Device and method for preparing metal matrix composite by adopting high-pressure gas to assist infiltration

A composite material and high-pressure gas technology, which is applied in the field of metal matrix composite material preparation devices, can solve the adverse effects of violent disturbance of metal liquid on the distribution of the second phase, affecting the stability and reliability of composite material parts, and the overflow and splash of matrix metal liquid and other issues, to achieve the effect of near-net shape, strong repeatability and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

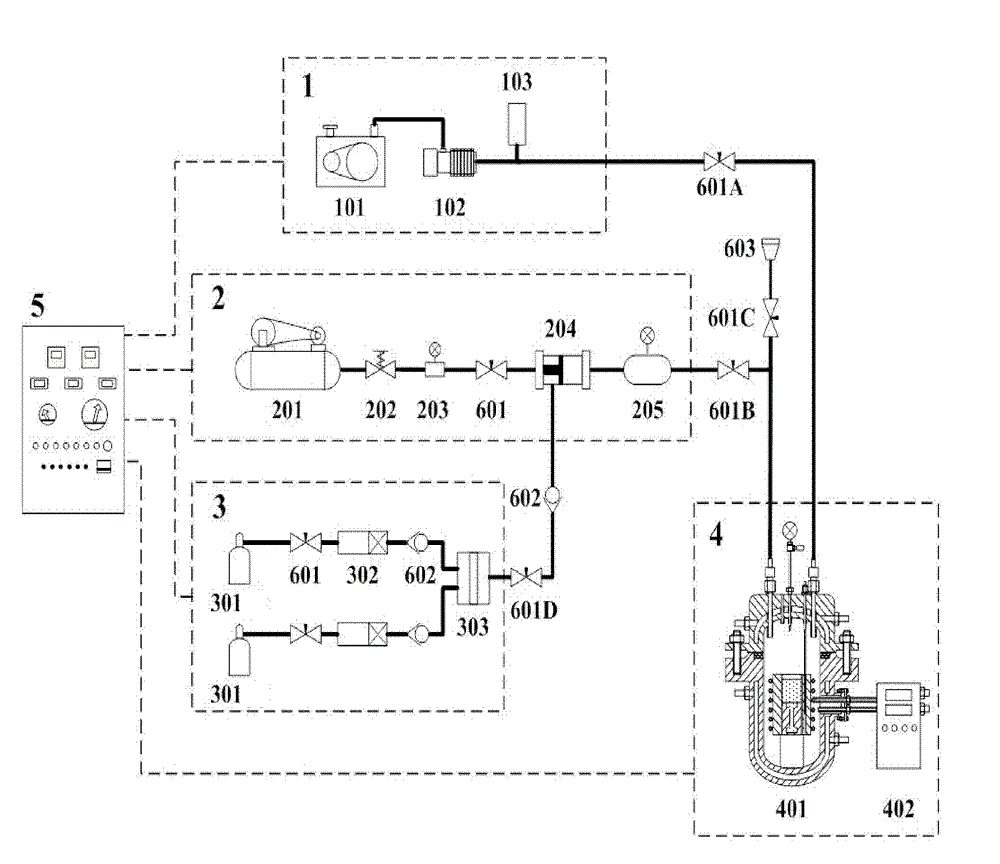

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of Al / Diamond composite material, the second phase Diamond particle size is 150 μm, the matrix metal is pure Al, preparation conditions: high-purity Ar in pressurized gas, temperature 800 O C, air pressure 0.55 MPa, heat preservation and pressure holding for 30 minutes.

