Fish splitting machine

A fish cutting and cutting knife technology, which is applied in the field of fish cutting machines, can solve the problems of high safety risks for ordinary workers, difficulty in grasping, inconvenient and accurate cutting of the knife, etc., and achieves assembly line production, simple structure, and reduced operation burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

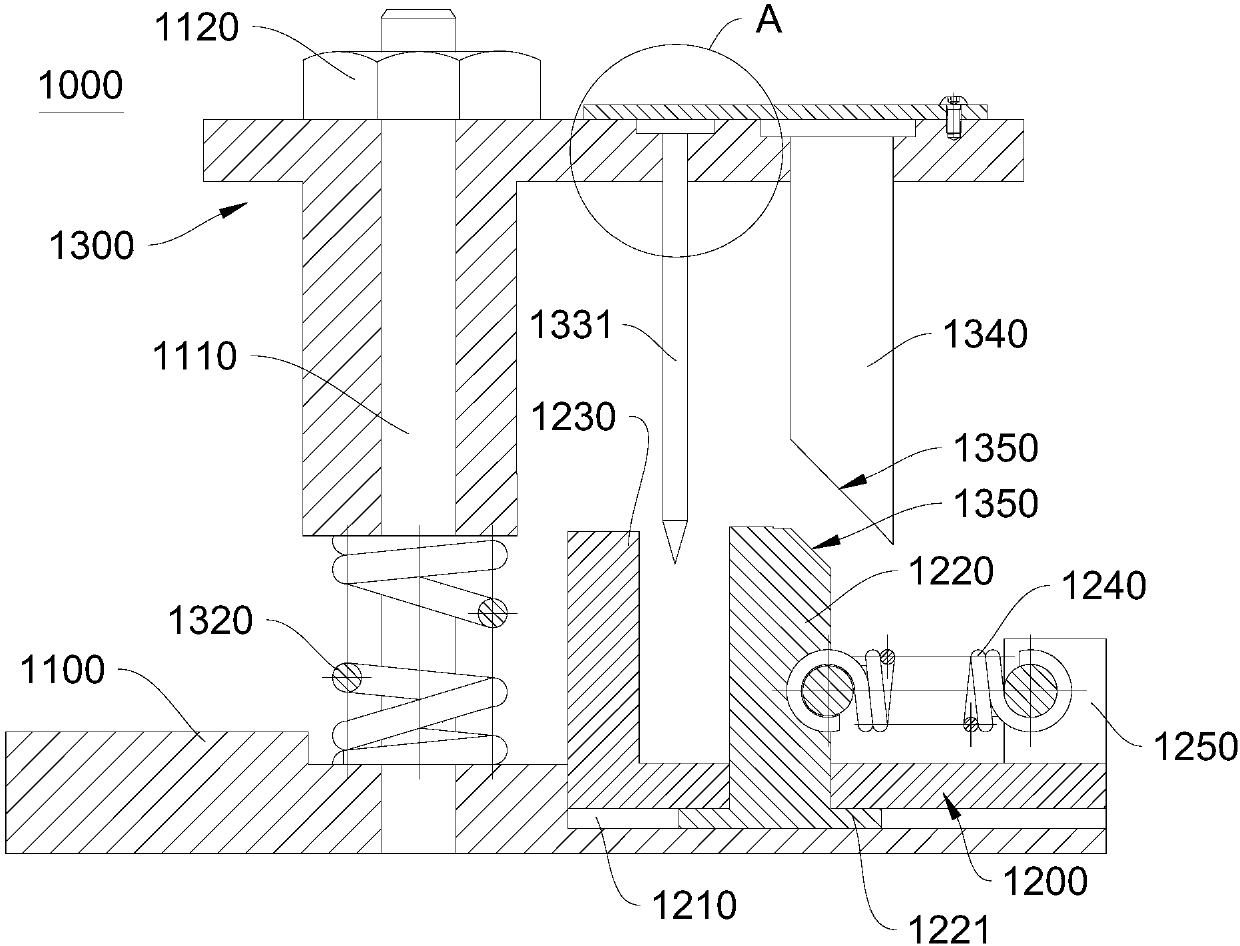

[0034] Please refer to Figure 1~2 , this embodiment provides a fish cutting machine 1000 . The fish cutting machine 1000 includes: a base 1100 , a fish cutting platform 1200 and a knife seat 1300 .

