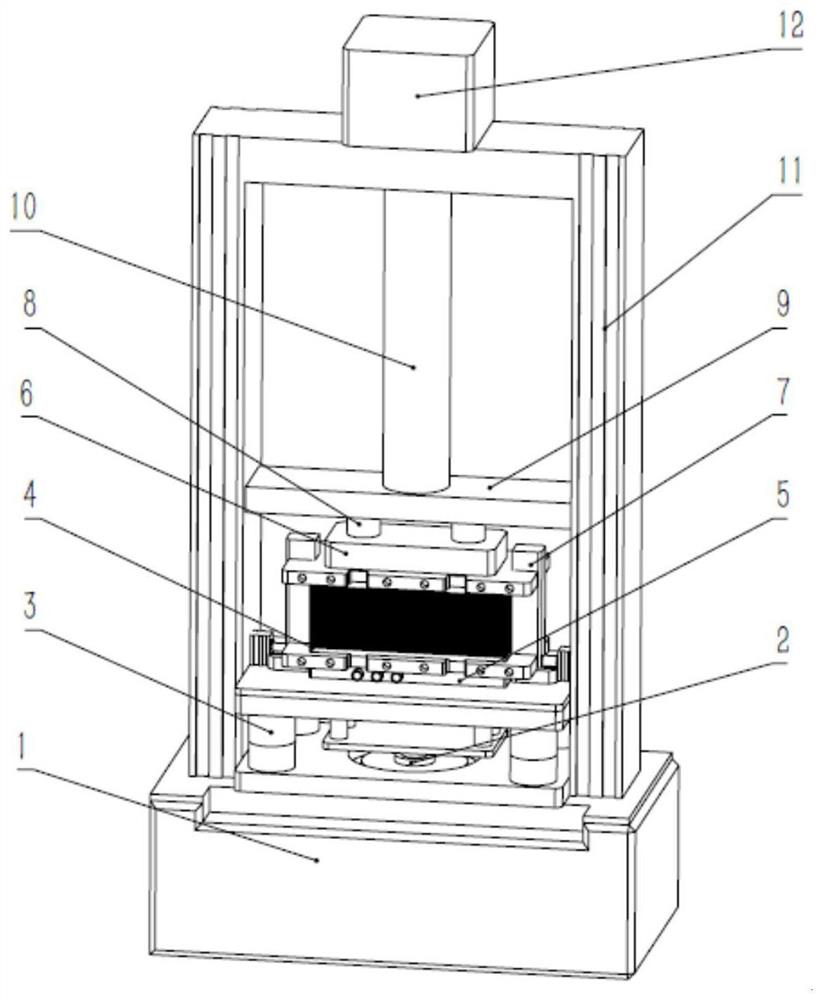

Fuel cell stacking leakage detection equipment

A fuel cell and leak detection technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of laborious handling, failure to meet actual use needs, and failure to meet actual production needs, and achieve the effect of avoiding damage and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

