Composite phase-change heat storage material

A technology of phase change materials and phase change heat storage, applied in heat exchange materials, heat storage equipment, indirect heat exchangers, etc., can solve the problems of low thermal conductivity, small heat capacity, poor stability, etc., and achieve high thermal conductivity, The effect of stable performance and stable melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

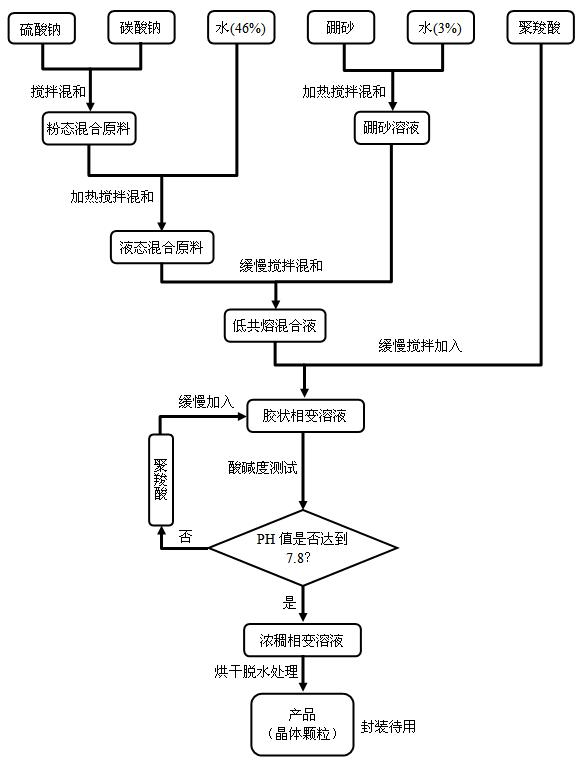

[0051] The present invention is a production technical solution of a product, and the present invention can be implemented through the organic combination of related materials.

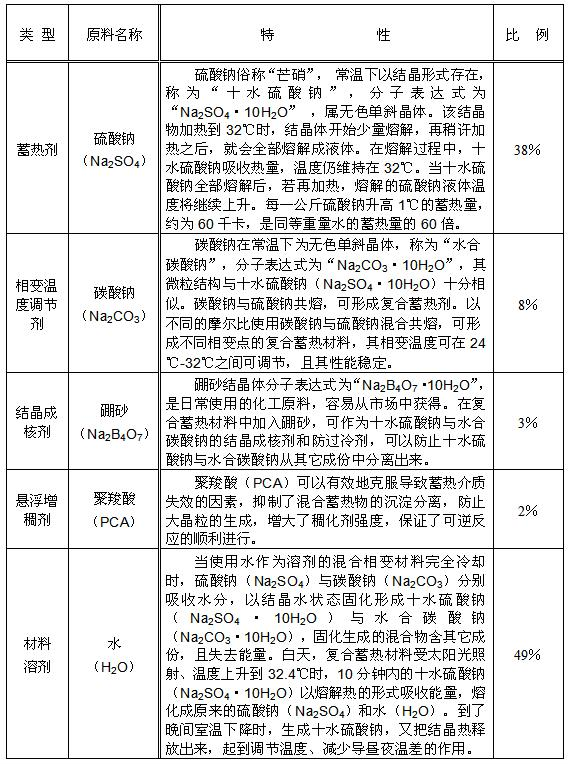

[0052] Components and proportions of the product-related materials of the present invention, such as figure 1 shown.

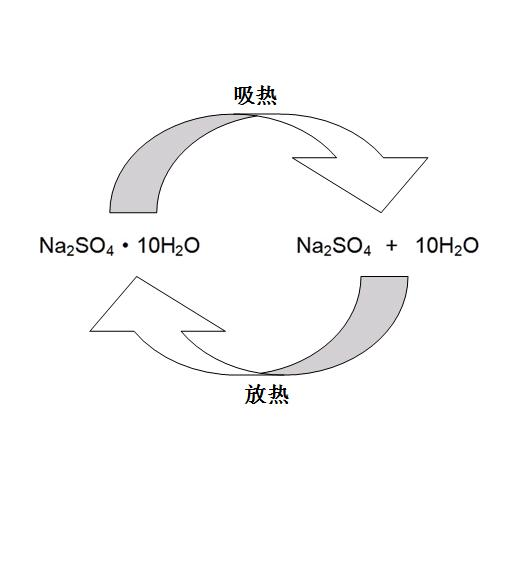

[0053] figure 1 Among them, the product of the present invention is composed of five types of raw materials: heat storage agent, phase change temperature regulator, crystallization nucleating agent, suspension thickener, and solvent. Different types of raw materials use different chemical substances. Among them, the heat storage agent uses Pure sodium sulfate (Na 2 SO 4 ) raw material, the phase change temperature regulator uses pure sodium carbonate (Na 2 CO 3 ) raw materials, pure borax (Na 2 B 4 o 7 ) raw material, polycarboxylic acid (PCA) raw material for suspension thickener, water (H 2 O) raw materials, their weight proportions in the whole product are 38%, 8%, 3%, 2%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com