[0035] The fish cutting platform 1200 is disposed on the base 1100 , and the fish cutting platform 1200 has a slide rail 1210 , a first stopper 1220 and a second stopper 1230 . The first stopper 1220 is slidably engaged with the slide rail 1210 , and the second stopper 1230 is disposed at one end of the slide rail 1210 . The first stopper 1220 is connected with an end of the slide rail 1210 away from the second stopper 1230 by a first elastic member 1240 .

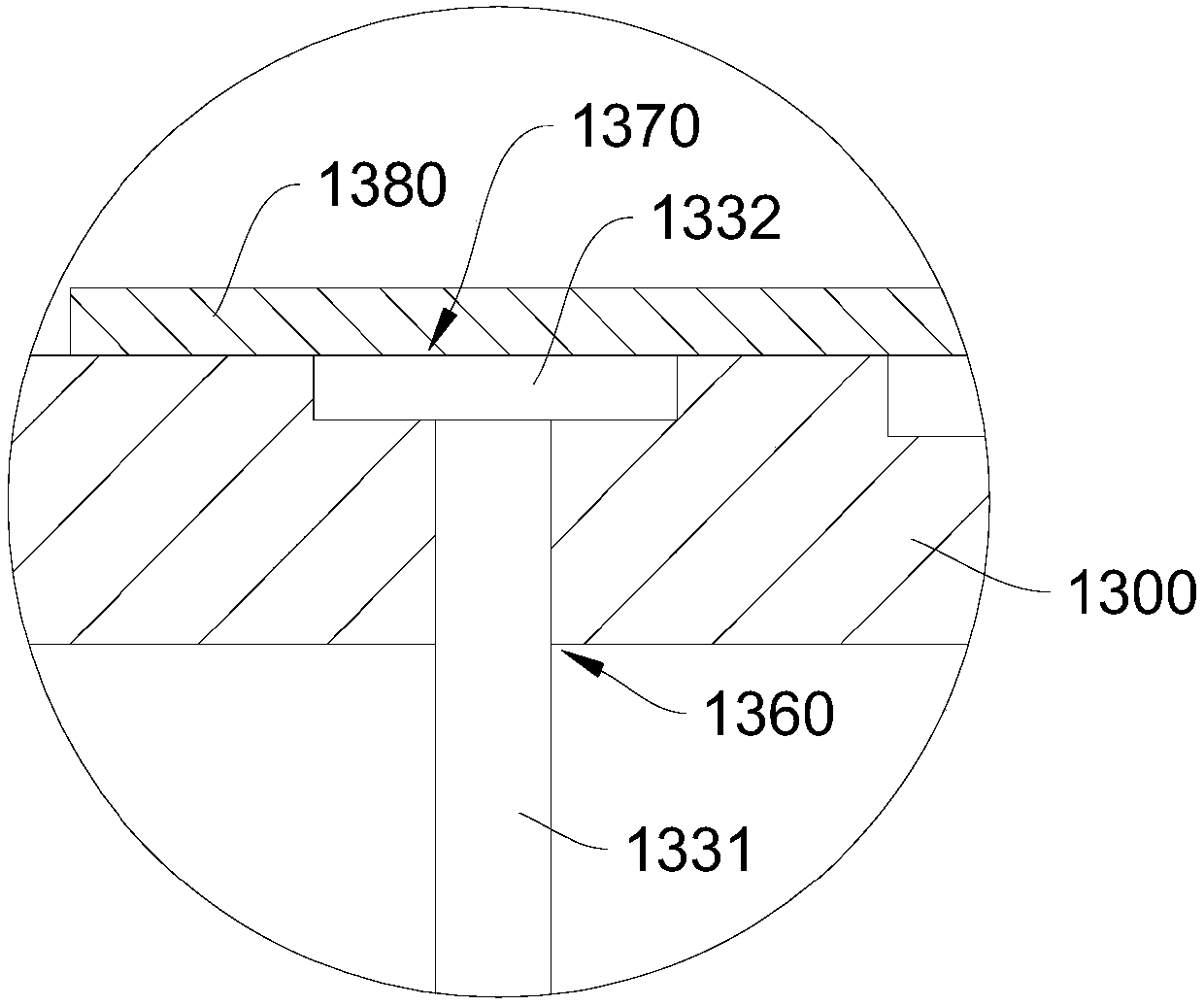

[0036] The base 1100 has a column 1110 , the knife seat 1300 has a through hole for matching with the column 1110 , and the knife seat 1300 is sleeved on the column 1110 through the through hole. Along the axial direction of the column 1110 , the column 1110 is flexibly connected to the tool seat 1300 . A second elastic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com