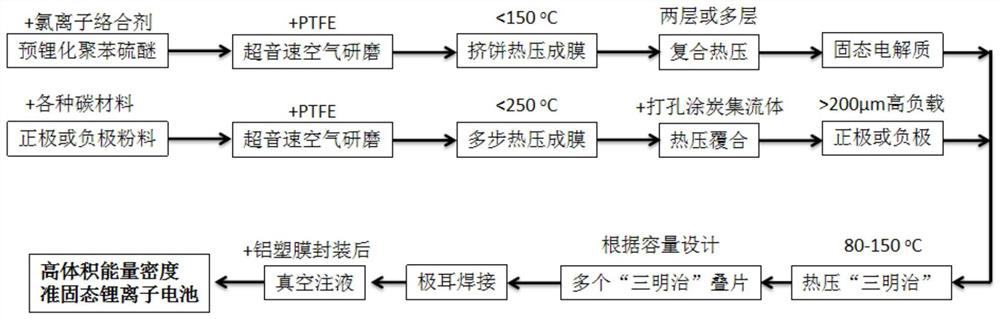

High-safety high-volume-energy-density quasi-solid-state lithium-ion battery and manufacturing method thereof

A lithium-ion battery and energy density technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, and final product manufacturing. Problems such as chip manufacturing, to achieve the effect of excellent practicability, large load capacity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Preparation of pre-lithiated polyphenylene sulfide film with high lithium solid solubility:

[0069] N-methylpyrrolidone (NMP), lithium sulfide Li 2S. Lithium hydroxide LiOH, according to the material ratio of 3:1:0.1, placed in a high-pressure reactor with stirring function, and heated to 200°C for high temperature dehydration for 4 hours to obtain a dehydration system; secondly, cool the dehydration system To 100°C, add 1,4-dichlorobenzene (p-DCB), same as Li 2 The molar ratio of S to substance is 1:1. It reacted at 220 degreeC for 130 minutes, and obtained the mixed slurry. Again, drop quantitative hydrochloric acid in the mixed slurry, the amount of HCl and LiOH is the same, just neutralize LiOH, and use evaporation or sublimation to remove NMP and H in the mixed slurry B 2 O, NMP and H in the mixed slurry 2 O, to obtain dry mixed powder. In the mixed powder, add calixarone, the amount of which is 0.17 of that of p-DCB, stir evenly, put it in a closed react...

Embodiment 2

[0075] (1) Preparation of pre-lithiated polyphenylene sulfide film with high lithium solid solubility:

[0076] N-methylpyrrolidone (NMP), lithium sulfide Li 2 S, Lithium hydroxide Li(OH), according to the molar ratio of the substances is 4:1:0.15, placed in a high-pressure reactor with stirring function, and heated to 200 ° C for high temperature dehydration for 4 hours to obtain a dehydration system; secondly, the Cool the dehydration system to 100°C, add 1,4-dichlorobenzene (p-DCB), same as Li 2 The substance ratio of S is 1:1.2. It reacted at 220 degreeC for 130 minutes, and obtained the mixed slurry. Again, drop quantitative hydrochloric acid in the mixed slurry, the amount of HCl and LiOH is the same, just neutralize LiOH, and use evaporation or sublimation to remove NMP and H in the mixed slurry 2 O, NMP and H in the mixed slurry 2 O, to obtain dry mixed powder. Add caliximidazole to the mixed powder, the amount of which is 0.05 of that of p-DCB, stir evenly, place...

Embodiment 3

[0082] (1) Preparation of pre-lithiated polyphenylene sulfide film with high lithium solid solubility:

[0083] N-methylpyrrolidone (NMP), lithium sulfide Li 2 S. Lithium hydroxide Li(OH), according to the molar ratio of the substances is 5:1:0.18, placed in a high-pressure reactor with a stirring function, and heated to 200 ° C for high temperature dehydration for 4 hours to obtain a dehydration system; secondly, the Cool the dehydration system to 100°C, add 1,4-dichlorobenzene (p-DCB), same as Li 2 The substance ratio of S is 1:0.9. It reacted at 220 degreeC for 130 minutes, and obtained the mixed slurry. Again, drop quantitative hydrochloric acid in the mixed slurry, the amount of HCl and LiOH is the same, just neutralize LiOH, and use evaporation or sublimation to remove NMP and H in the mixed slurry 2 O, NMP and H in the mixed slurry 2 O, to obtain dry mixed powder. In the mixed powder, add cuppyrrole, the amount of which is 0.2 of that of p-DCB, stir evenly, place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com