Cooling structure for high-temperature rotating wheel disc

A technology of cooling structure and rotating wheel, which is applied in the direction of supporting elements of blades, engine elements, machines/engines, etc., can solve problems such as not being able to meet the high-efficiency cooling of the wheel disk, lowering the temperature of the mainstream gas, and reducing the working ability of the turbine, etc., to achieve extended Thermal fatigue service life, reduce the temperature of the plate body, and optimize the effect of temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

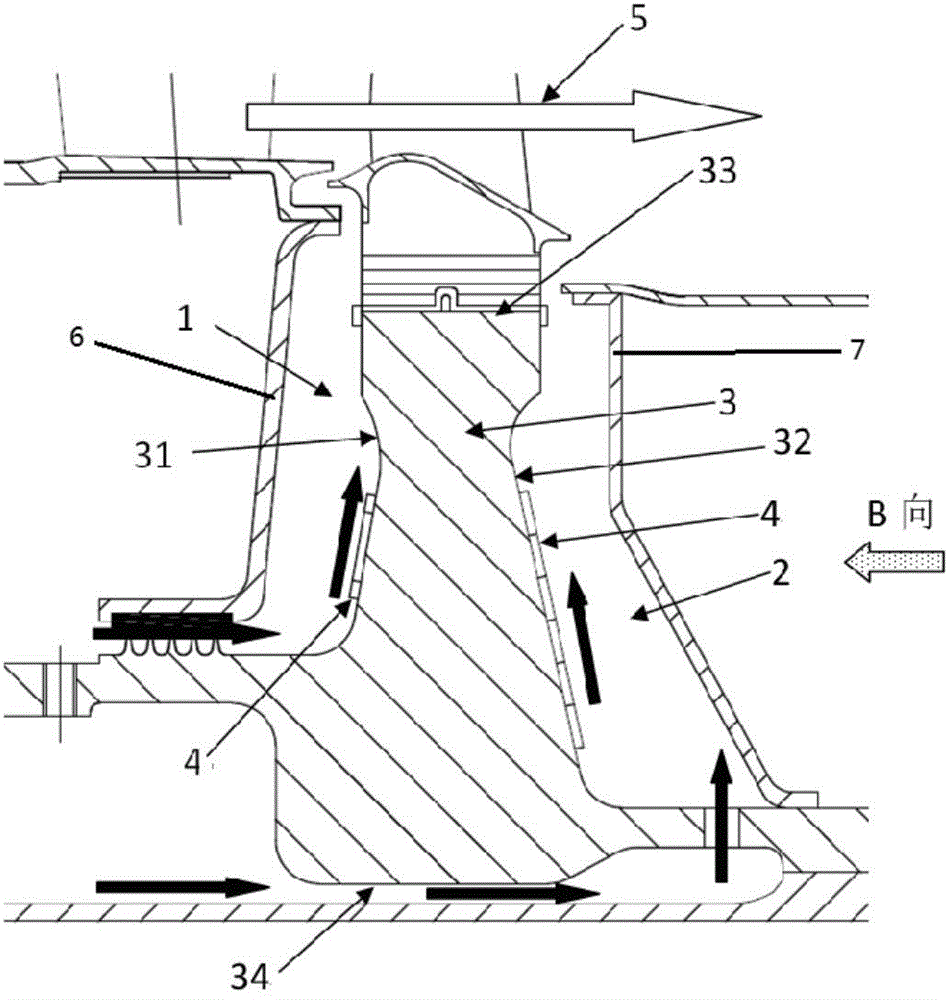

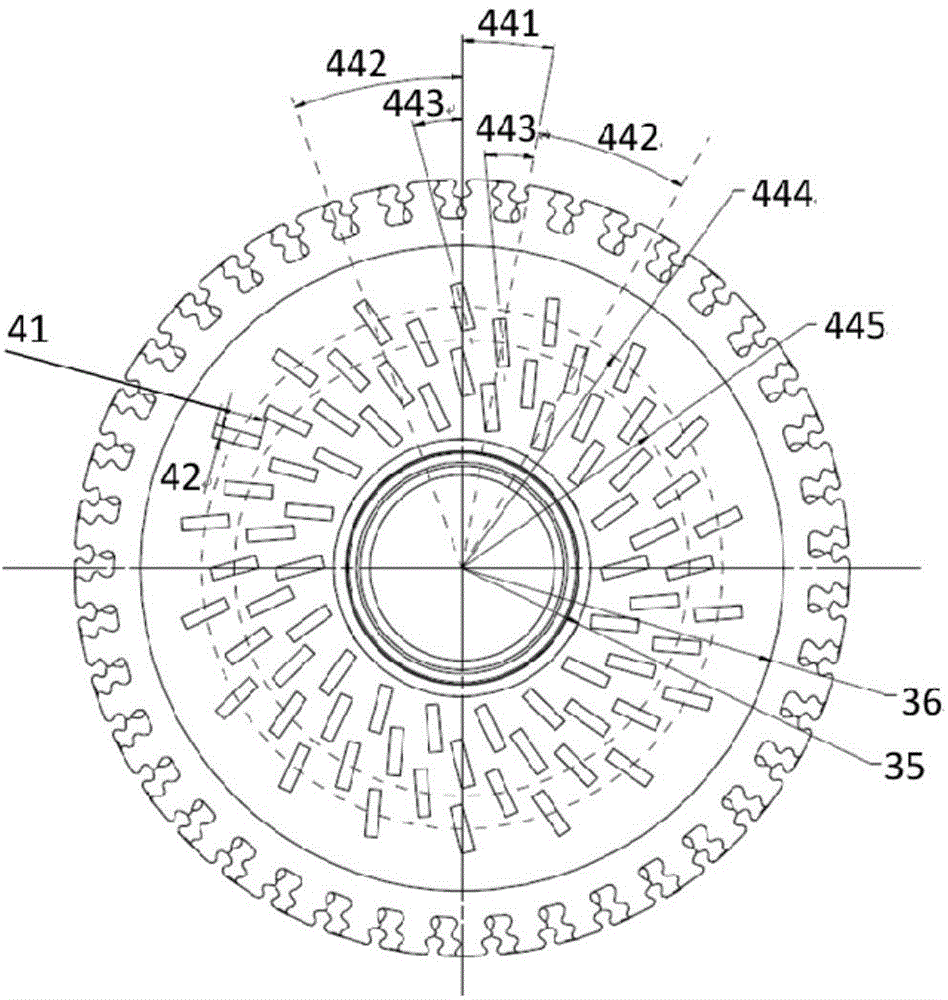

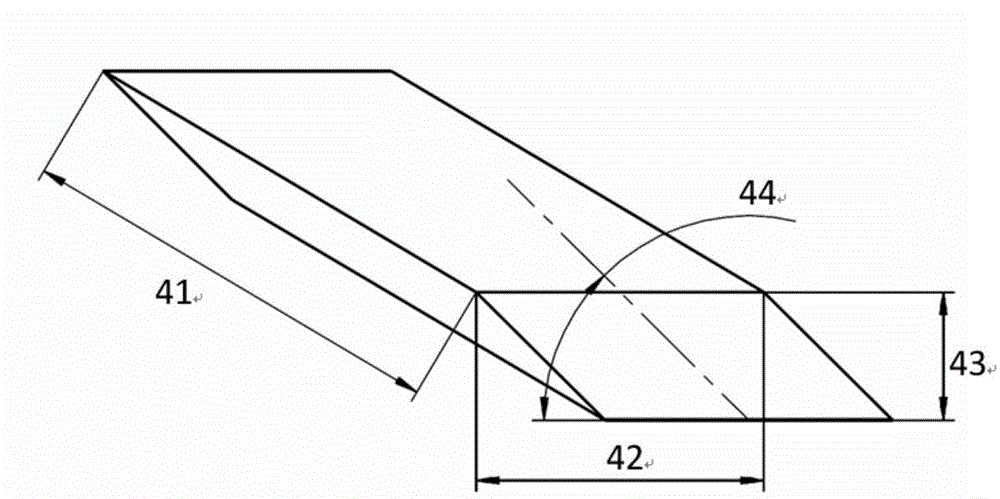

[0028] Such as figure 1 and figure 2 As shown, the cooling structure for the high-temperature rotating wheel of the present invention includes a high-temperature rotating wheel 3, a front baffle 6 and a rear baffle 7, and the front end face 31 of the front baffle 6 and the high-temperature rotating wheel forms a rotating wheel The front cooling chamber 1, the rear baffle plate 7 and the rear end surface 32 of the high-temperature rotating wheel form the rear cooling chamber 2 of the rotating wheel, and the first cooling airflow is formed between the lower end of the front baffle plate 6 and the grate tooth sealing ring of the high-temperature rotating wheel Channel, a second cooling airflow channel is opened between the high-temperature ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com