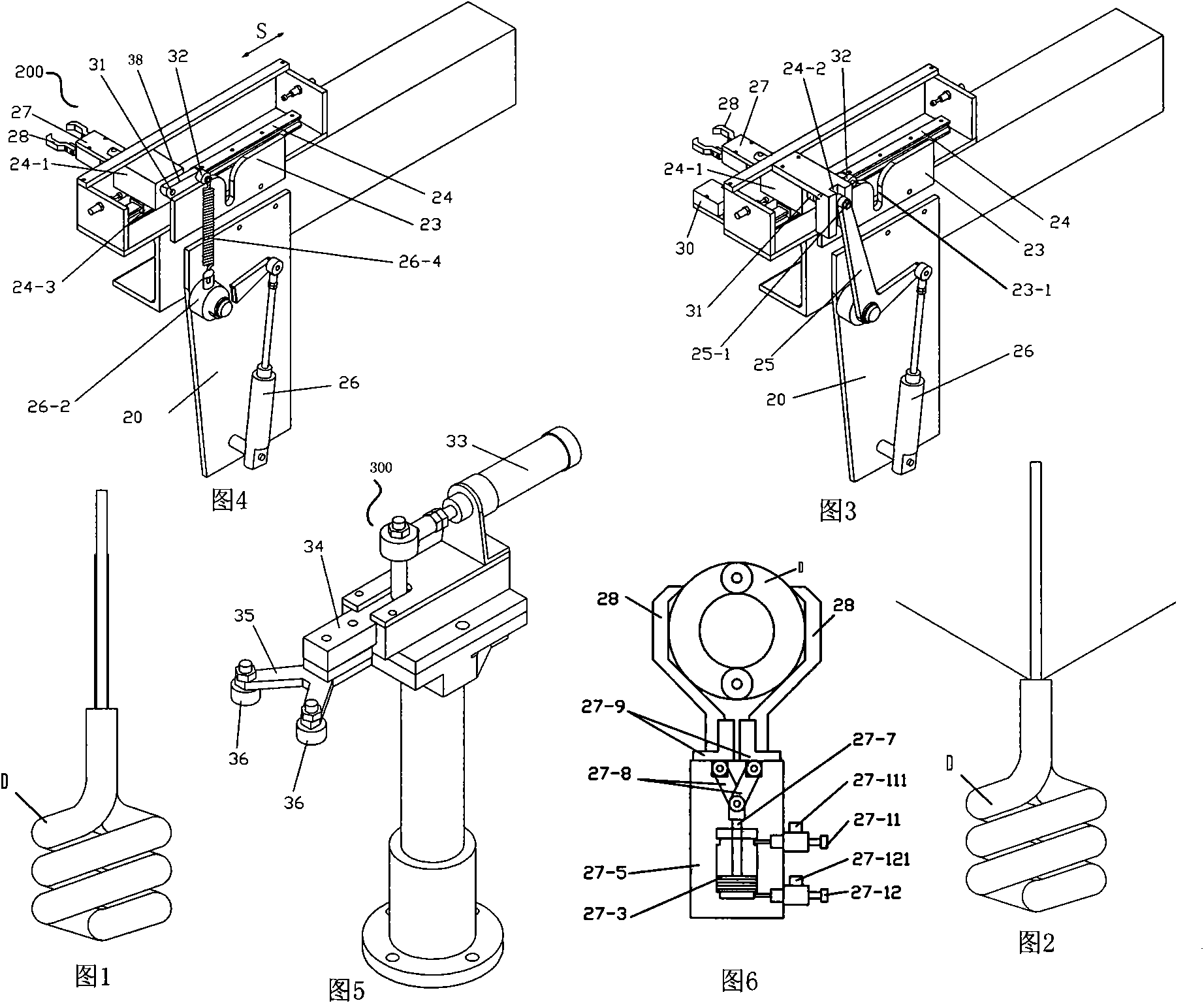

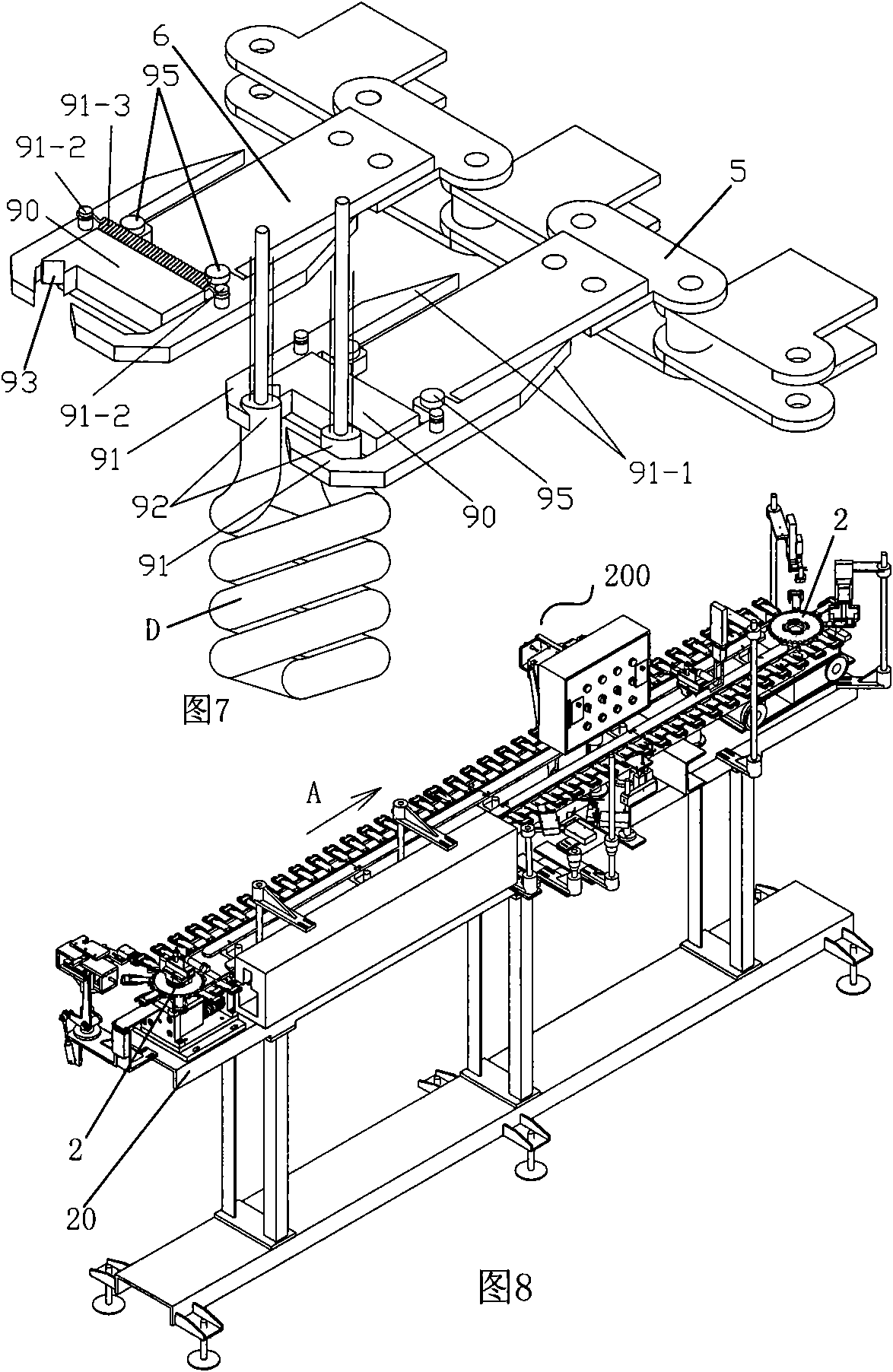

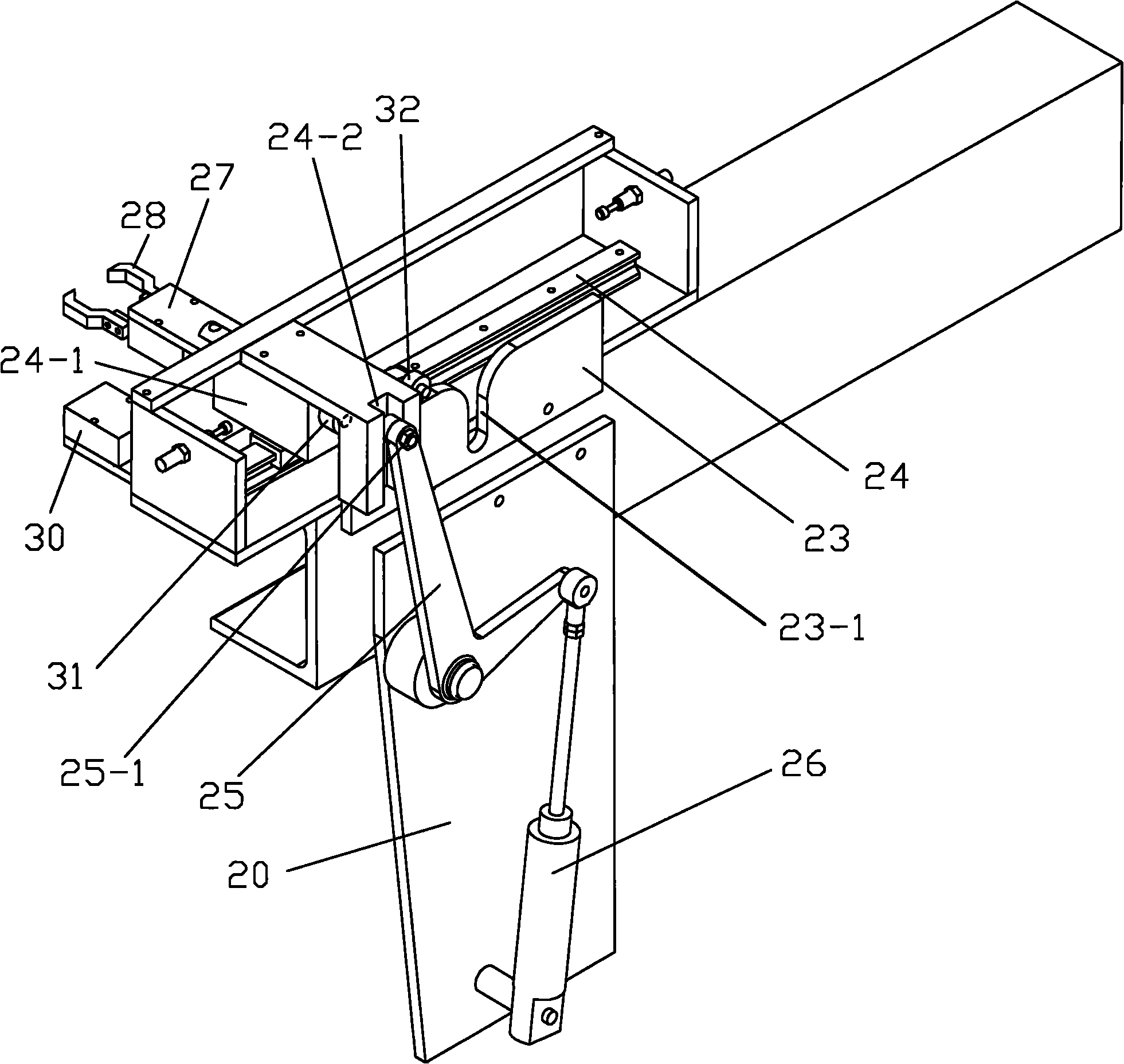

[0025] Figure 8 The shown semi-spiral energy-saving lamp tube automatic wire management machine includes a bar-shaped frame 20, a control device installed on the frame, and a plurality of stations arranged around the frame; A lamp tube feeding mechanism 200, a positioning mechanism, a wire management mechanism, a discharge pipe breaking mechanism, a lamp tube limit mechanism, a lamp tube preheating mechanism, and a lamp tube unloading mechanism are arranged; a sprocket mechanism is also arranged on the frame. Drive the chain 5 of the delivery fixture moving around the frame (the direction is shown by arrow A) (the two ends of the frame are respectively rotatably positioned with a sprocket 2 arranged vertically on the axis, and the chain 5 is connected to the two sprockets respectively. Engage and cooperate and connect end to end to form a closed loop, and a plurality of clamps 6 for clamping and fixing half-spiral energy-saving lamp tubes are fixed on the chain (such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com