Iron ore roasting technique

A roasting process and iron ore technology, applied in the field of iron ore roasting process, can solve the problems of Qijiang iron ore not being mined and used, Qijiang iron ore roasting treatment, etc., achieve good roasting effect and reduce roasting cost , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

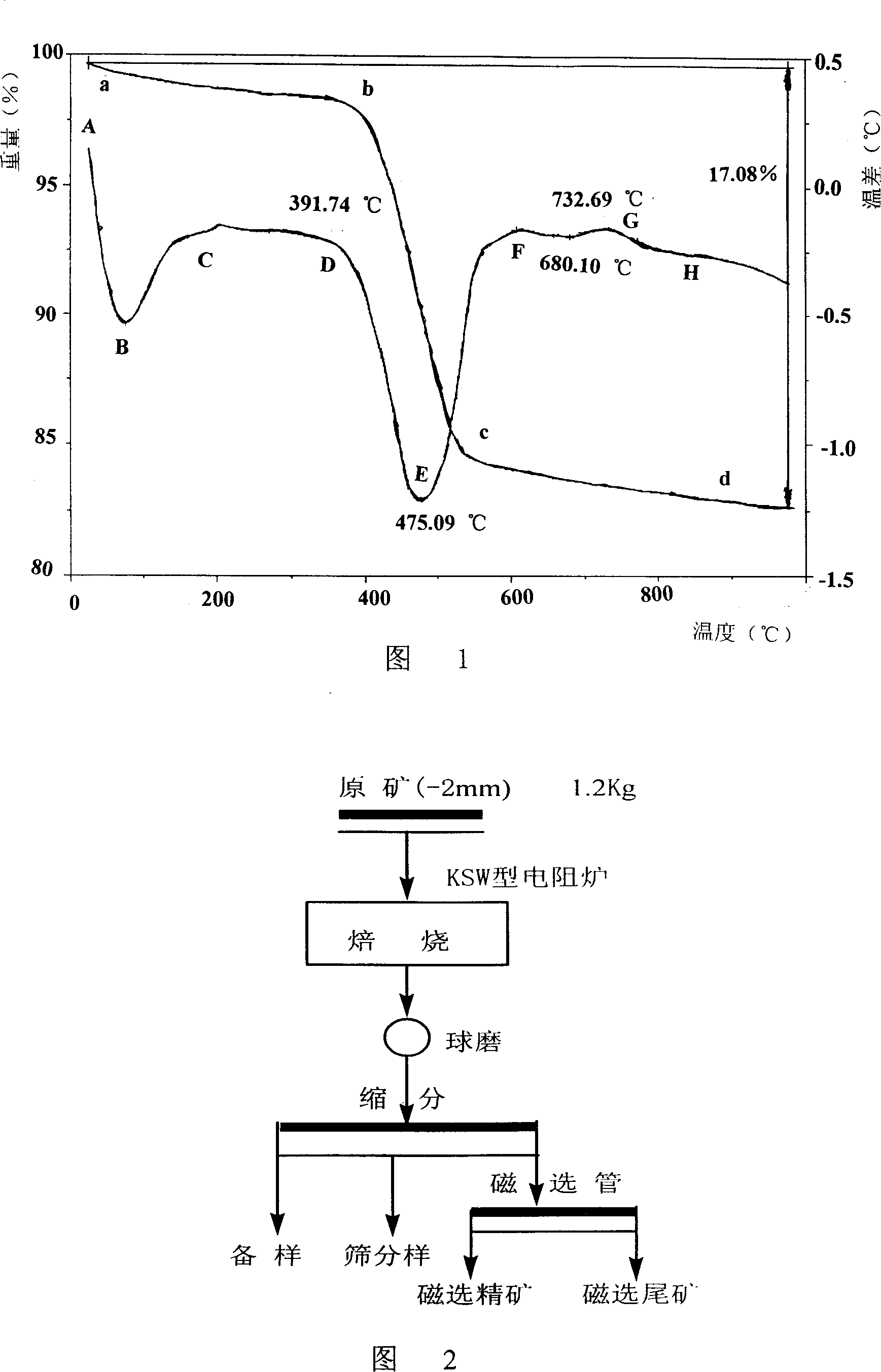

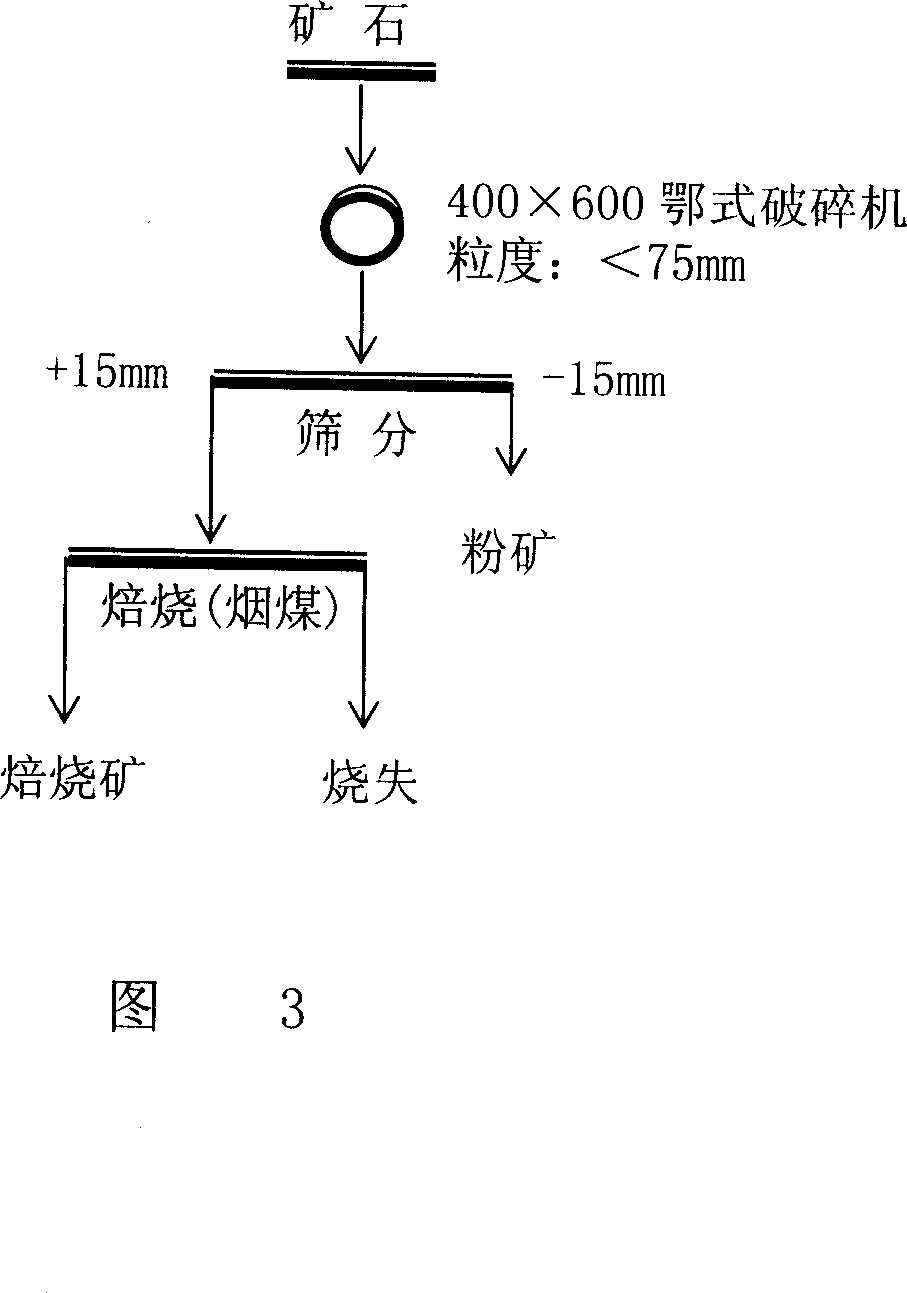

[0037] Embodiment 1, adjust siderite and hematite weight ratio, mix according to the ratio of siderite and hematite weight ratio greater than 1, actual ratio is about 1.1; Weigh -2mm ore 1.2kg, pack into metal container, When the temperature of the resistance furnace rises to the set temperature, put it into the roasting furnace. When the furnace temperature rises to the set temperature, record the roasting time and carry out magnetization roasting. After the set time, take out the container and quickly seal it with water to cool it. After the ore is cooled, grind ore (fineness-0.043mm98.54%) by 50% concentration again, divide the sample, get about 20g small sample and do magnetic separation tube test, check the content of strong magnetic iron minerals in the roasted ore, To test the quality of roasted ore.

[0038] The experimental indicators obtained are as follows:

[0039] Test Index Table (%) Table 1

[0040] temperature(℃)

[0041] Test conclusion: It is feas...

Embodiment 2

[0042] Embodiment 2, (1), take respectively 600 tons of adit samples and 300 tons of Shitan ore samples in a ratio of 2: 1 in the Qijiang Iron Mine Pingdong mining area and Baishitan mining area, a total of 900 tons. The weight ratio of siderite to hematite is about 1.05 to 1.25. After mixing, crushing, and screening to two particle sizes of 75-15mm and 15-0mm, the 75-15mm was put into the furnace for roasting. The iron grade of the ore in the furnace was 41.08%, and the loss on ignition was 21.83%. The ore sample has a good representativeness. Siderite and hematite are mixed, crushed and screened, and processed to two particle sizes of 0-15mm and 15-75mm, and the 15-75mm particle size is put into the roasting furnace. It falls into the heating zone, and enters the cooling zone at the bottom after the decomposition reaction is completed in the heating zone (780°C). It is discharged out of the furnace by the ore discharge roller and the unloading machine and fed into the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com