Board detecting mechanism for wood packing box

A detection mechanism and packaging box technology, applied in the direction of counting mechanism/items, counting of items shipped through the conveying device, instruments, etc., can solve the problems of high labor intensity, recording errors, low detection efficiency, etc., and improve the accuracy of detection performance, orderly production process, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

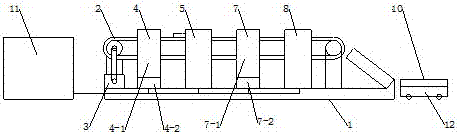

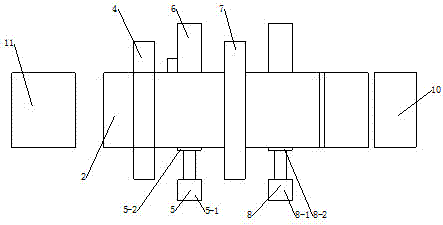

[0017] A kind of plank detection mechanism for wooden packing box that the present invention relates to, comprises frame 1 and conveyer belt 3, and described conveyer belt 2 is connected with stepping motor 3, and one side of described conveyer belt 2 is provided with frame 1 The first detection device 4 used to detect the size of the plank is provided on the right side of the first detection device 4 with a first pushing device 5 fixed on the frame 1, and the first pushing device 5 is symmetrical along the conveyor belt The position is provided with a receiving device 6 for receiving qualified products, the right side of the first pushing device 5 is provided with a second detection device 7 fixed on the frame, and the right side of the second detection device 7 is provided with The second pushing device 8, the second pushing device 8 is provided with a rework box 9 at a symmetrical position along the conveyor belt, the tail end of the conveyor belt 3 is provided with a scrap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com