Inorganic nonmetal cladding high-temperature phase change heat storage microcapsule and preparation method thereof

An inorganic non-metallic, high-temperature phase change technology, applied in metal processing equipment, chemical instruments and methods, metal material coating technology, etc., can solve the problems of poor acid and alkali resistance and oxidation resistance, unsuitable for corrosion and oxidizing atmosphere , to achieve the effect of high yield, high heat storage density and uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

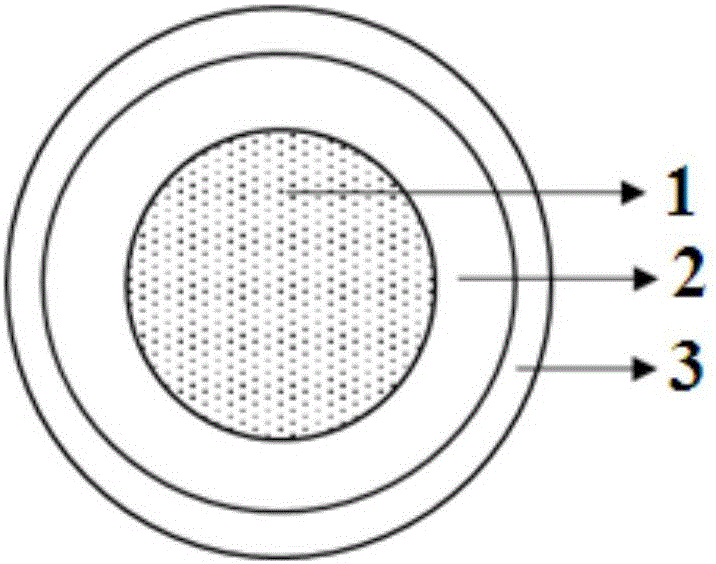

[0031] This embodiment provides an inorganic non-metallic cladding high temperature phase change heat storage microcapsule, its structure is as follows figure 1 As shown, it includes a titanium ball core 1, a loose pyrolytic carbon layer 2 and a dense pyrolytic carbon layer 3, wherein the loose pyrolytic carbon layer 2 surrounds the titanium spherical core 1, and the dense pyrolytic carbon layer 3 surrounds the loose pyrolytic carbon layer. Decarbonization layer 2 is set, and the specific preparation steps include:

[0032] S1, core preparation: choose a titanium ball with a diameter of 800 μm as the core. After being ultrasonically cleaned with acetone, deionized water and ethanol, the titanium ball core 1 was obtained by drying in a drying oven.

[0033] S2, preparation of loose pyrolytic carbon layer: put titanium spherical core 1 in a high-temperature fluidized bed chemical vapor deposition device, wherein the reaction gas is a mixture of acetylene and argon (volume ratio...

