Humic acid type adsorbing material and preparation method and application thereof

A technology of adsorption material and humic acid, which is applied in the field of material preparation and environmental science, can solve the problems of high technical requirements and cost of synthesis process, complex synthesis method, poor selectivity, etc., and achieve low requirements for reaction conditions, simple synthesis process and high treatment effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

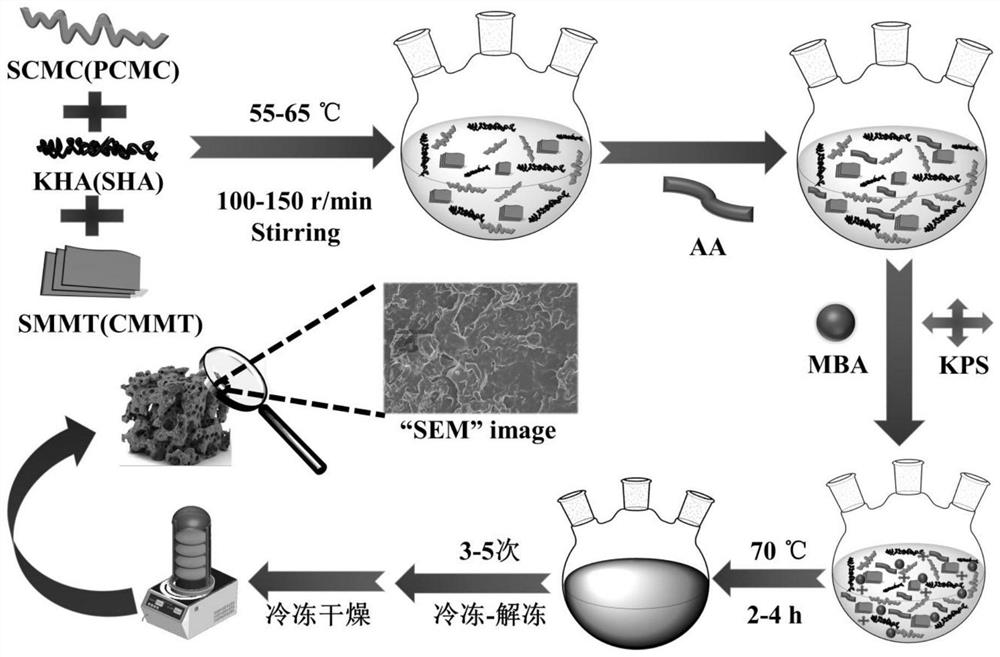

[0055] Mix 10g of 0.5% carboxymethyl cellulose solution, 10g of 0.1% sodium humate solution and 6g of 0.5% sodium montmorillonite aqueous dispersion solution at 55°C under stirring at a speed of 100r / min to form a mixed solution A. Then, 10 g of 0.2% N,N'-methylenebisacrylamide solution was added to 10 g of 20% acrylic acid solution to form a mixed solution B, which was dropped into the mixed solution A at a rate of 3 drops / s. At the same time, 10 g of 0.4% ammonium persulfate solution was dropped into the mixed solution A at a rate of 2 drops / s. After the above solution was added dropwise and the mechanical stirring was continued for 20 min, the temperature was raised to 70° C., and the stirring was continued for 2 h to obtain a viscous gel material. The gel material was frozen at -4°C for 12 hours, then thawed at room temperature for 6 hours, frozen and thawed three times under the same conditions and operations, and then placed in a freeze dryer to freeze-dry to obtain humi...

Embodiment 2

[0057] Mix 15g of 0.6% sodium carboxymethylcellulose solution, 10g of 0.8% potassium humate solution and 8g of 1.0% calcium-based montmorillonite water dispersion solution at 60°C under stirring at a speed of 125r / min to form a mixed solution A. Then add 10g of 0.3% N,N'-methylenebisacrylamide solution into 10g of 40% acrylic acid solution to form mixed solution B, which is dropped into mixed solution A at a rate of 4 drops / s. At the same time, 10 g of 0.7% potassium persulfate solution was dropped into the mixed solution A at a rate of 3 drops / s. After the dropwise addition of the above solution was completed, the mechanical stirring was continued for 30 minutes, and then the temperature was raised to 70° C., and the stirring was continued for 3 hours to obtain a viscous gel material. The gel material was frozen at -4°C for 12 hours, then thawed at room temperature for 8 hours, frozen and thawed four times under the same conditions and operations, and then placed in a freeze ...

Embodiment 3

[0059] Mix 20g of 0.7% potassium carboxymethylcellulose solution, 10g of 1.5% sodium humate solution and 10g of 1.5% sodium montmorillonite aqueous dispersion solution at 65°C under stirring at a speed of 150r / min to form a mixed solution A. Then add 10g of 0.5% N,N'-methylenebisacrylamide solution into 10g of acrylic acid solution with a mixing degree of 60% to form a mixed solution B, which is dropped into the mixed solution A at a rate of 5 drops / s. At the same time, 10 g of 1.0% ammonium persulfate solution was dropped into the mixed solution A at a rate of 4 drops / s. After the above solution was added dropwise, the mechanical stirring continued for 40 minutes, and then the temperature was raised to 70° C., and the stirring was continued for 4 hours to obtain a viscous gel material. The gel material was frozen at -4°C for 12 hours, then thawed at room temperature for 10 hours, frozen and thawed 5 times under the same conditions and operations, and then placed in a freeze d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com