A solid-state heat storage and heating characteristic matching design method based on heat transfer rate balance

A heat transfer rate and design method technology, applied in the field of high-temperature solid-state heat storage design optimization, can solve problems such as shortening the service life of resistance wires, affecting the reliability and economical operation of heat storage devices, and overheating of heating elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

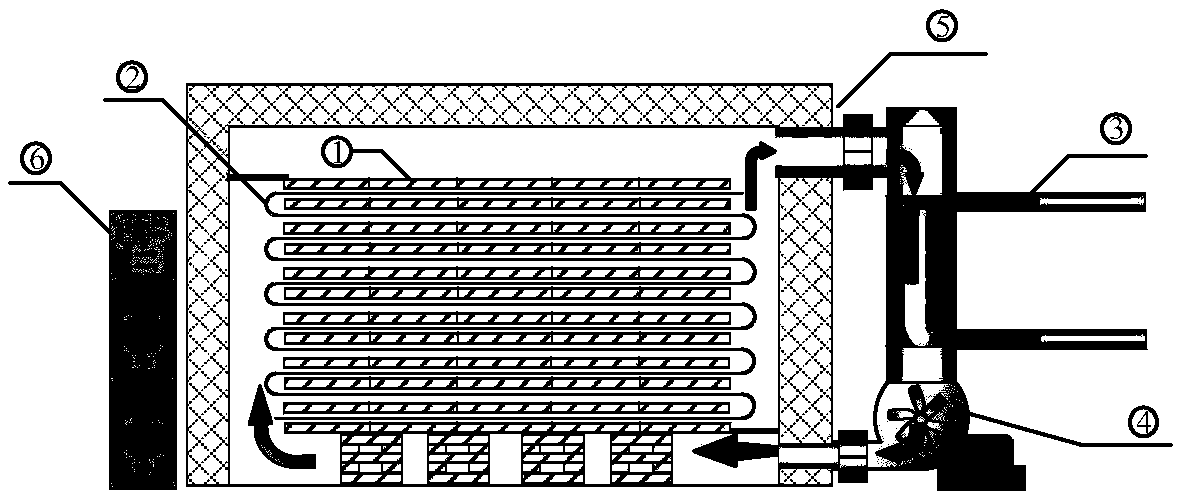

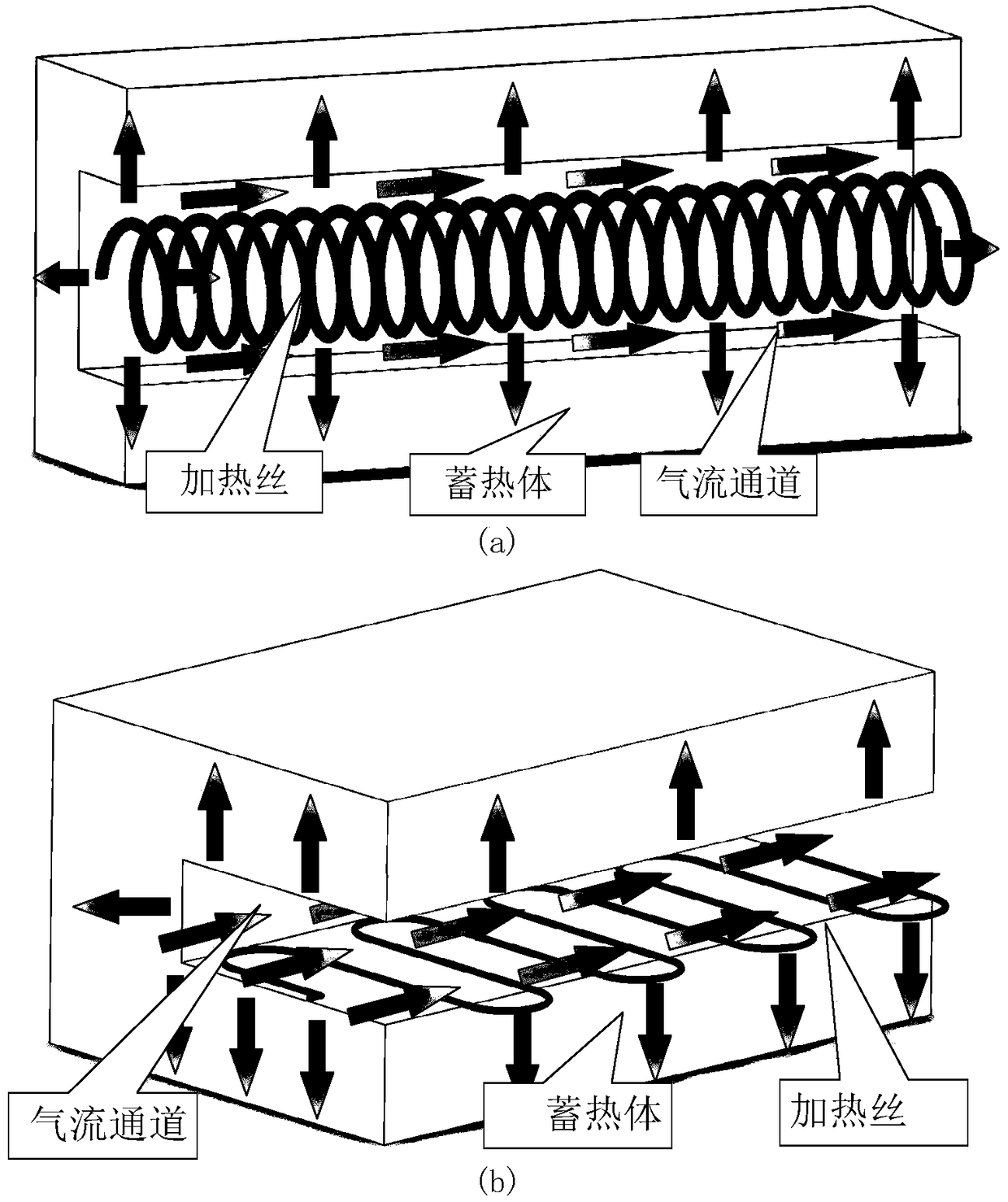

[0074] This invention is mainly aimed at the design of heat storage materials and electric heating wires in high-temperature solid-state heat storage systems, and proposes a matching design method for solid-state heat storage heating characteristics