A core-shell composite tank

A core-shell and tank technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as single product structure, and achieve the effect of various product structures, rich forms, and strong adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

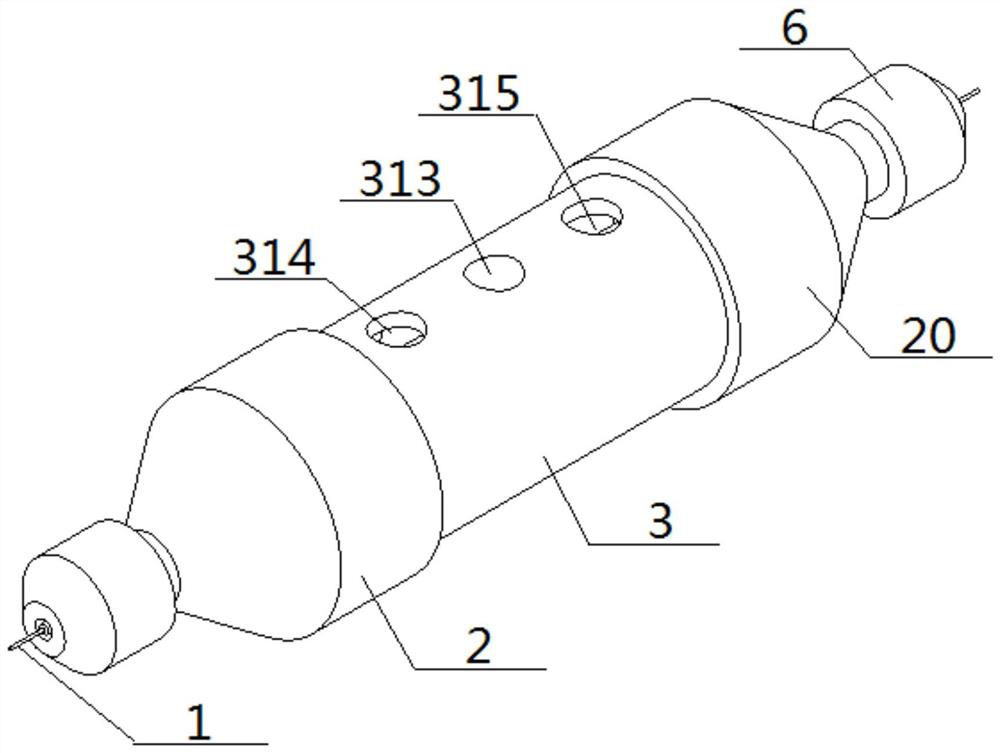

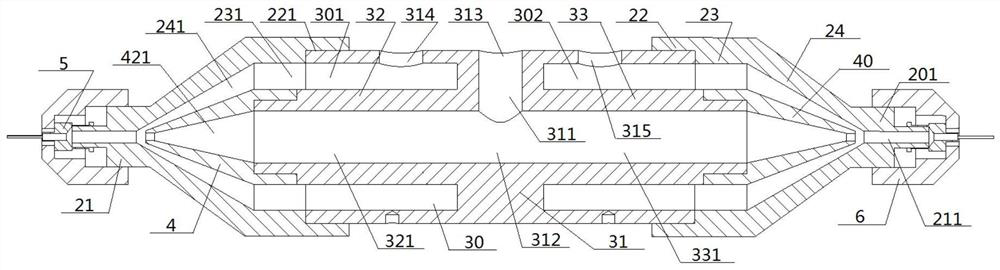

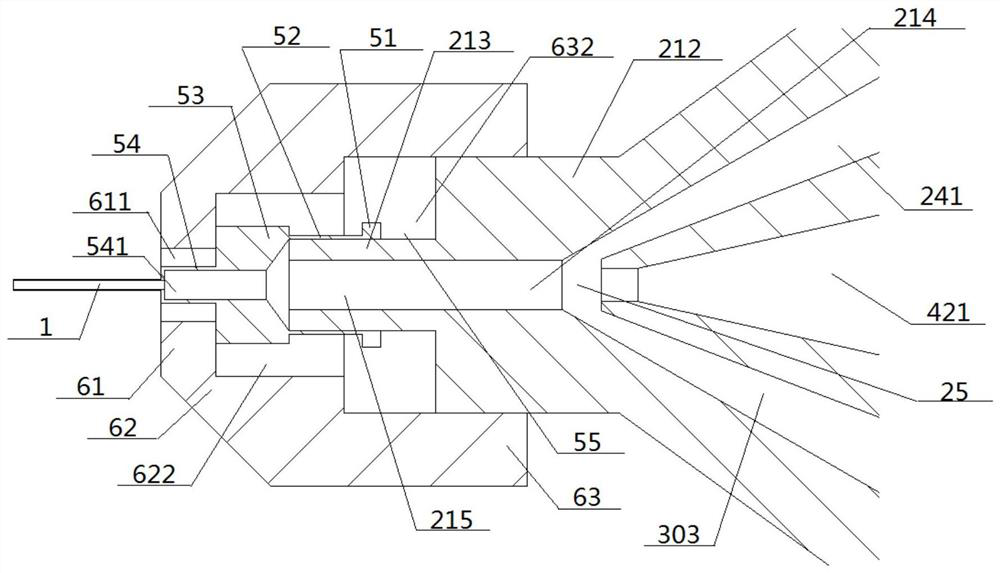

[0067] See Figure 1 — Figure 10 , a kind of core shell composite tank, comprising a tank body 3, the left outer nozzle 2 and the right outer nozzle 20, the internal of the tank body 3 is provided with a coaxial tank cavity 30, the left and right ends of the tank body 3 are connected to the left outer nozzle 2, the right outer nozzle 20, and the left and right ends of the tank cavity 30 are connected to the left outer nozzle 2, the inner cavity of the right outer nozzle 20 is connected; the internal of the tank body 3 is provided with a vertical axis of the tank body 31, The parts of the tank body 3 located on both sides of the pie body 31 are the left circumference cavity 301, the right circumferential cavity 302, the left circumferential cylindrical cavity 301, the inner portion of the right circumferential cylindrical cavity 302 respectively corresponding to the left cylinder 32, the right cylinder 32 of the inner end of the pie body 31 is connected, the outer end of the left c...

Embodiment 2

[0069] The basic content is the same as Example 1, the difference is that:

