Production method of vacuum browning-resistant quick-frozen fruit dices

A production method and technology of diced fruit, applied in food freezing, functions of food ingredients, food science, etc., can solve the problems of consuming large water resources, electric energy, heat energy, product hardness and brittleness reduction, and loss of nutritional components, etc., to achieve The effect of saving blanching water, excellent tool material, and reducing processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

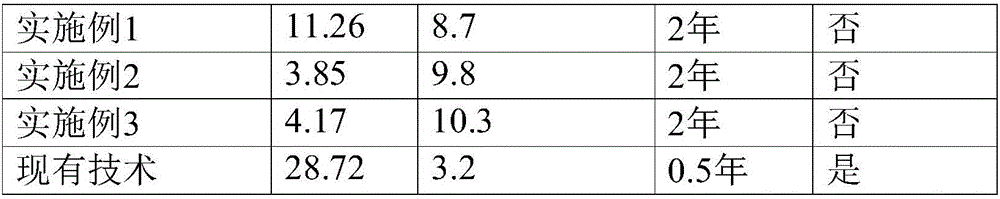

Embodiment 1

[0039] A production method of vacuum anti-browning quick-frozen fruit dices, specifically comprising the steps of:

[0040] (1) Selection of raw materials: select fresh, non-polluting, and pest-free raw materials and place them in a cool place to cool down. Handle and unload raw materials with care, clean the surface of raw materials with clean water in a clear water pool, and discharge waste water;

[0041] (2) soaking: put into the color protection solution that is made up of water, D-sodium erythorbate, citric acid, the volume percentage of D-sodium erythorbate in the color protection solution is 0.3%, and the volume percentage of citric acid is 0.3% %;

[0042] (3) open the petal and dig the core: remove the fruit core;

[0043] (4) Disinfection: put the fruit petals that have been dug into the solution concentration of 50-100ppm for disinfection in D-sodium erythorbate solution, the disinfection time is 1-2 minutes, the concentration critical limit of disinfection proces...

Embodiment 2

[0052] A production method of vacuum anti-browning quick-frozen fruit dices, specifically comprising the steps of:

[0053] (1) Selection of raw materials: select fresh, non-polluting, and pest-free raw materials and place them in a cool place to cool down. Handle and unload raw materials with care, clean the surface of raw materials with clean water in a clear water pool, and discharge waste water;

[0054] (2) soaking: put into the color protection solution that is made up of water, D-sodium erythorbate, citric acid, the volume percentage of D-sodium erythorbate in the color protection solution is 0.4%, and the volume percentage of citric acid is 0.4% %;

[0055] (3) open the petal and dig the core: remove the fruit core;

[0056] (4) Disinfection: Put the cored fruit petals into the D-sodium erythorbate solution with a solution concentration of 50-100ppm for disinfection. The disinfection time is 1-2 minutes. The concentration critical limit of the disinfection process CL:...

Embodiment 3

[0064] A production method of vacuum anti-browning quick-frozen fruit dices, specifically comprising the steps of:

[0065] (1) Selection of raw materials: select fresh, non-polluting, and pest-free raw materials and place them in a cool place to cool down. Handle and unload raw materials with care, clean the surface of raw materials with clean water in a clear water pool, and discharge waste water;

[0066] (2) soaking: put into the color protection solution that is made up of water, D-sodium erythorbate, citric acid, the volume percentage of D-sodium erythorbate in the color protection solution is 0.5%, and the volume percentage of citric acid is 0.5% %;

[0067] (3) open the petal and dig the core: remove the fruit core;

[0068] (4) Disinfection: Put the cored fruit petals into the D-sodium erythorbate solution with a solution concentration of 50-100ppm for disinfection. The disinfection time is 1-2 minutes. The concentration critical limit of the disinfection process CL:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com