Manufacturing method for multi-layer ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, etc., can solve the problems of reduced effective positive area, extreme degree, and decreased capacitance of capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

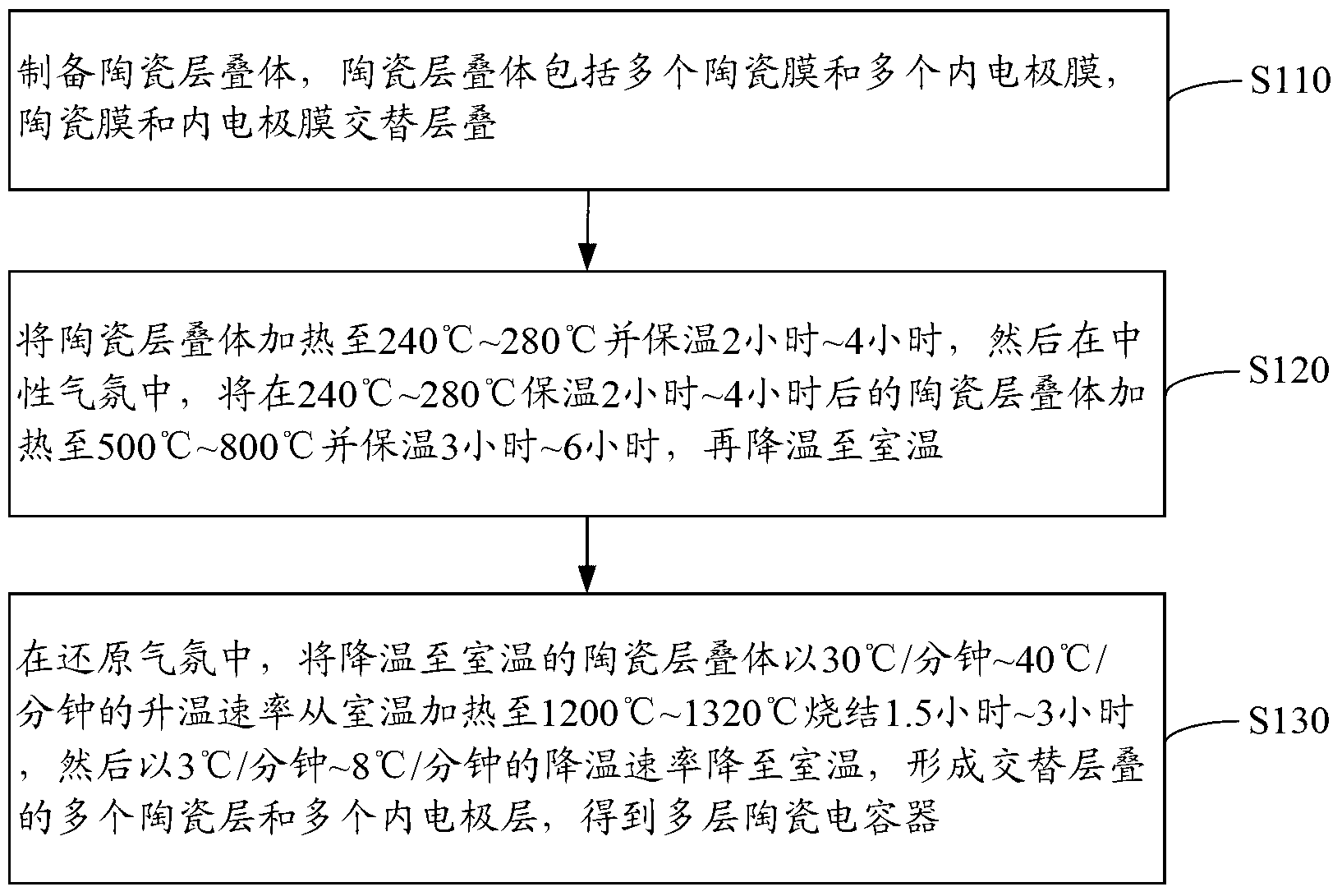

[0048] Fabrication of Multilayer Ceramic Capacitors

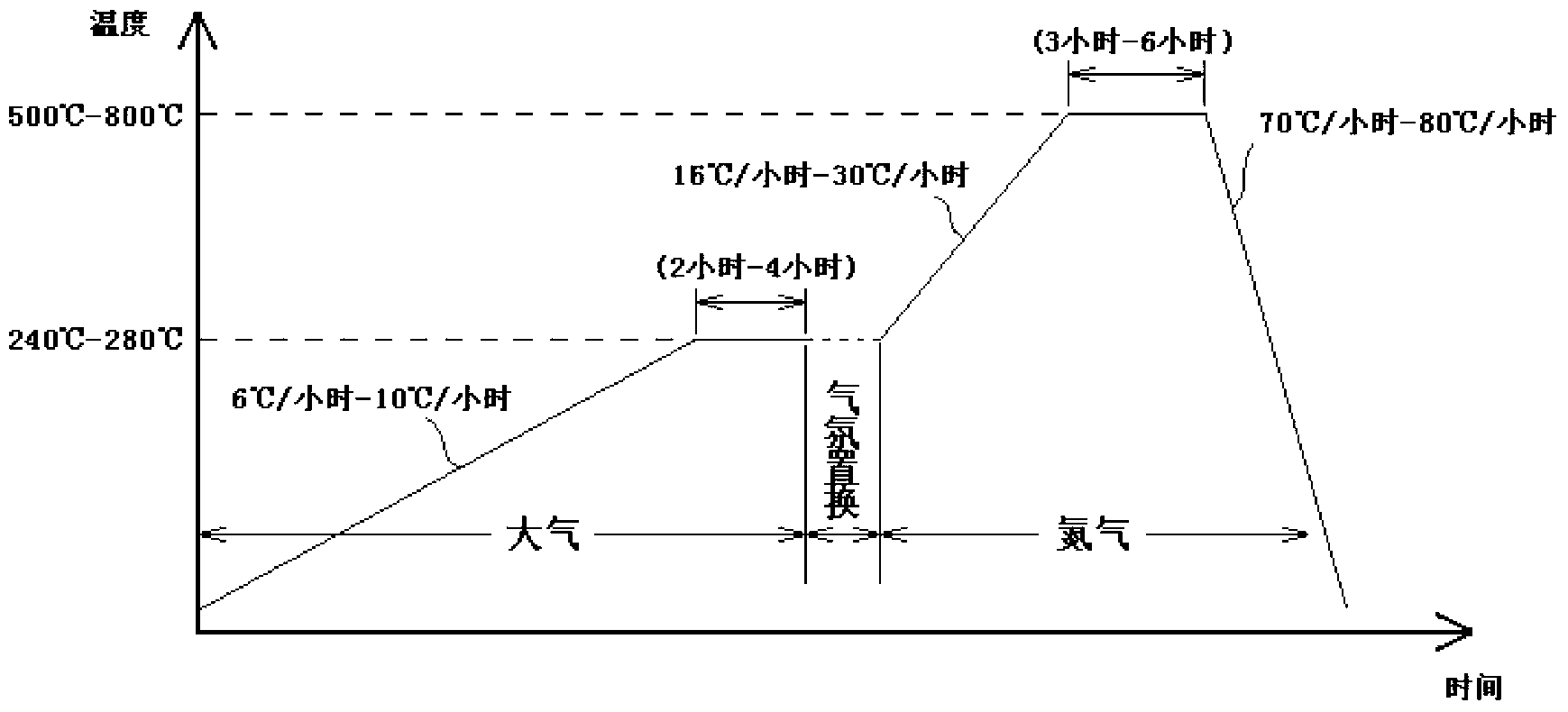

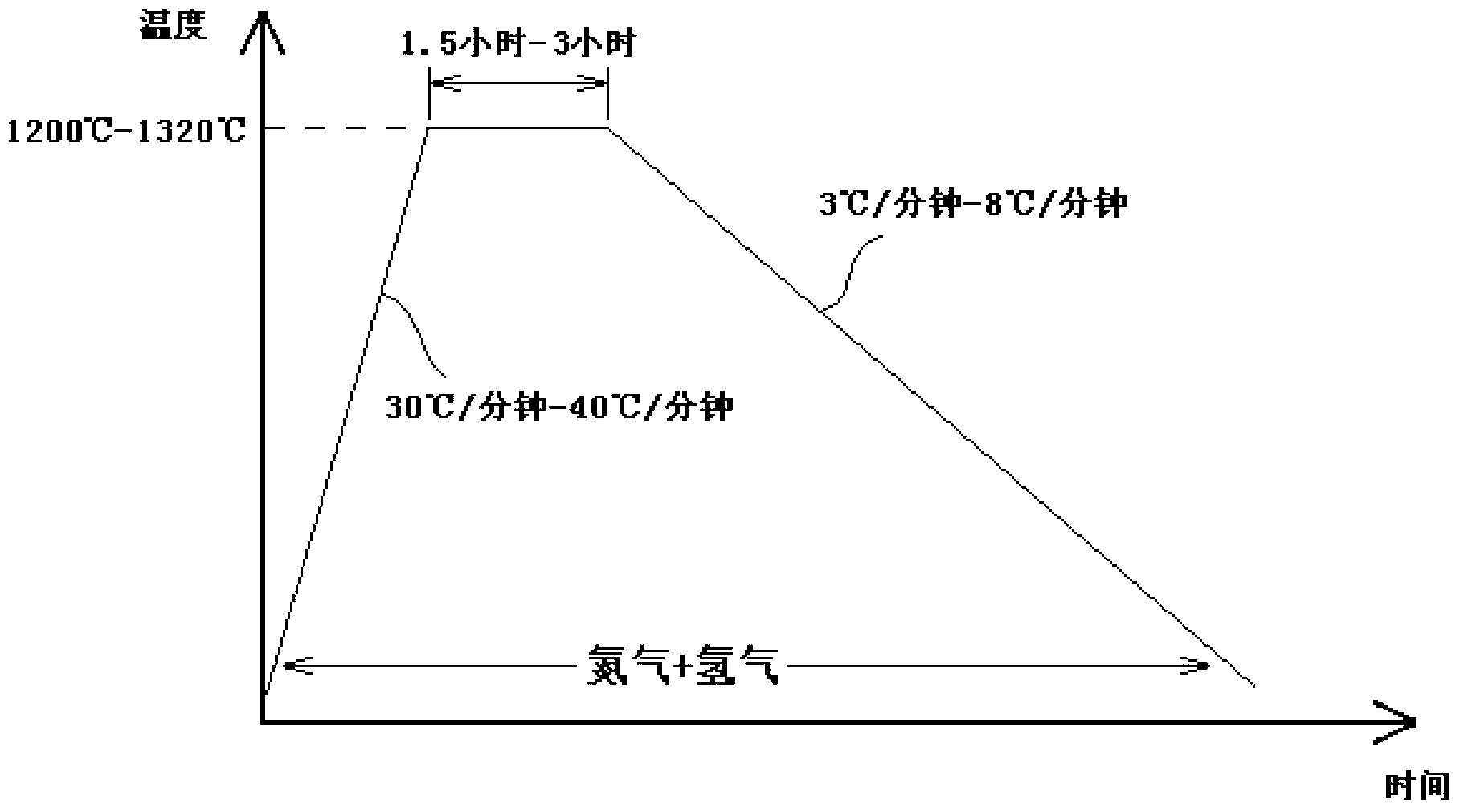

[0049] 1. Ball mill the barium titanate ceramic powder, polyvinyl butyral, toluene and ethanol in a volume ratio of 2:1 to obtain a ceramic slurry, and then cast the ceramic slurry to form ceramic film, and then use the screen printing process to print the nickel internal electrode paste on the ceramic film to form a predetermined internal electrode pattern, and dry it at 70°C to form the internal electrode film, and obtain a ceramic film laminated with the internal electrode film. After obtaining a plurality of ceramic films laminated with internal electrode films, the multiple ceramic films laminated with internal electrode films are laminated and hot-pressed to form a ceramic laminate substrate, and