Precision forging and cold pressing forming machining process and die for end tooth side inverted cone combined teeth

A technology of precision forging and cold pressing, applied in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of low efficiency of combined tooth milling, difficult milling processing, complaints from the end market, etc. Productivity, Anisotropy Elimination, Strength Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

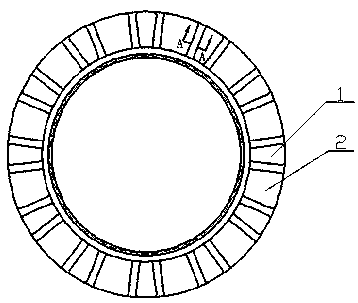

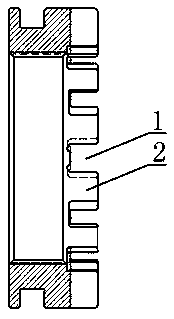

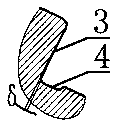

[0047] Specific embodiment 1: A precision forging and cold-press forming processing technology for end tooth side inverted cone combined teeth, including the end combined tooth preforming die forming process, the end combined tooth precision forging process, and the overall tooth shape The forming process of the cold-pressed finishing tooth mold and the cold-pressing forming process of the end tooth side inverted taper joint tooth, firstly, according to the end joint tooth product drawing provided by the customer (as shown in the attached manual) figure 1 shown), according to the back taper angle of the side of the combined tooth, the depth of the combined tooth, and the effective length of the combined tooth in the radial direction, the volume of the inverted cone part of the combined tooth at the end (the cross section is a right triangle), that is, the wedge, is calculated, and the combined tooth The volume of the inverted cone part is enlarged by a certain multiple, and tra...

specific Embodiment 2

[0048] Specific embodiment 2: A precision forging and cold-press forming processing technology for end tooth side inverted cone combined teeth, including the end combined tooth preforming die forming process, the end combined tooth precision forging process, and the overall tooth shape The forming process of the cold-pressed finishing tooth mold and the cold-pressing forming process of the end tooth side inverted taper joint tooth, firstly, according to the end joint tooth product drawing provided by the customer (as shown in the attached manual) figure 1 shown), according to the back taper angle of the side of the combined tooth, the depth of the combined tooth, and the effective length of the combined tooth in the radial direction, the volume of the inverted cone part of the combined tooth at the end (the cross section is a right triangle), that is, the wedge, is calculated, and the combined tooth The volume of the inverted cone part is enlarged by a certain multiple, and tra...

specific Embodiment 3

[0049] Specific embodiment 3: A precision forging and cold-press forming processing technology for end tooth side inverted cone combined teeth, including the end combined tooth preforming die forming process, the end combined tooth precision forging process, and the overall tooth shape The forming process of the cold-pressed finishing tooth mold and the cold-pressing forming process of the end tooth side inverted taper joint tooth, firstly, according to the end joint tooth product drawing provided by the customer (as shown in the attached manual) figure 1 shown), according to the back taper angle of the side of the combined tooth, the depth of the combined tooth, and the effective length of the combined tooth in the radial direction, the volume of the inverted cone part of the combined tooth at the end (the cross section is a right triangle), that is, the wedge, is calculated, and the combined tooth The volume of the inverted cone part is enlarged by a certain multiple, and tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com