Preparation method of nodular cast iron-bronze composite material for cylinder body of plunger pump

A technology of ductile iron and composite materials, which is applied in the field of preparation of ductile iron-bronze composite materials, can solve the problems of large interface bonding strength and small thermal stress gradient, and achieve the effect of improving the interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

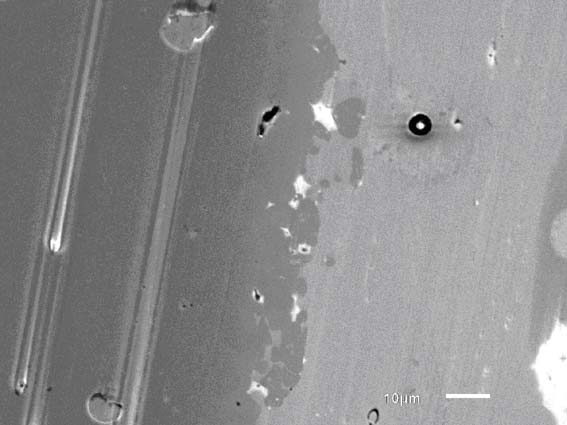

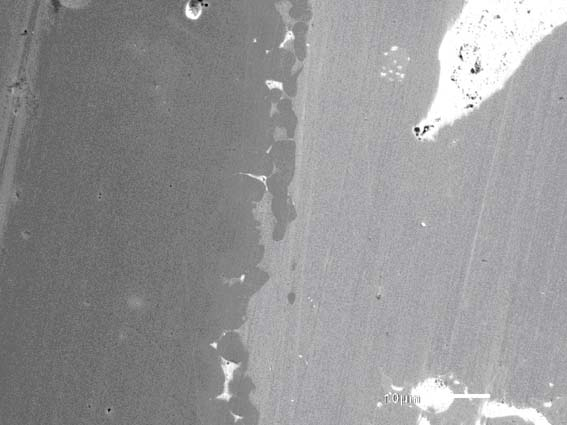

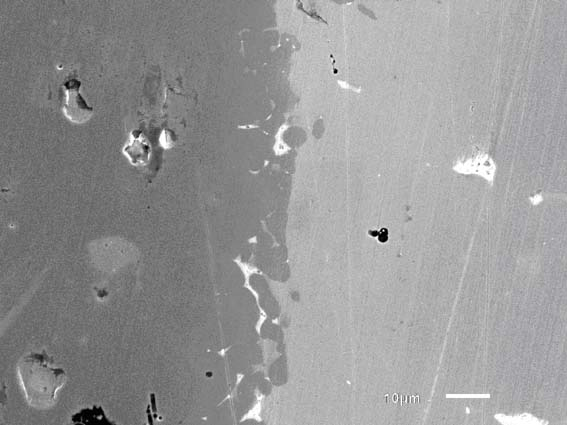

Image

Examples

Embodiment 1

[0026] Embodiment 1, a method for preparing a nodular cast iron-bronze composite material for a plunger pump cylinder, the manufacturing steps are:

[0027] Ductile iron surface treatment

[0028] First, use water sandpaper to polish the surface of graphite cast iron, then pickle with 10% H2SO4 and 2% HF mixture for 30 seconds, rinse with hot water for 15 minutes, then wash with 5% NaOH solution for 30 minutes, and then rinse with hot water for 15 minutes. Minutes to remove rust and oil on the surface of ductile iron as much as possible.

[0029] Ductile iron electroplated nickel

[0030] The electroplating solution was prepared with nickel sulfate as the main salt. The composition of the plating solution was NiSO4·6H2O: 330 g / l, NiCl·6H2O: 45 g / l, H3BO3: 37 g / l, H2O2: 0.5 ml / l, and placed in a water bath Heating to about 60°C, then using high-purity graphite rod as anode and ductile iron as cathode, control the current density at about 5A / dm2 for 10 minutes, and the t...

Embodiment 2

[0037] Embodiment 2, a method for preparing a nodular cast iron-bronze composite material for a plunger pump cylinder, the manufacturing steps are:

[0038] Ductile iron surface treatment

[0039] First, use water sandpaper to polish the surface of graphite cast iron, then pickle with 10% H2SO4 and 2% HF mixture for 30 seconds, rinse with hot water for 15 minutes, then wash with 5% NaOH solution for 30 minutes, and then rinse with hot water for 15 minutes. Minutes to remove rust and oil on the surface of ductile iron as much as possible.

[0040] Ductile iron electroplated nickel

[0041] Prepare the electroplating solution with nickel sulfamate as the main salt. The components of the plating solution are Ni(NH2SO3)2: 340 g / l, NiCl2 6H2O: 40 g / l, H3BO3: 40 g / l, C12H25SO4Na: 0.1g / l, And heat it to about 50°C in a water bath, then use the nickel plate as the anode and the ductile iron as the cathode, and control the current density at about 5A / dm2 for 20 minutes, and the...

Embodiment 3

[0048] Embodiment 3, a method for preparing a nodular cast iron-bronze composite material for a plunger pump cylinder, the manufacturing steps are:

[0049] Ductile iron surface treatment

[0050] First, use water sandpaper to polish the surface of graphite cast iron, then pickle with 10% H2SO4 and 2% HF mixture for 30 seconds, rinse with hot water for 15 minutes, then wash with 5% NaOH solution for 30 minutes, and then rinse with hot water for 15 minutes. Minutes to remove rust and oil on the surface of ductile iron as much as possible.

[0051] Ductile iron electroplated nickel

[0052] Prepare the electroplating solution with nickel chloride as the main salt. The composition of the plating solution is NiCl2 6H2O: 300 g / l, H3BO3: 30 g / l, NaCl: 10 g / l, C12H25SO4Na: 0.1g / l, and in a water bath Heat to about 70°C, then use the nickel plate as the anode and the ductile iron as the cathode, control the current density to about 5A / dm2 for 50 minutes, and the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com