A method for optimizing the heat dissipation structure of the micro-channel of a multi-chip module

A technology of multi-chip components and optimization methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems that take a lot of time and energy, and achieve the effect of simple calculation and convenient parameter optimization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

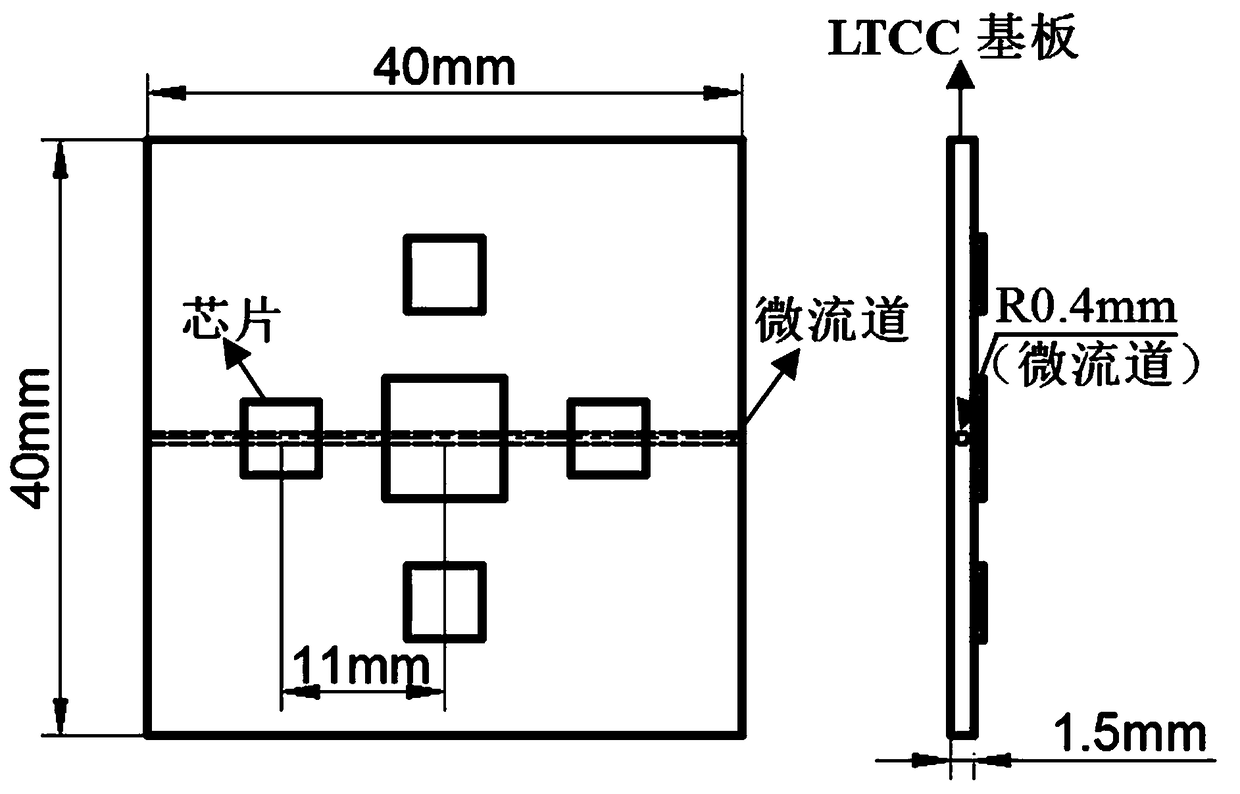

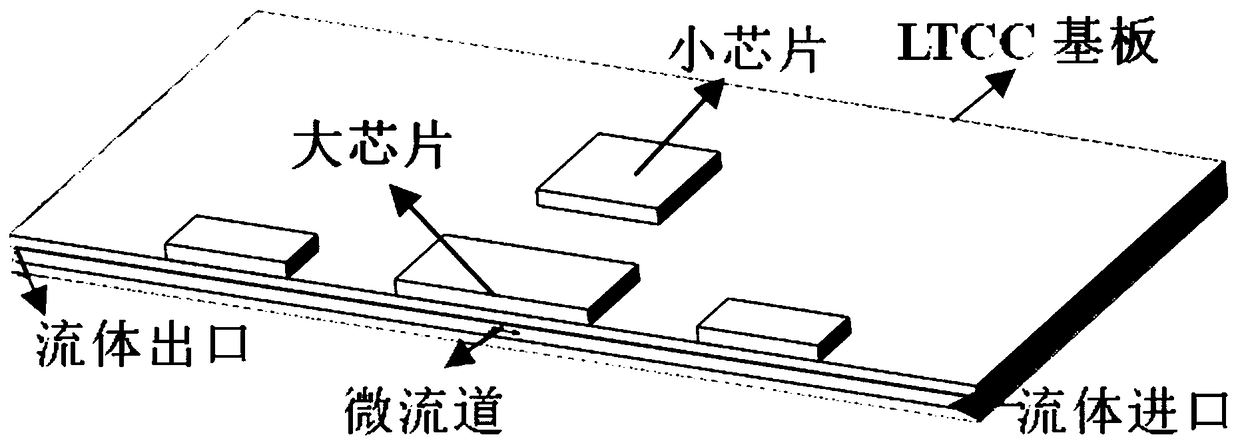

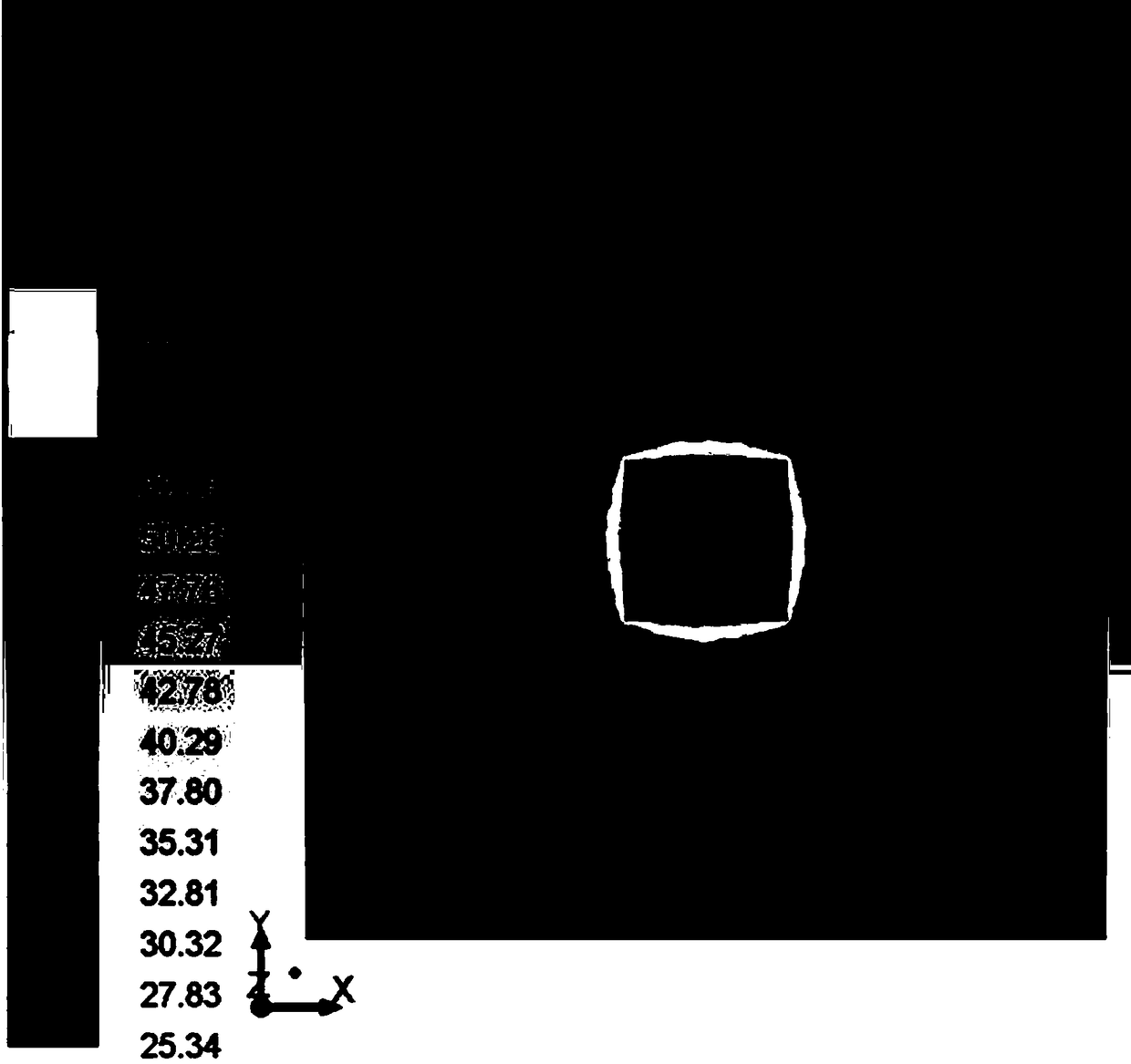

[0028] A method for optimizing the heat dissipation structure of a multi-chip component microchannel, first of all, for the microchannel structure in the substrate, the structural factors that affect the heat dissipation performance of the substrate are proposed, which is the selection of factors in the orthogonal test design, and then the corresponding structural factors are designed. level variable. In this case, first use the orthogonal design method to design an orthogonal table for experimental design. This time, 9 sets of test combinations are designed. According to these 9 sets of test parameters, corresponding 9 sets of simulation models are established. After the simulation calculation, the corresponding temperature results are obtained. After the range analysis of the obtained data, the primary and secondary relationship of the factors affecting the heat dissipation performance of the basic microchannel structure can be obtained. The significance of the influencing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com