Photosensitive resin composition for photocuring 3D printing as well as preparation method and application of photosensitive resin composition

A 3D printing, photosensitive resin technology, applied in the direction of additive processing, can solve the problems of anisotropy of resin mechanical properties, different molding directions, etc., to achieve the effect of improving service performance and eliminating anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

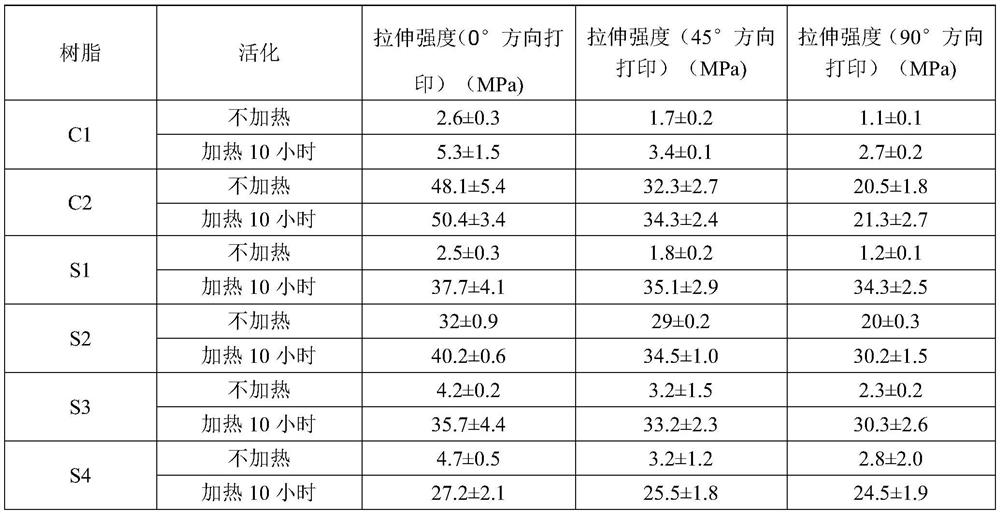

Embodiment 1

[0046] Under dark conditions, in a 200mL container, add 40 grams of tricyclodecane dimethanol diacrylate, 20 grams of triethylene glycol dimethacrylate, 20 grams of tetrakis (3-mercaptopropionic acid) Pentaerythritol ester, 10 grams of glycidyl methacrylate, 2 grams of 1,5,7-triazabicyclo[4.4.0]dec-5-ene·tetraphenylborate (TBD·HBPh 4 ), 2 grams of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), 0.05 grams of phloroglucinol and 0.05 grams of 2-isopropylthioxanthone, stirred and mixed Finally, the photosensitive resin S1 was obtained and stored away from light.

Embodiment 2

[0048] Under dark conditions, in a 200mL container, add 50 grams of diurethane dimethacrylate, 30 grams of 1,6-hexanediol dimethacrylate, 10 grams of tetrakis (3-mercaptopropane acid) pentaerythritol ester, 2 grams of glycidyl methacrylate, 3 grams of 1,5,7-triazabicyclo[4.4.0]dec-5-ene·tetraphenylborate (TBD·HBPh 4 ), 5 grams of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), 2 grams of phloroglucinol and 0.05 grams of 2-isopropylthioxanthone, stirred and mixed Finally, the photosensitive resin S2 was obtained and stored away from light.

Embodiment 3

[0050] Under dark conditions, in a 200mL container, add 25 grams of tricyclodecane dimethanol diacrylate, 15 grams of triethylene glycol dimethacrylate, 40 grams of tetrakis (3-mercaptopropionic acid) Pentaerythritol ester, 20 grams of glycidyl methacrylate, 2 grams of 1,5,7-triazabicyclo[4.4.0]dec-5-ene·tetraphenylborate (TBD·HBPh 4 ), 1 g of isopropyl-9H-thioxanth-9-one, 2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO), 0.5 g of phloroglucinol and 0.05 g of 2-isopropylthioxanthone were stirred and mixed to obtain photosensitive resin S3, which was stored away from light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com