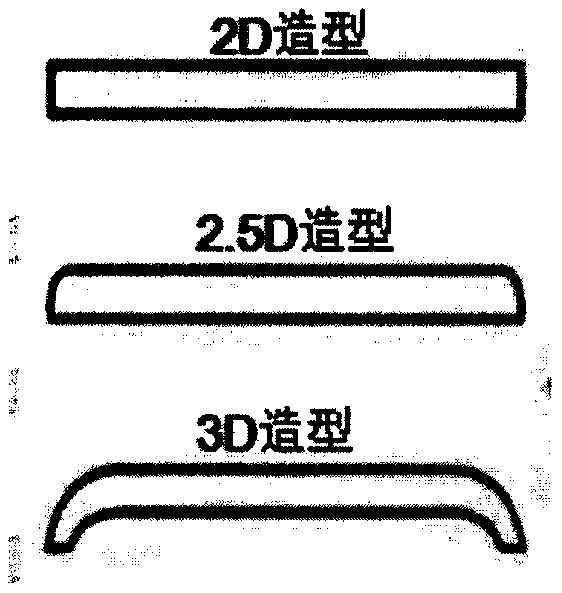

Method and device for strip-shaped glass feeding and mobile phone cover glass on-line 3D compression molding

A technology of compression molding and mobile phone cover, which is applied in glass molding, glass cutting device, glass re-molding, etc., can solve the problems of low production efficiency, low efficiency of 3D cover glass protection glass hot bending and high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

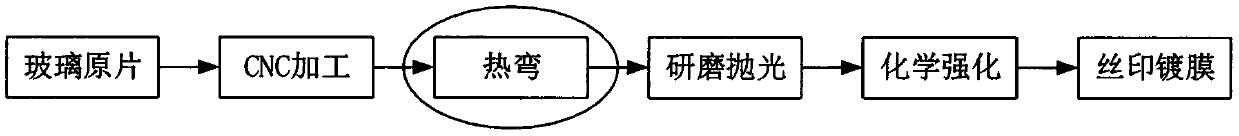

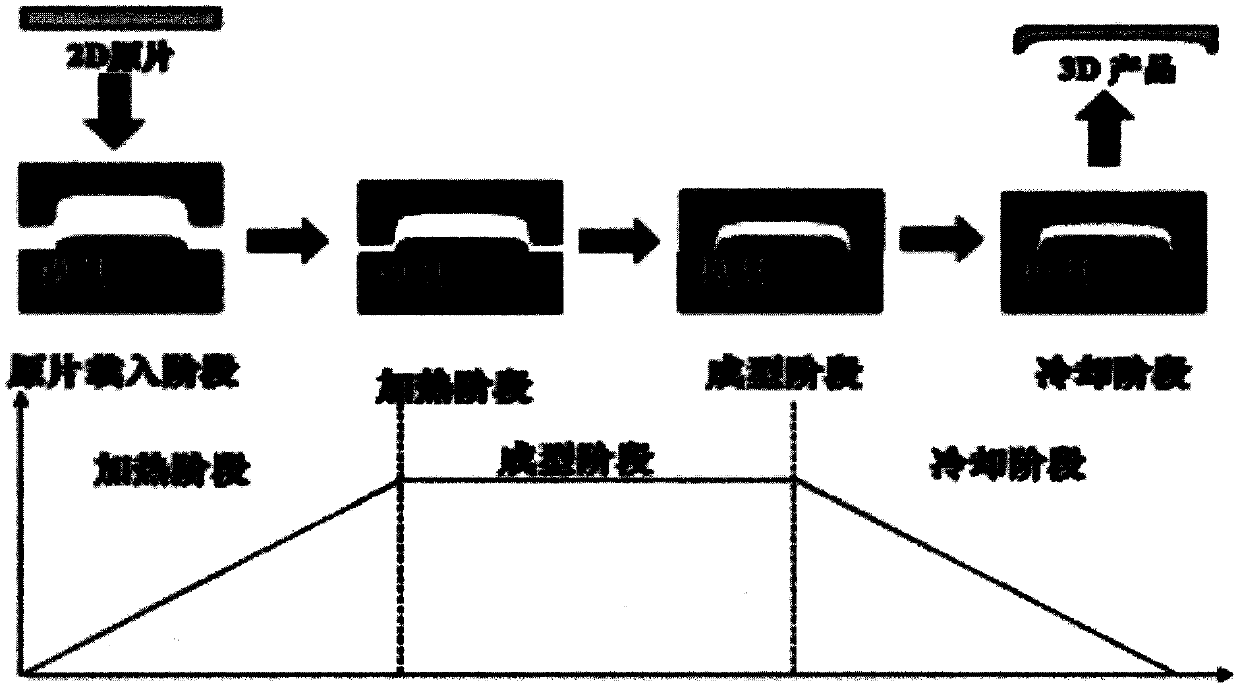

Method used

Image

Examples

Embodiment Construction

[0050] The invention discloses a protective glass for a 3D mobile phone cover plate with a thickness of 0.6-1.5mm, which can cover the size specification of 5-7 hours, and can also be extended down to 0.5 hours according to needs, and can be extended upward to produce 18 hours. , and even larger curved 3D screens for cars, ships, aviation, aerospace, media machines, etc.

[0051] The melting system is used to realize the melting, clarification and homogenization of cover glass batch materials, and to provide qualified glass melt for forming. 2-2.5 dPa.s. The melting system includes glass raw material 1 and glass melting furnace 2 . Glass raw material 1 is various mineral raw materials, chemical raw materials, clarifying agents and auxiliary agents that constitute the chemical composition of the protective glass of the mobile phone cover, such as quartz sand, alumina, soda ash, magnesium oxide, potassium carbonate, etc. The glass melting furnace 2 includes, but is not limited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com