Movable heat supplying plant

A heating station and mobile technology, which is applied in the direction of household heating, heating system, space heating and ventilation, etc., can solve the problem of latent heat, sensible heat with low heat storage density, complex heat exchange device, low heat storage density, etc. Problems, to achieve the effect of widely popularizing value and development prospects, small size, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

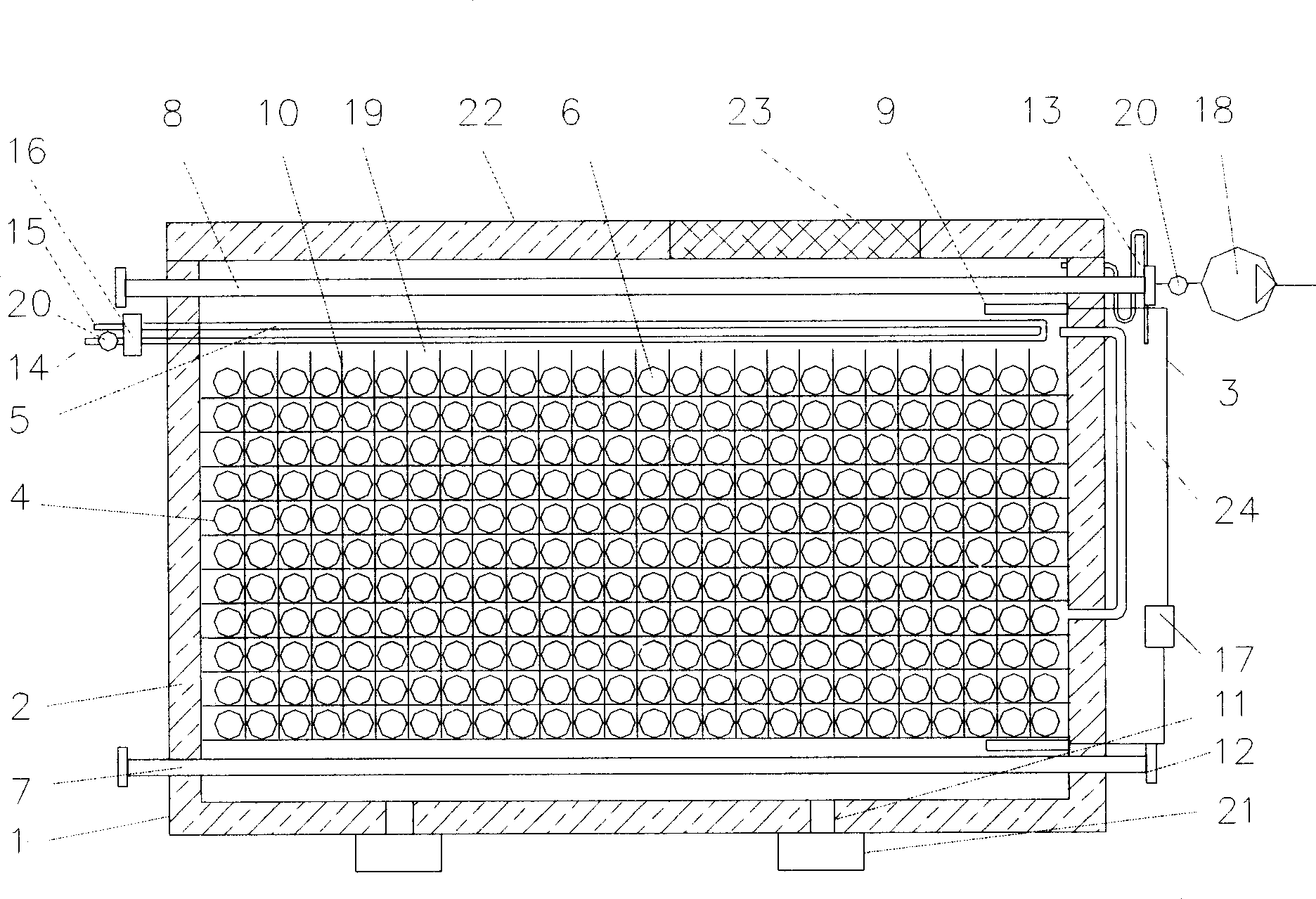

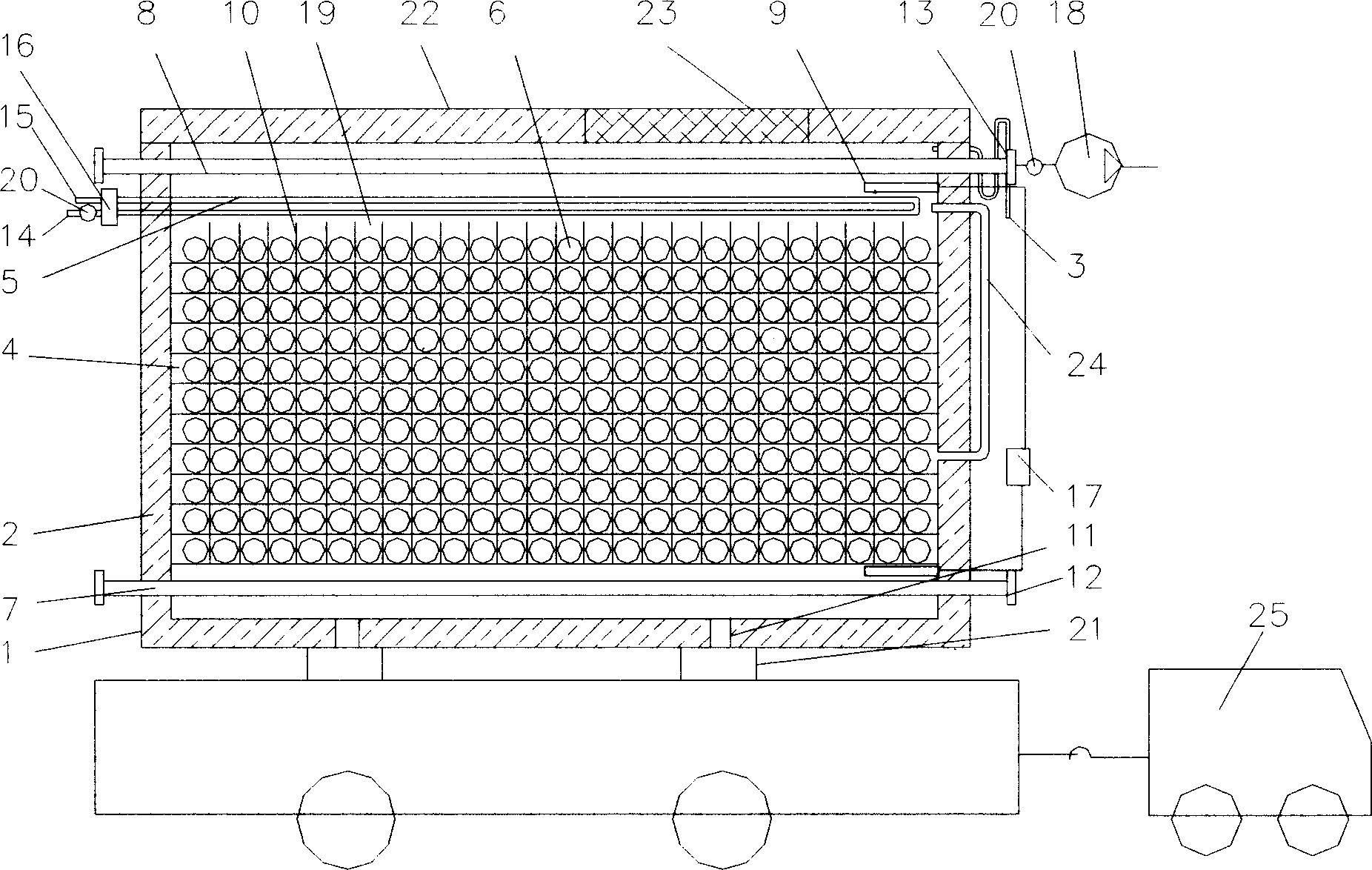

[0046] The present invention can use steam to heat and store heat in a thermal power plant. The outer dimensions of the box body 1 are 5500×2100×1600 mm, and 36 tons of phase change heat storage materials are installed inside. The hot steam enters through the heating distributor 8 in the box body 1 and heats the heat-conducting medium 19 in it. The temperature of the medium continues to rise, and at the same time, heat is transferred to the phase-change heat storage material 6, so that the temperature of the phase-change heat storage material 6 gradually rises. High, store sensible heat before reaching the phase change temperature-melting point, after the phase change heat storage material 6 obtains enough heat, when it reaches the phase change temperature-melting point of 79.4°C, the phase change gradually occurs to store latent heat, and the phase change ends and reaches the set point. When the temperature is fixed, the heat storage process is completed. This process takes ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com