Method for improving iron content and reducing sulfur content by direct reduction of carbon-containing pellets in rotary hearth furnace

A rotary hearth furnace, a direct technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of sulfur reduction, high sulfur content in products, and addition of sulfur reducing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The method for the direct reduction of carbon-containing pellet rotary hearth furnace of the present invention to raise iron and reduce sulfur, its preferred embodiment is:

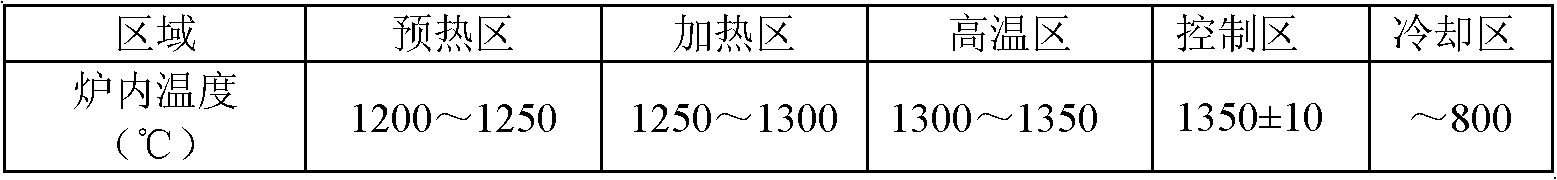

[0012] Mix 64-84 parts by weight of iron oxide scale, 19-25 parts of semi-coke, 4-10 parts of limestone, and 9-11 parts of composite binder, press balls, dry, and spread in the rotary hearth furnace Internal reduction at 1200-1400 °C, the atmosphere in the rotary hearth furnace is a neutral atmosphere or a weakly reducing atmosphere, and the reduction time is 25-45 minutes;

[0013] After the reduction product is cooled, the metal particles are separated from the sulfur-rich gangue or slag by fine grinding and magnetic separation.

[0014] Said iron oxide scale: it is produced during forging and hot rolling of steel, with a particle size of ≤3mm.

[0015] In the semi-coke or semi-coking coal: fixed carbon ≥ 78% by weight, ash content ≤ 10% by weight, volatile matter ≤ 8% by weight, S ≤ 0.50% by we...

specific Embodiment

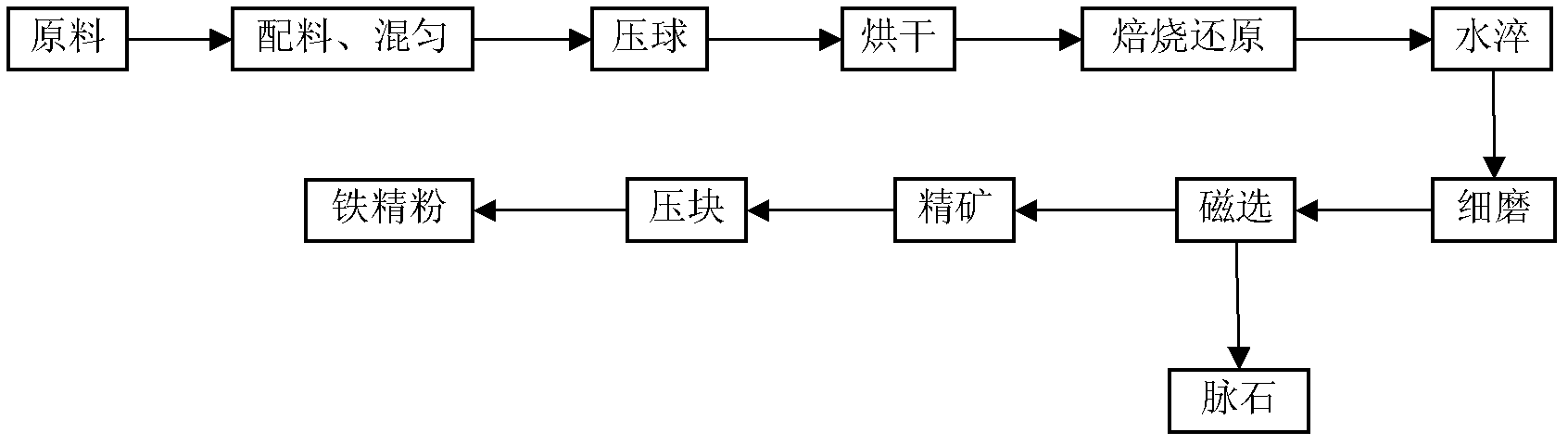

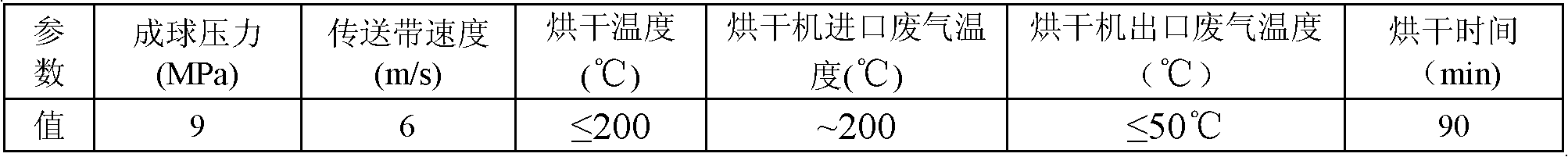

[0022] Schematic diagram of the method for direct reduction of iron, iron, and sulfur reduction in a carbon-containing pellet rotary hearth furnace—— figure 1 Among them, the raw materials include powdered iron oxide scale, semi-coke powder, powdered limestone particles, and the composite binder is composed of solid bentonite and PVA solution. The quality requirements of each raw material are: powdered iron oxide scale particle size ≤ 3mm; fixed carbon of blue charcoal powder ≥ 78wt%, ash content ≤ 10wt% volatile matter ≤ 8wt%, S ≤ 0.50wt%, particle size ≤ 2mm and particle content greater than 70wt% ; CaO ≥ 55wt% of limestone, SiO ≤ 3wt%, particle size ≤ 0.074mm and particle content greater than 70wt%; the solid bentonite content of the composite binder is 30wt%, and the PVA solution content is 70wt%, wherein the concentration of PVA is 5-7wt%. The operating points of the batching and mixing process: dry mix all solid powders on the mixer for 5 minutes according to the determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com