Preparation method of graphene hybrid carbon nanotube

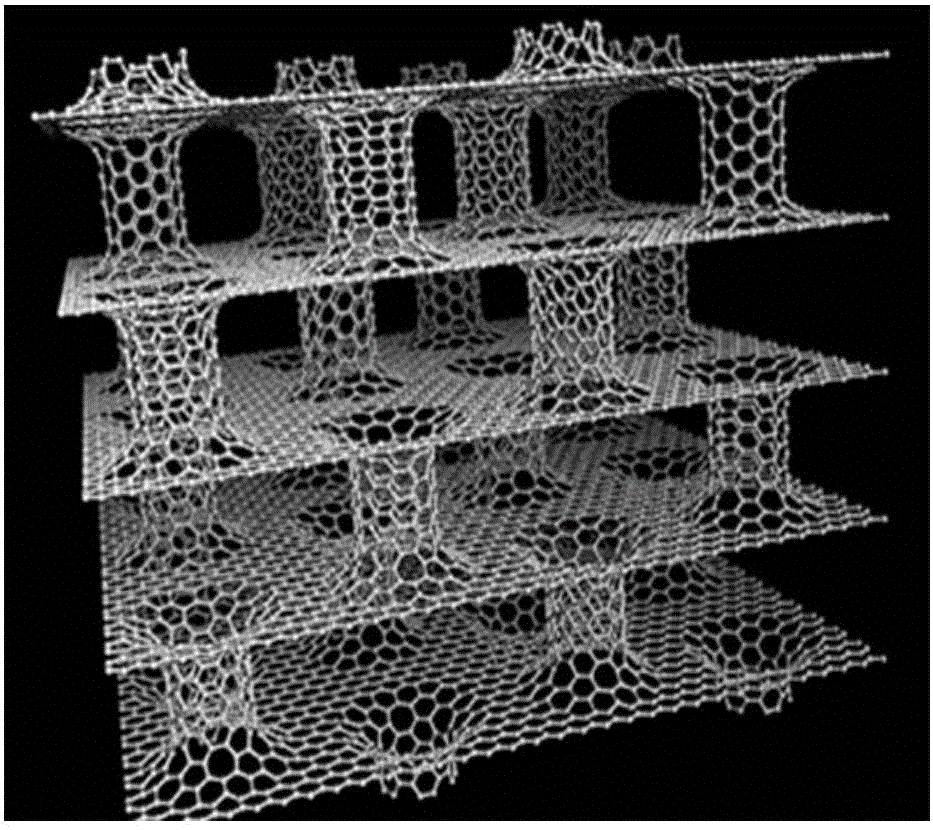

A technology of ene hybrid carbon and carbon nanotubes, which is applied in the field of new materials and its preparation, can solve the problems of reduced synergy between carbon nanotubes and graphene, difficult interface contact, etc., to facilitate engineering scale-up and mass production, and improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The method for preparing the catalyst is an ultrasonic method or a high pressure method.

[0036] The ultrasonic method refers to mixing the homogeneous solution containing the active component with the catalyst carrier, and then ultrasonically mixes it at a frequency of 15KHz to 30HZ for 0.1 to 24 hours; the high pressure method refers to mixing the homogeneous solution containing the active component The solution is mixed with the catalyst carrier, and then kept under the pressure of 0.1-70 MPa for 0.1-24 hours.

