Production method of NAK80 high-grade mirror surface plastic rubber mold material for mobile phone mold

A technology for plastic molds and production methods, which can be applied to the improvement of process efficiency, electric furnaces, furnaces, etc., and can solve the problems of low polishing performance requirements, processing performance, and polishing performance that cannot meet the requirements of A2-level mirrors for mobile phone moulds. To achieve the effect of eliminating segregation of the ingot tail, eliminating the shrinkage cavity defect of the riser, and reducing the effect of internal segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

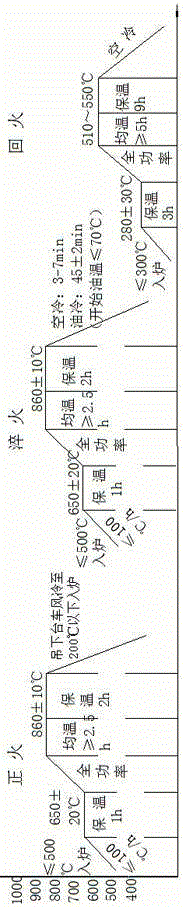

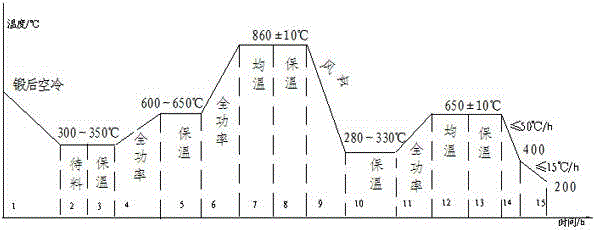

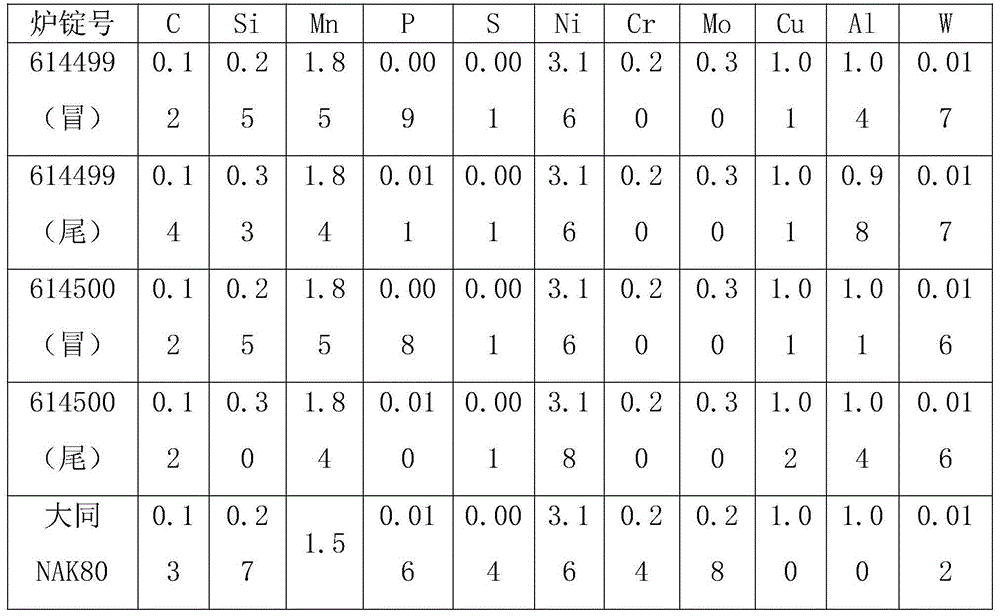

[0017] The production method of NAK80 advanced mirror plastic mold materials for mobile phone molds uses a 40-ton electric furnace. The raw materials are composed of 20 tons of Q235 continuous casting billets, 18 tons of special low-P and S steelmaking pig iron, and 8 tons of sponge iron. The production method includes: Furnace charge After melting, sample and analyze the chemical composition, among which the harmful elements Pb, As, Sn, Sb, Bi, etc. are not more than 0.015%. When the temperature is higher than 1560°C, it will start to oxidize. Add nickel plate and copper plate to the electric furnace, continue to heat up and oxidize, tap the steel when the temperature is higher than 1640°C, add the baked medium carbon ferromanganese and aluminum according to 1% [Mn] and 1.2% [Al] during the tapping process Iron, transferred to the refining furnace for refining, when the temperature is higher than 1560°C, add the remaining alloy in batches, heat, stir with argon gas, all the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com