finally the ceramic laminate substrate is cut vertically and horizontally according to a predetermined size to obtain a ceramic laminate, The ceramic laminate includes multiple ceramic films and multiple internal electrode fi...

Embodiment 2

[0058] Fabrication of Multilayer Ceramic Capacitors

[0059] 1. Ball mill the barium titanate ceramic powder, polyvinyl butyral, toluene and ethanol in a mixed solvent with a volume ratio of 1.5:1 to obtain a ceramic slurry, and cast the ceramic slurry to form ceramic film, and then use the screen printing process to print the nickel internal electrode paste on the ceramic film to form a predetermined internal electrode pattern, and dry it at 60°C to form the internal electrode film to obtain a ceramic film laminated with the internal electrode film. After obtaining a plurality of ceramic films laminated with internal electrode films, the multiple ceramic films laminated with internal electrode films are laminated and hot-pressed to form a ceramic laminate substrate, and finally the ceramic laminate substrate is cut vertically and horizontally according to a predetermined size to obtain a ceramic laminate, The ceramic laminate includes multiple ceramic films and multiple inter...

Embodiment 3

[0068] Fabrication of Multilayer Ceramic Capacitors

[0069] 1. Ball mill the barium titanate ceramic powder, polyvinyl butyral, toluene and ethanol in a volume ratio of 1:1 to obtain a ceramic slurry, and then cast the ceramic slurry to form ceramic film, and then use the screen printing process to print the nickel internal electrode paste on the ceramic film to form a predetermined internal electrode pattern, and dry it at 80°C to form the internal electrode film, and obtain a ceramic film laminated with the internal electrode film. After obtaining a plurality of ceramic films laminated with internal electrode films, the multiple ceramic films laminated with internal electrode films are laminated and hot-pressed to form a ceramic laminate substrate, and finally the ceramic laminate substrate is cut vertically and horizontally according to a predetermined size to obtain a ceramic laminate, The ceramic laminate includes multiple ceramic films and multiple internal electrode fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com