based on heat transfer rate balance, which is used to solve the problem of heat storage materials and electric heating wires in heat storage systems. Adaptive design of the heating wire.

[0075] The method comprises the steps of:

[0076] 1) Obtain the structural data, material data and operating condition parameters of the high-temperature solid-state heat storage device;

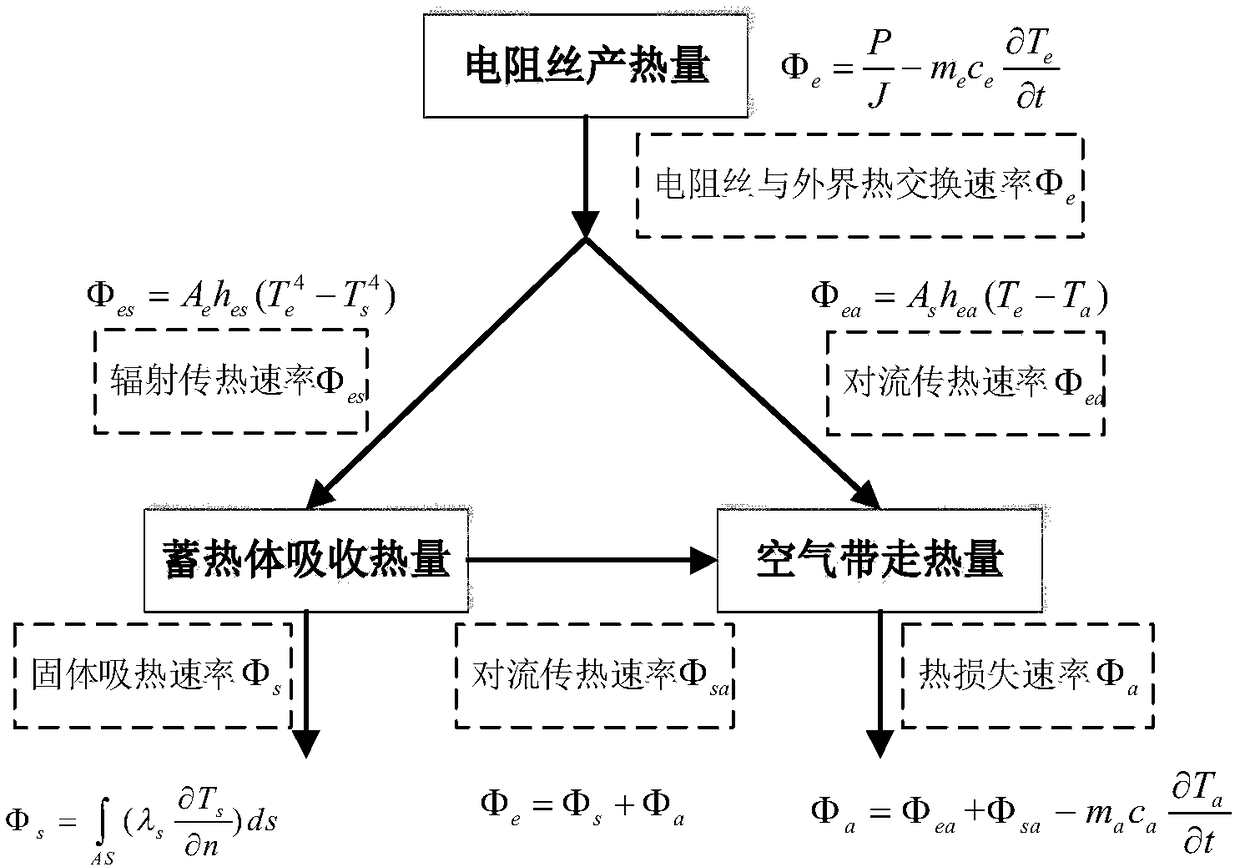

[0077] 2) Set the target parameters such as the heating power of the electric heating element and the expected temperature rise rate, and establish the heat transfer rate balance model between the high-temperature heat storage material and the resistance heating element:

[0078]

[0079] In the formula: P is the heating power of the electric heating eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com