Sodium sulfate decahydrate phase change energy storage material compositions

A material composition, phase change energy storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of not completely solving the problem of delamination, delamination phenomenon, phase change latent heat value attenuation, etc., and achieve excellent Effect of temperature regulation function, high phase transition stability, high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

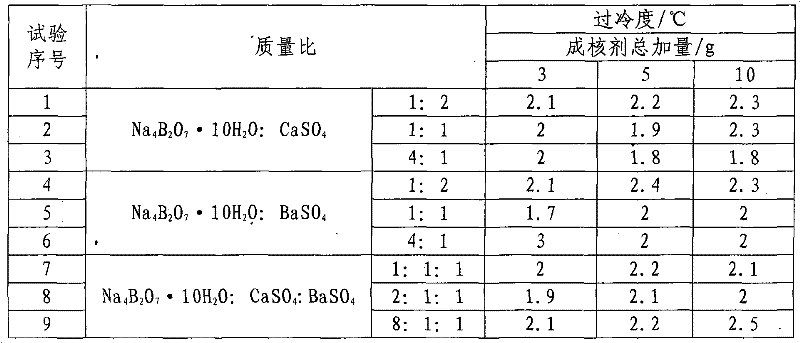

[0022] First take anhydrous Na 2 SO 4 And water molar ratio 1:10 at 40 ℃ temperature conditions to form Na 2 SO 4 Saturated solution and solid Na 2 SO 4 mixture. The nucleating agent composition was respectively dissolved in 100 g of the above mixture at 40° C. with stirring, and the stirring time was 1 hour. According to the T-History test method to test its supercooling degree, the cooling environment is a constant temperature water bath at 25°C. The analysis results are shown in Table 1:

[0023] Table 1 Effect of composition and dosage of nucleating agent on undercooling degree of phase change material

[0024]

Embodiment 2

[0026] Add 360g of water into an airtight container and heat it to 40°C, then add 284g of anhydrous Na 2 SO 4 , 6.44g Na 4 B 2 o 7 10H 2 O, 12.88g CaSO 4 , 3.86gNaBr, 0.32g (NaPO 3 ) 6 After stirring evenly, 26.83g of lithium-based bentonite and 5.37g of carboxymethylcellulose were successively added, and the stirring was continued for 1 hour at 40°C. The phase transition temperature of the obtained mixture was measured to be 31.7° C., the degree of supercooling was 2.5° C., and the latent heat of phase transition was 215.3 kJ / kg. After 3000 times of cold and heat cycle tests, the latent heat value of phase transition was 210.7kJ / kg, and no Na appeared visually when it was higher than the crystallization temperature. 2 SO 4 Substantial settlement.

Embodiment 3

[0028] Add 72g of water into an airtight container and heat it to 40°C, then add 56.8g of anhydrous Na 2 SO 4 , 3.22g Na 4 B 2 o 7 10H 2 O, 3.22g BaSO 4 , 2.58g NaBr, 0.13g (NaPO 3 ) 6 , after stirring evenly, successively add 11.45g of calcium-based bentonite and 1.43g of carboxyethyl cellulose, and continue stirring for 1 hour at 40°C. The phase transition temperature of the obtained mixture was measured to be 31.0° C., the supercooling degree was 2.1° C., and the phase transition latent heat value was 210.3 kJ / kg. After 3000 times of cold and heat cycle tests, the latent heat value of phase transition is 209.7kJ / kg, and no Na appears visually when it is higher than the crystallization temperature. 2 SO 4 Substantial settlement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase change latent heat value | aaaaa | aaaaa |

| Phase change latent heat value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com