Wireless charging annular magnet assembling device

A ring magnet and assembly device technology, applied in assembly machines, metal processing equipment, connecting components, etc., can solve the problems of damaged fixing stickers, excessive waste, and prolong assembly time, so as to reduce labor intensity, reduce consumables costs, and improve The effect of production assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below according to the accompanying drawings and specific embodiments.

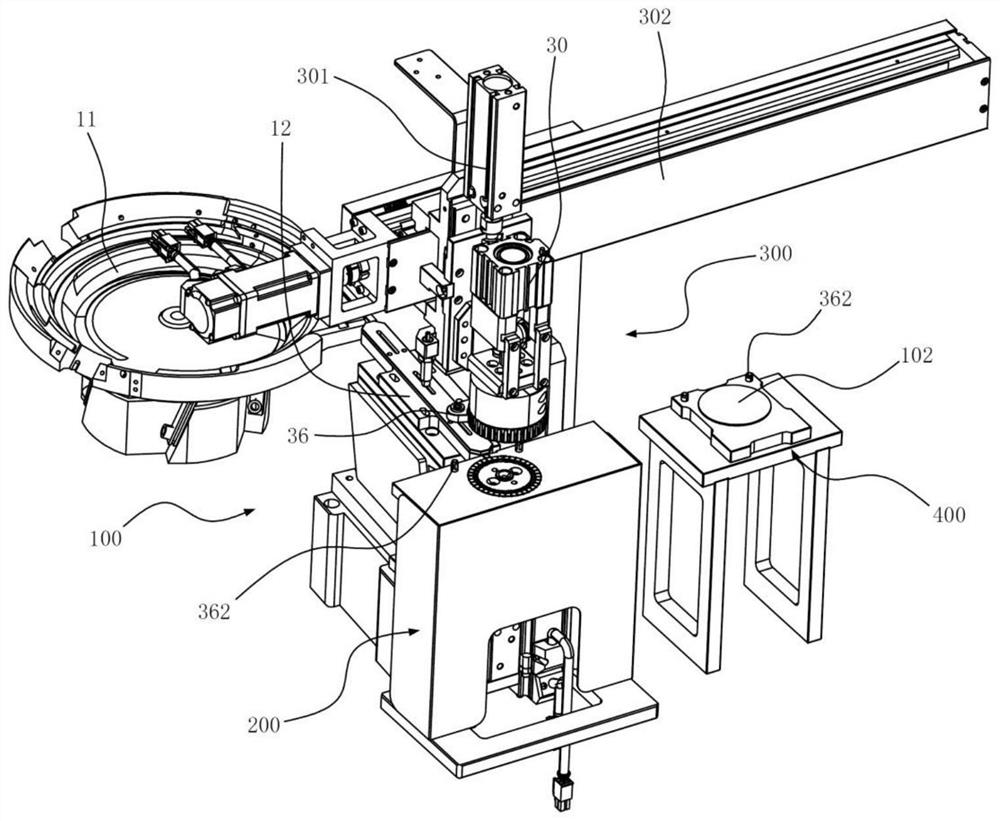

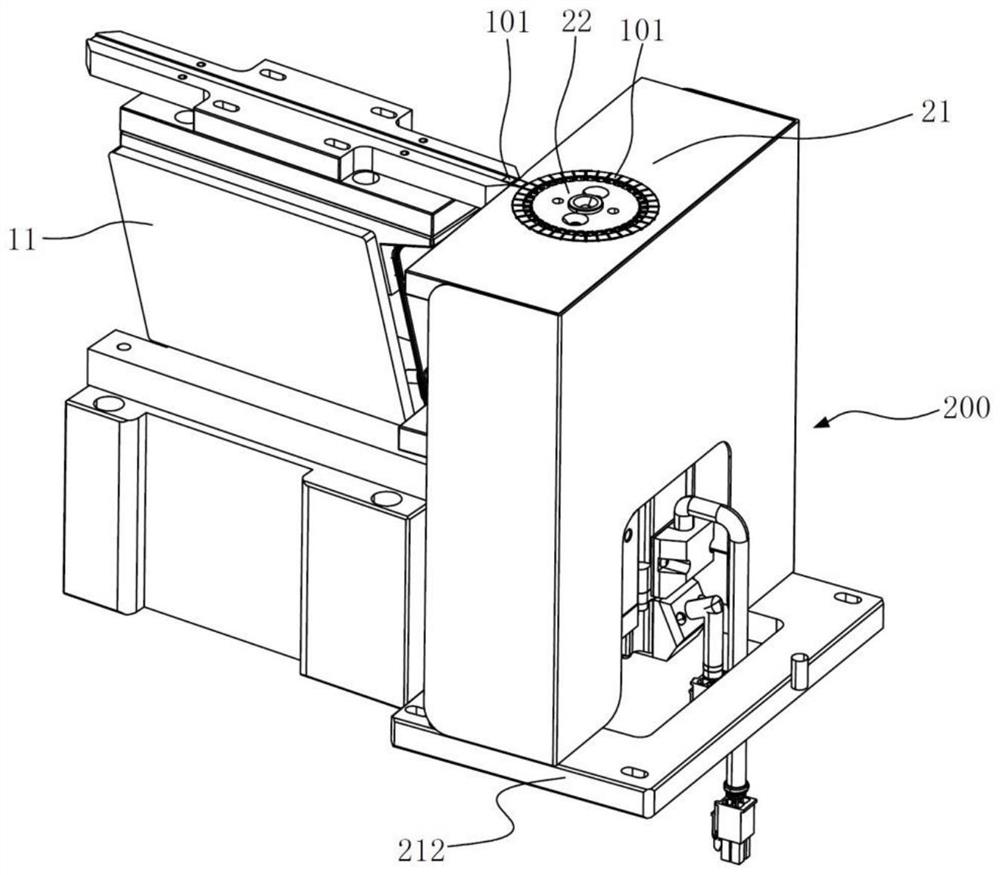

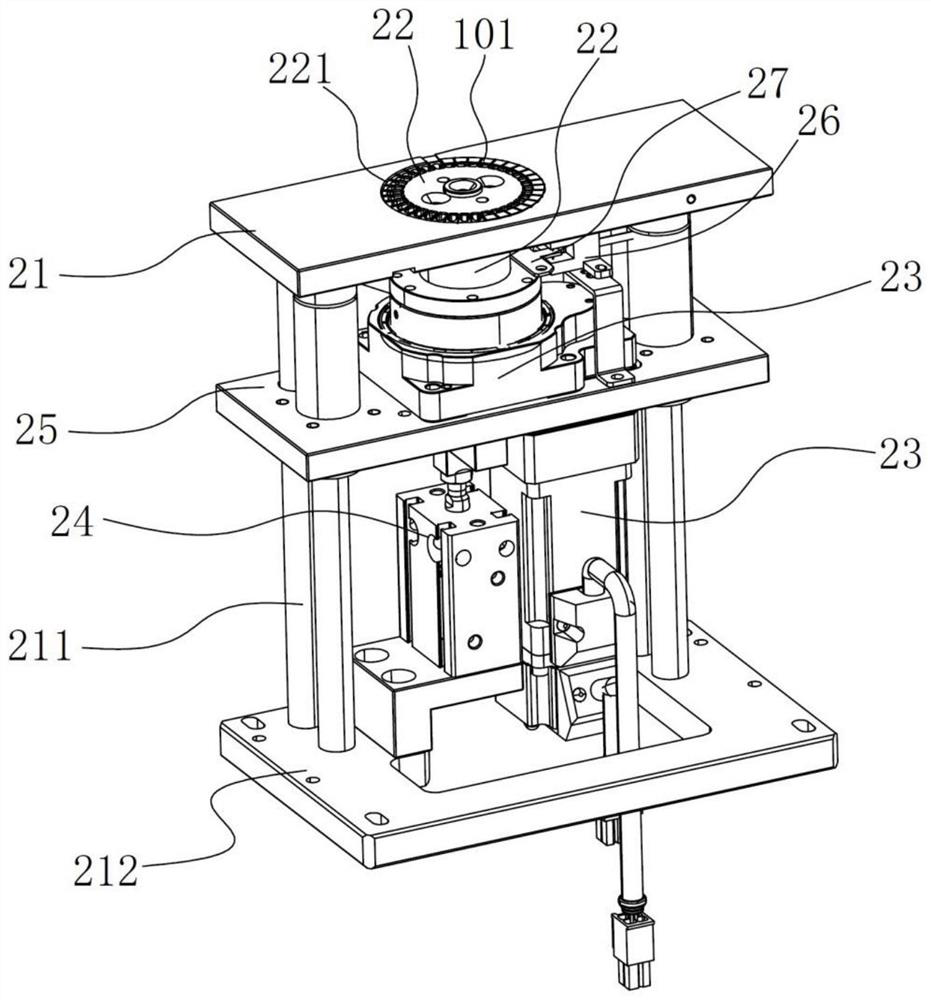

[0032] Depend on figure 1 As shown, this embodiment discloses a wireless charging ring magnet assembly device, including a feeding assembly 100 for realizing the feeding of the magnet workpiece 101, a positioning assembly 200 for realizing the arrangement of the magnet workpiece 102, The gripping assembly 300 for moving the magnet workpiece 101 , and the table 400 for placing the fixing sticker 102 . The grasping assembly 300 includes a gripper, the gripper is fixed on the lift plate of the lift cylinder 301, the lift cylinder 301 is fixed on the traverse plate of the traverse cylinder 302, and the positioning assembly 200 and the worktable 400 are located on the front side of the traverse cylinder and are parallel to each other. Set side by side.

[0033] The feeding assembly 100 includes a vibrating plate 11 and a linear vibrating plate 12. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com