[0070] The structure of the left inner nozzle 4, the right inner nozzle 40 is consistent; the left inner nozzle 4 comprises an inner cylinder 41 and an inner cone 42, the inner end of the inner column 41 is socketed on the side circumference of the outer end of the left cylinder 32, the outer end of the inner cylinder 41 is connected to the large diameter end of the inner cone 42, and the small diameter end of the inner cone 42 extends outward; the inner cylinder 41 and the interior of the inner cone 42 are respectively opened with an inner column cavity 411 and an inner cone cavity 421, and the inner cone cavity 421 is connected to the left column cavity 321. The outer end of the left column 32, the outer end of the right column 33 is consistent; the outer end of the left column 32 includes a narrow column 322 and a wide column 323 located outside the left circumferential cavity 301, the diameter of the ...

Embodiment 3

[0072] The basic content is the same as Example 2, the difference is that:

[0073] The structure of the left external nozzle 2, the right outer nozzle 20 is consistent; the left external nozzle 2 includes an outer posterior column 22, an outer middle column 23, an outer anterior cone 24, and its interior corresponding to the opening of the outer posterior column cavity 221, the outer middle column cavity 231, the outer front cone cavity 241, the diameter of the outer posterior column cavity 221 is greater than the diameter of the outer middle column cavity 231, the outer posterior column cavity 221 is socketed on the outer side of the left end of the tank body 3, the two ends of the outer medial cylindrical cavity 231 are respectively and the left circumference cylindrical cavity 301, The large diameter end of the outer anterior cone cavity 241 is connected, the small diameter end of the outer front cone cavity 241 is connected to the inner nozzle cavity 211, and the nozzle chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com