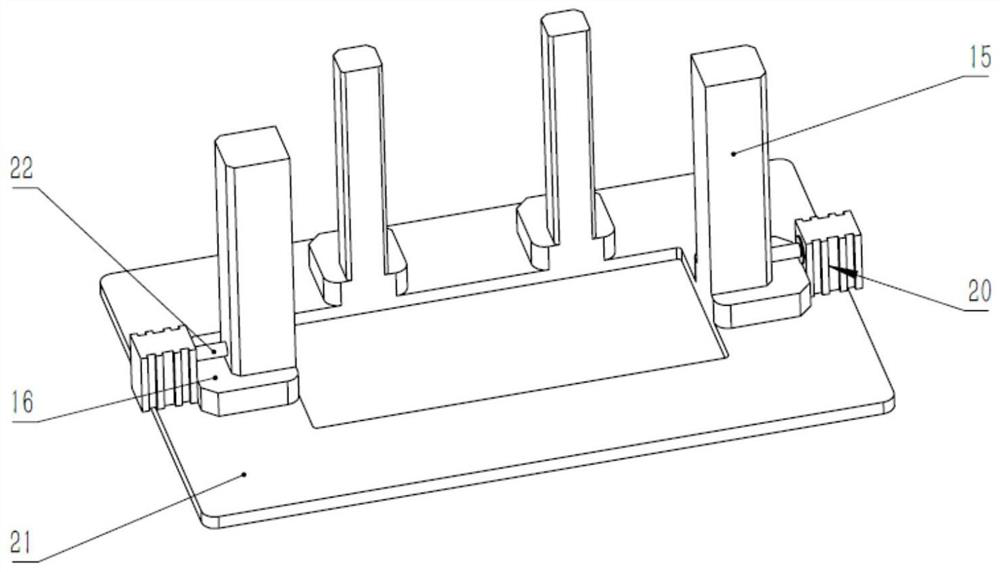

[0036] Embodiment 1: fully automatic scheme

[0037]Before stacking, the push rod of the positioning cylinder is in a tightened state, and the positioning column is in a direction away from the stack. The manipulator sequentially stacks the components such as the stack tail plate, the negative and positive bipolar plates, and the membrane electrode on the leak detection tooling in the specified order, and slowly falls along the positioning column. After the last piece of component assembly is completed, the positioning cylinder controls the positioning push rod to push The two positioning rods on the left and right tighten the various components of the stack to align each component. The pressure motor is started, and the pressure rod is extended to compress the pressure contact plate and the electric stack and apply a certain pressure. The air tightness detection mechanism is activated, and the externally connected gas path is connected to the anode air inlet, cathode air inl...

Embodiment 2

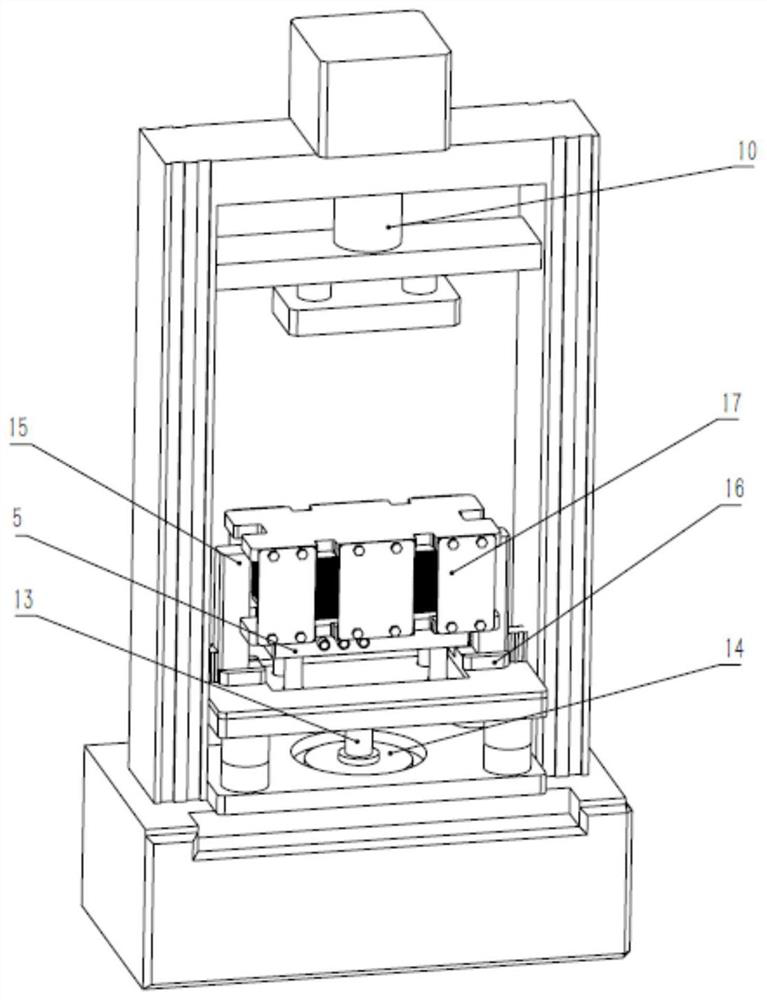

[0038] Embodiment 2: semi-automatic scheme

[0039] This solution is suitable for small-batch production to deal with various packaging methods that may appear, and the stack packaging is completed manually. Before stacking, the push rod of the positioning cylinder is in a tightened state, and the positioning column is in a direction away from the stack. The manipulator sequentially stacks the components such as the stack tail plate, the negative and positive bipolar plates, and the membrane electrode on the leak detection tooling in the specified order, and slowly falls along the positioning column. After the last piece of component assembly is completed, the positioning cylinder controls the positioning push rod to push The two positioning rods on the left and right tighten the various components of the stack to align each component. The pressure motor is started, and the pressure rod is extended to compress the pressure contact plate and the electric stack and apply a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com