Preparation method of organic phase change energy storage material

A technology of energy storage materials and organic phases, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low melting point, large volume change, and low cost of organic matter, and achieve high heat of solution, simple preparation process, and good Use the effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

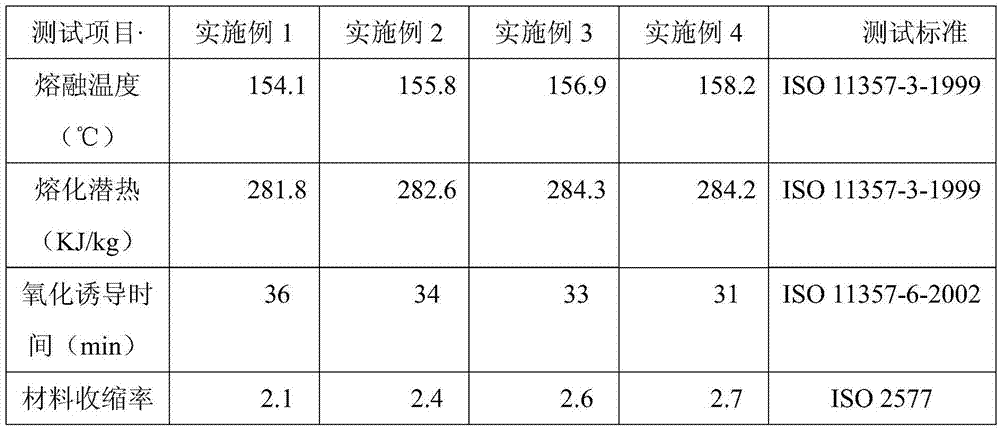

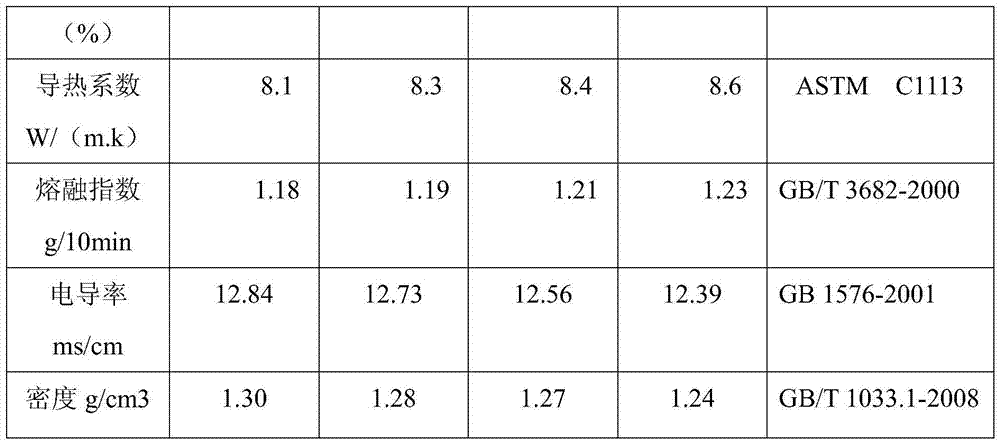

Examples

Embodiment 1

[0020] The organic phase change energy storage material of the present embodiment, its raw material contains the following components by weight: 48 parts of polyethylene (molecular weight: 400,000); 8 parts by weight of paraffin wax (molecular weight: 600); 3 parts by weight of copper powder; 2 parts by weight of aluminum powder Parts by weight; 2 parts by weight of graphite powder.

[0021] Preparation method: take polyethylene, heat and melt, mix with paraffin wax at 145°C for 2 hours, then add graphite powder, aluminum powder, copper powder, and mix for 1 hour to obtain an organic phase change energy storage material.

Embodiment 2

[0023] The high-density phase-change energy storage material of this embodiment, its raw material contains the following components by weight: 46 parts by weight of polyethylene (molecular weight 500,000) paraffin (molecular weight 800) 5 parts by weight; Copper powder 4 parts by weight; Aluminum powder 4 parts by weight Parts by weight; 4 parts by weight of graphite powder.

[0024] Preparation method: take polyethylene, heat and melt, mix with paraffin wax at 145°C for 2 hours, then add graphite powder, aluminum powder, copper powder, and mix for 1 hour to obtain an organic phase change energy storage material.

Embodiment 3

[0026] The high-density phase change energy storage material of this embodiment, its raw material contains the following components by weight: polyethylene (molecular weight 450,000) 45 parts paraffin (molecular weight 700) 6 weight parts; Copper powder 2 weight parts; Aluminum powder 3 parts by weight; 6 parts by weight of graphite powder.

[0027] Preparation method: take polyethylene, heat and melt, mix with paraffin wax at 145°C for 2 hours, then add graphite powder, aluminum powder, copper powder, and mix for 1 hour to obtain an organic phase change energy storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com