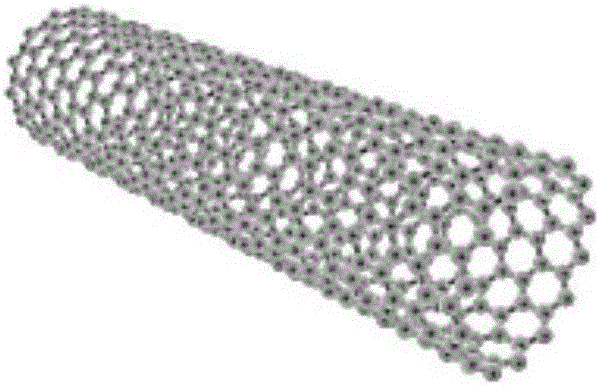

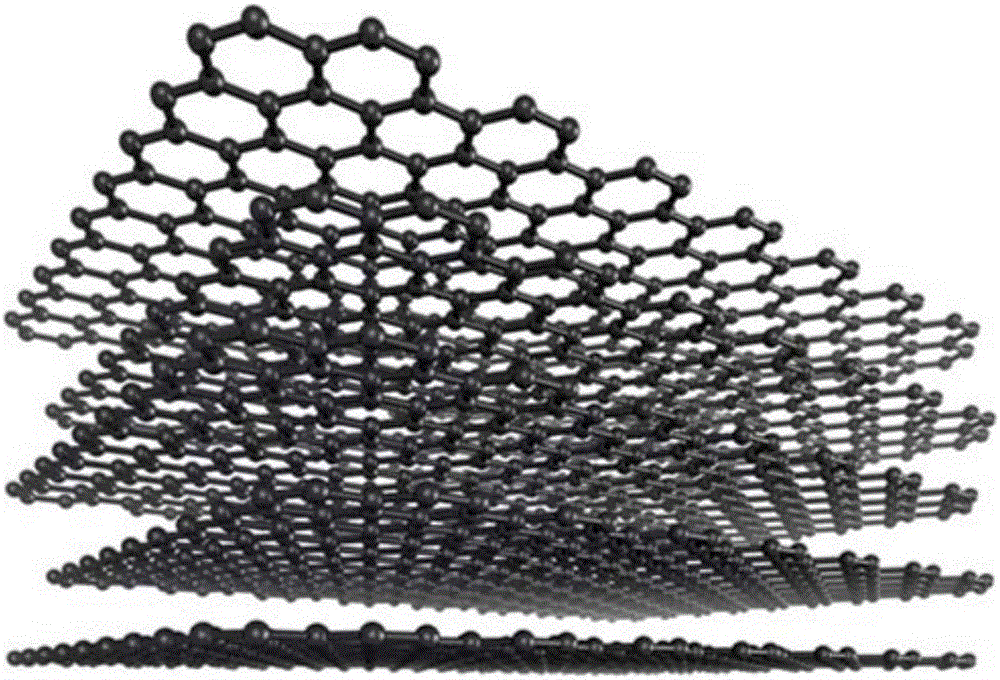

[0037] 2) the catalyst is placed in the reactor, through the chemical vapor deposition process, carbon nanotubes or graphene are deposited on the surface of the catalyst. The described chemical vapor deposition process is to use the mixed gas of carbon source and carrier gas, in 600-950°C, carbon nanotubes and graphene are generated. The deposition of carbon nanotubes and graphene is carried out simultaneously or step by step.

[0038] Described carbon sou...

Embodiment 1

[0041] Embodiment 1: Graphene hybrid carbon nanotubes are prepared by fixed bed with flake graphite as catalyst carrier.

[0042] Flake graphite is a natural layered carbon material. Fe(NO 3 )2 solution, and then take 500 mesh flake graphite and impregnate it into the above solution. Ultrasonic at 15KHz for 24 hours, the solution basically penetrated into the graphite flakes. The graphite flakes after ultrasonic impregnation were then dried at 60 °C for 12 hr. Then it was calcined at 400° C. for 30 minutes and then cooled to form a catalyst having a structure in which the metal active component is distributed among the layered carbon material support sheets, and the active component iron accounts for 10% of the mass fraction of the catalyst. Then take 1g of the above-mentioned catalyst and place it in a fixed-bed reactor with a diameter of 20mm and a length of 1100mm, using hydrogen and hydrogen as carrier gas, and the flow rates are 400sccm and 50sccm respectively. Under ...

Embodiment 2

[0043] Embodiment 2: Prepare graphene hybrid carbon nanotubes by fixed bed with expanded graphite as catalyst carrier.

[0044] Configuration mass concentration is 20% Ni (N0 3 ) 2 solution, then take 4g of expanded graphite and impregnate it into the above solution. Ultrasonic at a frequency of 30HZ for 0.1 hour, the solution components penetrate into the expanded graphite. Then the impregnated expanded graphite was dried at 100° C. for 12 hours. After calcination at 200°C for 120min, after cooling, the catalyst has a structure in which the metal active component is distributed between the layered carbon material support sheets, and the active component Ni accounts for 0.1% of the mass fraction of the catalyst. Take 3.0 g of catalyst and place it in a fixed bed with a diameter of 150 mm and a length of 1100 mm, using helium and hydrogen as carrier gases with flow rates of 400 sccm and 20 sccm respectively. Under this atmosphere, the temperature was raised to 950° C., and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com