Thermal energy storage

a technology of energy storage and thermal energy, which is applied in the direction of indirect heat exchangers, electric propulsion mountings, lighting and heating apparatus, etc., can solve the problems of more than 30% of the fuel energy supplied to an internal combustion engine (internal combustion engine) being lost to the environment via engine exhaust, and the internal combustion engine operating inefficiently, etc., to achieve high heat storage density, high surface area, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In the following detailed description, the specific embodiments of the present invention are described in connection with its preferred embodiments. However, to the extent that the following description is specific to a particular embodiment or a particular use of the present techniques, it is intended to be illustrative only and merely provides a concise description of the exemplary embodiments. Accordingly, the invention is not limited to the specific embodiments described below, but rather; the invention includes all alternatives, modifications, and equivalents falling within the true scope of the appended claims.

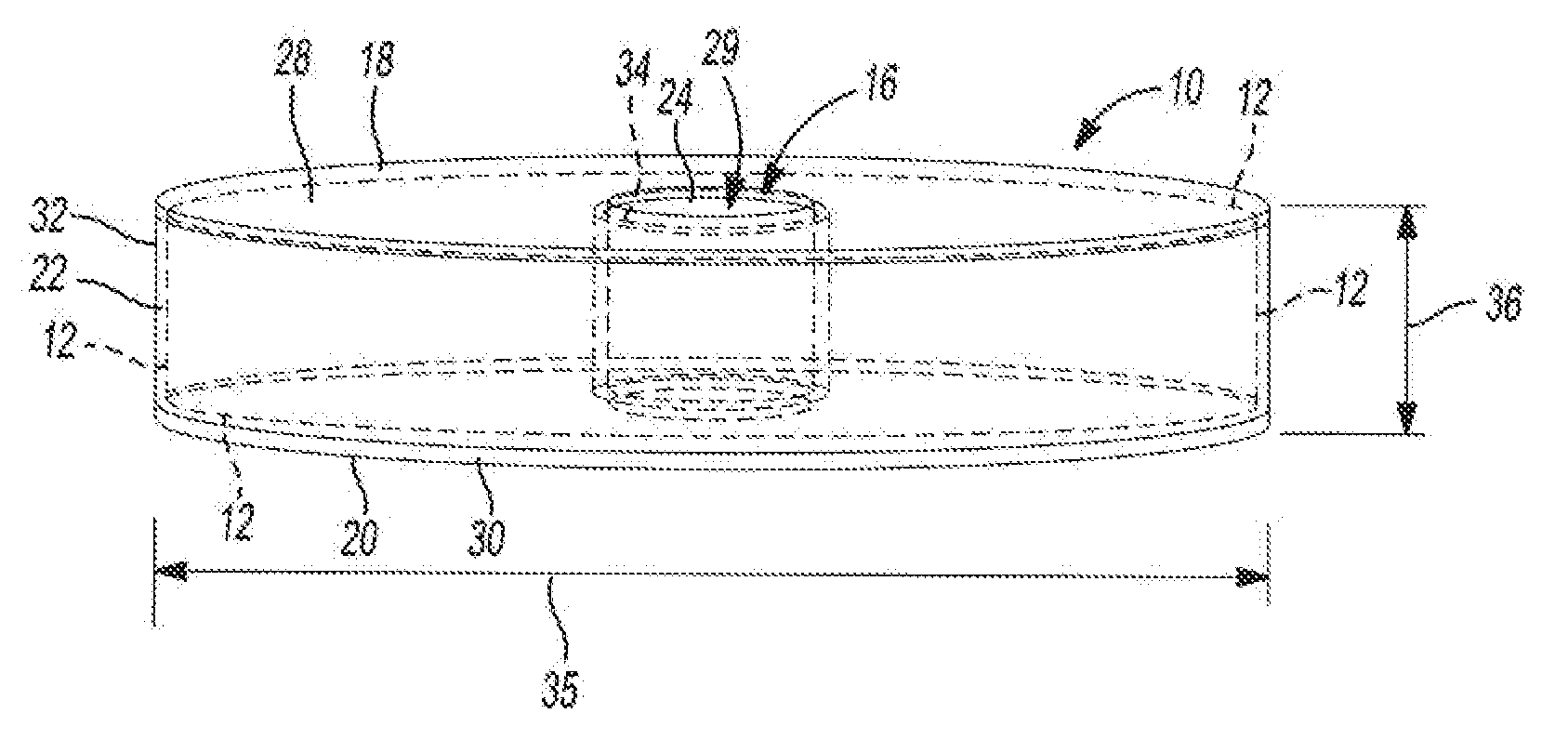

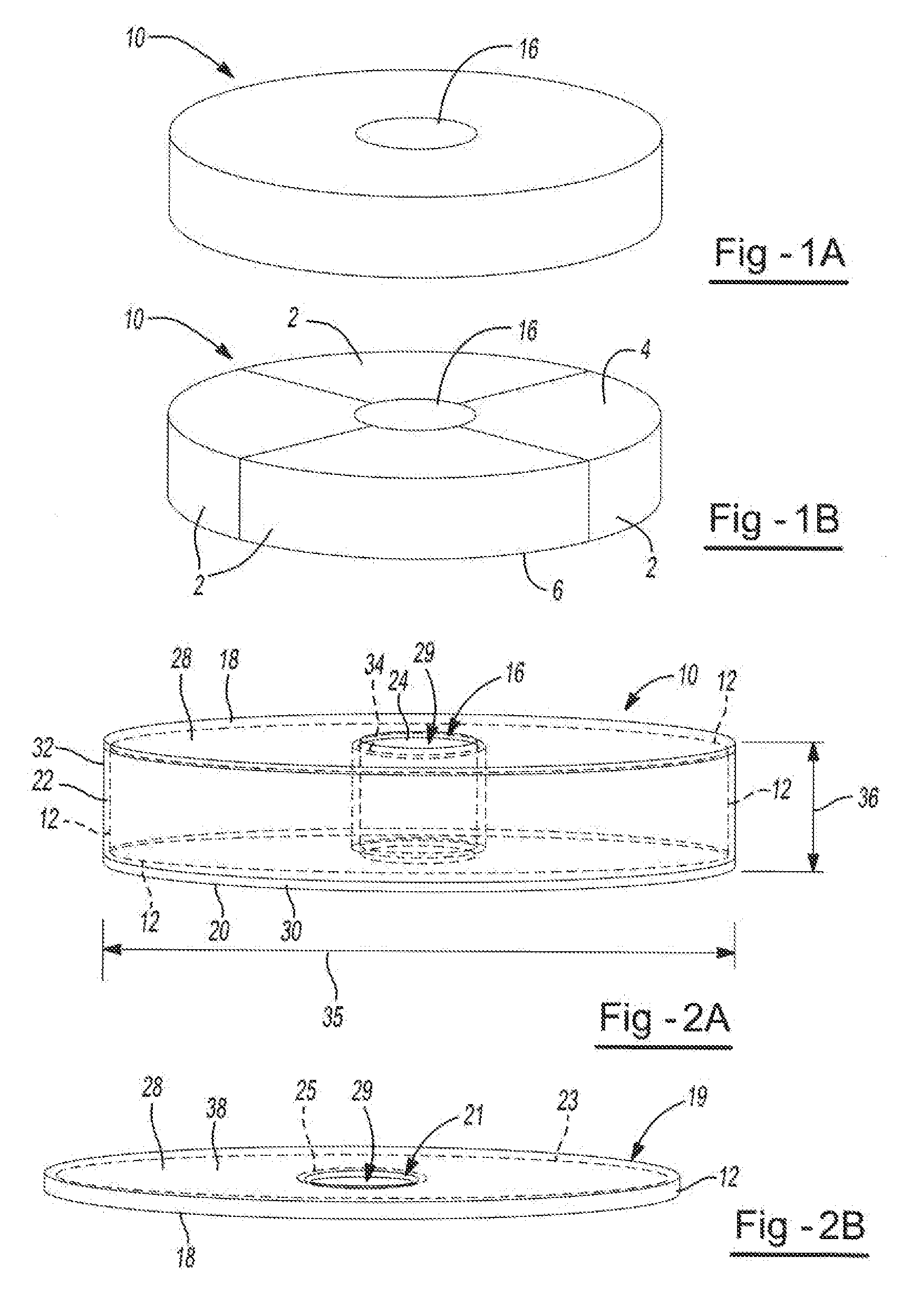

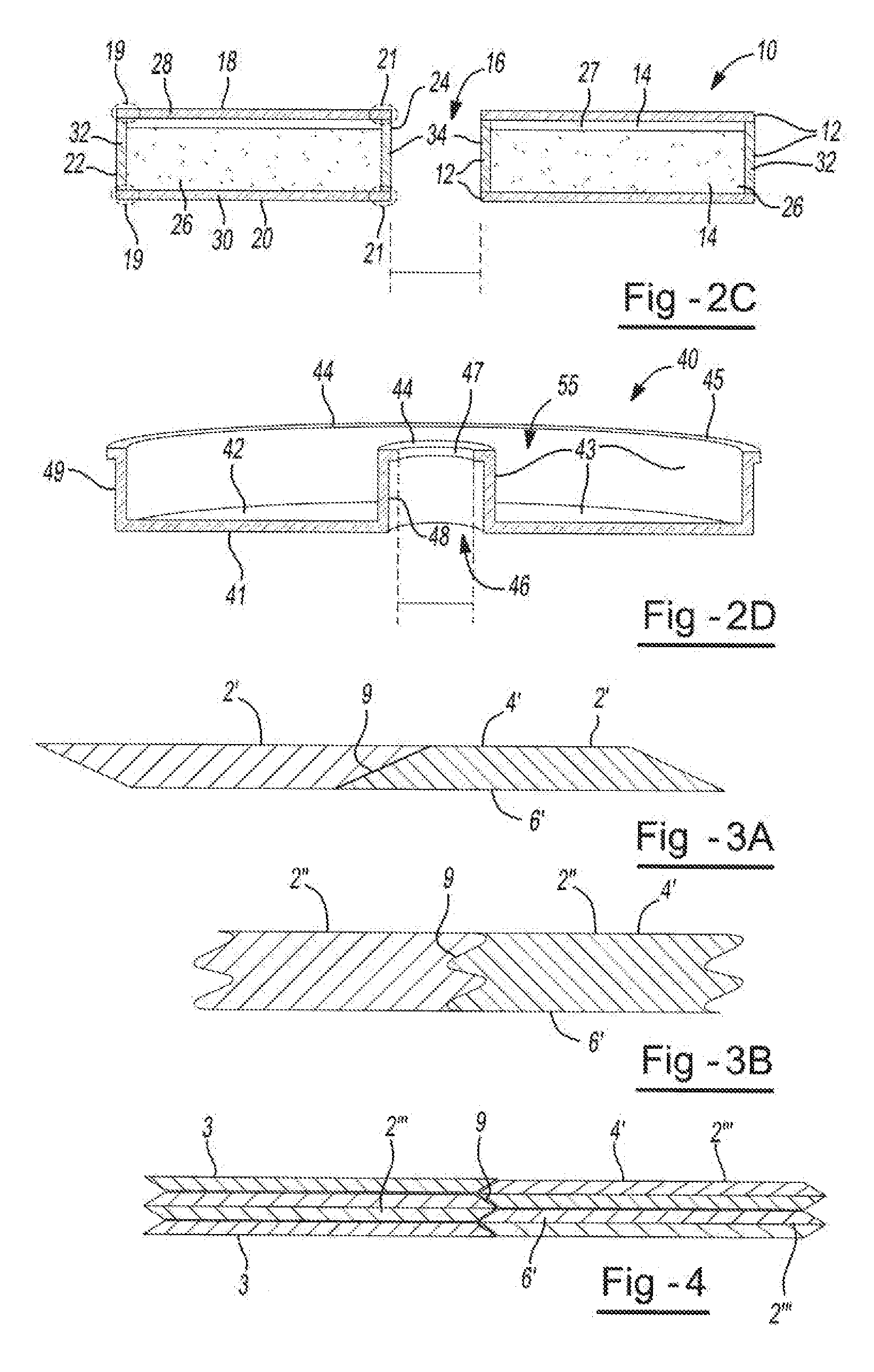

[0036]As will be seen from the teachings herein, the present invention provides unique articles, devices, systems, and process for storing thermal energy and / or transferring stored thermal energy to a fluid. For example, the articles and devices for storing thermal energy of the present invention are more efficient at storing thermal energy, allow for transferring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com