Extraction system of ultra high molecular weight polyethylene fiber with high strength and high modulus

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber processing, textiles and papermaking, etc., can solve the problems of limited extraction capacity, high extraction cost, difficult to recycle, etc., to maintain stability performance, improve extraction efficiency and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

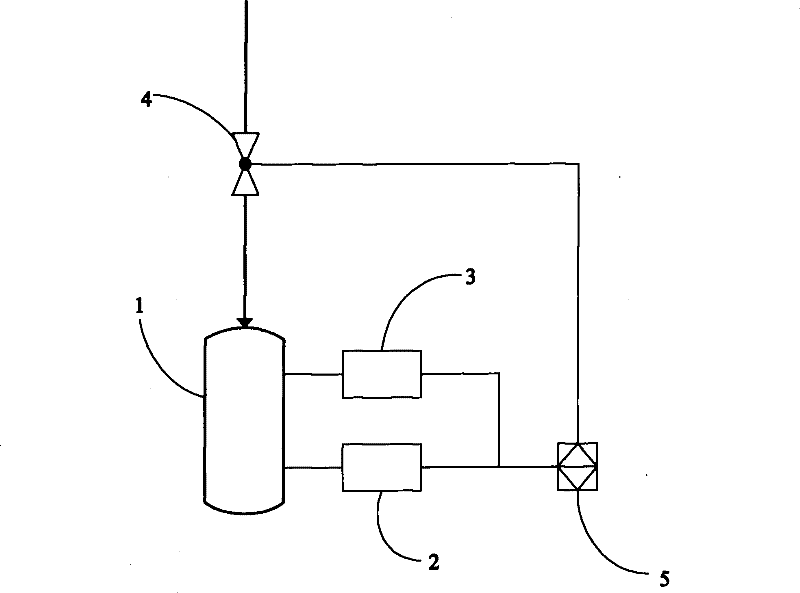

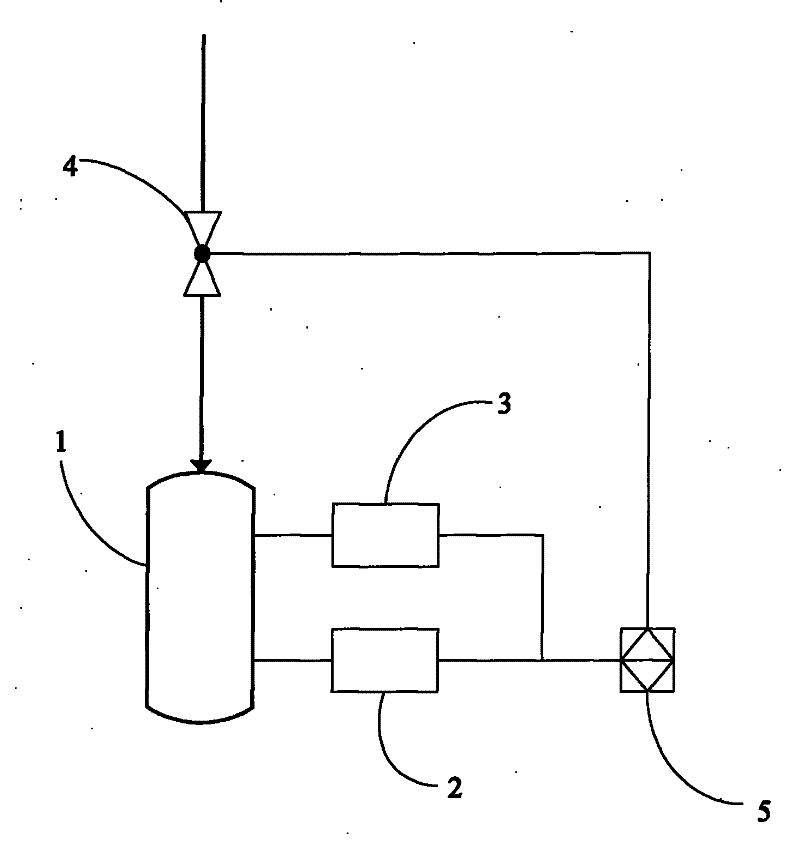

Method used

Image

Examples

Embodiment 1

[0030] Selection of raw materials: there are 4-8 spindles of ultra-high molecular weight polyethylene jelly yarn produced in the spinning section, 120-480f, with a solvent content of about 50-90%, and the extraction agent is halogenated alkanes.

[0031] Extraction process: the speed of entering the extraction tank is 8-12m / min, the speed of leaving the extraction tank is 18-20m / min, and turn on the small magnetic pumps in all tanks.

[0032] Silk quality inspection: The measured strength of high-strength and high-modulus ultra-high molecular weight polyethylene fibers is 20-23cN / dtex; the modulus is 600-800cN / dtex, the elongation at break is less than 10%, and the solvent content is less than 4%.

Embodiment 2

[0034] Selection of raw materials: there are 4-8 spindles of ultra-high molecular weight polyethylene jelly yarn produced in the spinning section, 120-480f, with a solvent content of about 50-90%, and the extraction agent is halogenated alkanes.

[0035] Extraction process: the speed of entering the extraction tank is 8-12m / min, the speed of exiting the extraction tank is 18-20m / min, and all small magnetic pumps in the tank are turned off.

[0036] Filament quality inspection: The measured strength of high-strength and high-modulus ultra-high molecular weight polyethylene fibers is 18-22cN / dtex; the modulus is 500-800cN / dtex, the elongation at break is less than 10%, and the solvent content is less than 5%.

[0037] By comparing the results of silk quality testing in Example 1 and Example 2, it can be seen that the extraction system using a magnetic pump to stir the extract has a high strength, high modulus, and ultra-high molecular weight polyethylene fiber in terms of strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com