Embodiment 2

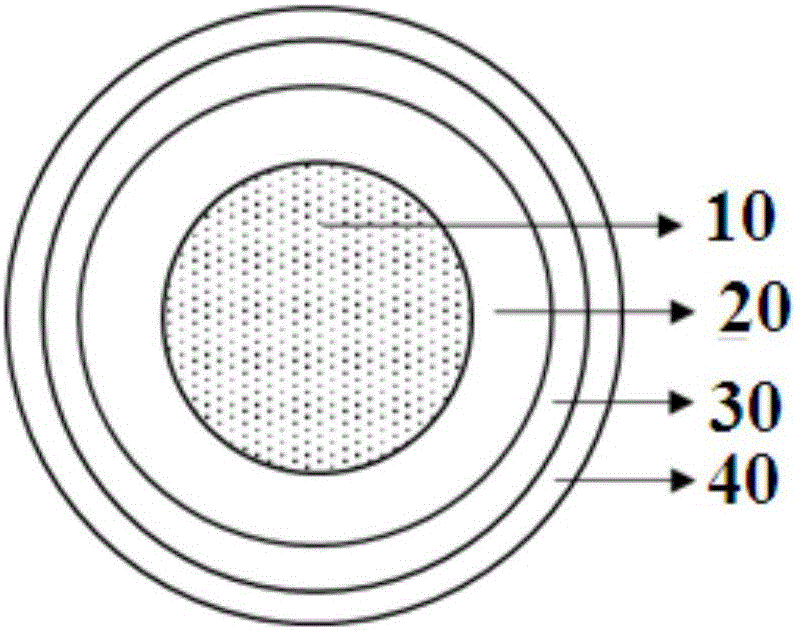

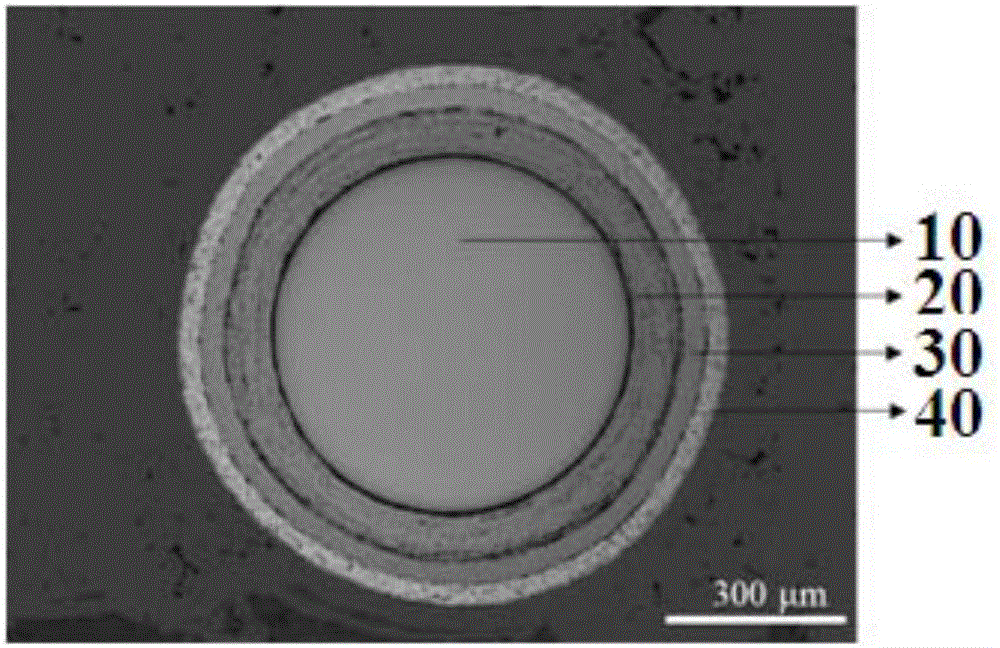

[0037] This embodiment provides another kind of inorganic non-metal cladding high temperature phase change heat storage microcapsules, its structure is as follows: figure 2 The corresponding optical micrographs are shown in image 3 As shown, it includes a copper ball core 10, a loose pyrolytic carbon layer 20, a dense pyrolytic carbon layer 30 and a silicon carbide layer 40, wherein the loose pyrolytic carbon layer 20 surrounds the copper ball core 10, and the dense pyrolytic carbon layer 30 is set around the loose pyrolytic carbon layer 20, and the silicon carbide layer 40 is set around the loose and dense pyrolytic carbon layer 30. The specific preparation steps include:

[0038] S1, core preparation: a copper ball with a diameter of 800 μm is selected as the core. After being ultrasonically cleaned with acetone, deionized water and ethanol, the copper ball core 10 is obtained by drying in a drying oven.

[0039] S2, preparation of loose pyrolytic carbon layer: the coppe...

Embodiment 3

[0044] This embodiment provides yet another inorganic non-metallic cladding high-temperature phase-change heat storage microcapsule, the structure of which includes an iron ball core, a loose pyrolytic carbon layer, a dense pyrolytic carbon layer, a silicon carbide layer and a zinc carbide layer, wherein, The loose pyrolytic carbon layer is set around the iron ball core, the dense pyrolytic carbon layer is set around the loose pyrolytic carbon layer, the silicon carbide layer is set around the loose and dense pyrolytic carbon layer, and the zinc carbide layer is set around the silicon carbide layer. The specific preparation steps include:

[0045] S1, core preparation: select an iron ball with a diameter of 800 μm as the core. After ultrasonic cleaning with acetone, deionized water and ethanol, the iron ball core was obtained by drying in a drying oven.

[0046] S2, preparation of loose pyrolytic carbon layer: the iron ball core is loaded into the high temperature fluidized b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com