Control method for regulating camber plate shape of outlet of finishing mill

A control method and camber bending technology, applied in metal rolling, profile control, metal rolling and other directions, can solve the problems of high rolling speed, difficult to observe, difficult to produce, etc., achieve good shape, improve labor efficiency, adjust immediate effect

Inactive Publication Date: 2017-01-04

BAOSHAN IRON & STEEL CO LTD

View PDF9 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When rolling thick-gauge steel strip, the thickness of the finished strip is thicker, and the slight "sickle" is difficult to observe; when the thickness of the finished strip is thinner, the rolling speed is faster, and when the "sickle" is observed and adjusted It will also cause shape defects at a certain distance. Therefore, in the above two cases, it is easy to miss the adjustment of the shape at the first time, which brings certain difficulties to the production of the next process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

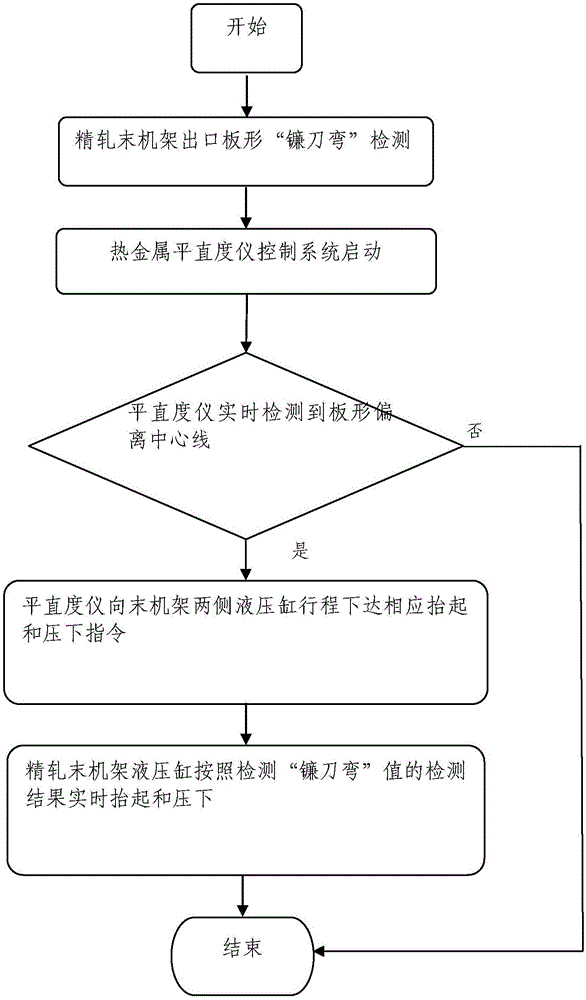

[0037] The present invention automatically adjusts the roll gap of the finish rolling mill in real time according to the deviation of the strip steel center line at the outlet of the last stand of the finish rolling mill, and further improves the control technology of the "sickle".

[0038] A method for controlling the shape adjustment of "sickle bend" at the exit of a finishing mill, the specific steps are as follows,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