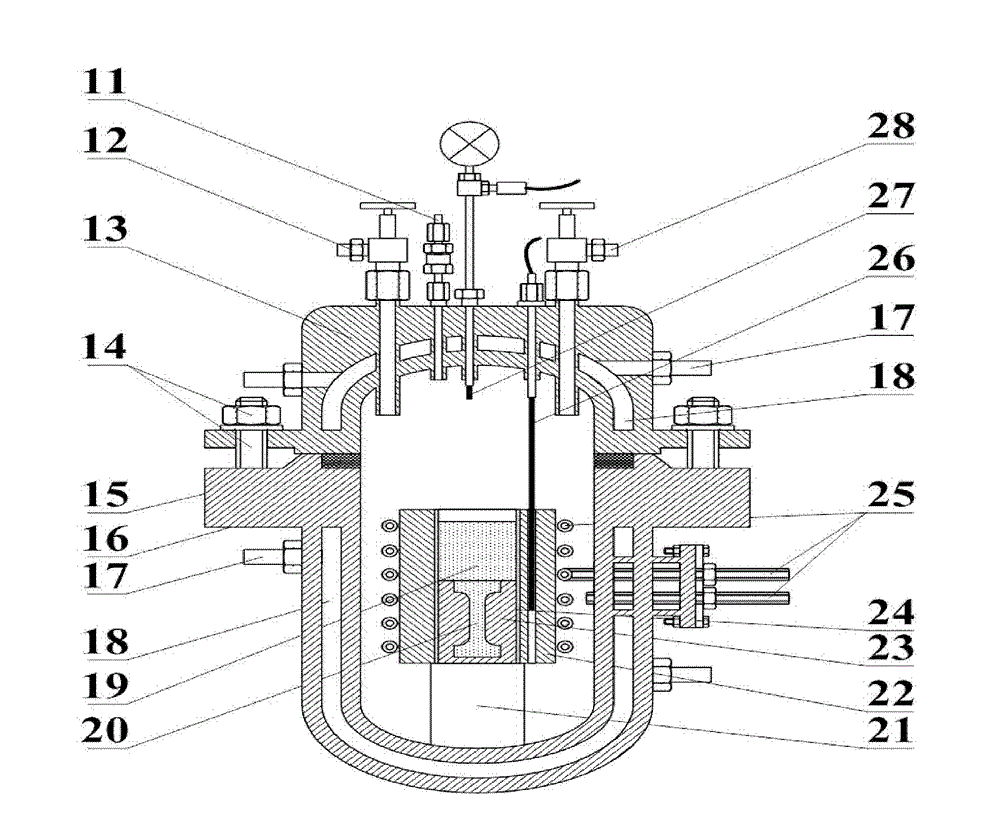

[0045] When this embodiment is applied, refer to figure 2 , the second phase Diamond particles 20 are filled in the mold 21, the filled mold is assembled with the jacket 24 and the graphite sleeve 22, the base metal aluminum 19 is placed on the upper part of the mold, and the mold equipment is completed, the whole set of mold Installed in the heating area of the induction coil 25; cover the furnace cover 13, place the temperature sensor 26 in the temperature measuring hole of the mold, and install the fastening device 14; connect the vacuum system with the vacuum valve port 28, and the pressurization and inflation system with the inflation / exhaust The valve port 12 is connect...

Embodiment 2

[0046] Example 2: Preparation of Cu / Diamond composite material, the second phase Diamond particle size is 25 μm, the matrix metal is pure Cu, preparation conditions: pressure gas 94 vol.% Ar+6 vol.% H 2 , temperature 800 O C, air pressure 3.0 MPa, heat preservation and pressure holding for 30 minutes.

[0047] The preparation process of this embodiment and embodiment 1 is basically the same, the difference is that the pressure gas adopts Ar and H 2 The mixed gas, the mixed gas composition ratio is 94 vol.% Ar+6 vol.% H 2 , so the mixing process is to open the Ar cylinder and H 2 For gas cylinders, the flow rates of the two gas paths are set to 4.70 SCM and 0.30 SCM respectively; the induction heating temperature is set to 1250 O C, the holding time is 20 min; the actual preparation pressure is 3.00 MPa, and the holding time is 10 min; under these process conditions, high-quality Cu / Diamond composite parts can be successfully prepared.

Embodiment 3

[0048] Embodiment 3: preparation Mg / SiC p Composite material, second phase SiC particle size 59 μm, matrix metal pure Mg, preparation conditions: pressure gas 99 vol.% N 2 +1 vol.% SF 6 , temperature 750 O C, air pressure 5.00 MPa, heat preservation and pressure holding for 10 minutes.

[0049] The preparation process of this example is basically the same as that of Example 1, except that the second phase filling method is SiC prepared by powder injection molding method. p Prefabricated parts; pressure gas adopts N 2 and SF 6 The mixed gas, the mixed gas composition ratio is 99 vol.% N 2 +1 vol.% SF 6 , so the aeration process is open N 2Cylinders and SF 6 For gas cylinders, the flow rates of the two gas paths are set to 4.95 SCM and 0.05 SCM respectively; the induction heating temperature is set to 750 O C, the holding time is 20 min; the actual preparation pressure is 5.00 MPa, and the holding time is 10 min; high-quality Mg / SiC can be successfully prepared under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com