Paracetamol vitamin C effervescent tablet and preparation process thereof

A technology of paracetamol and preparation process, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, organic active ingredients, etc., can solve the problems such as reducing the production efficiency of effervescent tablets, and achieve the Good, rapid disintegration, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

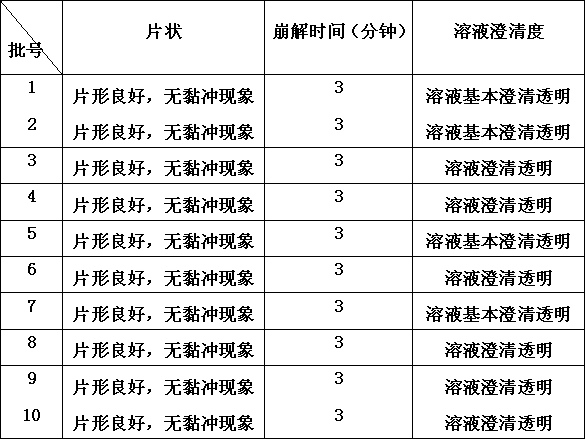

Examples

Embodiment 1

[0031] (1) Crushing and sieving: use TF-260 turbo self-cooling pulverizer and XZS-400 vortex vibration sieving machine to take 9.5kg of mannitol, 2.375kg of glycine, and 42.75kg of citric acid under an 80-mesh sieve. Crush and sieve. Material balance: 99.95-100.00%.

[0032] (2) Mixing: Use GH-500 three-dimensional motion mixer to pre-mix 9.5kg of vitamin C, glycine, 15.675kg of acetaminophen, mannitol, citric acid, and 61.75kg of sodium bicarbonate at a speed of 900r / min , mixed for 30min. The mixed material is compressed into large pieces by a tablet press, and granulated by a YK-160A swinging granulator through a 16-mesh sieve. Finally, the dry granules and 2.375 kg of sodium lauryl sulfate were mixed in a three-dimensional motion mixer at a speed of 600 r / min, and mixed for 10 minutes. Yield: ≮99.00% Material balance: 99.80-100.00%.

[0033] (3) Tablet compression: pass the mixed material through a ZPY-27B rotary tablet press machine, and press it with a Φ23mm fl...

Embodiment 2

[0035] (1) Crushing and sieving: use TF-260 turbo self-cooling pulverizer and XZS-400 vortex vibration sieving machine, take 10kg of mannitol, 2.5kg of glycine, and 45kg of citric acid to pulverize under a 80-mesh sieve. sieve. Material balance: 99.95-100.00%.

[0036] (2) Mixing: Use GH-500 three-dimensional motion mixer to pre-mix 10kg of vitamin C, glycine, 16.5kg of acetaminophen, mannitol, citric acid, and 65kg of sodium bicarbonate at a speed of 900r / min for 30min. . The mixed material is compressed into large pieces by a tablet press, and granulated by a YK-160A swinging granulator through a 16-mesh sieve. Finally, the dry granules and 2.5 kg of sodium lauryl sulfate were mixed in a three-dimensional motion mixer at a speed of 600 r / min for 10 minutes. Yield: ≮99.00% Material balance: 99.80-100.00%.

[0037] (3) Tablet compression: pass the mixed material through a ZPY-27B rotary tablet press machine, and press it with a Φ23mm flat punch. The room temperature ...

Embodiment 3

[0039] (1) Crushing and sieving: use TF-260 turbo self-cooling pulverizer and XZS-400 vortex vibrating sieving machine to take 10.5kg of mannitol, 2.625kg of glycine, and 47.25kg of citric acid under a 80-mesh sieve. Crush and sieve. Material balance: 99.95-100.00%.

[0040] (2) Mixing: Use GH-500 three-dimensional motion mixer to pre-mix 10.5kg of vitamin C, glycine, 17.325kg of acetaminophen, mannitol, citric acid, and 68.25kg of sodium bicarbonate at a speed of 900r / min , mixed for 30min. The mixed material is compressed into large pieces by a tablet press, and granulated by a YK-160A swinging granulator through a 16-mesh sieve. Finally, the dry granules and 2.625 kg of sodium lauryl sulfate were mixed in a three-dimensional motion mixer at a speed of 600 r / min for 10 minutes. Yield: ≮99.00% Material balance: 99.80-100.00%.

[0041] (3) Tablet compression: pass the mixed material through a ZPY-27B rotary tablet press machine, and press it with a Φ23mm flat punch. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com