Low-stress manufacturing process for eliminating anisotropism of 2A12 aluminum alloy forging

A manufacturing process, 2A12 technology, applied in the field of low-stress manufacturing process, can solve the problems of low material elongation, potential safety hazards, out-of-tolerance and other problems, and achieve the effect of improving product performance, saving cycle and cost, and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

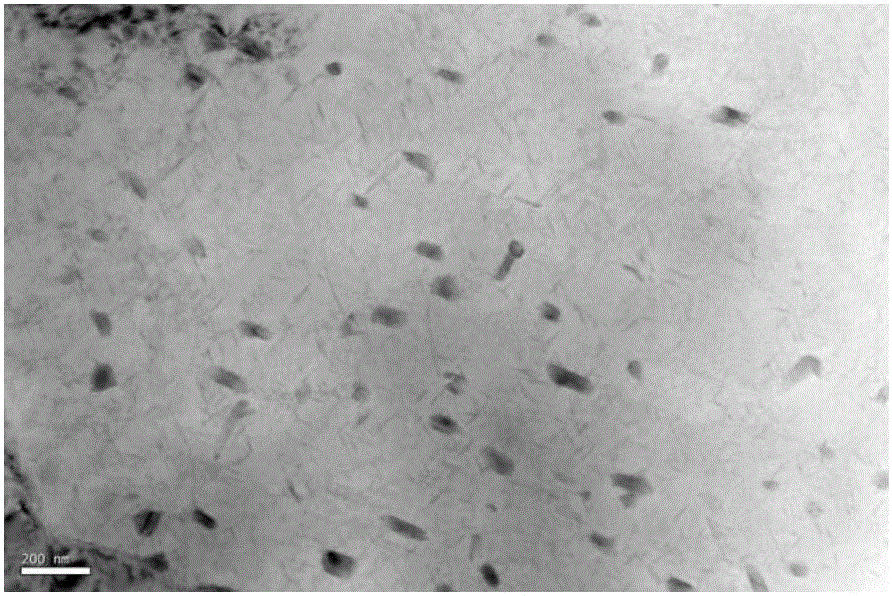

Image

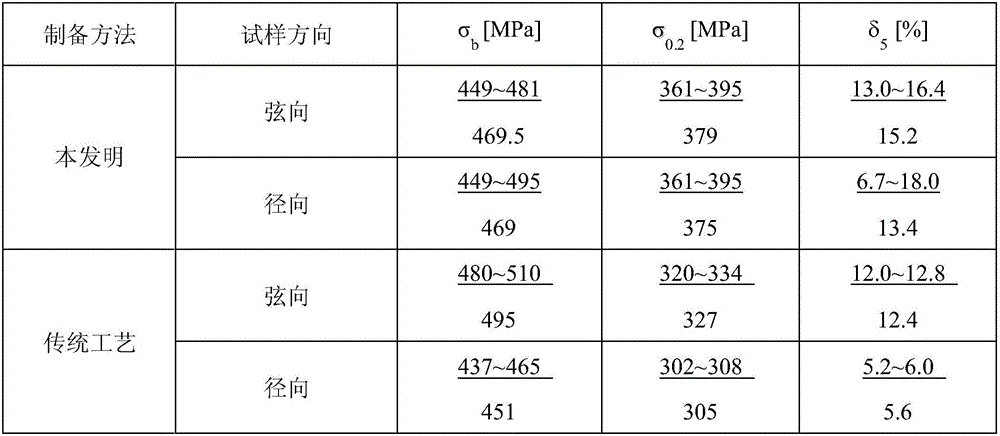

Examples

Embodiment Construction

[0018] A low-stress manufacturing process for eliminating the anisotropy of 2A12 aluminum alloy forgings, specifically comprising the following steps:

[0019] (1) The raw material is an extruded aluminum alloy bar in the state of Ф150mm2A12-O1 conforming to GJB3539;

[0020] (2) The 2A12 aluminum alloy forging of the required product size is prepared by the free forging process of two upsetting and one pulling. The specific process is: blank heating system: 380-420°C / 3-6h; mold heating temperature: 380-420°C; The size of the billet is Ф150mm×505mm, and the forging process is as follows: the first upsetting to 200mm, the first drawing and reversing drawing to Ф200mm, and the second upsetting to 135mm;

[0021] (3) Quenching system for 2A12 aluminum alloy forgings: 490-505°C / 2-6h, water quenching at room temperature, and immediately carry out 1-5% pre-compression deformation.

[0022] (4) In the process of artificial aging, combined with cold and hot cycle technology, the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com