Jetting rolling equipment and method of application of jetting rolling equipment to aluminum alloy plate strip preparing process

A rolling equipment and secondary rolling technology are applied in the development of sheet metal manufacturing equipment and applications to achieve the effects of fast solidification, excellent formability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A silicon-aluminum alloy with a silicon content of 27% is prepared by spray rolling technology, and the specific process and parameters are as follows:

[0055] 1) The silicon content in the alloy is 27%, and the balance is aluminum.

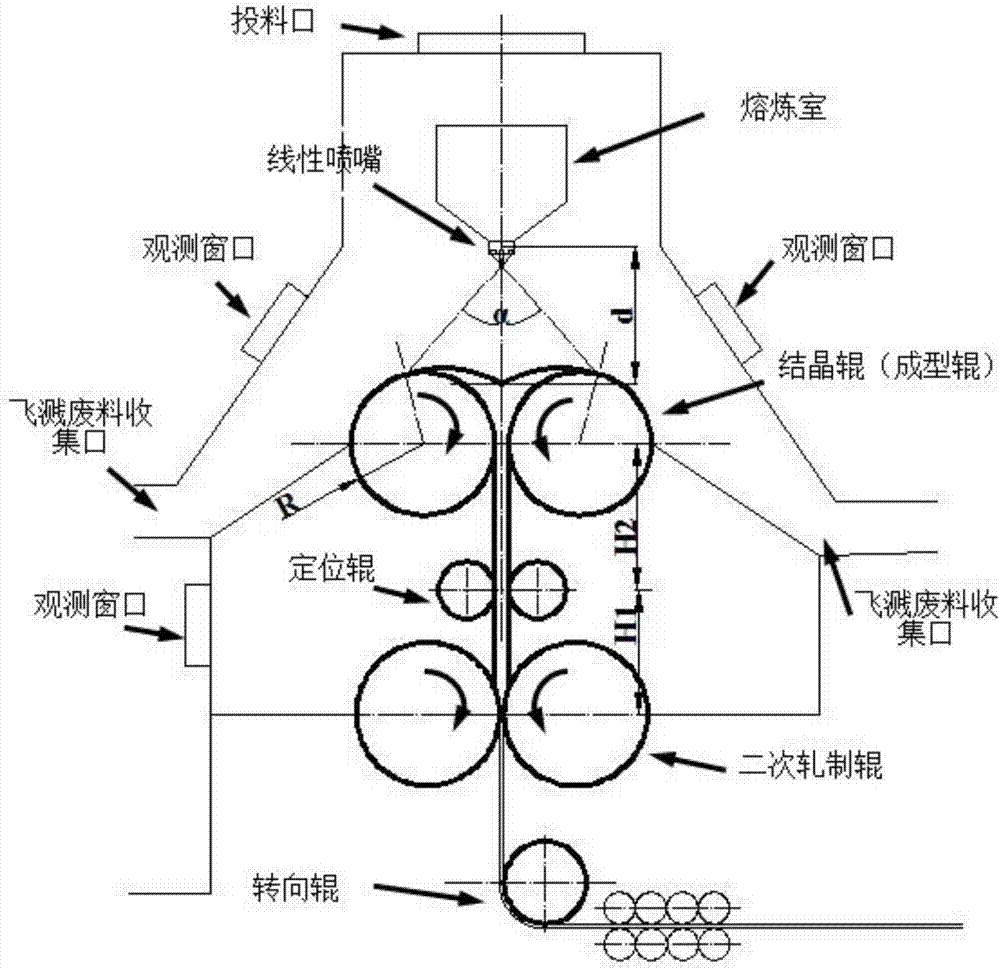

[0056] 2) As attached figure 1 As shown, a linear nozzle is set above the vertical height of the two counter-rotating crystallization rollers (also forming rollers) with a vertical height of 550mm. Above the linear nozzle is the melting chamber. Solid state, deposited on the crystallization roller after flying for a certain distance, due to the continuous impact of the atomized metal, the semi-solid particles stick to each other, and bite into the crystallization roller with the rotation of the crystallization roller, and the metal layer is further densified to form a plate with a certain thickness; crystallization A pair of positioning rolls is set at a vertical distance of 650mm directly below the roll gap, which is used to accurately ...

Embodiment 2

[0068] The 7055 aluminum alloy was prepared by spray rolling technology. The specific process and parameters are as follows:

[0069] 1) The contents of zinc, magnesium, copper and zirconium in the alloy are 8.5%, 2.2%, 2.5% and 0.2% respectively, and the balance is aluminum.

[0070] 2) As attached figure 1As shown, a linear nozzle is set above the vertical height of the two counter-rotating crystallization rollers (also forming rollers) with a vertical height of 550 mm. Above the linear nozzle is a melting chamber. After the alloy raw material is smelted, the molten metal is atomized into a semi-solid state through the nozzle. , deposited on the crystallization roller after flying for a certain distance, due to the continuous impact of the atomized metal, the semi-solid particles stick to each other, and bite into the crystallization roller with the rotation of the crystallization roller, and the metal layer is further densified to form a plate with a certain thickness; the ...

Embodiment 3

[0082] The 2024 aluminum alloy was prepared by spray rolling technology. The specific process and parameters are as follows:

[0083] 1) The contents of copper, magnesium, manganese and silicon in the alloy are 4.9%, 1.8%, 0.9% and 0.5% respectively, and the balance is aluminum.

[0084] 2) As attached figure 1 As shown, a linear nozzle is set above the vertical height of the two counter-rotating crystallization rollers (also forming rollers) with a vertical height of 550 mm. Above the linear nozzle is a melting chamber. After the alloy raw material is smelted, the molten metal is atomized into a semi-solid state through the nozzle. , deposited on the crystallization roller after flying for a certain distance, due to the continuous impact of the atomized metal, the semi-solid particles stick to each other, and bite into the crystallization roller with the rotation of the crystallization roller, and the metal layer is further densified to form a plate with a certain thickness; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com