A drying device for resin waste recycling

A drying device and technology for waste products, applied in recycling technology, drying, drying machines, etc., can solve problems such as adhesion, poor temperature control, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

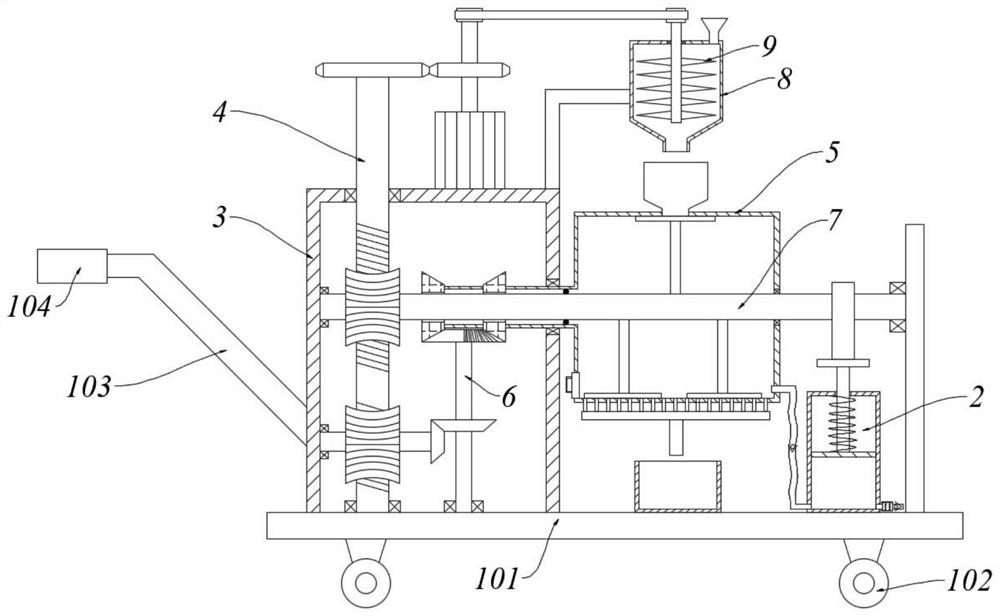

[0049] With reference to the accompanying drawings, a drying device for recycling resin waste products includes a car body, a transmission box 3, a drying tank 5, a pulverizing bucket 8 and a ventilation assembly 2;

[0050] The vehicle body includes a vehicle panel 101 and a wheel 102 installed below the vehicle panel 101; the left part of the vehicle panel 101 is provided with a transmission box 3; the transmission box 3 is provided with a drive assembly 4 and a swing assembly 6, and the drive assembly 4 and the swing assembly 6 cooperate; The right side of the transmission box 3 is provided with a drying tank 5; the drying tank 5 is arranged horizontally, and a stirring assembly 7 is arranged inside; 5. The ventilation assembly 2 is arranged on the right side.

Embodiment 2

[0052] With reference to the accompanying drawings, a drying device for recycling resin waste products includes a car body, a transmission box 3, a drying tank 5, a pulverizing bucket 8 and a ventilation assembly 2;

[0053] The vehicle body includes a vehicle panel 101 and a wheel 102 installed below the vehicle panel 101; the left part of the vehicle panel 101 is provided with a transmission box 3; the transmission box 3 is provided with a drive assembly 4 and a swing assembly 6, and the drive assembly 4 and the swing assembly 6 cooperate; The right side of the transmission box 3 is provided with a drying tank 5; the drying tank 5 is arranged horizontally, and a stirring assembly 7 is arranged inside; 5. The ventilation assembly 2 is arranged on the right side.

