Production method of support tubes and production system adopting method

A technology of production system and production method, which is applied in the field of production system, can solve the problems of waste of resources, waste of manpower, increase of production cost, etc., and achieve the effect of saving cost, saving manpower cost and realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

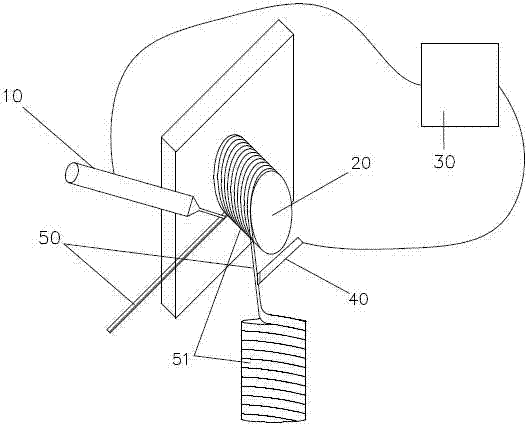

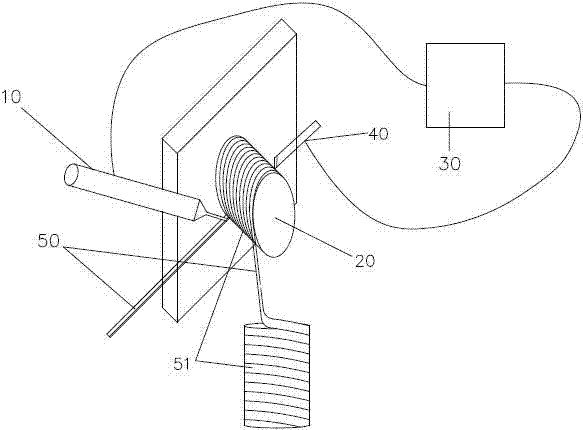

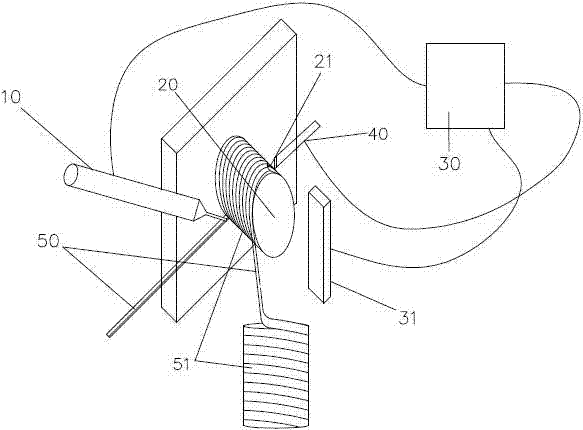

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0017] The invention provides a production method of a support pipe, which includes the following steps: firstly, the support bar is wound on the rotating mold shaft of the pipe welding machine, and the strip-shaped groove of the support bar is heated by a heating and welding device, so that the support bar is melted and bonded to form a support When the support tube is produced to the specified length, suspend the welding of the support bar by the heating and welding device, so that the support bars cannot be bonded; when the mold shaft drives the support tube to rotate a certain distance, start the welding of the support bar by the heating and welding device again , continue to produce the support tube, then the support tube will be separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com