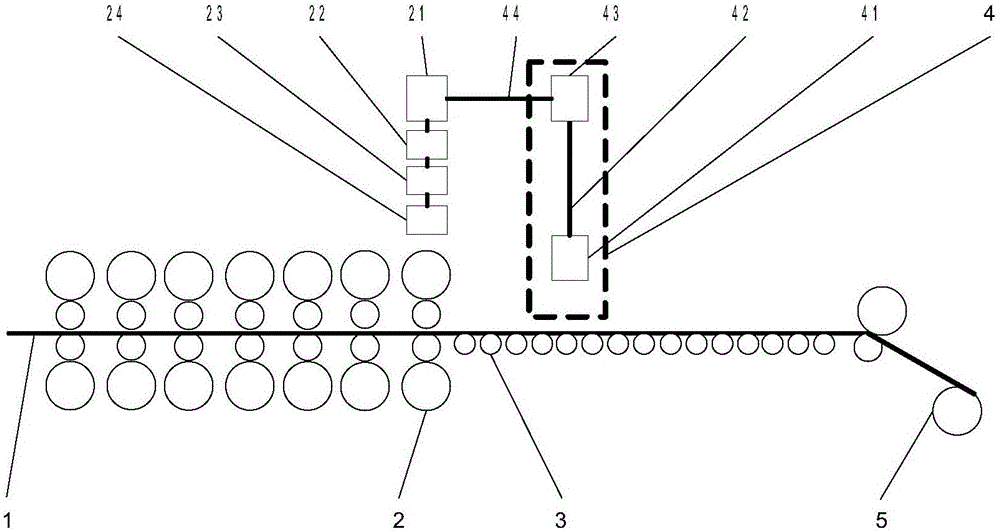

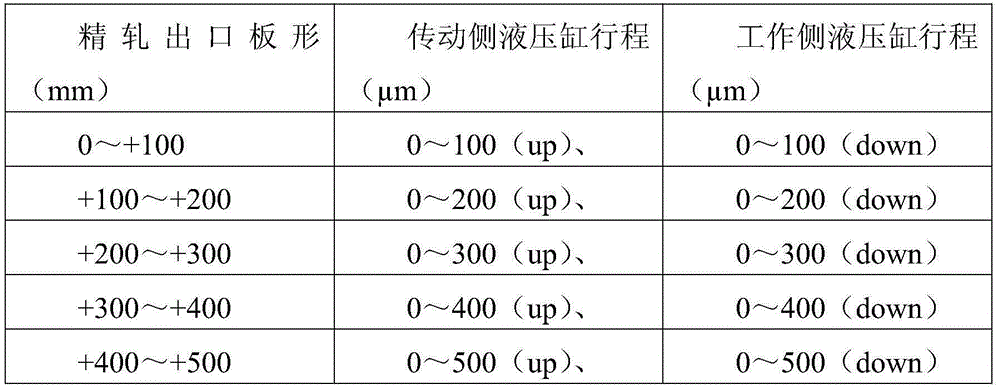

The invention discloses a control method for regulating a camber plate shape of an outlet of a finishing mill, and the control method is used for controlling the plate shape in a strip steel rolling process. The control method is characterized by comprising the following steps: step 1, carrying out camber detecting on the plate shape of strip steel 1 rolled by a finish-rolling tail rack (rack F7) 2 by use of a control system device which is composed of a hot metal flatness detecting system and a finishing mill hydraulic control system; step 2, feeding the strip steel 1 into a rolling machine 5 to roll, and scanning the plate shape of the strip steel by a sensor 41 of the hot metal flatness detecting system; and step 3, introducing information to a processing computer 43 of the hot metal flatness detecting system by an optical cable 42 . Compared with the prior art, the control method for regulating the camber plate shape of the outlet of the finishing mill ensures good plate shape of the strip steel at the outlet of the finishing mill, has the advantages of timely regulation and an accurate direction, improves labor efficiency and improves product quality.

Description

technical field [0001] The invention relates to a control method for adjusting and controlling the shape of the exit of the last stand of a finishing mill, in particular, the invention relates to a method for controlling the shape adjustment of a "sickle" shape at the exit of the last stand of a finishing mill. The "sickle" shape adjustment control method can detect the center line deviation of the finish rolling exit in real time, and automatically adjust and correct it in time to improve the "sickle" shape defect at the finish rolling exit. Background technique [0002] The hot rolling finishing stand is to roll the strip blank rolled out of the rough rolling mill into a finished strip steel with smooth surface, standardized size, consistent performance and good shape. During the production process of finish rolling, the strip blank must be cut head and tail first, this is to ensure the stability of rolling during strip threading and throwing. device, roll cooling water h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B31/16B21B37/28B21B38/04

Inventor 胡平张志超

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com