Process for preparing alloy composite negative electrode material for lithium ion batteries

A lithium-ion battery and negative electrode technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as difficult large-scale production, pollution, difficult to recover surfactants, etc., and achieve simple process, low technical cost, and excellent battery life. The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

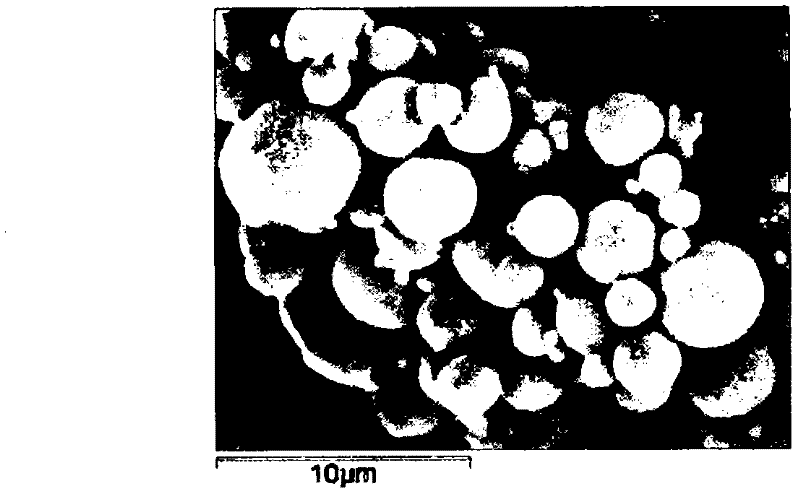

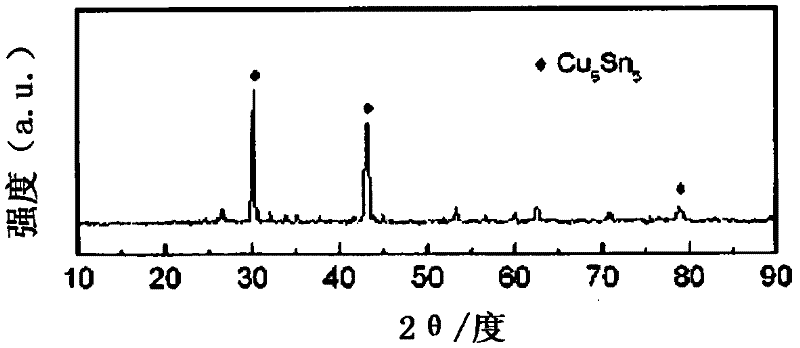

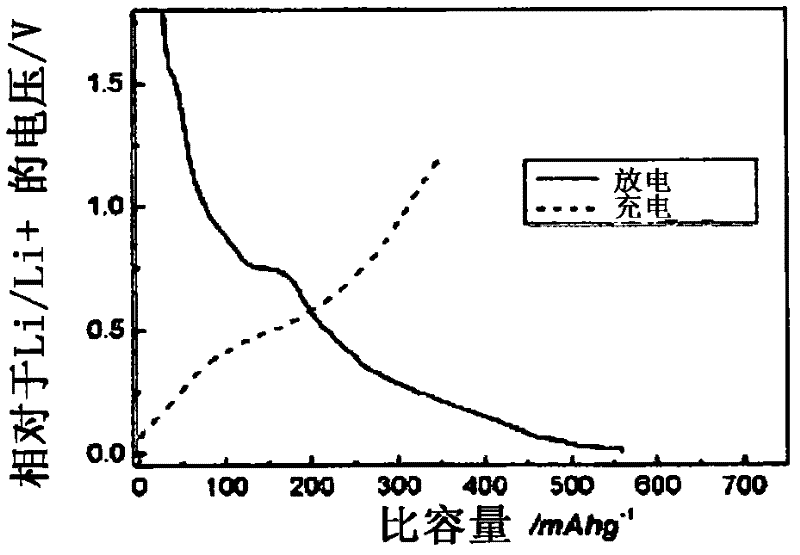

[0044] First, weigh CuO and SnO with a molar ratio of Cu:Sn of 6:5 2 Nano oxide; Then take by weighing 60% water-soluble phenolic resin solution and obtain resin: (CuO+SnO 2 )=5:3 weight ratio; adding deionized water therein to form a 15wt% solution. The resulting solution is dried with an air flow spray dryer, and the raw material solution is loaded with a peristaltic pump at a speed of 15ml / min; the airflow at the atomizing nozzle is controlled by the pressure of the compressed gas so that it is atomized at about 0.4MPa; The temperature at the gas inlet is controlled at 300°C, and the temperature at the outlet is controlled at 130°C; and the gas at the outlet is released after one-stage vortex separation. The metal oxide-embedded phenolic resin obtained by spray drying was calcined at 1000 °C for 5 hours under the protection of high-purity nitrogen to obtain Cu with spherical morphology 6 sn 5 / C composite negative electrode material. figure 1 SEM photos are given; fig...

Embodiment 2

[0054] First, weigh Co with a molar ratio of Co:Sn of 1:2 3 o 4 and SnO 2 Nano oxide; Then take by weighing 60% water-soluble phenolic resin solution and obtain resin: (Co 3 o 4 +SnO 2 )=5:3 weight ratio; and deionized water is added therein to form a 15wt% solution. The resulting solution is dried with an airflow spray dryer, and the raw material solution is loaded with a peristaltic pump at a speed of 15ml / min; the airflow at the atomizing nozzle is controlled by the pressure of the compressed gas so that it is atomized at about 0.4MPa; The temperature at the gas inlet was controlled at 300°C, and the temperature at the outlet was controlled at 120°C; and the gas at the outlet was released after one-stage vortex separation. The powders of tin dioxide and cobalt tetraoxide beads containing phenolic resin obtained by spray drying were calcined at 900 °C for 10 hours under the protection of high-purity nitrogen, and finally obtained CoSn with spherical carbon matrix struct...

Embodiment 3

[0056] First, weigh Sb at a molar ratio of Sb:Sn of 1:1 2 o 3 and SnO 2 Nano oxide; Then take the alcohol-soluble phenolic resin powder and obtain the resin: (Sb 2 o 3 +SnO 2 )=5:1 weight ratio; and ethanol is added therein to form a 20wt% solution. The resulting solution is dried with an airflow spray dryer, and the raw material solution is loaded with a peristaltic pump at a speed of 10ml / min; the airflow at the atomizing nozzle is controlled by the pressure of the compressed gas so that it is atomized at about 0.4MPa; The temperature at the gas inlet was controlled at 300°C, and the temperature at the outlet was controlled at 100°C; and the gas at the outlet was released after one-stage vortex separation. The tin dioxide and antimony trioxide beads powder containing phenolic resin obtained by spray drying were calcined at 800 °C for 10 hours under the protection of high-purity nitrogen, and a SnSb / C composite negative electrode material with a spherical carbon matrix s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com