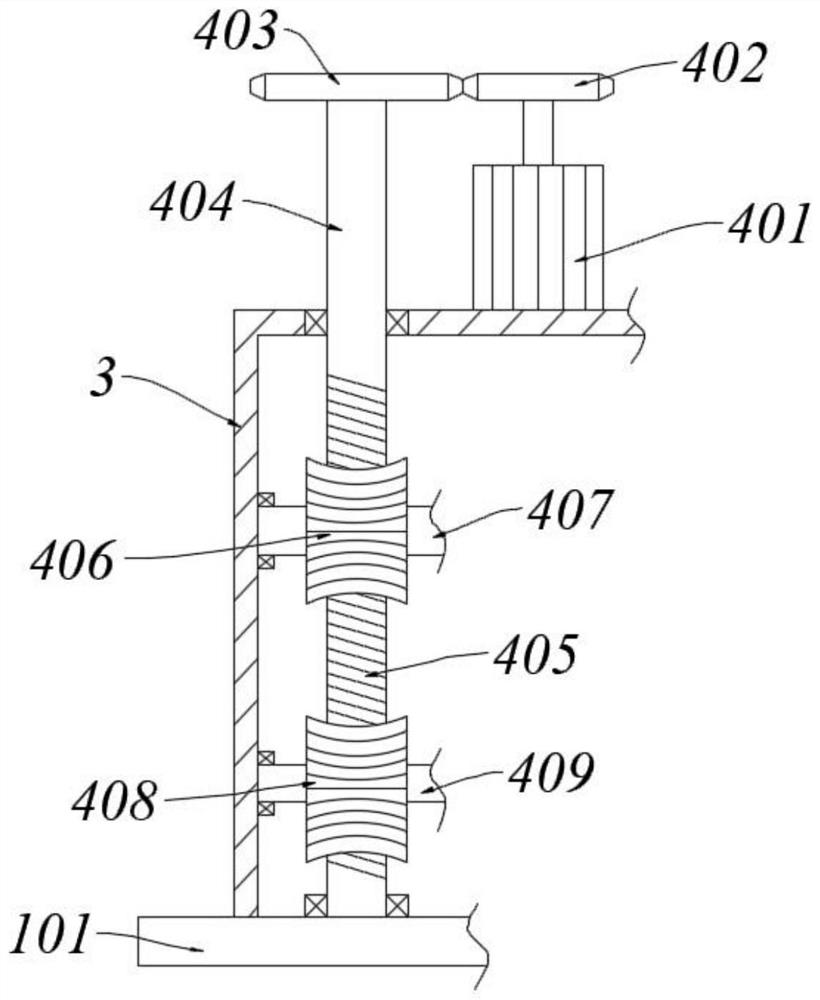

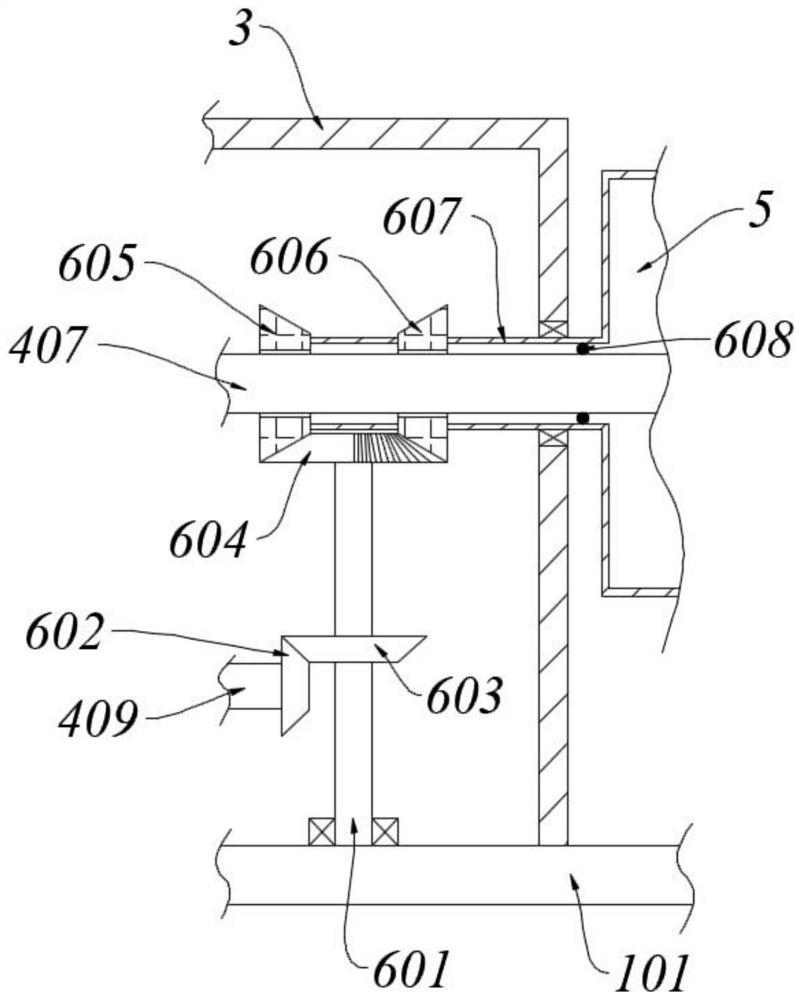

[0054] Wherein, the driving assembly 4 includes a servo motor 401, a No. 1 gear 402, a No. 2 gear 403, a No. 1 rotating shaft 404, a worm 405, a No. 1 worm wheel 406, an upper rotating shaft 407, a No. 2 worm wheel ...

Embodiment 3

[0076] Wherein, the same or corresponding components as in Embodiment 1 and Embodiment 2 adopt the reference numerals corresponding to Embodiment 1 and Embodiment 2. For the sake of brevity, only the differences from Embodiment 2 are described below. The difference between this embodiment and embodiment two is:

[0077] Transmission box 3 left side also is connected with push-pull assembly, and push-pull assembly comprises push-pull bar 103 and plastic cover 104, and push-pull bar 103 is a bent bar, and the right end is affixed to drive box 3, and left end horizontal setting and plastic cover 104 are housed.

[0078] Specifically, the plastic sleeve 104 is manually held to push the device to move through the push-pull assembly.

[0079] The electrical components mentioned above are all provided with a power supply, and the control means and circuits are all prior art, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com